How Does the Wavelength of the Laser Beam Affect the Welding Process?

In the laser welding process, the wavelength of the laser beam is one of the key factors that determine the processing quality and efficiency. This article will systematically explore the concept of laser wavelength and its typical values in different types of laser generators (such as Nd: YAG laser generators, fiber laser generators, and CO2 laser generators); analyze the relationship between wavelength and material absorptivity; explain how laser wavelength affects welding characteristics (including penetration depth, heat-affected zone, welding speed and quality); compare the advantages and disadvantages and challenges of different wavelengths; and propose strategies to optimize the selection of welding wavelengths in combination with typical application scenarios such as automobiles, aerospace, electronic manufacturing, and medical devices. After reading this article, you will understand why accurately matching laser wavelengths is so important to improving welding results, reducing costs, and meeting industry needs, and provide a decision-making reference for subsequent procurement or process improvements.

目次

レーザー波長の理解

This section will clearly explain the scientific definition and practical significance of “laser wavelength” and detail the typical wavelengths, characteristics, and welding applications of Nd: YAG, fiber laser generators, and CO2 laser generators. The explanation is divided into paragraphs to keep it clear and easy to understand and compare.

Laser wavelength concept

Laser wavelength λ refers to the distance between adjacent wave crests, usually expressed in nanometers (nm). The wavelength determines the energy of the photon (energy is proportional to frequency), which directly affects the ability of the beam to focus and interact with the material (such as absorption, reflection, and scattering). Short-wavelength lasers can be focused to a smaller spot, thereby achieving high energy density, which is beneficial to improving the accuracy and depth of the weld.

Overview of different types of laser generators and their typical wavelengths

The three common industrial laser generators have their characteristics in terms of wavelength: Nd: YAG laser generators emit 1064nm near-infrared beams, have good beam quality and pulse/continuous output capabilities, and are particularly suitable for metal micro-welding, mold repair, and surface treatment. Its shorter wavelength than that of CO2 laser generators brings a higher material absorption rate, making it highly efficient in metal processing.

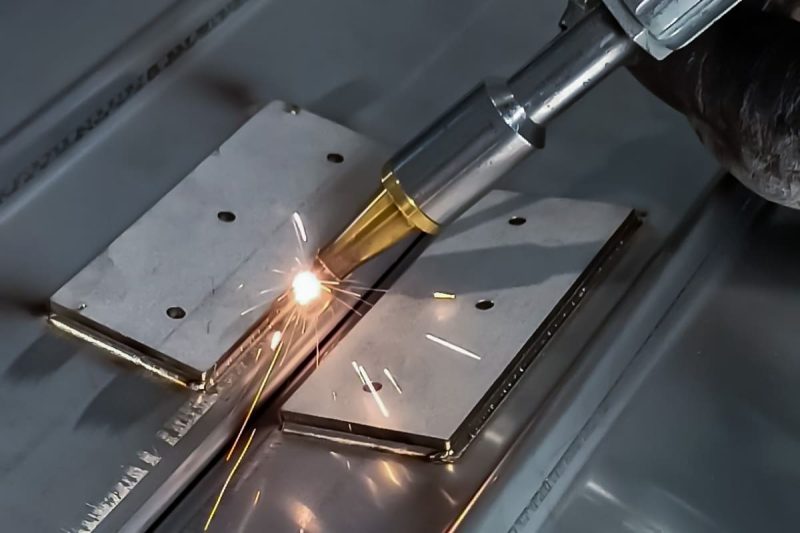

The emission wavelength of the fiber laser generator is between 1070-1090nm. It uses optical fiber as a gain and transmission medium, making the optical path almost lossless, the system compact, and the photoelectric conversion efficiency up to 30-40%. Therefore, it is widely used in automotive spot welding and large-scale structural parts processing. Although it is slightly inferior to Nd: YAG in ultra-short pulse processing, it is regarded as the mainstream of industrial welding due to its high efficiency and low maintenance advantages.

CO2 laser generators emit far-infrared light at 10600nm, with a wide power range and high absorption rate for non-metallic materials (such as wood and plastic), but the absorption rate on metal is only about 20%, which is easy to reflect and leads to low energy utilization. Despite this, it is still commonly used for thick plate cutting, high-power welding, and surface marking, but the system has high requirements for the environment and optical path cleanliness.

In general, laser wavelength is a key parameter that directly affects the focusing effect, energy absorption efficiency, and welding performance. Nd: YAG (1064nm), fiber (1070–1090nm), and CO2 (10600nm) laser generators each have their advantages. When choosing the material to be welded, the required weld characteristics and the process environment should be comprehensively considered to ensure excellent and stable welding results. The subsequent chapters will combine material absorption and process parameters to deeply analyze how different wavelengths determine the performance of welding characteristics.

Relationship between wavelength and material absorptivity

This section will explore how the laser wavelength determines the absorption mechanism on the surface and inside of the material, revealing its important influence on welding efficiency and weld quality.

Material absorption spectrum

The interaction between laser and material starts from the absorption rate: the absorption rate of different materials at different wavelengths varies significantly. For example, the absorption rate of carbon steel in the 1μm band (such as 1064nm) can reach more than 60%, while in the 10.6μm band (CO2 laser) it is only about 20%. This means that at the same laser power, a 1μm laser is absorbed more by the metal, and the weld is deeper and more efficient. In addition, the state of the material surface also has a significant effect on the absorption rate: for example, after 304 stainless steel is coated with graphite or the surface roughness is increased, its absorption rate will increase significantly with the increase in temperature. The metal surface with a smooth or oxide layer may have a lower absorption rate and a lower thermal efficiency.

Selective absorption

Selecting a laser wavelength that matches the material’s absorption peak can greatly improve energy utilization and molten pool performance. Taking stainless steel as an example, using a 1μm band laser can achieve a more stable molten pool morphology and a higher aspect ratio than using a 10μm band laser. In high-power welding (such as 10kW fiber laser welding of stainless steel), the measured absorption rate can be as high as 90%, which is mainly due to the energy accumulation of multiple internal reflections after the formation of the key hole due to the appropriate wavelength. When the welding speed is increased, the absorption rate decreases slightly, but it remains above 80%, ensuring the deep-penetration weld characteristics.

- Wavelength is an important parameter that determines absorption efficiency: short-wavelength (~1μm) lasers absorb metals significantly more than long wavelengths (10μm), which can improve welding depth and energy efficiency.

- Surface condition is also critical: coating and roughening treatment can improve the high absorption rate, especially at high temperatures.

- Choose the best matching wavelength: Choosing a wavelength based on the material absorption curve is a prerequisite for improving welding efficiency, weld pool stability, and depth-to-width ratio.

After understanding these absorption mechanisms, the next step is to deeply analyze the actual impact of laser wavelength on key indicators such as welding depth, heat-affected zone, and welding speed.

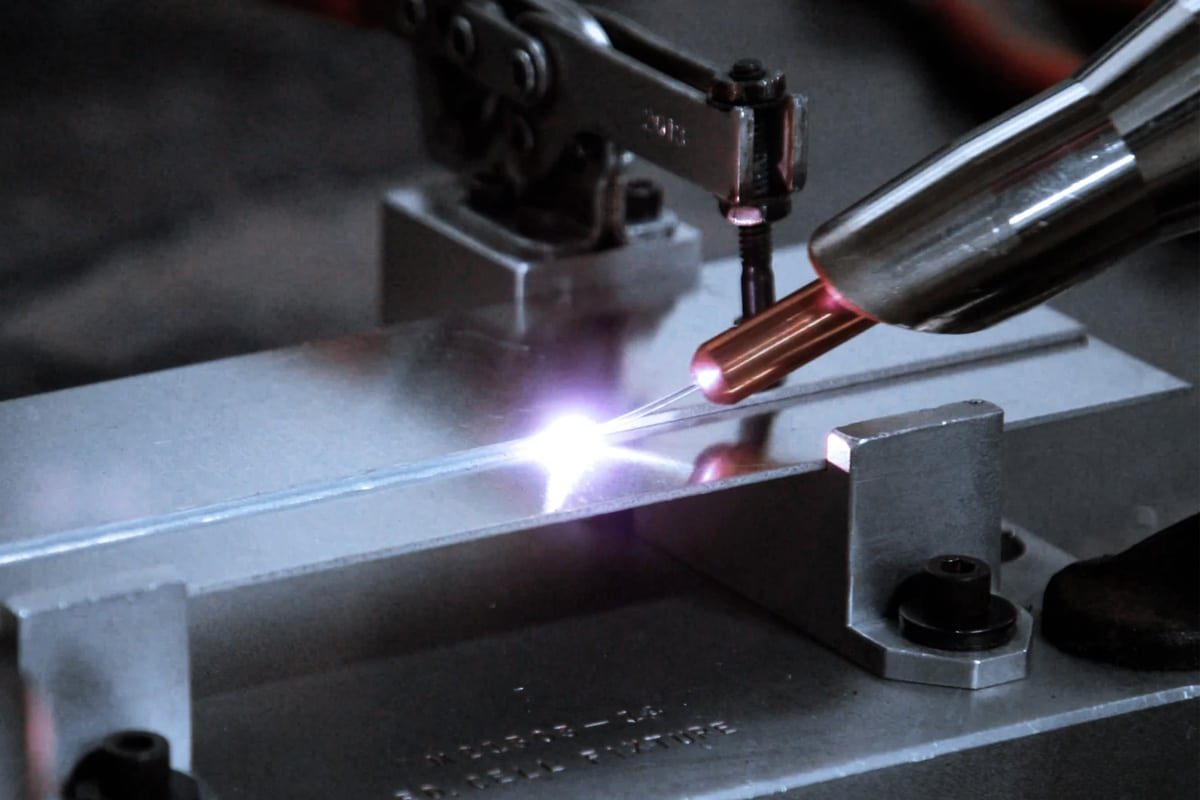

Effect of laser wavelength on welding characteristics

Wavelength is a key parameter that determines the energy distribution and temperature field morphology in laser welding. Laser beams of different wavelengths have significant differences in heat transfer and molten pool behavior in metals. The following four aspects show the direct impact of wavelength on welding performance.

浸透深度

- Short wavelength (≈1 μm): 1 μm-class lasers (such as Nd: YAG or fiber lasers) can form a depth of several millimeters or even more than ten millimeters in the material due to their tighter spot focus and higher energy density. Smaller spot and high energy input make the heat energy more concentrated, greatly improving the ability of deep penetration welding, especially suitable for deep welding of thick plates and high-strength alloys.

- Long wavelength (≈10.6 μm): The 10.6 μm wavelength of the CO2 laser has more significant absorption and skin effect on the metal surface, resulting in heat energy mainly concentrated in the surface layer, and the penetration depth is usually limited to 1-2 mm. Therefore, it is more suitable for surface strengthening, thin plate welding, or conditions that require a wide molten pool but low penetration.

熱影響区域 (HAZ)

- Near-infrared band: The heating zone of 1 μm wavelength laser is highly limited, the heat diffusion radius is small, and the cooling rate is fast, so that the HAZ width is usually kept in the range of 0.5-1 mm, effectively reducing the thermal deformation of the substrate and the accumulation of residual stress.

- Far-infrared band: When 10.6 μm laser output is used, due to the longer wavelength, a wider range of thermal radiation is generated on the material surface, and the HAZ width often extends to 2-4 mm, which may cause more obvious changes in material hardness and coarsening of microstructure, requiring additional post-processing or thermal control measures.

溶接速度

- 1 μm laser generator: With high absorption rate and compact focusing, fiber and solid laser generators can achieve welding speeds of up to 8–12 m/min in continuous welding mode, greatly improving production efficiency, especially in long seam welding and high-production scenarios.

- CO2 laser generator: Due to the limitations of absorption efficiency and thermal diffusion characteristics, the typical welding speed is mostly 2–5 m/min; although a stable molten pool can still be maintained at high power, the overall speed is much lower than that of near-infrared lasers, which is suitable for processes that do not require high speed or require a large molten width.

溶接速度

- Matching absorption peak: When the wavelength matches the absorption peak of the material, the pores and microcracks caused by the instability of the molten pool can be reduced. For example, when welding stainless steel, a 1 μm laser obtains a smooth keyhole molten pool through high absorption efficiency, significantly reducing the weld defect rate.

- Improper wavelength selection: If a long-wavelength laser is used to weld highly reflective materials (such as copper and aluminum), the reflection loss and uneven heating will lead to insufficient penetration, increased molten pool fluctuations, and even surface overburning or increased spatter, affecting the surface finish of the weld and the uniformity of the internal structure.

Laser wavelength directly affects welding penetration, heat-affected zone width, welding speed, and weld quality. In actual process design, the most suitable wavelength must be accurately selected according to material type and production requirements to achieve efficient and high-quality laser welding.

Advantages and challenges of different wavelengths

By comparing Nd: YAG, fiber, and CO2 laser generators, we can more clearly understand their advantages and limitations in welding applications. The following content is based on professional information and industry standards to help you make a more accurate selection decision.

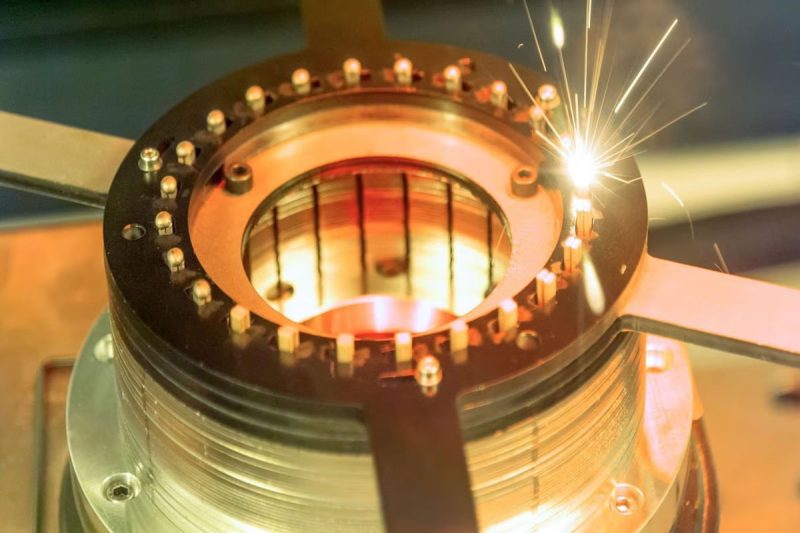

Nd:YAG laser generator (wavelength: 1064nm)

- Advantages: Mature technology, widely used in industrial micro-welding and precision machining industries, especially in medical devices and mold repair, with high reliability. Flexible output mode, supports pulse settings from nanoseconds to milliseconds, suitable for micro-welding and spot welding. Highly matched wavelength and absorption characteristics of metal materials can achieve deep fusion welding and a heat-affected zone.

- Challenges: Complex optical systems, including cavities, fiber transmission, or precision lenses, require frequent alignment and maintenance, and have high structural complexity and maintenance costs. The transmission loss in the optical path is high, which is not suitable for high-power long-distance transmission.

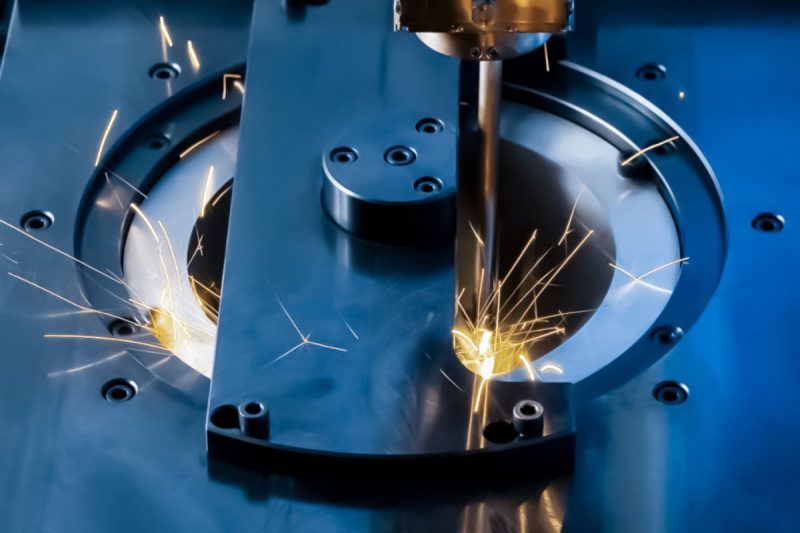

Fiber laser generator (wavelength: 1070–1090nm)

- Advantages: Optical fiber is used as a gain medium and transmission channel, with almost no light loss, compact system structure, almost maintenance-free, and conversion efficiency up to 30–40%. Good beam quality and stable output, suitable for spot welding of automobile bodies, high-speed thick plate welding, and large-scale precision welding. Long equipment life (about 100,000 hours) and easy maintenance.

- Challenges: The peak energy of the pulse output mode is slightly lower than that of Nd: YAG, resulting in slightly weaker control accuracy in micro-welding applications. Nonlinear effects (such as Raman scattering) exist at high peak power, requiring fine parameter control.

CO2 laser generator (wavelength: 10600nm)

- Advantages: It can provide high power output from hundreds of watts to tens of kilowatts, which is ideal for cutting thick plates, engraving, and large-area welding. It is low-cost and suitable for non-metallic material processing such as wood, plastic, leather, etc.

- Challenges: Low metal absorption rate (about 12-20%), not suitable for efficient metal welding, requiring higher power or preheating. The optical path is sensitive to the environment, relies on waveguides or reflectors, must be dustproof and waterproof, and has high maintenance requirements. The lifespan is short (about 20,000 hours), and the photoelectric conversion efficiency is 10-20%.

Each laser generator has its own characteristics in terms of wavelength, power output, efficiency, and maintenance. Nd: YAG is more suitable for precision welding but is expensive; fiber laser generators perform well in industrial scenarios and are the current mainstream; CO2 laser generators have advantages in high power and non-metallic applications. The final selection should comprehensively consider material properties, process requirements, equipment costs, and maintenance conditions to determine the best matching solution.

Application-specific considerations

Focusing on the four major fields of automobile, aerospace, electronic manufacturing, and medical devices, we analyze their special needs and precautions for laser wavelengths, aiming to help you develop accurate and efficient laser welding solutions.

自動車産業

- Material characteristics: The body is mainly composed of low-carbon steel and galvanized steel, with good welding plasticity and moderate reflectivity.

- Wavelength recommendation: It is recommended to use a 1µm band fiber laser (1070–1090nm).

- Advantage analysis: Fiber laser has a high absorption rate and excellent depth-to-width ratio in low-carbon steel welding, and the welding speed can be as high as multiple meters/minute, which is suitable for large-scale continuous welding of body structural parts and thin plate welding. It can also accurately control the penetration depth and heat-affected zone, reduce thermal deformation, and improve weld consistency.

- Industry trend: In hybrid and electric series, battery connection, motor component welding, and electrical connection use laser welding technology, which can further reduce weight and enhance welding reliability.

航空宇宙産業

- Material characteristics: The welding objects are mostly Ti-6Al-4V titanium alloy and aluminum alloy. The materials are sensitive and need to be controlled to avoid HAZ and cracks.

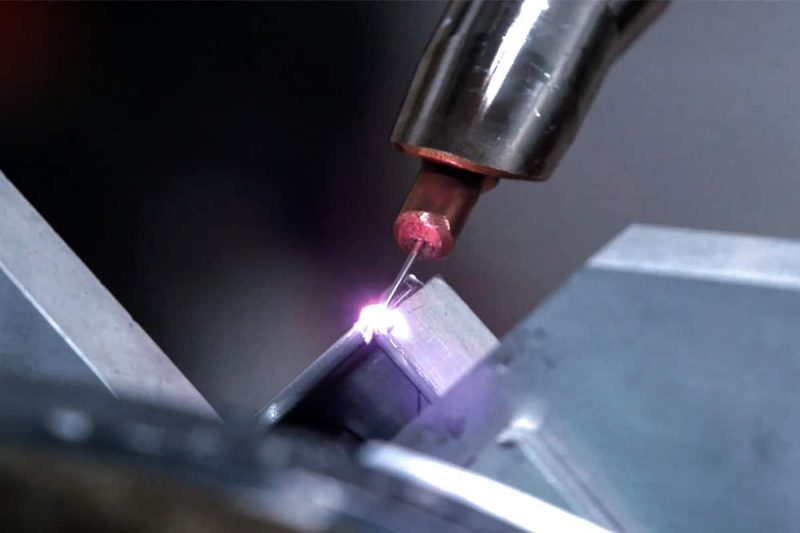

- Wavelength recommendation: 1064nm Nd: YAG laser is preferred, and pulse mode output is recommended.

- Advantage analysis: Pulsed Nd: YAG laser can accurately control heat input and molten pool forming, optimize weld geometry, and reduce carbonization and weld defects. Studies have shown that low porosity and high mechanical properties can be achieved by adjusting the focal length, power, and pulse width.

- Points to note: Shielding gas (such as argon nozzle for material) is required during titanium alloy welding to prevent oxidation and control weld quality.

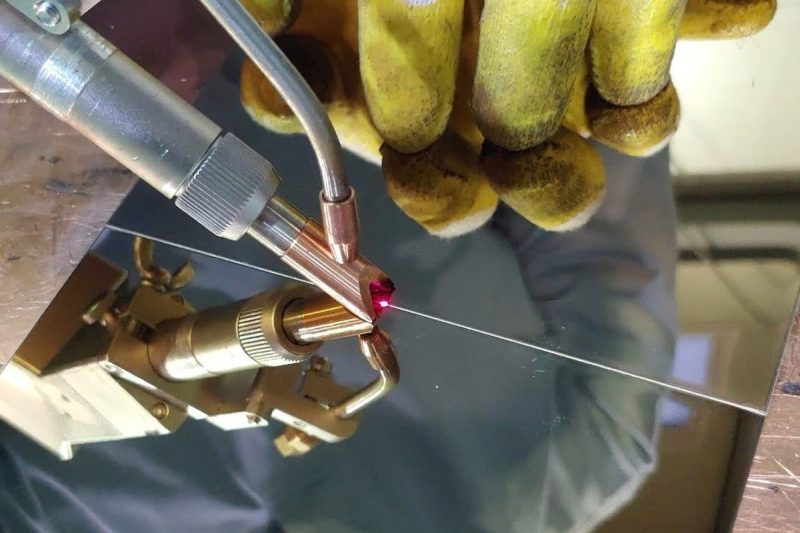

電子機器製造

- Parts features: PCB substrates, circuit connections, and tiny components are small in size, and have high requirements for heat-affected zones and precision.

- Wavelength recommendations: Short-pulse Nd: YAG or ultraviolet laser (UV, 350–400nm) is preferred.

- Advantages: Nd: YAG short pulses can provide extremely high peak power and accurately weld small solder joints; UV 400nm lasers further improve focusing accuracy and reduce thermal damage. The use of laser welding in the electronics industry can effectively avoid the thermal diffusion and bridging of traditional solder, and improve precision and reliability.

医療機器製造

- Material characteristics: Common materials are stainless steel and special alloys, which have high requirements for weld surface quality and biocompatibility.

- Wavelength recommendation: A 1µm fiber laser is an ideal choice.

- Advantage analysis: Fiber laser has a stable wavelength, small weld heat-affected zone, and forms regular, smooth, spatter-free weld characteristics, which meet the stringent specifications of medical devices for details and quality. It is particularly suitable for dental instruments, surgical tools, and implant parts, providing high batch and automated welding possibilities.

Different industries have different trade-offs between welding quality, production speed, and cost control. The choice of wavelength must be precisely determined based on material properties and process standards to maximize welding efficiency and product reliability.

Optimizing wavelength selection for welding applications

In order to help you develop an efficient, economical, and reliable welding solution, this section systematically expands the wavelength selection strategy from three dimensions: material compatibility, process parameters, and cost considerations, ensuring that readers can comprehensively weigh and select the best solution.

材料の適合性

- Reference material absorption spectrum: Prioritizing the wavelength that matches the material absorption peak can significantly improve energy utilization. For example, the absorption rate of metals in the 1μm band (such as 1064–1070nm) is as high as 60–90%, while in the 10.6μm band it is only about 20%.

- Matching requirements for different materials: Steel, aluminum alloy, copper, and other metals are preferred in the 1μm band; non-metallic materials such as wood, plastic, and leather are suitable for 10.6μm CO2 lasers; special requirements (such as glass, ceramics) may require UV or different frequency bands.

- Surface state influence: The presence of an oxide layer, coating, or polishing on the surface of the material will change the absorption rate curve. Material and surface state tests should be performed before selection.

Process parameters

- Trade-off between penetration depth and welding speed: 1μm laser wavelength and high energy density are more suitable for deep penetration welding, and can achieve a welding speed of up to 10m/min; 10.6μm is more suitable for applications with moderate penetration depth and low speed requirements.

- Focus spot size and mode control: The smaller the focus spot, the higher the energy density, and the easier it is to form keyhole welding; pulse width and frequency are equally important for depth control and heat conduction.

- Process stability: Combine the optimization scheme of focal length, spot, power, and wavelength to improve the stability of the molten pool and the consistency of the weld; reasonably set the pulse energy and pulse width, taking into account the molten pool control and the size of the heat-affected zone.

コストに関する考慮事項

- Equipment purchase and maintenance costs: Nd: YAG and CO2 laser generators usually have low initial investment, but high maintenance frequency (waveguides, pump sources, etc. need to be replaced); although the initial investment of fiber laser generators is high, the maintenance cost is low and the life is long (about 100,000 hours).

- Optical path maintenance cost: CO2 lasers need to keep the lenses and waveguides clean, and have high requirements for environmental control; fiber lasers have more advantages in terms of consumables and labor costs because the system is maintenance-free.

- Energy efficiency and operating costs: The photoelectric conversion efficiency of fiber laser generators is as high as 30-40%, which is more energy-saving; CO2 lasers have lower efficiency (photoelectric conversion efficiency is about 20%) and higher operating energy consumption.

When selecting a laser wavelength, the following steps should be considered comprehensively: Matching material absorption properties: ensuring that the selected wavelength is close to the material absorption peak; Controlling process response: designing the spot, mode and power parameters according to the required depth, speed and weld stability; Evaluating the overall cost of ownership: coordinating equipment investment, maintenance frequency, energy consumption and processing capacity. Through the comprehensive optimization of these three dimensions, the most cost-effective welding wavelength solution can be obtained under the premise of controllable costs.

まとめ

This article comprehensively and systematically explores the key role of laser wavelength in the welding process and provides you with important insights: We start with the basic physical concept of laser wavelength and explain how wavelength affects photon energy, focusing ability and material absorption efficiency; then introduce the three mainstream laser generators – Nd: YAG (1064nm), fiber (1070–1090nm) and CO2 (10600nm) – their typical wavelengths and their differences in welding performance. In-depth analysis of the relationship between wavelength and material absorption reveals why short-wavelength lasers work better in metal welding. Subsequently, we explain the decisive influence of wavelength on welding penetration depth, heat-affected zone, welding speed, and weld quality, and compare the advantages and challenges of the three laser generators.

At the application level, for the four major fields of automobiles, aerospace, electronic manufacturing, and medical devices, we put forward professional wavelength selection recommendations based on material properties and industry needs. Finally, from the three dimensions of material compatibility, process parameters, and cost, a scientific wavelength selection strategy is constructed to help achieve welding solutions that take into account efficiency, quality, and economy. Through the above analysis and suggestions, this article aims to provide you with a comprehensive reference for selecting the most suitable laser wavelength, improving welding efficiency, ensuring weld quality, and maximizing the overall value of the welding system.

レーザー ソリューションを入手する

If you want to know more about AccTek レーザー レーザー溶接機 (including Nd: YAG laser generators, fiber laser generators, and CO2 laser generators), professional solutions, and customized services, please お問い合わせ. We have rich industry experience and a technical team, and are committed to providing you with efficient, stable, and economical laser welding overall solutions.

連絡先

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 ゾーン A、Lunzhen 工業地帯、玉城市、山東省。

レーザー ソリューションを入手する