How Does Beam Quality Affect the Performance of a Laser Welding Machine?

In modern industrial manufacturing, laser welding technology is being increasingly used in many industries such as automobile manufacturing, electronic products, and medical devices due to its advantages of high precision, high efficiency, and high degree of automation. Among the many parameters that determine the welding effect, beam quality is undoubtedly one of the key factors affecting laser welding performance. This article will systematically analyze the definition and influencing factors of beam quality, as well as how it determines welding quality, efficiency, and stability in actual welding, and put forward optimization suggestions to help companies better utilize laser welding equipment to improve production competitiveness.

สารบัญ

Understanding Beam Quality

The beam quality is usually measured by the M² factor, which indicates how close the laser beam is to an ideal Gaussian beam. The closer M² is to 1, the stronger the focusing ability of the beam and the higher the energy density, which is suitable for applications with higher welding requirements.

Factors Affecting Beam Quality

In the laser welding process, the beam quality is directly related to the welding accuracy, speed and consistency of the finished product. The factors that affect the beam quality mainly include the following aspects:

Laser generator: The laser source itself is the basis for determining the beam quality. Different types of laser generators (such as fiber laser generators, CO₂ laser generators, and semiconductor laser generators) have different beam divergence angles, wavelengths, and mode structures. For example, single-mode fiber laser generators usually have higher beam quality (smaller M² value), can achieve finer focus points, and are suitable for high-precision welding processes. The design structure, power stability, and working mode (continuous wave or pulse mode) of the laser generator will have a direct impact on the final beam quality.

Beam transmission system: In many industrial laser systems, the beam is transmitted over long distances via optical fibers or light guide arms. Any mechanical vibration, loose connections, or fiber bending in the transmission path may cause beam shape distortion, increased divergence, or decreased transmission efficiency. These problems not only reduce beam quality but also cause welding instability, increased spatter, and other problems.

System stability: The operating environment of the laser welding system will also have a lasting impact on the beam quality. For example, changes in ambient temperature may cause the optical components to expand and contract, which in turn affects the beam collimation; mechanical vibrations may cause the components to shift, affecting the stability of the optical path; and aging of the laser generator may cause output power fluctuations, resulting in a decrease in beam consistency. Therefore, maintaining the overall stability of the system is essential to ensure continuous high-quality welding output.

Beam quality is one of the core indicators for measuring laser welding performance, which directly affects the accuracy, welding depth, and overall stability of the weld. By understanding the M² factor and its measurement criteria, and an in-depth understanding of key influencing factors such as laser generators, optical components, transmission systems, and system stability, companies can more specifically optimize equipment configuration and maintenance strategies, thereby improving the overall efficiency and quality level of laser welding.

The Importance of Beam Quality in Laser Welding

In laser welding applications, beam quality not only determines the degree of energy concentration but also directly affects the accuracy, efficiency, and quality of the welding process. Good beam quality means stronger focusing ability and energy density, which is of vital importance for improving welding effects, reducing defects, and adapting to a variety of materials. The following points further illustrate the important value of beam quality:

Welding quality: High-quality laser beams have smaller divergence angles and stronger focusing capabilities, which can accurately focus laser energy on the welding area. This focusing performance makes the weld narrower and deeper, and the weld fusion is more complete, which significantly improves the welding strength and sealing. At the same time, due to the uniform energy distribution, it can effectively reduce common defects such as spatter, ablation and burrs, improve the overall appearance quality and structural integrity of welded parts, and is particularly suitable for welding products with high requirements for appearance and performance, such as electronic components, medical devices and automotive parts.

Precision and accuracy: In the field of high-precision manufacturing, such as microelectronics, precision instruments, and micro-components processing, the requirements for welding precision are extremely strict. High-quality beams can effectively control the size of the molten pool and the width of the weld, and achieve point-to-point and line-to-line precise operations. This controllability not only improves the repeatability of the welding process but also ensures the consistency of each welding result, reducing rework and loss caused by errors.

Heat input control: Lasers with good beam quality can accurately adjust heat input and reduce the range of the heat-affected zone (HAZ) through meticulous energy control. This can effectively prevent structural deformation caused by overheating of the material and maintain the mechanical properties and organizational stability of the material itself. Especially in the welding of thin-walled materials, heat-sensitive alloys or multi-layer structure processing, good heat input control ability is particularly critical, which helps to prevent problems such as burn-through, discoloration, and hardness loss.

Excellent beam quality is the basis for achieving efficient and high-precision laser welding. It not only determines the welding strength and appearance, but also affects the controllability and yield of the overall production process. For companies pursuing high-quality welding solutions, continuously optimizing beam quality is one of the core strategies to enhance competitiveness and meet diversified welding needs. By selecting high-performance laser sources, optimizing optical path systems, and combining advanced control technologies, companies will be able to stand out in the fierce manufacturing market.

The influence of beam quality on welding performance

In the laser welding process, beam quality is not only a physical parameter but also a key variable that determines the stability of welding performance and the quality of the final product. Excellent beam quality can accurately control energy input, improve welding efficiency, and adapt to the welding requirements of different materials. The following specifically analyzes the actual impact of beam quality on laser welding performance from multiple angles:

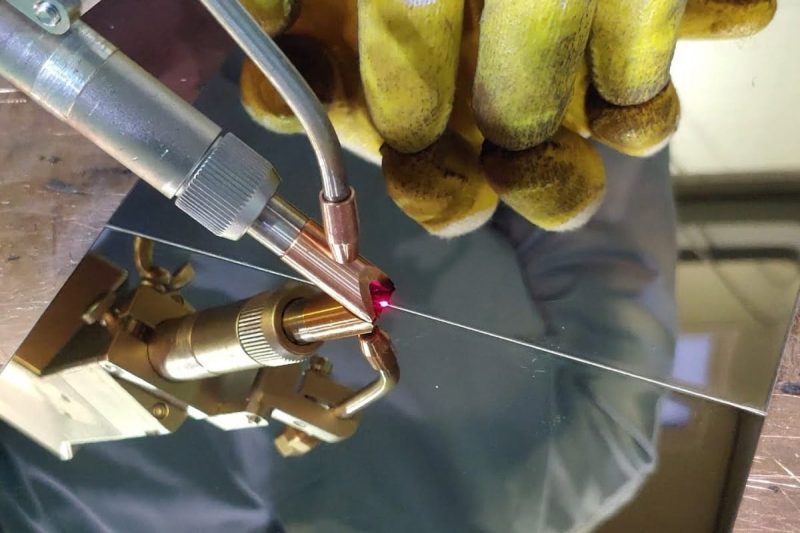

Beam focus: The focusing ability of the laser beam determines its power density at the focus. The better the beam quality, the closer its M² value is to 1, the smaller the spot size after focusing, and the more concentrated the energy. This high energy density can quickly melt the material, increase the welding depth and welding speed, especially for thick plate welding or welding scenes requiring high penetration depth. At the same time, it also helps to control the weld geometry and improve processing accuracy.

Welding speed: Laser generators with high beam quality have stronger heat input control capabilities, which can complete the melting and cooling process in a shorter time, greatly increasing the welding speed. This not only helps to improve the production line’s beat, but also reduces the heat diffusion effect of the laser on the surrounding materials, thereby improving the overall welding efficiency and finished product yield.

Material compatibility: For highly reflective or thermally conductive materials such as อลูมิเนียม และ ทองแดง, laser welding often faces the problems of high energy reflectivity and high welding difficulty. At this time, only laser beams with strong focus and high stability can effectively couple to the material surface and achieve fast and stable welding effects. High-quality beams can also reduce the risk of welding defects caused by uneven heat input and improve the welding ability of dissimilar metals.

Welding quality and consistency: The stability of beam quality is directly related to the consistency of energy input during welding. If the laser beam diverges or jitters during transmission, it is very easy to cause problems such as uneven weld width and depth. A stable beam can ensure that the molten pool state is constant during continuous welding, thereby significantly reducing the probability of welding defects such as pores, cracks, and lack of fusion.

Reduce defects: High-quality laser beams have more uniform energy distribution at the focus, and can finely control the depth and width of the melt to avoid local overheating or insufficient energy. This control capability not only improves the quality of the weld but also effectively reduces common defects such as burn-through, slag inclusions, or collapse, providing a solid guarantee for high-demand welding.

Good beam quality is not only related to the surface effect of welding, but also has a deeper impact on the efficiency, stability, and material adaptability of the welding process. For manufacturing companies that want to improve product consistency and processing efficiency, improving the beam quality of the laser system is one of the core strategies to enhance overall competitiveness. By properly selecting laser generators, optical systems, and stable transmission structures, the process advantages of laser welding can be maximized to achieve efficient, reliable, and low-defect welding production.

Optimizing the beam quality of laser welding

Beam quality is one of the core determinants of laser welding results. It is directly related to the forming quality of the weld, welding stability, and overall production efficiency. With the continuous development of high-precision welding applications, how to systematically optimize the laser beam quality has become a key link in improving welding performance. The following will discuss the three aspects of equipment maintenance, technology upgrade, and process control.

Proper maintenance and calibration: Keeping the optical system clean and stable is the basis for ensuring beam quality. Dust or scratches on the reflector, focusing mirror, and protective lens in the laser system will cause laser energy attenuation and beam distortion. Therefore, the optical components should be checked and cleaned regularly, and the optical path should be accurately calibrated using professional tools to ensure that the laser beam is stably transmitted to the welding station to avoid beam deviation, uneven energy distribution, and other problems.

Advanced beam shaping technology: With the diversification of welding tasks, a single Gaussian beam mode can no longer meet all application requirements. By using advanced technologies such as mode converters (such as DOE optical elements), multimode couplers or dynamic adjustable focus systems, the spot shape and energy distribution can be flexibly adjusted according to different welding requirements, so that the laser energy can act more accurately on the target area, thereby improving the adaptability and refinement of welding. For example, in thin plates or micro welding, it can be adjusted to a smaller spot to concentrate energy; in thick plate welding, the spot can be enlarged to improve efficiency.

Quality control measures: By integrating high-performance sensors and monitoring systems, the laser output power, spot shape, and energy fluctuations can be detected in real time, which can effectively warn of abnormal changes in the beam. With the closed-loop control system, the laser output can be dynamically adjusted during the welding process to maintain a constant energy density and ensure the consistency of welding quality. This intelligent control can not only reduce manual intervention and improve the level of equipment automation, but also significantly improve the stability and reliability of the production process.

Improving the beam quality of laser welding not only depends on the performance of the laser generator itself but also requires a systematic quality assurance system through meticulous daily maintenance, advanced beam shaping technology, and intelligent monitoring methods. By continuously optimizing beam quality, companies can achieve comprehensive improvements in welding accuracy, process adaptation, and finished product consistency, thereby maintaining their leading position in technology and quality in the laser manufacturing industry.

สรุป

Beam quality not only determines the processing performance of the เครื่องเชื่อมเลเซอร์ but also affects the efficiency and yield of the entire production system. Improving beam quality is the core technology that every company using laser welding technology must pay attention to.

ในฐานะผู้ผลิตอุปกรณ์เลเซอร์ระดับมืออาชีพ แอคเทค เลเซอร์ always puts beam quality control at the top of product research and development and manufacturing. Our laser welding equipment is equipped with a high-stability fiber laser generator, a precise focusing system, and an intelligent control platform, which can be widely used in a variety of metal welding tasks, helping customers achieve higher quality and more efficient welding results. If you are looking for high-performance laser welding solutions, please feel free to ติดต่อเรา. We look forward to working with you to create a new era of intelligence in industrial manufacturing.

ข้อมูลติดต่อ

- [email protected]

- [email protected]

- +86-19963414011

- หมายเลข 3 โซน A เขตอุตสาหกรรม Luzhen เมือง Yucheng มณฑลซานตง

รับโซลูชันเลเซอร์