How Does a CO2 Laser Cutting Machine Achieve High-Precision Cutting?

In modern manufacturing, the demand for high-precision cutting of non-metallic materials is steadily increasing. CO2 laser cutting machines, with their excellent cutting performance and flexibility, have become the ideal choice for industries such as advertising, decoration, packaging, and handicrafts. This article will provide a detailed analysis of how CO2 laser cutting machines achieve high-precision cutting, along with an overview of their structural components, advantages, and typical applications.

目次

CO2レーザー切断機の概要

CO2 laser cutting machines use carbon dioxide gas as the working medium and generate a 10.6μm wavelength infrared beam through excitation for cutting. They are primarily used for the precision processing of non-metallic materials. Compared to fiber laser cutting machines, CO2 laser generators offer better absorption for non-metal materials, making them suitable for cutting acrylic, wood, fabric, leather, cardboard, plastic, and more.

CO2 laser cutting machines not only offer fast cutting speeds and high precision but also support engraving operations. They are widely used in various creative and industrial fields, making them the preferred digital manufacturing equipment for many small and medium-sized enterprises.

Core Technologies for Achieving High-Precision Cutting

To achieve high-precision laser cutting of non-metal materials, CO2 laser cutting machines rely on the synergy of multiple advanced technologies. These key components not only enhance cutting quality but also ensure stability and consistency throughout the machining process, forming a solid technical foundation for precision manufacturing. Below is an in-depth analysis of the core technologies that enable high-precision cutting:

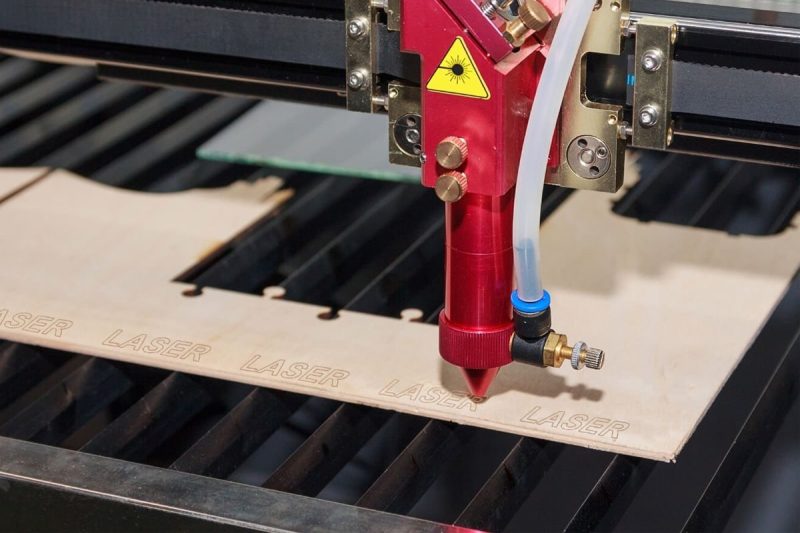

High-Quality CO2 Laser Generator

One of the core components of a CO2 laser cutting machine is the CO2 laser generator, which excites carbon dioxide gas to produce an infrared laser beam with a wavelength of 10.6μm. This laser beam is characterized by excellent beam quality and energy stability. After focusing, it forms a uniform spot size with high energy density and a small heat-affected zone. These laser output conditions ensure smooth edges and fine lines during cutting, effectively avoiding issues such as melting edges and carbonization—making it the foundation for precise machining.

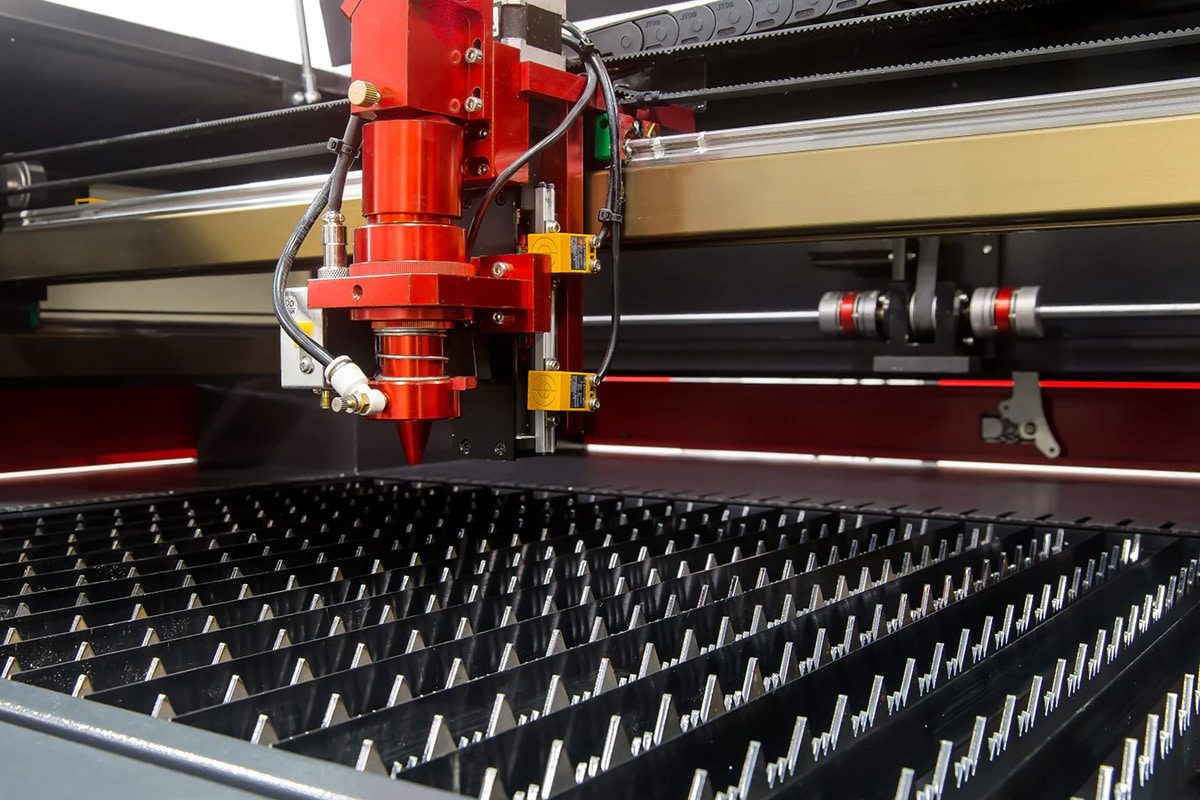

Precision Guide Rails and Motor Drive System

Laser cutting requires extremely high mechanical movement accuracy. CO2 laser cutting machines are typically equipped with high-strength linear guide rails and paired with imported servo motors or high-performance stepper motors to ensure smooth and stable laser head movement. The repeat positioning accuracy can reach ±0.01mm, ensuring each detail of complex cutting patterns is executed flawlessly. Moreover, the high-precision transmission system significantly reduces vibration and deviation during operation, which is critical for maintaining pattern consistency.

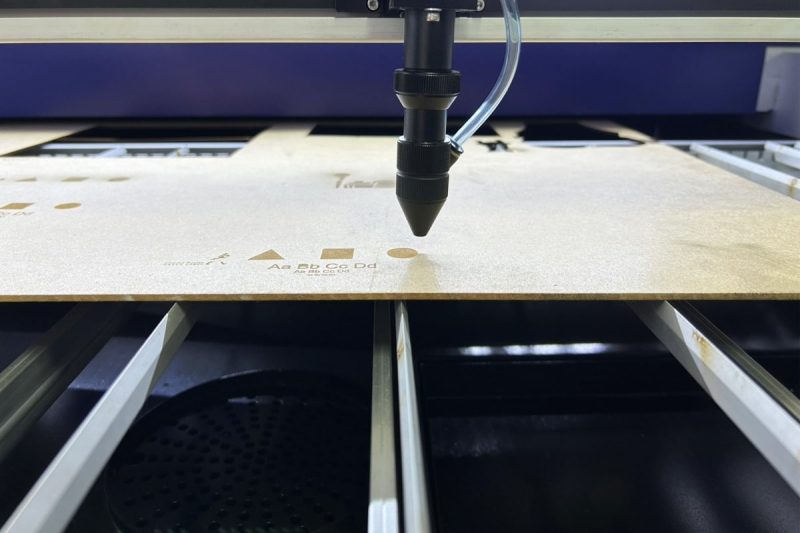

High-Performance Focusing System

Cutting quality is largely determined by the energy density after laser focusing. CO2 laser cutting machines are equipped with high-quality focusing lenses and mirror mounts that concentrate the laser beam into a very small spot (as small as 0.1mm), generating ultra-high energy density. This enables ultra-fine kerf widths and precise edge processing. A high-performance focusing system plays a vital role in improving cutting clarity, reducing burn marks, and supporting micro-engraving applications.

Intelligent Control Software System

The optimization of cutting paths and smoothness of motion are closely tied to the control software. CO2 laser cutting machines come with advanced software that supports multiple design file formats (such as DXF, AI, and PLT), and includes features such as auto-nesting, path optimization, speed adjustment, and graphic editing. Operators can set optimal cutting parameters based on different materials and shapes, enabling efficient, high-precision, and intelligent machining.

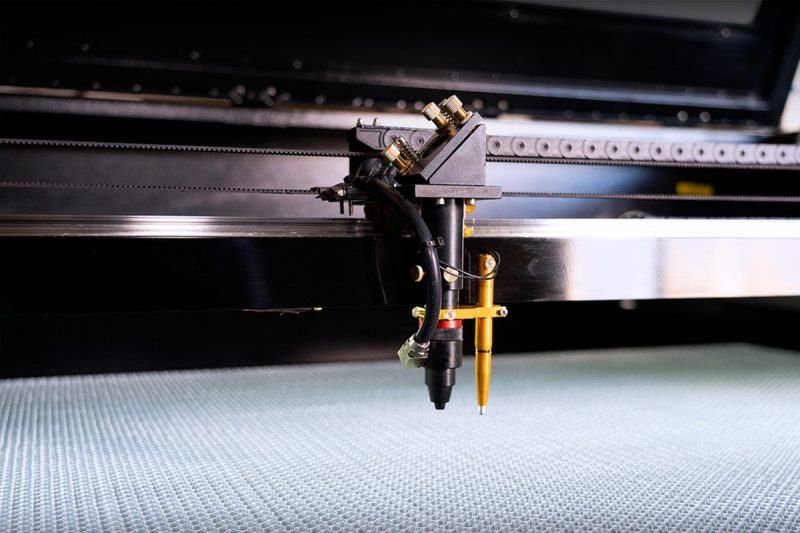

Auto-Focus System (Optional for Certain Models)

The precision of laser focus directly impacts cutting quality, especially when processing materials of varying thicknesses. High-end CO2 laser cutting machines are often equipped with an auto-focus system that detects material height changes in real time and quickly adjusts the laser head position accordingly. This ensures that the laser remains accurately focused on the cutting surface, effectively preventing issues such as discontinuous cuts or inconsistent depth due to focal length deviation.

Efficient Cooling System

During continuous operation, CO2 laser generators produce significant heat. If not properly dissipated, this can lead to decreased laser power and unstable beam quality, ultimately affecting cutting performance. To ensure stable operation of the laser generator, CO2 laser cutting machines are generally equipped with industrial-grade chiller systems. These systems monitor and regulate the laser tube temperature in real time, preventing thermal drift from compromising precision and extending the machine’s lifespan.

The widespread application of CO2 laser cutting machines in high-precision non-metal processing is attributed to their technological strengths in laser output, mechanical transmission, focusing systems, intelligent control, auto-focusing, and thermal management. The integration of these advanced configurations and intelligent functions allows the equipment to maintain stable, efficient, and accurate performance even when handling complex patterns, diverse materials, and high-volume production. For small and medium-sized manufacturers that prioritize product detail and craftsmanship, a CO2 laser cutting machine is undoubtedly a powerful and worthwhile investment for high-precision processing.

Structural Analysis of CO2 Laser Cutting Machines

To truly understand the high precision of a CO2 laser cutting machine, it is essential to start with its structural components. Each part of the system works in synergy during operation, ensuring the machine’s cutting performance, operational stability, and long-term reliability. Below is a detailed breakdown of the core structure of CO2 laser cutting machines:

レーザー発生器

The laser generator is the heart of the CO2 laser cutting machine. There are two main types:

- Glass Tube Laser Generator: Features a relatively simple structure and cost-effective performance, making it suitable for most standard non-metal cutting scenarios.

- Metal RF Laser Generator: Features a sealed metal design for greater stability, longer service life, and superior laser beam quality. Ideal for industrial applications that require higher precision and continuous processing.

The type, power, and stability of the laser generator directly determine the machine’s cutting capacity, speed, and processing quality.

Optical System: Reflecting Mirrors and Focusing Lens

The optical system consists of multiple high-reflectivity mirrors and one high-precision focusing lens. Its primary role is to guide the laser beam from the generator to the cutting head and focus it into a fine spot:

- Mirrors transmit the laser beam along the X/Y/Z axes and must ensure low energy loss and high stability.

- Focusing Lens concentrates the laser beam into a high energy density spot to achieve fine cutting.

The performance of this system directly affects the kerf width, edge quality, and the size of the heat-affected zone.

モーションシステム

The motion system controls the movement of the laser head or working platform and serves as the machine’s “skeleton.” It includes:

- High-precision guide rails to ensure smooth movement and accurate positioning.

- Stepper/Servo motors for high responsiveness and fast positioning.

- Transmission mechanisms, such as synchronous belts (for high-speed movement) or ball screws (for high-precision cutting).

An excellent motion system guarantees smooth and accurate cutting paths, which is especially crucial for complex patterns or high-speed cutting tasks.

制御システム

The control system acts as the “brain” of the entire machine, typically comprising a human-machine interface (HMI) and control software. It supports:

- File import (compatible with DXF, PLT, AI formats)

- Automatic nesting, path optimization, and cutting sequence control

- Multi-process integration, such as engraving and cutting

- Real-time parameter adjustment and fault alert functions

An intelligent and user-friendly control system not only improves operational efficiency but also plays a key role in ensuring cutting accuracy.

冷却システム

The laser generator generates significant heat during operation. If temperature is not properly controlled, it can lead to power drops or equipment damage. The cooling system—often an industrial chiller—serves to:

- Maintain the laser generator’s operating temperature

- Prevent thermal drift and enhance laser output stability

- Protect critical components like mirrors and laser tubes

An efficient cooling system is fundamental to ensuring long-term stable operation and consistent processing quality.

Exhaust and Auxiliary Gas Systems

During the cutting process, smoke, gases, and molten debris are generated. To maintain a clean workspace and cutting quality, the machine must be equipped with:

- Exhaust and filtration systems to promptly remove fumes and dust

- Auxiliary gas systems (air, nitrogen, or oxygen) depending on the material, to cool the cutting zone, clear slag, and improve edge quality

This system not only enhances workplace safety but also contributes significantly to cutting efficiency and product quality.

Thanks to its precisely engineered structure and well-coordinated subsystems, the CO2 laser cutting machine excels in the field of non-metal cutting. From the stable light source provided by the laser generator, the accurate energy delivery of the optical system, to the smooth performance of the motion and control systems, and the stable support from cooling and exhaust systems—each component contributes to the machine’s ability to deliver high precision, high efficiency, and high consistency.

Main advantages of CO2 laser cutting

With the continuous development of laser processing technology, CO2 laser cutting machines have gradually become the preferred solution in the field of non-metallic material cutting due to their excellent processing performance, wide material compatibility, and extremely high cost performance. Whether it is used for industrial production, personalized customization, or creative process design, CO2 laser cutting machines have shown significant advantages. The following will analyze its core competitiveness from multiple dimensions.

High cutting accuracy and stability

CO2 laser cutting machines have extremely high repeatability positioning accuracy, usually up to ±0.01mm, and the cutting edges are flat and smooth, without burrs, and no secondary grinding is required. This performance is particularly critical for processes such as wood carving, acrylic assembly, and leather hollowing that require strict cutting quality. Compared with traditional mechanical processing methods, laser cutting is contactless and pressure-free, avoiding precision errors caused by tool wear or material deformation, and ensuring long-term stable operation.

Strong compatibility with multiple materials

CO2 laser technology can be widely used in a variety of non-metallic materials, such as 木材, アクリル, plexiglass, cloth, leather, プラスチック, rubber, paper, and some composite materials. Users can adjust the laser power and cutting speed according to different material types and thicknesses, and flexibly respond to various process requirements. This feature makes it widely used in industries such as advertising, decoration, gift packaging, clothing accessories, and model making.

High cost performance, low operating and maintenance costs

The equipment itself has a mature structure and is easy to maintain. Taking the glass tube laser generator as an example, its purchase cost is low and its service life can reach 3000~6000 hours. The operation process of the CO2 laser cutting machine requires almost no consumables. It only needs to regularly replace the optical lens and maintain the cooling system, and the energy consumption is relatively low. For small and medium-sized enterprises with limited budgets or cautious initial investment, it is an attractive cost-cutting solution.

Easy to operate and get started quickly

Most CO2 laser cutting machines are equipped with intelligent control systems and intuitive operation interfaces, support the import of multiple common design file formats such as AI, DXF, PLT, and can realize automatic typesetting, path optimization, parameter memory and other functions. Novice users can operate independently through simple training and quickly put into actual production, greatly reducing employment costs and learning curves.

Support small batch and personalized customization needs

CO2 laser cutting has the characteristics of non-contact processing and high-response switching, which is very suitable for small batch and diversified customized production. Especially in the fields of craft gifts, personalized accessories, creative packaging, educational experiments, sample proofing, etc., it can easily meet customers’ diverse needs for complex patterns and customized sizes, helping companies expand more customized business scenarios.

The reason why CO2 laser cutting machines continue to be favored by users in the non-metal processing market is precisely because of their multiple advantages of precision, flexibility, low cost and easy operation. Whether it is large-scale production or personalized customization, it can provide users with high-quality and efficient processing solutions, creating greater economic value and market competitiveness for enterprises.

Typical application scenarios of CO2 laser cutting machines

As CO2 laser cutting technology continues to mature, its application in multiple industries is becoming more and more extensive, especially in the field of non-metallic material processing, showing strong adaptability and creativity. Whether it is industrial manufacturing or creative industries, CO2 laser cutting machines play an irreplaceable role in multiple scenarios with their advantages of high precision, strong flexibility and fast processing speed. The following are the more typical application areas on the market:

Advertising logo production

CO2 laser cutting machines can efficiently process materials such as acrylic, PVC boards, and plexiglass. The cutting pattern lines are clear, the edges are bright and transparent, and no post-polishing is required. It is particularly suitable for the production of various luminous characters, signs, display racks, window decorations, etc., and is widely used in advertising production, exhibition display and brand image building.

Wood crafts and architectural models

Wood and plywood are one of the common processing materials for CO2 laser cutting machines, which can achieve high-quality cutting of complex patterns and fine structures, and the accuracy can be controlled within ±0.01mm. This feature is very suitable for rapid proofing and small-batch production of architectural models, creative homes, cultural and creative gifts, and teaching models.

Laser processing of leather and fabrics

Laser cutting is becoming more and more common in the leather and fabric industries, especially for upper cutting, clothing patterns, and auxiliary material production. CO2 laser cutting can achieve automated continuous processing, with fine cutting seams and no loose edges, effectively improving production efficiency and product quality, and widely serving the clothing manufacturing, leather products, and home fabric industries.

Paper and packaging engraving

Paper, cardboard, kraft paper and other materials can achieve complex patterns, relief effects, and hollow designs after laser cutting, which are suitable for high-end gift packaging, handmade paper carvings, wedding invitations, and creative packaging boxes. Laser cutting is fast and efficient, especially suitable for short-cycle, small-batch customization needs.

Interior decoration and custom design

In home and commercial space design, CO2 laser cutting is widely used to make hollow carved panels, art partitions, background walls, ceiling lighting, etc. Its non-contact processing method ensures the integrity of the material surface, while easily achieving personalized patterns and exquisite details, enhancing decorative effects and artistic value.

CO2 laser cutting machines have a wide range of applications, covering a variety of industries from advertising logos, model making to decorative design. It not only improves processing efficiency and product quality, but also gives design greater freedom and innovation space. With the continuous increase in market demand for high-precision, high-efficiency, and personalized processing, the application potential of CO2 laser cutting machines is also being continuously released, becoming an indispensable and important equipment in the field of non-metallic material processing.

Why choose AccTek's CO2 laser cutting machine?

When facing diverse cutting needs and ever-changing application scenarios, choosing a stable and reliable CO2 laser cutting machine is the key to ensuring processing quality and production efficiency. As a professional laser equipment manufacturer in China, AccTek Laser has been committed to providing high-precision, high-performance, and high-reliability laser cutting solutions to global users with more than ten years of industry-intensive cultivation and continuous technological innovation. We are well aware of the diverse needs of different customers in terms of equipment configuration, material adaptability, and service support, so we continue to optimize the product structure and service system to help customers achieve longer-term development.

Flexible selection of multiple models and power

We provide a variety of CO2 laser cutting machine models ranging from 40W to 300W, covering glass tube and metal tube laser generator configurations, and working formats ranging from 300×500mm to 1600×3000mm. Whether it is used for paper engraving, acrylic cutting, or wood board proofing, we can match customers with suitable solutions to ensure the best balance between performance and cost.

Core components are from international high-quality brands

Equipment accessories are key factors affecting performance stability, and service life. The laser generators, power modules, guide rails, lenses, and electronic control systems we use are all from mature brands in the industry, such as RECI, Ruida, Hiwin, etc., to ensure that the equipment still performs well under long-term high-load operation, with low maintenance frequency and strong stability.

Intelligent control system to improve operating experience

Equipped with advanced laser control systems, AccTek Laser’s CO2 models support multiple file formats such as AI, DXF, PLT, BMP, JPG, and built-in automatic typesetting, path optimization, layered processing, and other functions. Users can quickly import design files to achieve precise cutting and efficient production, which is especially suitable for small and medium-sized enterprises to quickly carry out customized processing business.

Full-process after-sales service support

In order to solve practical problems of customers during installation, operation and maintenance, we provide detailed English operation manuals, video teaching and remote guidance, and support spare parts supply and technical response services worldwide. We also provide regular equipment training and application optimization suggestions for cooperative customers to help customers quickly improve processing efficiency and quality control level.

Overseas market verification, good customer reputation

At present, our CO2 laser cutting equipment has been exported to Europe, America, Southeast Asia, the Middle East, Africa and other countries and regions, and is widely used in advertising decoration, furniture manufacturing, handicraft processing, educational institutions and other industries, and has won a good reputation from many customers. We firmly believe that the continuous choice of customers is the biggest driving force for us to keep moving forward.

を選択する CO2レーザー切断機 is not only a consideration of equipment performance, but also a trust in brand service and subsequent guarantees. With rich industry experience, a perfect product system, and considerate service support, AccTek レーザー is becoming a trusted partner for more and more companies. If you are looking for high-quality, cost-effective CO2 laser cutting equipment, AccTek Laser will be your preferred brand worth considering.

連絡先

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 ゾーン A、Lunzhen 工業地帯、玉城市、山東省。

レーザー ソリューションを入手する