레이저 세척의 효과에 영향을 미치는 요소는 무엇입니까?

Laser cleaning (laser cleaning, pulsed laser cleaning, laser rust removal, laser surface preparation, etc.) is a non-contact, high-precision, and environmentally friendly surface treatment technology that is being used more and more widely in manufacturing, maintenance, and cultural heritage protection. Compared with traditional mechanical cleaning or chemical cleaning, laser cleaning does not require chemical reagents to avoid secondary pollution; by precisely controlling laser parameters, non-destructive cleaning of the substrate can be achieved; and it has both high efficiency and automation potential, which is in line with the trend of green manufacturing and sustainable development.

With the decline in equipment costs and the maturity of technologies such as fiber laser, the market demand for 레이저 청소 기계 continues to rise, and the industry growth rate is obvious (such as increasingly stringent restrictions on chemical solvents in many countries and growing demand for non-destructive surface preparation). Therefore, a deep understanding of the basic principles of laser cleaning and its influencing factors will help optimize cleaning solutions, improve efficiency and quality, and enhance corporate competitiveness.

목차

The basic principle of laser cleaning

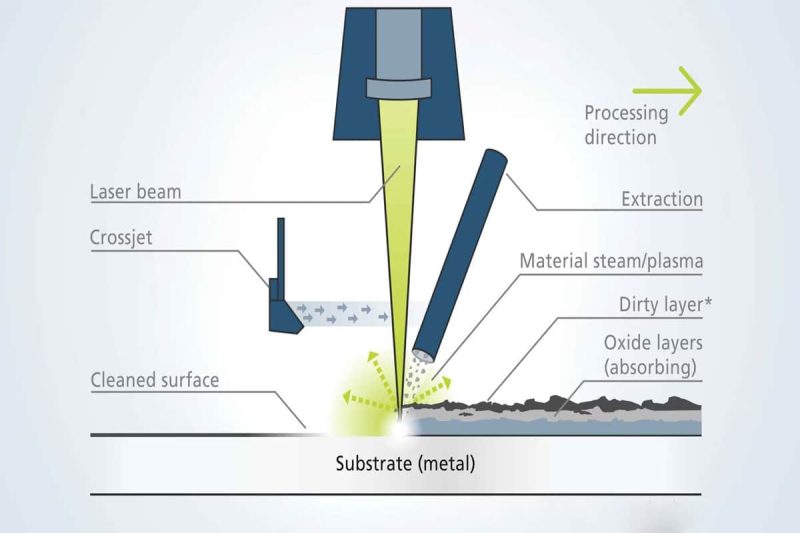

The core of laser cleaning is to utilize the interaction between high energy density laser beam and surface contaminants to remove or vaporize the contaminants from the substrate surface through instantaneous heating, vaporization, thermal expansion or plasma formation, without damaging the substrate under ideal conditions. Its technical essence is usually called laser ablation process.

- Laser type and pulse characteristics: Most industrial laser cleaning uses pulsed lasers (such as nanosecond, picosecond, and femtosecond pulses), which achieve high peak power through short pulses to ensure that the instantaneous energy is sufficient to destroy the binding force of pollutants without causing excessive thermal effects. Continuous wave lasers can also achieve ablation under high-intensity conditions, but it is more challenging to control the heat-affected zone.

- Interaction between light and matter: When the laser irradiates the surface pollutant, the pollutant material absorbs the laser energy and the temperature rises rapidly. If the energy density is high enough, plasma can be directly formed; at lower energy density, the pollutant vaporizes or thermally expands and peels off. The key lies in the difference in absorption characteristics between the pollutant and the substrate, so that the energy acts more on the pollutant rather than the substrate, thereby achieving selective cleaning.

- Cleaning process stages: Generally, it can be divided into photothermal heating stage, vaporization/ablation stage, thermal expansion/impact stage, and microparticle vibration and shedding stage. By reasonably regulating the pulse energy, repetition frequency, and scanning method, the optimal cleaning rate and effect can be achieved while avoiding damage to the substrate.

The basic principle of laser cleaning is based on the efficient energy transfer between the laser beam and the contaminant, and relies on laser ablation technology to achieve precise removal of the contamination layer. By selecting the appropriate pulse laser type and controlling the laser parameters, the absorption difference between the contaminant and the substrate can be effectively utilized to complete selective cleaning without damaging the substrate. Understanding the interaction mechanism between the laser and the material and the various stages of the cleaning process is the key to achieving high-efficiency and high-precision laser cleaning.

Key factors affecting laser cleaning effect

The effectiveness of laser cleaning depends not only on the quality of the equipment itself, but also on a combination of factors at multiple technical and application levels. In order to achieve high-efficiency, high-precision cleaning effects under different materials, pollution types, and working conditions, it is necessary to deeply understand and optimize various parameters. In general, the effect of laser cleaning is mainly affected by the following four dimensions: laser parameters (such as wavelength, pulse duration, energy density, etc.), material properties (such as absorption coefficient, thermal conductivity, type of pollutants, etc.), environmental conditions (such as temperature and humidity, air cleanliness, etc.), and system settings (such as power configuration, scanning path, optical transmission system, etc.).

Next, we will analyze these factors one by one and provide key points for technical optimization to help users use laser cleaning technology more scientifically and improve process consistency and economic benefits.

레이저 매개변수

- Wavelength: Wavelength determines the difference in light absorption between pollutants and substrates. Common industrial laser cleaning light sources include Nd: YAG (1064nm, 532nm second harmonic), fiber laser (~1064nm), CO2 laser (10.6μm), and ultraviolet femtosecond/picosecond light sources (~200-355nm). The greater the difference between the optical absorption spectrum of the pollutant and the substrate, the better the cleaning selectivity. For metal oxide layers or oil stains, the 1064nm band is often used; for high-precision microstructures or cultural relics surfaces, the ultraviolet band has better control capabilities.

- Pulse Duration: From nanoseconds, picoseconds to femtosecond pulses, different pulse widths determine the size of the heat-affected zone. Short pulses (nanoseconds and below) can deliver energy to the pollutant layer in a very short time, reducing heat diffusion to the substrate. Ultrashort pulses (picoseconds, femtoseconds) are more suitable for scenarios with high precision or to prevent secondary thermal damage, but the equipment cost and complexity are higher.

- Pulse Fluence and Peak Power: Fluence must exceed the contaminant ablation threshold, but if it is too high, it may damage the substrate or cause slag reattachment. The optimal threshold range needs to be determined based on experimental or literature data, and adjusted continuously in combination with material testing.

- Repetition Rate: High frequency can increase the cleaning speed, but too high frequency may cause heat accumulation, causing the substrate temperature to rise. It is necessary to balance efficiency and safety in combination with cooling or scanning strategies.

- Spot Size and Beam Quality (M2): The spot size determines the single action area, and a smaller spot can obtain a higher local energy density; beam quality affects the focusing effect and uniformity. High-quality beams (low M2) can achieve smaller focused spots and uniform energy distribution, improving cleaning consistency and accuracy.

- Scanning Strategy: Including scanning speed, scanning line spacing (overlap rate), cumulative action times per point, etc. Optimizing scanning parameters can ensure uniform and efficient cleaning while avoiding hot spot accumulation and substrate damage.

- Polarization (in specific applications): In some cases, polarization can affect light absorption distribution and removal efficiency, but it is less involved in conventional industrial applications and should be considered as appropriate based on specific needs.

재료 특성

- Absorption Coefficient: The difference in absorption capacity between the contaminant and the substrate for the selected wavelength is the basis for selective cleaning. Highly absorbing contaminant layers are more likely to heat up quickly under laser irradiation. It is recommended to obtain absorption spectrum data through spectroscopy or laboratory testing during the testing phase to select the most appropriate wavelength.

- Thermal Conductivity: Highly thermally conductive materials (such as copper and aluminum) tend to quickly conduct heat to the deep layers of the substrate, which may reduce the surface ablation efficiency or induce overheating of the substrate. For highly thermally conductive substrates, short pulses and high peak power strategies can be adopted to reduce the thermal diffusion time.

- Melting Point and Thermophysical Parameters: The higher the melting point of the substrate, the less likely it is to be accidentally melted during the cleaning process. However, the contaminant layer (such as rust and coating) has a relatively low melting point and can be preferentially vaporized or ablated without damaging the substrate.

- Surface Roughness: The initial roughness affects the interaction between the laser and the surface. Very smooth or highly complex morphologies may affect energy distribution and absorption, which need to be evaluated in actual applications or tests. Different microscopic morphologies will lead to local absorption differences, and the scanning and pulse parameters need to be optimized based on the actual situation.

- Material composition: The chemical composition of the substrate and the contaminant determines their optical and thermal properties. Some alloys or composite materials may have complex reactions during the cleaning process, such as the generation of new oxides and compounds, which need to be focused on during the testing phase.

- Contaminant types: including oxide layers, rust, oil stains, organic matter, coatings, etc. Different types of contaminants have different light absorption spectra, thermal properties, and bonding strengths, and laser parameters and methods (dry, wet, or plasma-assisted, etc.) need to be selected in a targeted manner.

- Coating thickness and hierarchical structure: If the contaminant or the layer to be removed has a multi-layer structure (such as multiple layers of coating on the paint), it may be necessary to adjust the energy in steps or multiple times to remove it layer by layer without damaging the substrate.

환경 조건

- Air quality and cleanliness: suspended particles, dust, etc. in the environment may be deposited on the surface with plasma or airflow during the cleaning process, affecting the effect. If necessary, use the laser cleaning machine in a relatively clean environment or combination with a blowing/dust extraction device.

- Ambient temperature and humidity (Temperature & Humidity): Extreme temperature or humidity may change the thermal properties and absorption characteristics of contaminants and substrates; for example, moisture in a high-humidity environment may affect laser energy absorption and the degree of loosening of contaminants. It is necessary to evaluate the environment before using the equipment, and take temperature control or moisture-proof measures if necessary.

- Atmospheric Interference: High concentrations of smoke, steam, or chemical gases may affect laser transmission (scattering, absorption) or form a plasma barrier, resulting in reduced cleaning efficiency. The beam transmission can be ensured to be stable through designs such as gas purge, local exhaust, or a closed hood.

- Vibration and mechanical stability: If the system or workpiece vibrates during the cleaning process, it may cause focus drift or uneven scanning. It is necessary to ensure the fixation and vibration isolation design of the equipment and workpiece.

- Safety and protection requirements: Appropriate protective measures (laser protection devices, protective covers, fume exhaust systems, etc.) must be installed in the environment to ensure the safety of operators and the surrounding environment, while preventing environmental pollution from affecting the cleaning effect.

System Parameters & Configuration

- Laser Power: directly affects the peak energy and ablation rate that can be achieved. The power level should be reasonably selected according to the cleaning area, the type of pollutant, and the characteristics of the substrate, and the average and instantaneous power should be determined in combination with the pulse parameters.

- Beam Delivery System: includes the fiber transmission path, the scanning head or the galvanometer system, the focusing lens, and the optical components. Transmission loss, the damage threshold of the optical component, and the heat dissipation design will affect the energy and spot quality that reaches the workpiece. High-quality optical components should be selected and maintained, and cleaned regularly.

- Scan Speed & Path Planning: affects the accumulated energy at each point. When the scanning speed is too fast, the single energy may not be enough to ablate the pollutant; when it is too slow, the accumulated heat may damage the substrate or reduce the efficiency. It is recommended to optimize through experiments or simulation tools, and combine the overlap rate setting (such as 20%-50% overlap between lines, etc.).

- Focal Position & Depth of Field: Focus position offset or insufficient focal depth may lead to uneven energy distribution or incomplete cleaning. The focal length and travel path should be adjusted flexibly for different surface morphologies and thicknesses.

- Cooling and heat dissipation design: The laser generator, scanning head, and optical elements need to dissipate heat effectively to ensure stable output of the system. If the workpiece overheats during a long cleaning process, it may also affect the cleaning quality or cause deformation, and it is necessary to combine strategies such as intermittent cleaning or water spray cooling.

- Control System and Software (Control Software & Monitoring): Modern laser cleaning equipment is often equipped with real-time monitoring and feedback systems, such as energy monitoring, temperature monitoring, online imaging, or online spectral analysis, to help dynamically adjust parameters for the best results. It is recommended to choose a system that supports automatic optimization or programmable scripts to improve efficiency and consistency.

- Auxiliary functions (such as gas/liquid assistance, plasma assistance): In some applications, the combination of gas blowing or thin liquid film and liquid assistance can improve cleaning efficiency or prevent re-adhesion; laser-induced plasma shock wave technology can also enhance removal capabilities, but attention should be paid to safety and complexity.

In summary, the effect of laser cleaning is affected by many factors. Improper settings in any link may lead to reduced cleaning efficiency, substrate damage or residual contaminants. When selecting and applying laser cleaning equipment, enterprises should comprehensively consider the matching of laser output parameters, the response characteristics of the materials to be cleaned, the stability of on-site environmental conditions, and the professionalism of system configuration.

Only by combining experimental verification and process monitoring methods, and continuously adjusting and optimizing cleaning process parameters, can a truly efficient, safe, and controllable laser cleaning solution be achieved in actual production or maintenance.

요약

As an efficient, environmentally friendly, and precise surface treatment technology, the effect of laser cleaning is affected by multiple factors. In practical applications, the cleaning solution should be optimized through the following steps:

- Demand analysis and test verification: Determine key indicators and quality requirements based on the cleaning object (such as metal parts rust prevention, coating removal, oxide cleaning, or cultural relics restoration); obtain material optical and thermal parameters through small samples or laboratory tests.

- Parameter optimization: Based on the test results, select the appropriate wavelength, pulse width, energy density, scanning strategy, etc., and make iterative adjustments in actual working conditions.

- Environment and system design: Ensure that the operating environment is clean and the beam transmission system is stable and reliable; equip with necessary protection and exhaust devices; improve the cooling and monitoring system to achieve long-term stable operation.

- Continuous monitoring and maintenance: timely discovery and adjustment of deviations through online monitoring and data feedback; regularly maintain optical components and laser generators to ensure stable output; summarize experience and improve cleaning process documents.

To achieve high-quality laser cleaning effects, it is necessary to organically combine “parameter tuning, system design, environmental management, and process monitoring” to form a complete cleaning optimization closed loop. Whether it is for rust removal of industrial parts, paint stripping of complex structures, or non-contact repair of the surface of cultural relics, only by fully understanding the material properties and application requirements, and continuously optimizing the laser parameters and system configuration, can we ensure cleaning efficiency while avoiding unnecessary thermal damage and physical damage to the substrate. Through scientific methodology and experience accumulation, companies can build a more stable, reliable, and cost-effective laser cleaning process to improve overall cleaning quality and production reliability.

레이저 솔루션 받기

If you are looking for high-quality, cost-effective laser cleaning machines or overall solutions, AccTek 레이저 is committed to providing advanced laser cleaning equipment, customized process optimization, and full-process technical support. Our equipment has stable output, high-precision control, and a perfect safety protection design, which can meet the needs of various metal surface cleaning, cultural relics restoration, industrial maintenance, etc. We provide global technical support, free sample testing, and remote debugging services to help customers achieve the best laser cleaning effect under complex working conditions. If you need to know more technical details or get a quotation, please 문의하기 to bring the best cleaning effect and commercial value to your project.

연락처 정보

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone, Yucheng City, Shandong Province.

레이저 솔루션 받기