The Difference Between Open-Loop Control System and Closed-Loop Control System of Fiber Laser Cutting Machine

In the modern manufacturing industry, machines de découpe laser à fibre have become the preferred equipment for sheet metal processing, machinery manufacturing, and the production of advertising signs and other sectors due to their advantages of high precision, high efficiency, and low maintenance. One of the key factors that determines the operating accuracy and stability of such equipment is the type of its control system: an open-loop control system and a closed-loop control system.

This article will deeply analyze the differences between these two control modes from the aspects of definition, operating characteristics, applicable scenarios, and comparison between the two, to help you make more informed decisions when purchasing and using fiber laser cutting machines.

Table des matières

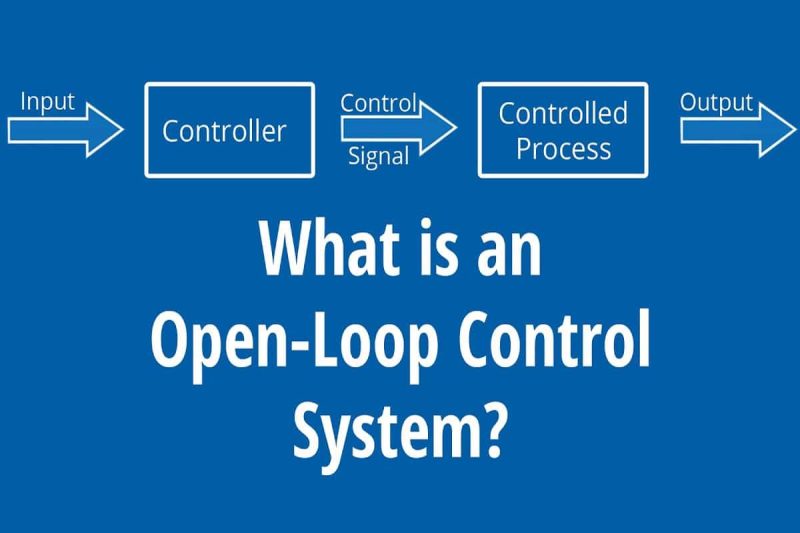

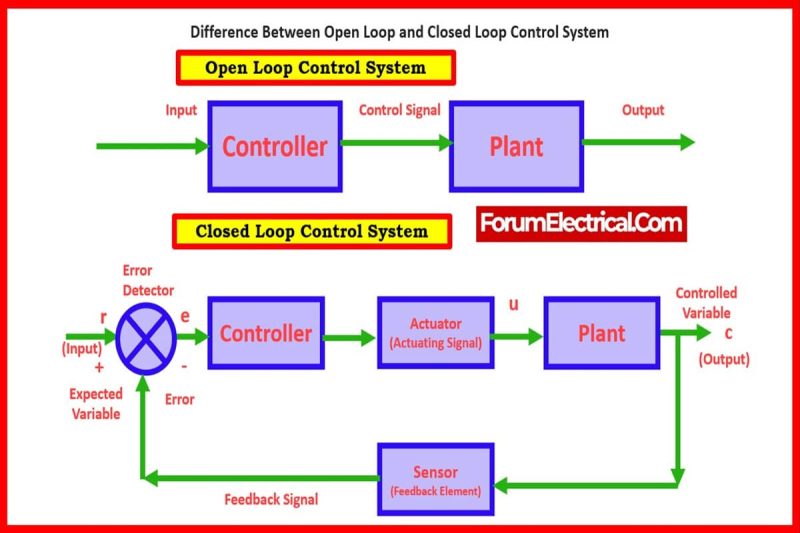

What is an open-loop control system?

The open-loop control system is the most basic and widely used control method in the early stages of industrial automation. In this system, the controller sends control signals directly to the actuator according to the pre-set program or parameters to complete the processing task. During the whole process, the system does not detect or adjust the actual output results, that is, it does not “sense” whether the actual processing meets expectations, and only relies on the instructions themselves to complete the work.

Operation principle

In fiber laser cutting equipment, the open-loop control system controls the laser generator, cutting head, or motion platform through the data preset by the controller. For example, when cutting a metal sheet in a straight line, the system performs the cutting action according to the input speed and path, but does not detect the laser focus position, speed changes, or sheet offset in real time. If there is a disturbance in the external environment, such as air pressure changes, cutting head vibration, etc., the system cannot correct itself.

Although there is a certain risk of error, for scenes with simple processing paths and stable environments, open-loop control systems can still achieve high operating efficiency.

System features

Simple structure, easy to integrate: The open-loop system does not contain complex sensors or feedback mechanisms, so the structural design is relatively simple, which is conducive to rapid integration and deployment in standard equipment.

Fast response speed, suitable for highly repetitive processes: Since there is no feedback process, the control instructions are transmitted directly, and the system responds quickly, which is very suitable for continuous processing tasks with high production rhythm requirements.

Low cost and convenient maintenance: The lack of a feedback loop means reduced hardware investment, low overall system cost, and relatively simple later maintenance, which reduces the threshold for enterprises to use.

Application scenarios

Open-loop control systems are widely used in medium and low power fiber laser cutting machines and tasks that do not require high processing accuracy, especially for:

- Cutting of non-metallic materials such as plastics, acrylic, and PVC sheets

- Scenarios with stable graphic paths, such as sign engraving and QR code marking

- Light load applications such as sample proofing, educational demonstrations, and handicraft production

- Metal sheet processing with single-size batch cutting

In these application scenarios, users pay more attention to the economy and ease of operation of the system, rather than extreme accuracy or dynamic compensation capabilities, so open-loop control systems can provide good cost performance.

In general, the advantages of open-loop control systems in fiber laser cutting equipment are a simple structure, rapid response, and economical and practical. Although it cannot automatically correct errors, it can still function efficiently in application scenarios where the production environment is relatively stable and the process repeatability is strong. For users who pursue cost control and convenient operation, the open-loop system is a mature and reliable solution. If the processing requirements do not involve complex paths or high-precision processing, choosing an open-loop system will be a wise and cost-effective choice.

What is a closed-loop control system?

Unlike traditional open-loop control, a closed-loop control system is an intelligent control mode with “self-correction” capabilities. It collects processing status data in real time through a built-in feedback mechanism during operation, and dynamically adjusts operating parameters based on this data to ensure that the actual output is highly consistent with the expected target, thereby significantly improving the accuracy, stability, and consistency of the system. In modern high-power fiber laser cutting machines, closed-loop control technology has become standard and is widely used in processing tasks that require extremely high precision of parts.

Operating principle

The core of the closed-loop system lies in its closed-loop feedback loop. The system is usually equipped with multiple highly sensitive sensors for real-time monitoring of the following key parameters:

- Cutting head position coordinates

- Moving speed and acceleration

- Laser output power

- Material temperature or heat-affected zone

- Spot diameter and focus status

These data will be transmitted to the central controller in real time. The controller compares the current state with the preset target. Once a deviation is detected, the system will automatically adjust, for example:

- Correct the cutting path or speed to adapt to local material thickness changes

- Automatic focus adjustment to maintain the best beam quality

- Adjust the laser power to achieve a constant cutting depth

The entire process is completed within milliseconds, achieving imperceptible dynamic compensation. This enables the closed-loop system to continuously ensure cutting quality and maintain precise control performance even in environments with external interference or process changes.

System Features

High precision and high repeatability: The feedback mechanism of the closed-loop control system can accurately control the laser movement and output, thereby achieving micron-level cutting accuracy. Even with large-scale repeated processing, it can maintain consistency and stability, greatly reducing the rework rate.

Strong anti-interference ability and adaptability to complex working conditions: Unlike open-loop systems that are easily affected by environmental factors (such as vibration and uneven materials), closed-loop systems can correct the errors caused by these interferences in real time to ensure that the processing quality is not affected by external changes and fluctuations.

Improve processing quality and overall efficiency: Stable output control and automatic compensation capabilities make the cutting edge smoother and less burred, reducing post-processing costs. At the same time, it can also improve processing efficiency and avoid interruptions and rework caused by parameter deviations.

Application scenarios

Due to their advantages of intelligence and high precision, closed-loop control systems are widely used in many industries with strict processing requirements, especially for:

- Aerospace parts manufacturing: complex cutting of high-strength metals such as titanium alloys and stainless steel requires precision control within extremely low tolerances.

- Automotive parts and precision sheet metal manufacturing: Maintaining consistency is particularly critical when mass-producing body parts and structural parts.

- High-power metal laser cutting tasks: For example, fiber laser cutting systems with a power of 12kW or above need to dynamically adjust the power output to match the cutting requirements of different thicknesses or materials.

- Intelligent automated laser processing production lines: When working in conjunction with CNC systems and robot arms, closed-loop systems can achieve high synchronization and adaptive control.

In general, closed-loop control systems have brought revolutionary performance improvements to fiber laser cutting machines. It can not only significantly improve cutting accuracy and processing consistency but also dynamically adapt to various process fluctuations, providing users with stable and efficient production capabilities. For manufacturing companies that pursue high-quality output and long-term sustainable operations, choosing a closed-loop control system is undoubtedly an important direction for future development.

At AccTek, we provide high-performance fiber laser cutting solutions equipped with advanced closed-loop control technology, and can be customized according to the needs of different industries to help you achieve intelligent and high-quality processing upgrades.

Open loop vs. closed loop: core difference comparison

When evaluating a fiber laser cutting machine, the choice of control system directly affects equipment performance, processing quality, and return on investment. Open-loop control systems and closed-loop control systems each have their advantages and disadvantages. Through in-depth comparison of key dimensions, users can make decisions from multiple aspects such as technical requirements, cost budgets, and process requirements. The following will be explained one by one around the feedback mechanism, cutting accuracy and repeatability, system cost, anti-interference ability, and scope of application.

Feedback mechanism

For an open-loop control system, its core feature is “no feedback mechanism, one-way control”. The controller sends signals to the laser cutting head and motion platform according to a pre-set program, but does not monitor or correct the actual operation results online. This method relies on the accuracy of the initial parameters and the stability of the external environment. Once an offset or process fluctuation occurs (such as a slight deviation of the cutting head, a need for fine-tuning the material position), the system cannot automatically sense and adjust, which may lead to cumulative cutting errors.

In contrast, a closed-loop control system has the ability of “real-time feedback and automatic adjustment”. The sensor monitors key information such as position, speed, laser power, and focus status in real time, and automatically corrects the motion trajectory or power output after comparing the feedback data with the preset target. For example, during the cutting process of the fiber laser cutting machine, if a slight change in material thickness or external vibration is detected, the closed-loop system can instantly adjust the cutting path or laser intensity to maintain the expected cutting effect. This feedback mechanism significantly improves the intelligence level of the system and makes the processing process more stable and reliable.

Cutting accuracy and repeatability

The cutting accuracy and repeatability under the open-loop control system are usually “general accuracy, dependent on environmental stability”. Because there is no automatic correction mechanism, any small error may accumulate during the processing process, especially in long paths or batch repeated processing, the deviation is more likely to be amplified. Therefore, the open-loop system is more suitable for scenarios where the accuracy requirements are not extreme, the path is relatively simple, and the tolerance for batch consistency is high.

The closed-loop control system can achieve “high accuracy and sustainable consistency” due to continuous online measurement and adjustment. When processing high-precision metal parts, cutting complex contours, or mass production, the closed-loop system ensures that each cutting result maintains a micron or sub-micron tolerance range through real-time error correction, greatly reducing rework rate and material waste, and improving production efficiency and yield rate.

System cost

In terms of cost investment, the open-loop control system is “low-cost and simple to maintain” because of its simple structure, no need for additional sensors, and complex software algorithms. For small and medium-sized enterprises or budget-sensitive users, this method can be quickly deployed and reduce initial investment, while maintenance and troubleshooting are relatively intuitive. But the cost is the sacrifice of a certain degree of accuracy and dynamic response capabilities.

The closed-loop control system is expensive and has a complex system structure because it needs to be equipped with high-precision sensors, a data acquisition module, and more complex control algorithms. The initial investment and maintenance costs are large, but from a long-term operation perspective, due to improved cutting accuracy, higher yield, and reduced rework, the closed-loop system can often bring higher comprehensive economic benefits in high-end applications or large-scale production environments. Therefore, in projects where the budget allows and quality requirements are strict, the value of the closed-loop system is more significant.

Anti-interference ability

Open-loop systems are weak in dealing with external disturbances and have difficulty dealing with external changes. Once the ambient temperature fluctuates, the equipment vibrates, or the material itself is slightly uneven, the system cannot actively compensate, which may lead to unstable cutting quality. Especially in metal cutting or high-power laser applications, this uncertainty may cause problems such as edge burrs, discontinuous cutting, or dimensional deviation.

Relatively speaking, closed-loop control systems have strong anti-interference capabilities that can dynamically adapt to external changes. By real-time monitoring and adjusting parameters, whether it is material thickness fluctuations, vibration interference, or changes in the state of the spot, the closed-loop system can respond and correct in time, thereby keeping the cutting edge smooth and the size consistent, significantly improving the stability and reliability of the equipment under complex working conditions.

Scope of application

Open-loop control systems are suitable for simple processing tasks and low-precision scenarios, such as non-metallic material cutting, sign engraving, sample proofing, or short batches and projects with stable process paths. In these applications, users are more concerned about the economy, ease of use, and rapid deployment of equipment, so the open-loop solution has a good cost-effectiveness.

Closed-loop control systems are more suitable for high-precision manufacturing and complex path cutting, including aerospace parts processing, mass production of automotive structural parts, high-power metal laser cutting, etc., where there are strict requirements for accuracy, repeatability, and dynamic response. In these industries, closed-loop systems can provide continuous and stable high-quality output to meet strict tolerance and consistency requirements.

Through in-depth comparison of feedback mechanisms, cutting accuracy and repeatability, system cost, anti-interference ability, and scope of application, we can see the different positioning and value of open-loop control systems and closed-loop control systems in fiber laser cutting machines. If the project does not require high processing accuracy, has a limited budget and a stable process path, the open-loop control system can meet basic needs with its simple, fast and economical characteristics; if you pursue higher cutting accuracy, yield and dynamic adaptability, and can afford higher investment, the closed-loop control system is more suitable for complex and high-end applications with its real-time feedback and automatic correction advantages.

In AccTek Laser’s fiber laser cutting machine product line, we can provide customized open-loop or closed-loop control solutions based on different needs to help customers achieve the best balance between cost and performance. If you need in-depth consultation or technical support, please contact AccTek Laser’s professional team to help your laser cutting project achieve efficient and stable production results.

Résumer

Whether to choose an open-loop control system or a closed-loop control system depends on your processing requirements, budget, and quality standards. If you are looking for cost-effectiveness and the workpiece complexity is not high, the open-loop system is sufficient. If you want to achieve higher processing accuracy and stronger stability, the closed-loop system is undoubtedly a better choice.

À Laser AccTek, we provide customers with a variety of types of fiber laser cutting machines that support open-loop and closed-loop configurations and can provide customized solutions based on your specific application scenarios. If you are looking for high-efficiency, high-precision, and excellently automated laser cutting equipment, please Contactez-nous for more technical support and quotation suggestions!

Coordonnées

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, zone industrielle de Lunzhen, ville de Yucheng, province du Shandong.

Obtenez des solutions laser