دليل شامل لاختيار آلة القطع بالليزر المناسبة

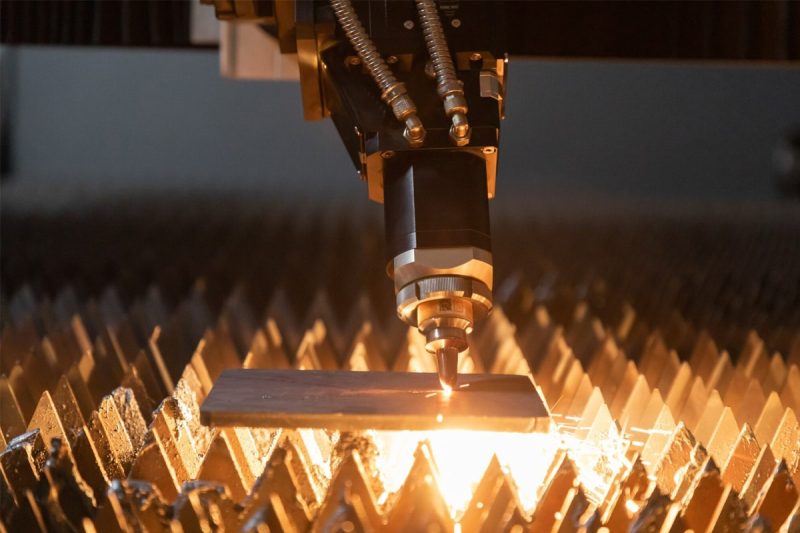

Against the backdrop of rapid transformation and automation upgrades in today’s manufacturing industry, laser cutting technology is gradually replacing traditional metal processing methods such as shearing, stamping, and plasma cutting, becoming one of the most widely used advanced processing technologies in various industrial production processes. Whether it’s precision medical devices, complex aerospace parts, high-strength automotive structural components, or high-precision metal nameplates, sheet metal processing, and electronic product casings, fiber laser cutting machines demonstrate significant advantages such as high speed, high stability, high precision, and lower production costs. Laser cutting not only effectively improves processing efficiency but also helps companies achieve flexible production and reduce reliance on manual labor through automated control systems and intelligent process libraries, thereby further enhancing market competitiveness.

With the continuous upgrading of laser technology, the types of laser cutting equipment are also increasing. From platform-type fiber laser cutting machines, fully enclosed laser cutting machines, and high-speed cutting machines with exchange tables, to laser tube cutting machines specifically designed for pipe and profile processing, laser cutting systems with different configurations and power are rapidly adapting to various industry scenarios. The significant differences in configuration among laser cutting machines on the market often leave companies facing confusion when selecting a model: should they choose a high-power laser cutting machine for efficiency, or a medium-power machine to balance cost and precision? Is it about brand and service guarantees, or is it about overall processing capacity and future expansion potential? Clearly, choosing laser cutting equipment is no longer a simple matter of “higher power is better” or “lowest price is the advantage.”

Therefore, when purchasing laser cutting equipment, companies need to evaluate and compare from multiple dimensions. This comprehensive guide will help you systematically analyze how to choose the most suitable laser cutting machine model and configuration for your company, starting from key factors such as actual application needs, material type, cutting thickness, laser power configuration, industry usage characteristics, brand comparison, after-sales service system, and long-term return on investment. Whether you are looking for a medium-power fiber laser cutting machine suitable for small to medium batch processing or planning a high-power, high-end laser cutting system for an automated production line, this article will provide you with professional, practical, and valuable selection ideas to help you avoid problems such as over-investment or insufficient equipment performance.

جدول المحتويات

Clearly Define Your Production Needs

Before choosing a laser cutting machine, the most crucial, yet often overlooked, step is to understand your processing needs thoroughly. Only by clearly defining key factors such as material properties, cutting accuracy, production efficiency, and future scalability can you truly determine which fiber laser cutting machine is best suited for your business. Laser cutting equipment is not a generic commodity but an industrial solution that must be highly compatible with your industry, production scenario, and processing goals.

Material Type Determines Laser Configuration

What do you primarily cut? Stainless steel? Carbon steel? Aluminum alloy? Or highly reflective materials such as copper and titanium? Different materials have completely different requirements for laser absorption rate, cutting stability, and beam quality. For example, stainless steel and carbon steel are suitable for most medium-to-high power fiber laser cutting machines, but highly reflective materials like aluminum and copper require higher beam stability and a high-quality laser source brand to avoid reflective damage to the optical system.

In addition, material thickness also determines the equipment selection:

- If you mainly process thin and medium-thick plates (1-12mm), a laser power of 1.5kW-6kW is generally sufficient;

- If you frequently process thick plates above 20mm or require high-volume processing, it is recommended to choose an 8kW, 12kW, or even higher power laser cutting machine, equipped with a professional laser cutting head and a stable cooling system.

- If your business includes pipe processing, consider models with a rotary axis (tube laser) or dedicated pipe laser cutting machines.

Consider the Required Cutting Accuracy and Speed

Many people buying a laser cutting machine for the first time usually only focus on “how fast it is and whether the power is sufficient.” However, in practical applications, accuracy requirements are often more important than speed, especially in the following scenarios:

- Aerospace, medical devices, precision sheet metal processing: requiring burr-free cutting edges and extremely low dimensional deviations;

- Advertising signs and creative decorations: pursuing rich detail in cutting patterns and smooth cuts;

- Prototype design and teaching research and development: requiring high material adaptability and stable repetitive cutting accuracy.

If your business focuses on high-precision processing, then the performance of the control system, beam quality, laser head brand, servo motor, and guide rail configuration are more important than laser power.

Production Modes and Capacity Planning Influence Equipment Selection

Production modes significantly determine the type of equipment needed: If you handle OEM bulk orders and prioritize production efficiency, delivery speed, and equipment stability, then high-power laser generators, exchange platforms, high-speed drive systems, and automatic loading and unloading functions become crucial.

However, if your business involves multi-variety, small-batch, and highly flexible orders, such as light manufacturing, custom decoration, R&D centers, or prototyping studios, then you should focus on:

- Ease of program switching

- Intelligent operating system

- Support for rapid drawing import

- Stable processing of various materials

Budget Constraints and Long-Term Investment Considerations

The return on investment for a laser cutting machine comes not only from the purchase price but also from long-term stable operation, production costs, safety performance, maintenance costs, and upgrade and expansion capabilities. When setting a budget, companies should consider the following long-term factors:

- Is the laser generator brand stable and reliable, with a sufficiently long service life?

- Are the long-term maintenance costs high, and are key components easy to replace?

- Is the operating system easy to understand, and does it require significant training costs?

- Does it support future laser power upgrades or the addition of automation features?

Sometimes, choosing equipment with a slightly higher initial investment but greater long-term stability and lower maintenance costs is the truly “cost-effective” option. A laser cutting machine is not just a machine; it’s the foundation for a company’s future intelligent manufacturing upgrade. From a technological development perspective, automated loading and unloading, integrated laser cutting and bending/welding, MES system integration, and remote maintenance and diagnostics are all becoming new standards in industrial manufacturing. If you plan to expand your business in the future, it is recommended to consider the following questions in advance:

- Does the equipment support power upgrades?

- Are there interfaces reserved for rotary axes or automation modules?

- Does the control system support remote monitoring or factory system management?

- Does the laser generator brand have technological scalability?

Clearly defining production needs is not simply saying, “I need to cut plates of a certain thickness and require a certain power,” but rather a comprehensive assessment from multiple perspectives, including materials, capacity, precision, investment, and future scalability. The more in-depth this analysis is, the more it will help you avoid blind investment and choosing the wrong equipment, leading to higher production efficiency and a faster return on investment for your company.

Understanding Laser Cutting Machine Configurations

After clarifying your production needs, the next step isn’t to immediately look at price quotes, but rather to gain a deep understanding of the core configurations of the laser cutting machine. Different equipment structures, laser source types, cutting head performance, cooling systems, control systems, and levels of intelligence will directly affect cutting results, stability, and maintenance costs. Correctly understanding these configurations is like understanding a car’s engine, chassis, and transmission system – it’s essential to truly assess a laser cutting machine’s “hard power” and “potential.”

Open Bed vs. Enclosed Bed

The appearance and structure of a laser cutting machine determine its operation method, safety, and applicable scenarios.

- Open bed: Simple design, easy loading and unloading, suitable for processing thin to medium-thick plates and small to medium-sized factories; easy for daily maintenance, and relatively lower price. However, its disadvantage is weaker dust and fume control and the lack of complete enclosed safety protection.

- Enclosed laser cutting machine (fully enclosed design): Equipped with a fully enclosed protective cover and a dust and fume filtration system, offering high safety and a cleaner cutting environment. Suitable for industries such as automotive manufacturing, medical equipment, and precision sheet metal processing, and also complies with industrial environmental standards in regions such as Europe and the United States. More suitable for companies with higher requirements for factory image, environmental protection, and stable production capacity.

The choice depends not only on workshop space and budget, but also on the nature of the industry, environmental policies, and the company’s future development direction.

Laser Power: Not the higher the better, but the better the match

Laser power directly determines cutting thickness, speed, and processing efficiency, but it doesn’t mean that higher power is always better. Companies should make a comprehensive judgment based on material thickness, cutting workload, and production capacity goals:

- 1kW–3kW: Suitable for thin plate processing, advertising signs, sheet metal prototyping, and small-batch custom processing.

- 3kW–6kW: Suitable for sheet metal factories, chassis and cabinets, kitchen equipment, and general manufacturing industries.

- 6kW–12kW: Suitable for industrial batch processing, thick plate cutting, vehicle manufacturing, and construction machinery.

- Above 12kW: Suitable for high-strength metal manufacturing industries such as shipbuilding, heavy industry, bridges, and energy equipment.

It’s important to note that increased power doesn’t just mean cutting thicker materials; it also brings higher cutting speeds, lower unit costs, and better cutting results (smoother edges, thinner oxide layers).

ماركة مولد الليزر

The laser generator is the “heart” of the laser cutting machine, directly affecting cutting results, equipment stability, and operating costs. Currently, mainstream fiber laser generator brands include IPG, Raycus, Max, and JPT. When choosing a laser generator, the following aspects should be considered:

- Is the beam quality stable?

- Does it support cutting thick plates and highly reflective materials?

- Are the maintenance costs controllable?

- Does it have intelligent monitoring functions (power detection, optical path diagnosis)?

- Does the brand have global after-sales support services?

Domestic brands have advantages in cost-effectiveness and maintenance costs, while imported brands are more competitive in high-power stability and precision processing.

رأس القطع بالليزر

The cutting head is not only responsible for focusing the laser beam, but also affects cutting accuracy, piercing effect, and service life. High-performance cutting heads usually have functions such as automatic focusing, intelligent anti-collision, temperature monitoring, and automatic cleaning, making them particularly suitable for processing highly reflective materials and thick plate cutting.

For industrial customers with large-scale production, automatic focusing and height following functions can significantly improve efficiency, reduce manual adjustment time, and maintain stable cutting quality.

Exchange Table, Rotary Axis, and Automatic Loading/Unloading System

If a company has a large number of orders, high daily cutting volume, and tight delivery schedules, a laser cutting machine with a dual exchange platform can significantly improve production efficiency – while the equipment is cutting, materials can be loaded and unloaded on the other side, resulting in almost no waiting time.

If the cutting involves pipes, stainless steel round pipes, square pipes, or profiles, models with a rotary axis or dedicated laser pipe cutting machines should be considered.

For companies preparing to upgrade to a smart factory, they can further integrate automatic loading and unloading systems, automated storage systems, and MES systems to achieve automated operation of the laser cutting production line.

نظام التبريد

The cooling system is one of the key configurations in laser equipment. Its function is to maintain the laser generator, cutting head, and electrical control system at a stable temperature. High-power laser equipment especially requires a professional chiller system to ensure stable beam output, extend the life of the laser generator, and reduce maintenance costs.

نظام التحكم

The control system not only controls the operation of the equipment but also affects production efficiency, drawing import methods, cutting path planning, piercing optimization, consumable management, and fault diagnosis. A high-quality laser control system usually has:

- Support for quick import of various drawing formats, such as DXF and IGES

- Automatic optimization of cutting paths to reduce idle travel

- Remote fault diagnosis, work order analysis, and intelligent maintenance reminders

- Can be integrated with MES intelligent manufacturing systems

The higher the level of intelligence, the more suitable the equipment is for the long-term development and automated production upgrades of the enterprise. Understanding the configuration of a laser cutting machine is like deciphering its performance DNA. Only by understanding the technical value behind the configuration can you truly “spend your money wisely, buy the right machine, and use it for a long time” when making a selection.

Considerations for Specific Industries and Applications

When purchasing a fiber laser cutting machine, the process requirements often differ significantly between different industries. The same equipment, power, configuration, or cutting platform may perform and deliver completely different value in different companies’ production environments. Therefore, making targeted selections based on your industry’s specific needs can not only improve cutting efficiency and processing accuracy but also avoid cost waste due to mismatched configurations.

Metal Processing Industry

The metal processing industry is one of the most widely used fields for fiber laser cutting machines. From thin sheet metal processing to thick plate cutting, from customized parts production to mass manufacturing, there are strict requirements for equipment stability, beam quality, and cutting consistency. For factories mainly processing الفولاذ الكربوني, الفولاذ المقاوم للصدأ، و الألومنيوم plates, whether the equipment has high-speed piercing technology, excellent cutting surface quality, and long-term operational reliability often directly affects overall production capacity and order delivery capabilities.

Metal processing companies usually need to handle multiple materials, so they should prioritize the completeness of the cutting parameter library and the adaptability to reflective materials. If mainly processing medium-thick plates (6–20mm), it is recommended to choose a power range of 6kW–12kW to obtain faster cutting speeds and more stable cutting surface quality. For factories operating multiple shifts or 24/7, the machine tool structural strength, guide rail brand, and servo system lifespan will also affect long-term investment value.

Automotive Manufacturing Industry

The automotive industry highly relies on the repeatability and dimensional consistency of laser cutting. Whether it’s body sheet metal, chassis parts, or structural components, laser cutting must meet strict process standards while ensuring high-speed processing and batch consistency.

Automotive processing usually requires a high degree of automation, so focus on configurations such as automatic loading and unloading, tower storage systems, automatic laser head focusing, and online monitoring. The ability to cut lightweight materials such as aluminum alloys and magnesium alloys is particularly crucial; choose equipment with real-time power control and excellent beam mode. If curved surfaces or irregularly shaped parts are involved, consider whether a 3D laser cutting machine or a robotic laser processing unit is needed.

Advertising and Signage Industry

The advertising industry mainly focuses on thin sheet metal cutting, with higher requirements for the smoothness of the cutting surface and the quality of small character cutting, especially for stainless steel laser cutting and galvanized sheet laser cutting, which are very sensitive to edge effects and the accuracy of small graphics.

The advertising industry typically uses thin materials (0.5–3mm), so high-power equipment is not necessary; 1.5kW–3kW is sufficient for most needs. The focus is on the ability to cut small circular holes, small fonts, and intricate shapes. Laser sources with excellent beam quality significantly improve fine processing results. The industry has diverse and rapidly changing orders, so the efficiency of material switching and the ease of use of the software are also crucial for production efficiency.

صناعة الطيران

The aerospace sector demands extremely high precision and material performance, often involving difficult-to-machine materials such as titanium alloys and nickel-based alloys, placing higher demands on the reliability and cutting quality of laser equipment.

For processing high-value materials, a high-end fiber laser cutting machine with stable beam quality and a low heat-affected zone should be chosen. For thick titanium alloys or heat-resistant alloys, high-power laser sources (≥12kW) offer significant advantages in efficiency and cutting consistency. Some aerospace components require complex curves or precise patterns, necessitating a high-precision follow-up system and an advanced motion control system.

Electronics and Medical Industries

Typical processing objects in this field include ultra-thin stainless steel sheets, precision parts, and small structural components, requiring extremely high precision, minimal heat-affected zone, and workpiece integrity.

The electronics industry emphasizes extremely small kerf widths and low-deformation processing, making laser sources with higher beam quality grades suitable. The medical industry often uses 316L stainless steel and titanium, requiring equipment with stable, low-power cutting capabilities and fine mode control functions. If mass production of medical devices is involved, the equipment’s repeatability and micro-cutting capabilities should be a key consideration.

In different industrial chains, the role of fiber laser cutting machines vary. The equipment truly suitable for a company is often not the one with the “highest power” or “most expensive configuration,” but rather a solution that precisely matches the industry’s process characteristics, material properties, and long-term production planning. Whether you are in metal processing, automotive manufacturing, advertising signage, aerospace, or electronics and medical industries, a comprehensive evaluation based on factors such as material thickness, cutting accuracy, production pace, automation level, and quality consistency is necessary. Only by deeply matching industry needs with equipment performance can fiber laser cutting machines truly deliver value in actual production, improve processing efficiency, optimize cost structures, and build a stronger production advantage and market competitiveness for the enterprise in future competition.

البحث والمقارنة بين الخيارات

Once you have clearly defined your production needs, the next step is the most crucial part of the laser cutting machine selection process – researching and comparing different equipment options. The laser cutting equipment market is highly competitive, with various brands, models, and configurations that may appear similar but differ significantly in core performance, stability, long-term maintenance costs, and actual processing results. Therefore, systematically comparing options is necessary to ensure a return on investment.

Differences in Equipment Positioning and Technological Approaches Across Brands

In the fiber laser cutting machine industry, each brand has different technological approaches and research and development priorities. Some brands focus on equipment structural stability and thick plate processing capabilities, while others prioritize lightweight bodies and high speed. Some focus on intelligent control systems and software ecosystems, while others emphasize laser source stability and long-term lifespan. When comparing brands, consider several key dimensions:

- Stability of core components: The laser generator, cutting head, servo system, and cooling system are fundamental to equipment performance. Brand differences directly affect equipment lifespan and maintenance costs.

- Technological maturity: Equipment systems from mature brands tend to be more stable, with more refined software optimization, avoiding long-term debugging and instability issues.

- Industry adaptability: Some brands excel in high-speed thin plate cutting, some specialize in thick plate heavy industry, and others are more suitable for advertising signage or small and medium-sized factories.

Understanding brand positioning can effectively prevent “blindly following trends and buying a big brand that doesn’t suit your business.”

Differences in Core Configurations Affect Actual Processing Results

When researching options, don’t just focus on power or price; compare the performance of core configurations in real-world scenarios. For example:

- Differences in beam quality between laser generator brands: High-quality light sources are more stable when cutting highly reflective materials such as copperand aluminum, and can maintain better penetration and cutting speed in thick plate cutting.

- Focusing speed and spot control capabilities of the laser cutting head: Cutting heads with fast automatic focusing speeds have a significant advantage in high-speed thin plate cutting, while also reducing manual intervention and improving processing continuity.

- Robustness of the machine tool structure: Machine vibration during high-speed processing directly affects accuracy. Lightweight machines may experience accuracy degradation after years of use, while heavy-duty welded beds can maintain long-term stability.

- Ease of use and intelligence of the control system: Is the operating interface user-friendly? Does it support flying cutting, automatic edge finding, and automatic calibration? Can it memorize process parameters? These factors directly impact productivity and personnel training costs.

Actual processing demonstrations and sample cutting comparisons usually provide a more accurate reflection of the equipment’s true performance than simply reviewing specification sheets.

Long-term operating costs are a crucial factor that must be included in the comparison

Many companies, when comparing laser cutting machines, only focus on the initial purchase price, neglecting the differences in long-term operating costs. In fact, the long-term expenses of a fiber laser cutting machine can far exceed the cost of the equipment itself, especially including:

- Energy consumption and lifespan of the fiber laser generator

- Replacement frequency of consumable parts in the cutting head

- Stability and energy consumption of the cooling system

- Whether the maintenance cycle is short, and whether high maintenance costs are required

- Whether parts are readily available and whether long overseas supply cycles are necessary

High-quality equipment is often more cost-effective in the long run because it reduces downtime, maintenance, and material waste, maintaining stable productivity.

On-site visits and sample cutting are the most reliable verification methods

No matter how professional the sales personnel’s descriptions are or how perfect the specification sheet looks, the final judgment should be based on the actual processing results. When researching options, it is highly recommended that you perform the following steps:

- Visit the factory to observe the equipment assembly process and production procedures.

- Observe the number of machines in the production workshop to assess the brand’s maturity.

- Provide your own materials for test cutting to check the surface finish, burrs, and heat-affected zone size.

- Observe whether the equipment is stable during high-speed processing and whether there are problems such as shaking or excessive noise;

- Inquire about the professionalism, response speed, and international support capabilities of the after-sales team.

These verification steps ensure that you not only buy “equipment that looks good,” but a solution that can truly meet your production needs.

Evaluate solutions by combining short-term needs with long-term strategies

The choice of a laser cutting machine should not be based solely on current order volume, but should be combined with the company’s future development direction. If you plan to expand production capacity, enter higher-precision fields, support automated factories, or intelligent manufacturing in the future, then you should consider the following when researching options:

- Whether it supports laser power upgrades;

- Whether automation interfaces are provided;

- Whether it can be connected to MES systems or automated warehousing;

- Whether there is a mature automatic loading and unloading solution;

- Whether it has advanced functions such as remote diagnostics and intelligent monitoring.

Choosing a laser cutting machine with upgrade potential often allows businesses to maintain technological competitiveness for the next 3-5 years without frequent machine replacements.

When researching and comparing laser cutting machine options, you need to make a comprehensive assessment from multiple dimensions, including performance, configuration, brand background, actual processing capabilities, long-term costs, and future scalability. A fiber laser cutting machine is a production asset, and its value is reflected not only in “whether it can cut,” but also in “how long it can cut, how fast it can cut, how stable it is, whether the costs are controllable, and whether it can propel the enterprise to a higher level of production.”

By thoroughly comparing different options, businesses can not only avoid investment risks but also select equipment that truly fits their industry and production capacity plans, thereby maintaining efficiency and technological advantages in the future market.

Evaluating Support and Services

When choosing a laser cutting machine, many companies often focus only on parameters, power, cutting speed, and price range, neglecting a factor even more important than the hardware itself—the service system and long-term support capabilities. As a high-precision industrial equipment, the stable operation of a fiber laser cutting machine depends not only on the machine itself but also on the professional capabilities of the after-sales team, the speed of spare parts supply, the maturity of the maintenance system, and cross-border technical support.

Excellent equipment is not just about “looking good at the time of purchase,” but about providing continuous production capacity throughout its entire lifecycle—this is the true meaning of industrial investment. Below, we will discuss from multiple dimensions why service support is a critical indicator that companies must carefully evaluate.

After-Sales System

Fiber laser cutting machines have a complex structure, consisting of numerous sub-modules such as the laser generator, cutting head, cooling system, servo drive system, fume extraction system, and control system. Any system malfunction can affect production efficiency. Therefore, a reliable after-sales team must possess:

- A team of engineers with a deep understanding of laser equipment: Engineers must not only understand the machine structure but also be familiar with optical systems, electronic equipment, and software control logic, and be able to provide accurate diagnoses and solutions in a short time.

- Rapid response and cross-time zone support capabilities: International customers need to assess whether the supplier can provide 24/7 remote support, respond to issues across time zones, and have a mature video diagnostic system and online debugging capabilities.

- Standardized service processes: Is there a clear service response mechanism? Does it provide a one-stop process for installation, training, maintenance, and upgrades? The more mature the service process, the higher the equipment stability.

A professional after-sales system means that you can avoid huge losses caused by downtime in your future production process.

Spare Parts Supply

For factories that are constantly processing orders, even one day of equipment downtime can mean significant cost losses. Therefore, when evaluating laser cutting machine brands, it is crucial to pay attention to their spare parts supply capabilities:

- Is there sufficient stock of commonly used spare parts, such as protective lenses, nozzles, ceramic rings, and sensors?

- Is the laser generator a mainstream brand in the industry, and can it be quickly procured?

- Are the cutting head components easily available, or do they require lengthy overseas shipping?

- Are there stable supply chains for key components such as chillers and servo drives?

Spare parts supply is not an “additional service” during equipment sales, but a core guarantee to ensure uninterrupted production.

Training and Operational Guidance

Even the most advanced fiber laser cutting machine cannot achieve its full potential in terms of speed, precision, and cutting quality if operated incorrectly. Therefore, when evaluating service systems, you should focus on the supplier’s training capabilities:

- Does it provide systematic operational training?

- Does it include instruction on process parameters, rather than simply teaching “how to turn it on”?

- Does it have a cutting sample parameter library and industry application guidance?

- Does it provide continuous learning resources such as video training, online courses, and documentation support?

An excellent training system not only allows new users to quickly get started but also enables companies to develop more materials and processes in the future, achieving profitability in a wider range of application scenarios.

Software Updates and Process Upgrades

Modern laser cutting machines are no longer traditional “hardware devices,” but rather “technology platforms” that include a large number of software algorithms, process databases, and intelligent parameter optimization functions. Therefore, when comparing suppliers, you should consider:

- Does the control system support continuous updates?

- Can you obtain free process optimization and parameter library upgrades?

- Does it provide industry-specific cutting solutions (such as thick plate perforation optimization, high-speed cutting of copper and aluminum, intelligent laser edge finding, etc.)?

- Do the laser generator and cutting head support future upgrades to improve production efficiency?

Software and process upgrade mechanisms are important guarantees for extending equipment life and improving production efficiency.

Overseas Service Network and Multinational Support Capabilities

For export-oriented companies or multinational manufacturing plants, choosing a laser cutting machine requires even greater attention to the supplier’s global service capabilities:

- Does it have local service points or cooperative technical centers?

- Does it have remote diagnostic and remote process debugging capabilities?

- Is installation and commissioning performed by experienced international engineers?

- Can it provide export documents, customs clearance support, and international logistics solutions?

For companies that frequently export products and operate internationally, a mature international service system can greatly reduce maintenance risks and improve equipment stability.

Company Reputation and Real User Feedback

In the laser industry, advertising can be exaggerated, but user experience never lies. Before making a purchase decision, we recommend that you learn about the real service level through the following methods:

- Check user reviews of the supplier on industry forums and social media platforms.

- Directly consult customers who are using the same brand of equipment.

- Understand the number of installation cases and industry coverage.

- Ask whether the after-sales team can independently solve optical system and electronic system problems.

The more mature the brand, the more real-world cases it has to support its claims, and the more trustworthy its service capabilities are.

Reliable after-sales service is not an optional add-on for equipment, but an indispensable core component of the entire laser cutting production chain. A comprehensive technical support system, a rapidly responsive team of engineers, ample spare parts supply, systematic operational training, and continuous software and process upgrades determine whether a fiber laser cutting machine can operate stably, maintain high production efficiency, and have a low failure rate for years to come.

Choosing a supplier with professional service capabilities not only avoids unnecessary downtime losses but also ensures that the equipment remains in optimal condition throughout its lifecycle, providing businesses with long-term and stable returns on investment.

Making Your Decision

Once you have completed the needs analysis, industry matching, equipment research, and service system evaluation, you have established a relatively comprehensive, objective, and rational framework for decision-making. At this point, choosing a fiber laser cutting machine suitable for your company’s future development is no longer just an “equipment purchase,” but a long-term investment decision that deeply impacts capacity improvement, cost structure optimization, and strategic layout upgrades.

When making your final decision, you need to consider multiple dimensions, including technology, budget, management, and growth potential, to ensure that the purchase truly achieves “sustainability, high returns, and scalability.”

Returning to Actual Production Needs

In the laser equipment market, there is a constant stream of “flashy features” such as exaggerated parameters, power stacking, and extreme prices. However, whether they are ultimately suitable depends on your actual business model. Before making your final decision, ask yourself again:

- Does the equipment truly match the thickness and types of materials processed daily?

- Does the actual order volume require such high power or speed?

- Is there a possibility of “over-purchasing” or “wasted performance”?

- If production capacity increases in the future, does the equipment have expansion capabilities?

Only equipment configurations that align with your long-term business plan can maximize the return on investment.

Comprehensive Evaluation

The purchase price of a laser cutting machine is only the initial cost. More importantly, consider the cost structure of the equipment over the next 5-10 years, including:

- استهلاك الطاقة

- Consumables and wear parts

- Daily maintenance costs

- Production losses due to downtime

- Software upgrades and service fees

- Spare parts supply speed and logistics costs

Often, cheaper equipment initially does not mean cheaper in the long run; while equipment with a slightly higher initial investment but excellent stability may save the company a significant amount of hidden expenses over the years.

Considering Future Automation and Intelligent Manufacturing Trends, Assess the Strategic Value of the Equipment

For companies that want to improve factory efficiency, reduce labor costs, and move towards intelligent manufacturing, a laser cutting machine is not only a production tool but also a core component of a digital factory. Before making a choice, you should clarify:

- Does the equipment support automated loading and unloading?

- Is it compatible with robotic cutting, material handling systems, and smart warehousing?

- Does the software support MES integration?

- Does it have functions such as remote monitoring, intelligent parameter adjustment, and data analysis?

These functions may not change the company on day one, but they will gradually determine the factory’s competitiveness in the coming years.

Final Verification Through Sample Cutting and Factory Evaluation

No matter how good the brand promotion, how strong the sales pitch, or how attractive the specifications, nothing can replace real processing performance. Therefore, before making a final decision, be sure to conduct the following verifications:

- Perform multiple test cuts using your own materials.

- Test the cutting effects on different thicknesses and materials.

- Observe the vibration performance during high-speed cutting.

- Observe the stability after long-term operation.

- Conduct on-site inspections of the supplier’s factory production process and manufacturing quality.

These practical experiences will help you confirm whether the equipment is truly suitable for your company, better than any specification sheet.

Consider service and support capabilities as a key weighting factor in the final decision

As emphasized in previous chapters, the service system actually determines whether a laser cutting machine can consistently create value in the future. Therefore, in the final selection stage, please ensure:

- Whether the engineers are professional and responsive.

- Whether remote support and international services are available.

- Whether there is a sufficient supply of spare parts.

- Whether long-term process support and software updates are available.

- Whether there are successful case studies and mature experiences.

Only suppliers with a combination of technology, equipment, and service systems can ensure that your investment is sound and reliable.

After making the decision, plan the subsequent production and management processes

Purchasing a laser cutting machine is not the end, but the beginning of production optimization. After the final selection, you need to:

- Plan the equipment installation and trial production phases.

- Develop operating procedures and training plans.

- Adjust the processing technology route.

- Plan material inventory and production rhythm.

- Set quality standards and inspection procedures.

- Establish a daily maintenance mechanism.

These actions will allow the new equipment to be smoothly integrated into the production system and quickly generate capacity.

Making a laser cutting equipment procurement decision is a complex process that requires data verification, technical comparison, industry understanding, and future strategic judgment. Reasonable configuration, stable performance, a professional support system, automation capabilities suitable for enterprise development, and controllable long-term costs constitute the criteria for a “correct choice.”

When you make your final decision based on thorough investigation, clear needs, and rational judgment, you can not only effectively avoid investment risks but also lay a solid foundation for your company’s future capacity upgrades, cost optimization, and enhanced competitiveness. This is not just an equipment purchase, but a strategic action to propel your company to a higher level of manufacturing.

ملخص

Choosing a laser cutting machine that suits a company’s long-term development is a systematic process involving needs analysis, technical configuration, industry applications, brand evaluation, service system, and future expansion capabilities. As the metal processing industry increasingly demands high precision, high efficiency, and automation, fiber laser cutting technology has become a crucial tool for many manufacturing plants to upgrade production capabilities, reduce labor costs, and improve delivery efficiency.

Throughout the decision-making process, you need to deeply understand your current production situation and plans, clearly defining processing materials, production pace, cutting quality standards, and budget constraints. During the equipment research phase, you need to objectively compare the technical characteristics, machine structure, laser quality, cutting head performance, and overall stability of different brands. At the industry application level, you must match the equipment’s actual performance with industry process requirements to ensure that the purchased equipment remains competitive for many years to come. When evaluating the service system, you must consider after-sales response speed, spare parts supply capabilities, engineer professionalism, and software and process upgrades as core evaluation criteria, as these factors will directly determine the equipment’s user experience and lifecycle value.

Ultimately, the right choice is not about pursuing the “highest power” or the “lowest price,” but about ensuring the equipment truly fits the company’s business structure and becomes a stable, reliable, sustainable, and expandable long-term production asset. Whether you are from the metal manufacturing, automotive parts, advertising signage, aerospace, or electronics and medical industries, a suitable fiber laser cutting solution can help you improve production efficiency, enhance processing quality, and steadily advance in a highly competitive market with a healthier cost structure.

If you are looking for a mature, stable, widely applicable, and comprehensive laser processing solution, AccTek Laser, as a laser equipment manufacturer with extensive industry experience, is committed to providing high-quality آلات قطع ألياف الليزر, ماكينات اللحام بالليزر، و معدات التنظيف بالليزر to users worldwide. With stable core technology, a rigorous quality management system, and a comprehensive international service network, we are happy to assist you in evaluating your needs, planning configurations, and providing practical laser processing solutions for your production line.

معلومات الاتصال

- [email protected]

- [email protected]

- +86-19963414011

- رقم 3 المنطقة أ ، المنطقة الصناعية لونجين ، مدينة يوتشنغ ، مقاطعة شاندونغ.

احصل على حلول الليزر