A Complete Guide to Safety Precautions for Laser Welding Machines

With the manufacturing industry’s growing demand for high-precision, high-efficiency processing technologies, laser welding machines have become essential equipment in industrial production. They deliver stable, fine welds when joining metal materials and are widely used in automotive, aerospace, precision electronics, medical devices, and new energy batteries.

However, laser welding is not risk-free. Because it inherently involves high-energy laser beams, electrical systems, thermal radiation, hazardous fumes, and complex mechanical structures, operators must pay close attention to safety precautions during use. Lack of effective safety measures can not only cause personal injury but also lead to equipment damage, production interruptions, and even legal compliance risks. Therefore, when introducing and using laser welding machines, companies should not only focus on equipment performance and production efficiency but also systematically implement laser welding safety precautions to ensure worker health, equipment stability, and environmental friendliness.

Оглавление

Понимание лазерной сварки

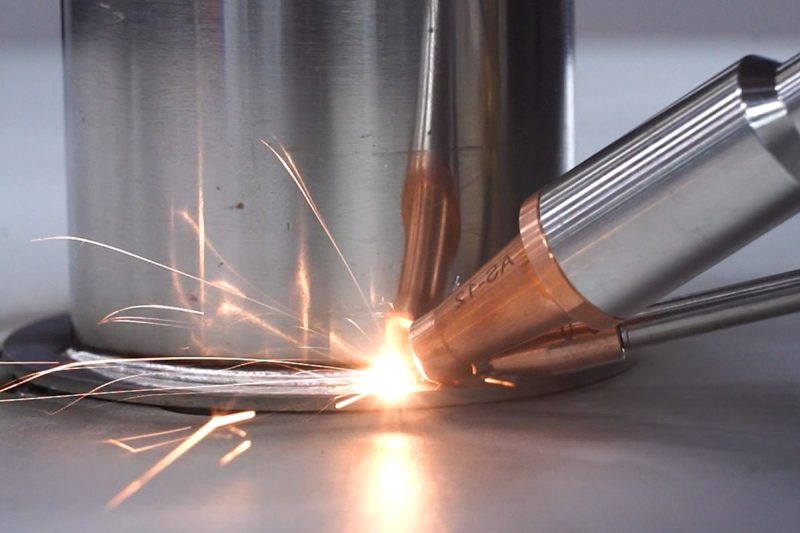

Laser welding is a process that uses a high-energy-density laser beam to rapidly melt and join metals or other materials. Compared to traditional welding methods, laser welding offers advantages such as a smaller heat-affected zone, minimal deformation, and aesthetically pleasing welds, making it widely used in precision manufacturing. However, the high-energy laser beam, strong current, thermal radiation, and industrial fumes all pose potential occupational hazards. Before delving into safety, it is important to understand the working principles and application scenarios of laser welding.

Принципы лазерной сварки

Laser welding uses a high-energy-density laser beam as a heat source to rapidly heat the contacting surfaces of materials to a molten state, thereby achieving a strong bond. Compared to traditional arc welding, laser welding offers highly concentrated energy, resulting in narrower welds and a smaller heat-affected zone, with virtually no damage to surrounding materials. Among various laser welding machine types, fiber laser welding is currently the most widely used due to its high efficiency, low maintenance, and strong stability. Fiber laser welding is gradually replacing traditional welding processes, particularly in metal processing, precision manufacturing, and new energy vehicle battery welding.

Волоконно-лазерные сварочные аппараты

Волоконно-лазерные сварочные аппараты transmit high-energy laser beams through optical fibers, focusing them and releasing energy at tiny welding points to achieve rapid melting and connection. This process has the following advantages:

- High Efficiency: High laser conversion rate, low energy loss, and fast welding speed.

- High Precision: Narrow and uniform welds require virtually no post-processing.

- Low Maintenance: Long lifespan of core components and excellent equipment stability make this machine suitable for long-term continuous production.

- Wide Applicability: Capable of processing a wide range of metal materials, including нержавеющая сталь, углеродистая сталь, алюминий alloys, and медь.

In contrast, CO2 laser welders and semiconductor laser welders each have specific application scenarios, but in mainstream metal manufacturing, fiber laser welders have become the preferred choice.

With their high efficiency, low cost, and excellent welding quality, fiber laser welders have become an indispensable piece of equipment in modern manufacturing. For companies seeking to improve production efficiency and ensure welding quality, fiber laser welders are undoubtedly the most valuable investment option.

Potential Hazards and Precautions in Laser Welding

Although laser welding is renowned for its efficiency and precision, it carries numerous hidden safety risks in production applications. If these risks are not addressed, they can not only harm the health of operators but also impact the stable operation of the equipment and overall factory safety. Therefore, identifying potential hazards and implementing appropriate preventive measures are essential for the safe use of laser welding machines.

Оптическое излучение

Of all the hazards, optical radiation is the most representative of laser welding risks. The laser beam itself has extremely high energy density, and both direct and reflected light can cause harm to the human body, particularly the eyes and skin. If an operator looks directly at the laser without protection, permanent retinal damage may occur, and exposed skin may also suffer burns from the intense light. Therefore, operators must wear safety glasses that meet the requirements of the laser wavelength, install protective barriers in the work area, and strictly control access to the welding area by unauthorized personnel to provide dual protection.

Электрические опасности

Laser welding equipment relies on a high-voltage power supply system, which carries the potential risk of electric shock and fire. This risk is particularly increased in cases of aging circuits, poor grounding, or humid environments. To avoid accidents, equipment installation and maintenance must be performed by professional electricians, and the electrical wiring and grounding systems must be regularly checked for integrity. Maintaining a dry operating environment and avoiding unauthorized tampering with electrical components are also crucial aspects of daily management.

Heat Risk

Laser welding is inherently a high-energy-density thermal process. Therefore, the welding area generates extremely high temperatures, accompanied by flying sparks. Without proper protection, burns can easily occur. Furthermore, sparks can cause fires if they come into contact with flammable materials. To effectively prevent and control this, operators must wear high-temperature-resistant gloves and protective clothing. Flammable materials must be kept away from the work area, and fire extinguishers must be readily available.

Smoke and Gas

Metal welding produces large amounts of metallic fumes and harmful gases. These substances can cause eye and nose irritation and throat irritation in the short term, while prolonged exposure can lead to respiratory problems. To minimize these risks, smoke exhaust and purification equipment must be installed in the workshop and good ventilation must be maintained. Operators should also wear respiratory protection masks when welding at high intensity or in restricted environments. Only through a multi-pronged approach can air quality and operator health be ensured.

Механические опасности

In addition to the direct risks of light and heat, the laser welding machine’s transmission structure can also pose a mechanical risk. High-speed motors and transmission devices, if unprotected, can easily cause pinching or impact injuries to operators. To prevent such accidents, protective covers should be installed on key parts of the equipment, and operators should maintain a safe distance from moving parts during operation to prevent clothing or limbs from being caught.

Шум

While not all laser welding equipment produces loud noise, some models are quite noisy during operation, and prolonged exposure to such noise can cause hearing damage. Wearing earplugs or noise-canceling earmuffs can reduce the impact of noise on hearing. Furthermore, soundproofing measures should be considered in workshop design to optimize the overall acoustic environment.

In summary, the use of laser welding machines carries multiple potential risks, including light radiation, electrical hazards, heat risks, fumes and gases, mechanical hazards, and noise. While these issues may appear independent, they often arise simultaneously in actual operation, necessitating the establishment of systematic safety management measures. Only by combining multiple measures such as personal protection, equipment maintenance, and workshop environment improvement can we ensure that laser welding can not only serve production efficiently, but also protect the health and safety of operators within a controllable range.

Machine Setup and Maintenance

The safe use of laser welding machines depends not only on the operator’s proper operation but also on the proper installation and ongoing maintenance of the equipment itself. Many accidents are not caused by momentary errors during the welding process, but rather by improper initial installation or lack of subsequent maintenance. Therefore, establishing a comprehensive equipment installation and maintenance system is key to ensuring the long-term stability of laser welding and protecting personnel safety.

Правильная установка

Before commissioning, laser welding machines must be installed by qualified personnel. Because the equipment involves multiple optical, electrical, and mechanical systems, improper installation can potentially degrade performance and even create safety hazards.

- Professional Installation: Installation should be performed by trained technicians, especially the electrical wiring and grounding, which must be performed by a licensed electrician. Unauthorized installation can compromise equipment accuracy and increase the risk of electrical fires and electric shock.

- Ensure Stable Installation: Laser welding machines are generally large and require installation on a stable foundation. The floor must be flat and stable to prevent vibration or uneven loads from causing the equipment to shift, potentially affecting welding accuracy.

- Electrical Safety Measures: When connecting to the power supply, ensure compliance with local electrical standards and install reliable grounding devices and circuit breakers. All cables should be insulated to prevent leakage caused by wear and moisture.

- Environmental Requirements: Laser welding machines have certain environmental requirements. They should be kept away from high dust, high humidity, and highly corrosive environments, as these will shorten the lifespan of the laser generator and optical components. Maintaining stable workshop temperature and humidity will help ensure long-term equipment operation.

These measures will ensure that the laser welding machine is in optimal operating condition from the start of production, laying a solid foundation for subsequent operation and maintenance.

Регулярное техническое обслуживание

Installation is only the first step; long-term maintenance and management truly determine the lifespan and safety of the equipment. Laser welding machines are high-precision equipment. Lack of maintenance can easily lead to performance degradation or even unexpected downtime.

- Routine Inspections: Operators should perform a routine inspection of the equipment before starting up, including the power supply, cooling system, optical system, gas supply, and safety devices. Any abnormalities must be immediately discontinued and reported to a technician.

- Preventive maintenance: In addition to routine inspections, regular professional maintenance is also required. For example, check the laser generator’s stable output power, the cleanliness of the optical lenses, and the tightness of the electrical connectors. This type of maintenance can detect problems before they escalate, preventing minor faults from leading to major accidents.

- Cooling system management: The cooling system is an integral part of the laser welding machine operation. Insufficient coolant or a clogged water path can damage the laser generator due to overheating. Regularly replace the coolant and inspect the pump and filter to ensure proper system operation.

- Record retention: Maintaining a complete maintenance log is essential. Detailed records of every inspection, repair, and parts replacement should be kept. This not only helps track equipment status but also provides a reference for future overhauls or replacements.

- Personnel training: Maintenance isn’t just the responsibility of technicians; operators also need to develop a basic understanding of equipment maintenance. Training enables operators to independently perform simple maintenance tasks, such as cleaning optical lenses and replacing consumables, which helps improve overall maintenance efficiency.

Safe operation of a laser welding machine is a systematic process that requires both proper initial installation and ongoing maintenance. Only by strictly adhering to standards during the installation phase and maintaining frequent maintenance during operation can downtime and safety incidents caused by equipment problems be avoided. For manufacturers, the time and cost invested in equipment safety management is far less than the losses caused by accidents or failures. Therefore, making machine installation and maintenance a core part of daily management is an inevitable choice to ensure the long-term stable operation of laser welding machines and maximize production efficiency.

Regulatory Requirements and Standards

Laser welding machines are widely used in industrial manufacturing. However, because they involve high-energy lasers, electrical systems, and metal fume emissions, they are subject to numerous international and regional safety standards. Compliance with these laser welding safety standards is not only a prerequisite for legal and compliant production, but also a crucial guarantee for enhancing customer trust and market competitiveness.

Laser Safety Standards

Countries have established detailed classification standards for laser products to regulate their use in industrial environments. Common international standards include IEC 60825-1, which categorizes laser equipment into different levels of hazard and specifies protective equipment requirements. For example, fiber laser welding machines are typically classified as Class 4, indicating an extremely high potential hazard and requiring the use of protective barriers and laser safety glasses. Companies must strictly adhere to these standards during installation and use; otherwise, they will face legal risks and production hazards.

Управление по охране труда (OSHA)

In the United States, OSHA (Occupational Safety and Health Administration) is responsible for developing and overseeing workplace safety regulations. OSHA has clear requirements for laser welding equipment:

- A risk assessment must be conducted to identify hazards such as optical radiation, electrical hazards, and smoke hazards;

- All operators must receive training and certification, and regularly update their safety knowledge;

- Personal protective equipment (PPE), such as laser-safe glasses, protective clothing, and respirators, must be available in the workplace;

- Workplaces must have ventilation and fume exhaust systems to prevent the accumulation of hazardous gases.

Complying with OSHA standards not only effectively reduces the risk of workplace injuries but also helps companies successfully pass audits and factory inspections in the North American market.

Агентство по охране окружающей среды (EPA)

In addition to personnel safety, environmental compliance is also a key responsibility for laser welding companies. In the United States, the EPA (Environmental Protection Agency) establishes emission standards for exhaust gases, wastewater, and solid waste from the metalworking industry. Metal particles and hazardous gases generated during laser welding, if discharged untreated, can impact air quality. Therefore, companies must equip fume extraction systems and properly dispose of filters and collected waste to prevent secondary contamination. Compliance with EPA standards not only avoids hefty fines but also enhances a company’s environmental image in the international market.

Whether it’s the IEC international laser safety standards, OSHA occupational safety standards, or EPA environmental standards, their core objective is to ensure the safe, compliant, and sustainable use of laser welding machines. Companies seeking to remain competitive in the global market must implement these standards throughout their production processes. Compliance goes beyond simply avoiding penalties; it’s also a crucial way to earn customer trust and enhance brand value. For laser welding machine manufacturers aiming for long-term growth and expansion into the international market, adhering to laser safety standards and environmental regulations is an essential strategic investment.

Laser Welding Safety Precautions

The value of laser welding machines is undeniable, but any high-energy processing equipment carries potential risks. To ensure a safe production process, clear safety procedures must be established before, during, and after the operation. A systematic laser welding safety operating procedure not only protects the health of operators but also extends the life of the equipment and improves production stability.

Pre-Operation Safety Measures

- Training and Certification: All operators must undergo professional training to understand the operating principles, risk categories, and emergency procedures of laser welding machines. Only qualified personnel can operate independently to avoid errors caused by a lack of knowledge.

- Risk Assessment: Before official use, a comprehensive risk assessment of the welding workshop should be conducted, including light radiation, electrical wiring, ventilation conditions, and fire protection facilities. A written risk report can identify potential hazards in advance and reduce the risk of accidents.

- Equipment Inspection: Before startup, a routine inspection of the welding machine is required to confirm that the power system, cooling system, optical path, laser protection barrier, and emergency stop device are functioning properly. Any abnormalities must be corrected before restarting the machine to ensure that the equipment is in a safe state.

Safety Measures During Operation

- Personal Protective Equipment (PPE): Operators must wear standard laser safety glasses, protective clothing, high-temperature-resistant gloves, respiratory masks, and hearing protection. These protective items provide the final defense against optical radiation, heat risks, hazardous gases, and noise.

- Controlled Access: Laser welding areas must be posted with warning signs and isolation barriers, and unauthorized access is prohibited. For Class 4 fiber laser welders, enclosed workstations or interlocked protective devices should be used to prevent stray laser light from leaking out.

- Proper Ventilation: The welding process generates metal fumes and gases. Local exhaust systems or fume extractors must be used to ensure acceptable air quality and prevent prolonged exposure to hazardous environments.

- Fire Safety: The welding area should be equipped with carbon dioxide or dry powder fire extinguishers, kept away from flammable materials, and emergency exits should be kept clear. Sparks generated by high-temperature welding can easily cause fires if not handled properly.

- Electrical Safety and Machine Guarding: During operation, electrical wiring must not be adjusted or protective devices removed without authorization. All protective switches must remain in the on position. The moving parts of the machine need to be equipped with protective covers to prevent operators from being pinched or accidentally touched.

Post-Operation Safety Measures

- Shutdown Procedures: After work is completed, the laser generator, power supply, and cooling system must be shut down according to regulations to avoid equipment damage or potential hazards caused by incorrect shutdowns.

- Inspection and Maintenance: After operation, the equipment surface must be cleaned, and the optical lenses, cables, and connectors must be inspected for any abnormalities. The equipment’s operating status should be recorded as necessary for subsequent maintenance.

- Waste Disposal: Metal residues and waste filters generated during welding should be collected and disposed of by a professional organization in accordance with environmental regulations to avoid secondary environmental pollution.

Laser welding safety precautions are a closed-loop management process: from pre-operation risk assessment and equipment inspection, to personal protection and controlled access during operation, to post-operation shutdown and waste disposal, every step must be carefully considered. Only by establishing a comprehensive safety operation system can companies truly achieve the goal of zero accidents and zero hidden dangers. For laser welding companies pursuing long-term development and international market recognition, investing in safety and compliance is key to enhancing brand reputation and market competitiveness.

Industry Applications and Market Prospects

Laser welding technology, with its advantages of high energy density, aesthetically pleasing welds, and minimal heat-affected zones, is being widely adopted across various manufacturing sectors.

In automotive manufacturing, laser welding is used to achieve high-strength connections in components such as body structures, gears, and exhaust systems, contributing to lightweight and high-precision assembly. In the electronics industry, it enables micro-welding, making it suitable for processing sensors, battery packaging, and precision electronic components. In the aerospace and new energy sectors, laser welding machines, with their contactless and highly consistent features, are an ideal solution for processing difficult-to-weld materials such as titanium and aluminum alloys.

With the rapid development of industrial automation and intelligent manufacturing, the laser welding market is entering a new growth cycle. According to forecasts from multiple industry research institutions, the global laser welding equipment market is expected to maintain an average annual growth rate of over 8% over the next five years, with particularly strong demand in the new energy vehicle, battery manufacturing, and metal processing sectors. More and more companies are transitioning from traditional welding processes to laser welding technology to improve production efficiency, reduce energy consumption, and ensure weld consistency.

As a company with many years of experience in laser manufacturing, AccTek Laser is committed to providing customers with high-performance, intelligent laser welding solutions. Whether for mass production or customized applications, our fiber laser welding machines strike the perfect balance between high efficiency and high precision, creating greater value for global manufacturing customers.

Future Development Trends of Fiber Laser Welding Machines

With the advent of Industry 4.0 and the era of smart manufacturing, fiber laser welding machines are entering a new phase of technological innovation. Traditional welding equipment is being gradually replaced by laser welding systems, which offer higher precision, greater intelligence, and improved energy efficiency and environmental friendliness. Future development trends will primarily be reflected in the following areas:

Intelligent and Automated Upgrades

The integration of artificial intelligence (AI) and machine vision is making laser welding systems even smarter. Future laser welding machines will automatically identify weld locations and intelligently adjust parameters, enabling adaptive welding and real-time quality monitoring. This will not only reduce manual intervention but also significantly improve welding consistency and product yield. For example, intelligent welding cells, which combine robotic arms with automatic loading and unloading systems, are already widely used in the automotive, hardware, and home appliance industries.

Multifunctional Integration

Increasing market demands for equipment flexibility and cost control are driving the evolution of fiber laser welding machines towards “multifunctional integration.” Future equipment will integrate multiple processes, such as welding, cutting, and cleaning, and utilize modular structures to enable rapid adaptation to different application scenarios. This multifunctional design not only optimizes production line space but also significantly improves equipment utilization.

Higher Energy Efficiency and Green Manufacturing

Green manufacturing is a key theme in the development of the global manufacturing industry. Compared to traditional welding methods, laser welding offers inherent energy-saving advantages, including concentrated energy, minimal thermal impact, and low material loss. Future fiber laser welding equipment will further optimize photoelectric conversion efficiency, reduce operating energy consumption, and be equipped with intelligent cooling systems and environmentally friendly fume purification devices to reduce emissions at the source, achieving truly sustainable manufacturing.

Wider Material Compatibility and Precision Welding Breakthroughs

With the continuous emergence of new materials, difficult-to-weld materials such as magnesium alloys, titanium alloys, and high-strength steel are becoming increasingly popular, and laser welding technology is also experiencing continuous breakthroughs. By combining optimized waveform control, dual-beam welding, and ultrafast laser technologies, fiber laser welding machines will play a key role in a wide range of high-end manufacturing fields, particularly in aerospace, medical devices, and new energy battery packaging.

Overall, future fiber laser welding machines will develop towards high precision, intelligence, green energy conservation, and multifunctional integration. This not only aligns with the trend of global manufacturing upgrades but also provides strong technical support for companies to gain an advantage in fierce competition.

Краткое содержание

Fiber laser welding machines, characterized by high precision, high efficiency, and a low heat-affected zone, have been widely used in industries such as automotive manufacturing, electronics, aerospace, and new energy. Although there are potential hazards during operation, such as optical radiation, electrical and thermal risks, as well as welding fumes and hazardous gases, a comprehensive safety management system, standardized operating procedures, and personal protective measures, such as wearing laser safety glasses, protective clothing, and respiratory protective equipment, can effectively ensure operator safety and stable equipment operation. In the future, fiber laser welding machines will develop towards intelligent, multifunctional, energy-efficient, and green manufacturing, providing companies with more efficient, environmentally friendly, and sustainable production solutions. Scientific selection and standardized operation will help companies improve production efficiency and welding quality, while maintaining a long-term competitive advantage in the global market.

Получить лазерное решение

Whether you need high-precision metal welding, mass production, or customized industrial applications, Актек Лазер offers comprehensive laser solutions. Our fiber laser welding machines combine intelligent control, high-efficiency processing, and stringent safety measures to deliver a stable, efficient, and sustainable welding experience for your production line. Связаться с нами today for a personalized laser equipment consultation and quote to elevate your manufacturing processes to higher standards and achieve both improved production efficiency and quality.

Контактная информация

- [email protected]

- [email protected]

- +86-19963414011

- Зона № 3 А, промышленная зона Лунчжэнь, город Юйчэн, провинция Шаньдун.

Получить лазерные решения