Can a CO2 Laser Cutting Machine Perform Cutting and Engraving Tasks at the Same Time?

With the rapid development of laser technology, CO2 레이저 절단기 have been widely used in advertising production, craft gifts, packaging design, home decoration, and other industries. This type of equipment is favored by users because of its smooth cutting edge, fine engraving effect, and wide range of applicable materials. However, in the actual purchase process, many customers often raise a key question: Can the CO2 laser cutting machine be competent for cutting and engraving tasks at the same time? Does it have the ability of “one machine for multiple uses” in the true sense?

This article will conduct an in-depth analysis around this issue, combining the working principle of CO2 laser and the functional characteristics of AccTek laser cutting machine to help you clarify the actual application boundaries and investment value of laser equipment. If you are looking for a laser processing equipment that can both accurately cut and carefully engrave, then this content will provide you with important reference.

목차

Brief description of the working principle of the CO2 laser cutting machine

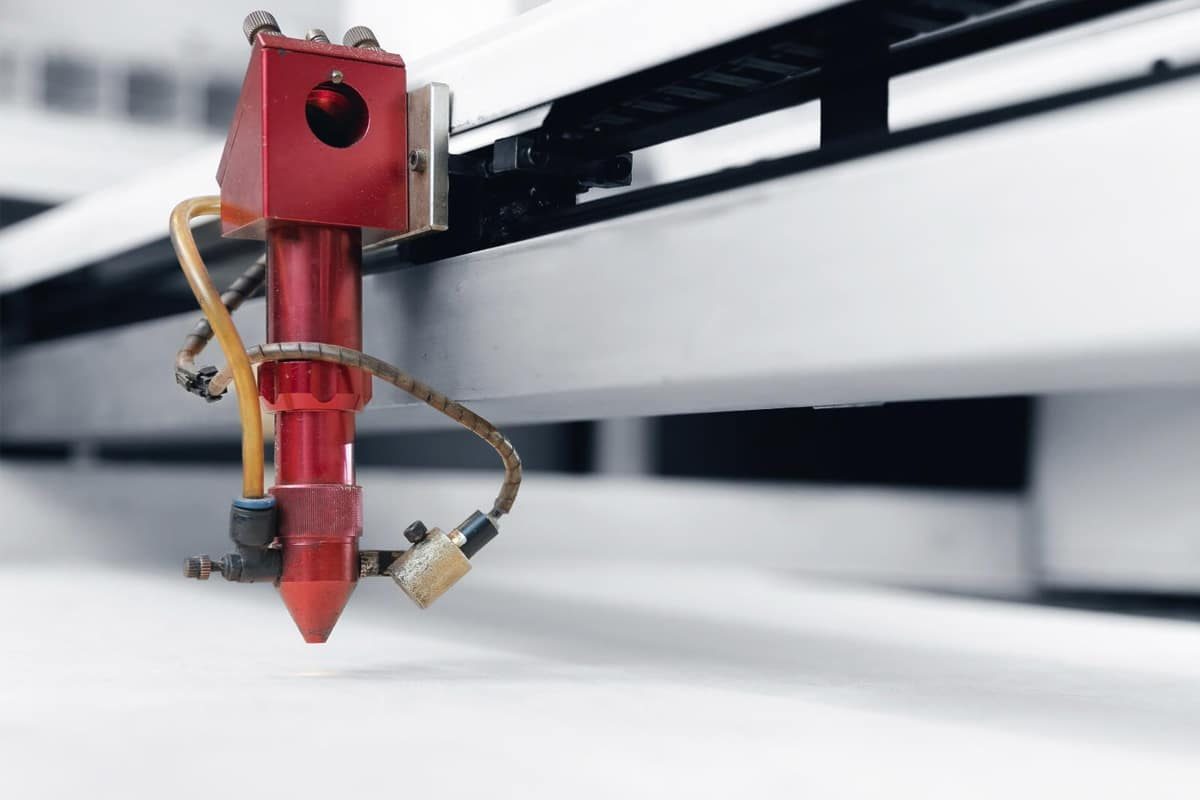

CO2 laser cutting machine belongs to the category of gas laser generator (Gas Laser), which mainly generates an infrared laser beam by exciting carbon dioxide gas. Its wavelength is generally 10.6μm, with strong thermal energy penetration, and is particularly suitable for cutting and engraving non-metallic materials, such as acrylic, wood, leather, paper, fabric, etc.

The laser generator excites CO2 mixed gas (usually containing nitrogen and helium) through electrical energy, releasing a high-energy infrared laser beam (Infrared Laser Beam), which is focused by the focusing lens to a very small spot. When the concentrated spot acts on the surface of the workpiece, the energy quickly heats and melts or vaporizes the material to achieve cutting or engraving functions.

In CO2 laser cutting mode, the laser power is usually in a high output state, with a slower running speed, so as to achieve complete penetration cutting of the material. In laser engraving mode, the system will automatically reduce the power or increase the running speed, and only act on the shallow surface of the material, thereby forming a pattern, text or texture effect.

This flexible adjustment of laser power and processing speed allows a CO2 laser cutting machine to switch freely between cutting and engraving, reflecting a high degree of process adaptability and production flexibility.

The Difference Between Cutting and Engraving and Their Implementation Mechanism

When using CO2 laser equipment for material processing, many users often confuse the concepts of “Laser Cutting” and “Laser Engraving”. Although both belong to the category of laser processing, they have significant differences in energy control, processing depth, path design and application goals.

Processing depth and laser power control

- Laser cutting: usually uses a higher laser power (such as 80W, 100W, 150W or even higher) to completely cut through the material by focusing the laser beam. This process requires the laser beam to have sufficient heat concentration and is assisted by gas to blow away the slag to achieve a smooth edge and burr-free cutting effect.

- Laser engraving: It relies on the precise control of the laser output power and only acts on the surface or shallow layer of the material, with controllable depth and rich details. Usually, lower power or multiple scans are used to achieve surface etching or relief texture effects.

Differences between run paths and design files

- In laser cutting mode, the software uses vector paths to accurately guide the laser to run along a closed trajectory to separate the contours of the graphics

- While engraving is mostly controlled by bitmap images or grayscale images, and the laser head runs back and forth in a scanning manner to restore the image point by point.

Applicable materials and practical applications

Although CO2 laser cutting machines are widely used in non-metallic materials such as wood, acrylic, leather, glass, paper, etc., there are still subtle differences in the actual application of cutting and engraving:

- Cutting is mainly used in sign making, model processing, packaging, die cutting, etc..

- Engraving is often used in fine pattern processing scenarios such as advertising display, customized gifts, and leather pattern processing.

The CO2 laser cutting machine launched by AccTek Laser is optimized based on the above mechanism. It not only supports efficient cutting, but also is compatible with high-resolution engraving tasks. It can be used for two purposes in one machine, significantly improving processing efficiency and return on equipment investment.

Multifunctional advantages of CO2 laser cutting machine

In the fierce competition in the manufacturing industry, companies have put forward higher requirements for the functional integration and flexibility of equipment. AccTek Laser has launched a variety of CO2 laser cutting machines, which are designed around the dual-mode fusion concept of “cutting + engraving”, becoming a truly dual-purpose laser machine, which is widely used in advertising, handicrafts, packaging, home furnishing, and other scenarios. The following are its main functional highlights and application advantages:

Support cutting and engraving dual mode switching

AccTek Laser CO2 laser cutting machine is equipped with advanced control system and software interface. Users can flexibly adjust power, speed, frequency and focal length parameters (adjustable laser parameters) according to processing requirements, and switch between high-power continuous cutting and low-power precision engraving with one button without changing equipment or tools, greatly improving production efficiency.

High precision engraving system

Equipped with a high-performance stepper motor and imported linear guide system, it realizes extremely smooth laser head running path and supports engraving resolution up to 1000 dpi. Whether it is complex patterns, photo-level grayscale images, or QR codes, LOGOs, etc., they can all be presented in detail. It is one of the CO2 laser cutter engravers with excellent performance on the market.

Automatic focusing and intelligent positioning system

Some high-end models of AccTek Laser support auto-focus lens and red light positioning function, ensuring that the laser beam is always accurately focused on the material surface, achieving barrier-free processing of materials of different thicknesses, effectively improving pattern consistency and cutting depth accuracy, and adapting to a variety of engraving and cutting needs.

Multiple working platforms and material compatibility

The machine can be equipped with a honeycomb platform, a blade platform, or even a lifting platform, which is suitable for the placement and support of materials of various thicknesses. It is also compatible with non-metallic materials such as wood, acrylic, paper, leather, rubber, and cloth, meeting a variety of processing scenarios such as personalized customization, mass production, and small maker studios.

Industrial-grade stability and durability

AccTek Laser always adheres to industrial-grade quality standards. The whole machine adopts an all-steel structure with strong anti-interference ability. It is equipped with an efficient cooling system (such as a CW-5200 industrial chiller) and a smoke and dust removal system to ensure long-term operational stability. It is a representative of the multi-functional laser system.

Complete after-sales service and global support system

When purchasing CO2 laser cutting and engraving equipment, the timeliness and professionalism of after-sales service directly affect the user experience and the long-term operating efficiency of the equipment. AccTek Laser is well aware that service quality is part of the core competitiveness of the corporate brand. Therefore, after the delivery of the equipment, it provides systematic, fast-response, and wide-coverage after-sales service support to global customers to ensure that users have no worries.

7×24 hours rapid response mechanism

AccTek Laser has established a professional laser technical support team that provides multilingual services. Through WeChat, WhatsApp, email, remote desktop tools, etc., it enables barrier-free communication despite global time differences, ensuring that users receive effective technical guidance and problem solutions as soon as possible.

Free remote installation guidance and training services

After receiving the equipment, every AccTek Laser customer can enjoy free remote installation and debugging guidance services. The technicians will assist the user to complete the whole process from startup to the processing trial operation. At the same time, AccTek Laser also provides comprehensive learning materials such as training videos, operation manuals, maintenance guides, etc., so that even inexperienced users can quickly master the key points of equipment operation.

Warranty period and original parts guarantee

All CO2 laser cutting machines enjoy a 12-month warranty on the entire machine. AccTek Laser will provide original replacement parts as soon as possible if there are non-human damage problems with key components such as laser tubes, motherboards, motors, and control cards. Outside the warranty period, customers can also receive lifetime technical support and enjoy factory-direct pricing on accessories and consumables services.

Overseas service network and local showroom support

AccTek Laser currently has a permanent showroom in Vietnam and has established cooperation with agents and service outlets in many countries to provide localized maintenance support and on-site commissioning services. This global support system has made us a favored laser equipment partner for many multinational buyers.

요약

With the continuous demand for personalized processing and efficiency improvement in the manufacturing industry, a CO2 laser machine with both cutting and engraving functions has become an ideal choice for many small and medium-sized enterprises and maker workshops. This article comprehensively analyzes the outstanding performance of CO2 laser cutting and engraving equipment in practical applications from equipment functions, applicable materials, industry applications, customer evaluations to after-sales service.

Whether you are engaged in advertising logos, craft customization, packaging printing, or educational maker projects, our laser equipment can provide you with accurate, efficient, and stable processing solutions. We not only provide you with advanced laser technology, but also promise to accompany the growth of every customer with high-quality services.

Choosing AccTek 레이저 is not just buying a machine, but also choosing a trustworthy partner. Welcome to visit our official website for more product details, or 문의하기 directly for product manuals and customized suggestions.

연락처 정보

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone, Yucheng City, Shandong Province.

레이저 솔루션 받기