What Materials Can Be Cleaned with Pulsed Laser Technology?

As industrial parts develop towards micron-level precision, traditional chemical cleaning and mechanical polishing are often inefficient and prone to secondary pollution, making it difficult to meet high cleanliness and environmental protection requirements. آلات تنظيف الليزر النبضي concentrate energy with nanosecond or picosecond short-pulse lasers to accurately remove rust, oil, and other contamination layers through photothermal and photomechanical effects. There is almost no heat-affected zone on the substrate, no chemical reagents are required, and online automated operations are achieved, greatly improving the efficiency and safety of the production line.

With non-contact processes, high-precision positioning, and extremely low material waste, pulse laser cleaning has been widely used in aerospace, automobile manufacturing, electronic packaging, and other fields. Through intelligent control systems, users can flexibly adjust pulse parameters to carry out targeted cleaning of various surface contaminants such as steel, aluminum, copper, composite materials, plastics, optical glass, or stone. As laser generator performance and control algorithms continue to be optimized, this technology will help more industries achieve green transformation and efficient upgrades.

جدول المحتويات

Introduction to Pulsed Laser Technology

Pulse laser technology is an advanced surface treatment process. It uses nanosecond (ns) or picosecond (ps) ultra-short pulse laser beams to concentrate extremely high peak power energy into the material surface in a very short time, thereby producing a synergistic effect of photothermal and photomechanical effects at the microscopic scale, accurately stripping various pollutants such as rust layers, paint adhesion, biological fouling or semiconductor adhesive layers. Compared with traditional chemical cleaning and mechanical grinding, pulse laser cleaning does not require any chemical reagents, does not produce secondary pollution, and almost does not leave a heat-affected zone on the substrate, which can provide a clean and non-destructive surface substrate for subsequent coating, welding, or precision machining. With its high peak value, short pulse width, and concentrated energy, this technology has shown excellent efficiency and precision in the fields of surface rust removal, paint removal, biological fouling cleaning, and semiconductor degumming, and can flexibly control the degree of surface contamination of different materials by adjusting the laser pulse parameters. With the continuous optimization of laser generators and control systems, pulsed laser technology is gradually becoming an indispensable non-contact, efficient, and environmentally friendly cleaning solution in modern manufacturing.

كيف تعمل تقنية التنظيف بالليزر النبضي

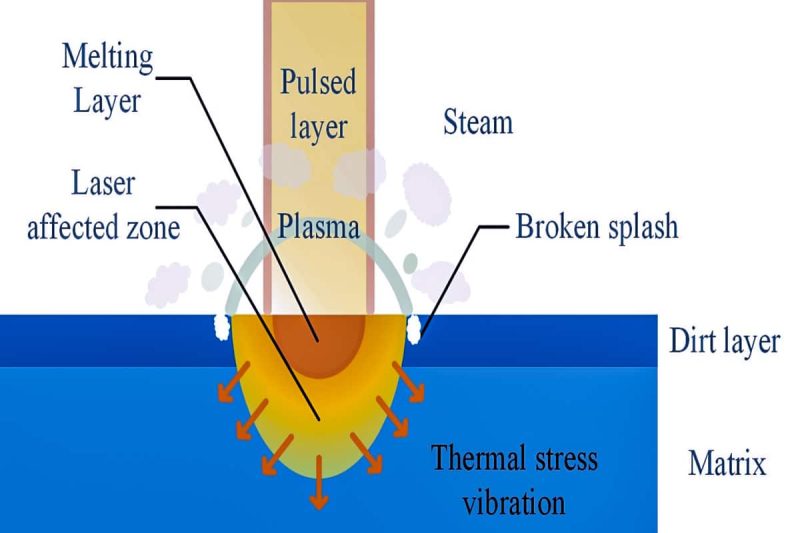

A thorough understanding of the core mechanism of pulsed laser cleaning can help engineers and technicians accurately set cleaning parameters to ensure efficient cleaning while maximizing protection of the substrate surface. Pulsed laser cleaning mainly relies on two physical processes: photothermal effect and photomechanical effect.

Photothermal effect: When a nanosecond or picosecond high-peak laser pulse is irradiated onto the surface to be cleaned, the contaminated layer (such as rust products, paint, or organic dirt) will first absorb this part of the light energy. The local temperature rises rapidly in a very short time, causing thermal expansion and thermal stress. When the temperature gradient exceeds the bonding strength between the contaminated layer and the substrate, tiny cracks will appear inside the contaminated layer, and eventually it will detach from the substrate surface in the form of peeling and flaking. Since the laser pulse energy is highly concentrated, the heat-affected zone is strictly confined to the contaminated layer, and almost no thermal damage will be caused to substrates such as metals, composite materials, or optical devices.

Photomechanical effect: In addition to thermal effects, ultrashort laser pulses also generate transient plasma at the interface between the contaminated layer and the clean surface. The plasma expands to form a very small but energetic shock wave, which further peels off the attachments and enhances the peeling effect. This process occurs extremely quickly and can completely remove tiny particles and even nanoscale contaminants while maintaining surface integrity. The mechanical impact of the shock wave and the photothermal effect complement each other, making pulsed laser cleaning both capable of deep removal and high-precision control.

Through the dual synergy of photothermal and photomechanical effects, pulsed laser cleaning technology not only eliminates the use of chemical reagents and avoids secondary pollution but also can achieve customized cleaning solutions by adjusting parameters such as laser pulse width, energy density, and repetition frequency according to different materials and pollution levels. Whether it is the removal of oxide films on precision metal parts or the cleaning of stubborn dirt on the surface of optical glass and composite materials, this “non-contact, efficient, and environmentally friendly” cleaning method can provide a clean and smooth workpiece surface for subsequent processes.

Materials suitable for pulsed laser cleaning

With highly adjustable energy density and pulse width settings, pulse laser cleaning can accurately strike the light absorption characteristics, thermal conductivity and mechanical strength of different material surfaces, ensuring efficient removal of various contamination layers without damaging the substrate. The following content details the application scenarios and process points of various common substrates.

معدن

Steel (stainless steel, carbon steel): Common oxide scale, rust layer and oil stains on the surface of steel parts will seriously affect the corrosion resistance and subsequent coating quality. Pulse laser cleaning can gently remove slight oxide film through low energy density mode, and switch to high energy mode to quickly peel off thick rust layer when deep rust removal is required. The whole process does not require chemical reagents, avoiding secondary pollution, and the heat-affected zone of the substrate is extremely small, ensuring the mechanical properties and geometric accuracy of the steel parts.

Light metals (aluminum, copper, titanium): Light metals such as aluminum, copper, and titanium are prone to form dense oxide films and grease films. Traditional chemical or mechanical cleaning often causes surface scratches or chemical residues. The use of medium-low energy, short pulse width pulse lasers can complete oxide film stripping and oil removal on a micron scale, while preventing the substrate from overheating, softening, or deformation, and retaining the metal’s original color and surface finish to the greatest extent, providing an ideal substrate for subsequent electroplating, welding, or coating processes.

المواد المركبة

Carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP): The resin, adhesive layer, and release agent residues on the surface of composite materials are usually firmly attached, and their fiber matrix is sensitive to heat. During the cleaning process, the pulsed laser generator uses a laser beam with extremely short pulse width and high peak energy to produce strong photothermal and photomechanical effects only on the organic contamination layer, achieving precise stripping without damaging the carbon fiber or glass fiber body. It can not only ensure structural strength but also improve surface adhesion performance. It is widely used in aerospace composite maintenance and high-performance sports equipment manufacturing.

بلاستيك

Polycarbonate (PC), polyethylene (PE): Engineering plastics such as PC and PE, whose surface aging layers, oil stains and scale are particularly common in optical transparent parts, food-grade containers and other fields. Pulsed laser cleaning uses low energy and relatively long pulse width settings to remove organic contamination layers while avoiding plastic melting or warping caused by high temperatures. This process is environmentally friendly and efficient. After cleaning, plastic parts can be directly put into packaging or molding processes without additional dehydration or drying steps.

زجاج

Architectural glass and optical glass: Architectural curtain walls, optical lenses, and high-precision optical components have extremely high requirements for surface cleanliness without scratches or microcracks. Pulse laser cleaning can remove scale, coating, and dust in the form of micron-sized particles through photomechanical effects without generating thermal stress cracks, so that the glass can restore its original light transmittance and surface flatness. The entire cleaning process does not require contact or chemical solvents, ensuring optical performance and service life.

حجر

Marble, granite: Natural stone is widely used in indoor and outdoor decoration, sculpture, and artwork, and its surface is often covered with cement residue, building mortar, and industrial dust. Pulse laser cleaning uses medium and high energy laser pulses to precisely act on the contaminated layer, micro-area stripping of dirt without touching the microscopic crystal structure of the stone, avoiding micro scratches and pits caused by mechanical grinding, retaining the natural texture and luster of the stone, and improving the decorative effect and service life.

textile

Natural fibers (cotton, silk) and synthetic fibers (polyester, nylon): Heavy oil stains, dye residues, and electrostatically adsorbed dust on textiles have a huge impact on the quality of the finished product and the downstream printing and dyeing process. By finely controlling the energy density and repetition frequency of the pulsed laser, pollutants on the fiber surface can be selectively cleaned while avoiding high-temperature damage to the fiber itself. This non-contact cleaning method not only does not require chemical additives, but also greatly shortens the cleaning cycle, providing a green and traceable cleaning solution for high-end clothing and functional textiles.

With multi-dimensional adjustable pulse parameters, pulse laser cleaning technology provides non-contact, high-precision, and environmentally friendly surface treatment solutions for a variety of substrates such as metals, composite materials, plastics, glass, stone, and textiles. Through process optimization based on the material, cleaning efficiency and cleanliness can be maximized, helping various industries achieve green production and sustainable development while ensuring product quality.

مزايا التنظيف بالليزر النبضي

Among many surface treatment technologies, pulsed laser cleaning has multiple significant advantages due to its unique physical mechanism and highly controllable process parameters. The following will analyze in depth why more and more industries choose pulsed laser cleaning as a priority solution from six dimensions: non-contact process, high precision, environmental protection, versatility, high efficiency, and minimal waste.

Non-contact process

- Zero secondary damage: Traditional mechanical grinding and sandblasting will cause direct friction or impact on the surface of the substrate, resulting in fine cracks, scratches, and even tensile stress concentration. Pulse laser cleaning only relies on focused light energy to act on the contaminated layer without any physical contact. During the cleaning process, a safe distance is maintained between the light beam and the workpiece, completely avoiding mechanical damage and stress concentration on the surface of the part. It is particularly suitable for workpieces with extremely high surface quality requirements, such as aircraft engine blades and precision valve bodies.

- Workpiece shape is not limited: irregular curved surfaces, deep holes, slender gears, or complex microstructures. Using traditional methods often requires customized fixtures or replacement of cleaning tools. The pulse laser cleaning system is equipped with a multi-degree-of-freedom scanning head, which can flexibly adjust the incident angle to achieve uniform coverage cleaning of workpieces with different geometric shapes. In this mode, there is no need to frequently change fixtures, which significantly shortens the equipment switching and debugging time.

تحكم عالي الدقة

- Micron-level stripping: Through a high numerical aperture focusing lens, the pulse laser spot diameter can be as small as tens of microns, and the stripping accuracy can reach the micron level. Engineers can perform high-resolution “point-line-surface” scanning basedon the thickness and distribution of surface contamination on the workpiece, accurately removing organic coatings, oxide layers, or tiny particles within the nanometer to micrometer scale without damaging the substrate itself.

- Flexible and adjustable parameters: Using advanced laser control software, parameters such as energy density (J/cm2), pulse width (ns/ps), repetition frequency (kHz or even MHz) and scanning speed can be adjusted in real time. For different types of contamination, such as mild rust, stubborn glue layer, or thick coating, a “one-button switching” process library can be developed to achieve rapid switching of multiple batches and multiple processes in mass production, ensuring “precise decontamination without damaging the material”.

Environmentally friendly and pollution-free

- Zero chemical reagents: The use of traditional acids, alkalis, or organic solvents is eliminated, reducing the risk of chemical exposure to operators and eliminating the adverse effects of chemical residues on subsequent processes (such as painting and electroplating).

- No wastewater and waste gas: The pollutants removed by pulsed laser are purged or adsorbed and collected in the form of tiny particles or micron-sized particles, and almost no aerosols and liquid waste are generated. With a simple dust collection and exhaust system, a “zero waste” working environment can be achieved, which complies with increasingly stringent environmental regulations and factory safety standards.

Multifunctionality: One machine for multiple uses

- Compatible with multiple pollutants: The same set of equipment can achieve multiple functions such as rust removal, paint removal, glue removal, wax removal, surface activation (mild etching), etc. Just switch the process mode on the control interface to quickly switch from grease and dirt removal mode to hard oxide layer stripping mode, greatly improving the comprehensive utilization rate of the equipment.

- Cross-material application: From high-hardness metal to flexible plastic, from optical glass to natural stone, cleaning can be completed by fine-tuning the laser pulse parameters. In this way, one device can serve multiple production lines, reducing repeated investment and maintenance costs, especially suitable for small and medium-sized enterprises to maximize asset utilization.

High efficiency and automation

- Fast cleaning: In common workpiece surface rust removal or paint stripping applications, traditional manual work often takes minutes to hours, while pulsed laser systems can complete the cleaning of the same area in seconds to more than ten seconds. The instantaneous pulses at the nanosecond/picosecond level greatly shorten the cycle of each process.

- Online integration: Modern pulsed laser cleaning systems support seamless docking with industrial robots, visual positioning systems, and production line PLCs, enabling automatic loading and unloading, real-time monitoring, and process feedback. By integrating SCADA or MES systems, production status and cleaning quality can be digitally tracked, fully assisting the implementation of smart manufacturing and Industry 4.0.

الحد الأدنى من النفايات المادية

- Minimal heat-affected zone: Due to the extremely short pulse duration, the heat during the cleaning process is almost concentrated in the contaminated layer, and the heated area of the substrate is limited to the contaminated thickness range, avoiding part warping, annealing softening, or microcracks.

- Reduced defective rate: The precisely controlled stripping depth and uniformity ensure that each cleaned workpiece can maintain a consistent surface state, avoiding material loss and rework caused by excessive cleaning. The overall production yield is significantly improved while reducing the cost of raw material procurement and waste disposal.

Through the above-mentioned in-depth analysis of multiple dimensions, it is not difficult to see that pulsed laser cleaning technology not only has the advantages of high efficiency, precision, and environmental protection but also has excellent flexibility and scalability. It is becoming the first choice for the modern manufacturing industry to pursue green production and high-quality surface treatment.

Challenges and considerations

When deploying a pulsed laser cleaning system, in addition to paying attention to technical performance and application effects, it is also necessary to comprehensively weigh multiple factors such as cost investment, personnel capabilities, material adaptation, and safety compliance to ensure the smooth progress of the project and achieve the best return on investment.

Initial cost: Pulse laser cleaning equipment usually includes a high-power laser generator, precision optical focusing components, a multi-axis scanning system, and supporting control software etc. The overall hardware investment is higher than that of traditional cleaning equipment. Although the one-time purchase cost may range from several thousand to tens of thousands of US dollars, laser cleaning does not require the consumption of chemical agents, occupies a small space, and has low maintenance costs. The long-term operating cost is significantly lower than chemical or mechanical cleaning methods. When the equipment reaches a certain usage volume, the comprehensive cost often shows a “high first and then low” trend, achieving a rapid return on investment in equipment.

Training requirements: Laser cleaning involves high-energy optical systems and precise parameter adjustment. Operators must undergo professional training to use the equipment safely and efficiently. The training content includes: laser safety protection (such as wearing laser goggles and setting up protective fences), basic optical principles, pulse width and energy density adjustment, scanning path and speed setting, daily maintenance, and troubleshooting. Enterprises should establish a complete training system and operating specifications, and conduct regular assessments and retraining to ensure that all operators have standardized operation and emergency response capabilities.

Material compatibility: Different substrates have significant differences in light absorption, heat conduction, and mechanical strength, and have different requirements for laser pulse width, energy density, and repetition frequency. For example, the oxide layer on the metal surface requires a higher energy density, while plastic parts require lower energy and longer pulse widths to prevent melting. Before introduction, companies should conduct small batch tests, combined with optical microscopy and surface morphology detection, to optimize the process parameter library to ensure fast switching and stable cleaning effects between different materials and pollution types.

Safety: If there are no strict protective measures for high-power laser operations, there are risks of light radiation hazards and smoke inhalation. Equipment installation should comply with national or industry laser safety regulations, equipped with protective fences, laser door interlocks and qualified goggles; at the same time, the micron-level peeling particles generated during the cleaning process must be removed in time through an efficient dust collection and exhaust system, and equipped with appropriate filtering devices to prevent dust from spreading or polluting the production environment. Enterprises should also formulate laser operation safety manuals and emergency plans, and organize safety drills regularly to ensure the safety of both personnel and equipment.

Through comprehensive planning and investment in the four dimensions of initial cost, training needs, material compatibility and safety protection, the high efficiency, precision and environmental protection advantages of pulsed laser cleaning technology can be maximized, and the operating risks and later maintenance pressure can be reduced, thereby bringing continuous and stable cleaning benefits and considerable economic returns to enterprises.

لخص

This article systematically sorts out the core principles, applicable materials, significant advantages, and implementation challenges of pulsed laser cleaning technology. First, pulsed laser achieves micron-level precision stripping of the contamination layer through

nanosecond/picosecond high-peak energy pulses, combined with photothermal and photomechanical effects; second, the technology can be flexibly adapted to a variety of substrates such as steel, light metal, composite materials, plastics, glass, stone and textiles to meet the cleaning needs of different industries; third, its non-contact, high-precision, zero chemical reagents, no wastewater and exhaust gas emissions and other characteristics completely meet the high standards of green manufacturing and Industry 4.0; finally, although the initial investment in equipment and personnel training and safety protection are high, by establishing a complete parameter library, training system and safety specifications, enterprises can significantly reduce the overall cost, improve the yield rate and achieve sustainable and efficient production in subsequent operations. Overall, pulsed laser cleaning technology is leading the surface treatment industry towards a higher precision, greener, and smarter future with unprecedented environmental performance and process flexibility.

احصل على حلول الليزر

Choosing a professional partner is crucial. With many years of experience in laser equipment OEM and rich industry application cases, AccTek Laser can provide you with one-stop customized services from equipment selection, process parameter optimization, to automation integration. Through systematic training and continuous technical support, we can help you quickly master the pulse laser cleaning process, improve production efficiency, and reduce material waste, to protect your green manufacturing and high-quality surface treatment.

اتصل بنا now to get professional pulse laser cleaning solutions, so that your production line can achieve a perfect balance between green, efficient, and high-quality!

معلومات الاتصال

- [email protected]

- [email protected]

- +86-19963414011

- رقم 3 المنطقة أ ، المنطقة الصناعية لونجين ، مدينة يوتشنغ ، مقاطعة شاندونغ.

احصل على حلول الليزر