Hogyan működik a lézerhegesztőgép fókuszáló optikai rendszere?

Fiber laser welding is an efficient and precise metal joining technology, in which focusing optics (laser welding optics) play a crucial role. Focusing optics precisely control the delivery of laser energy, forming a stable, high-intensity spot in the weld area. By optimizing the beam’s focusing characteristics, the weld quality, appearance, and depth can be significantly improved. This article will explain the basic principles, components, and optimization key points of the focusing system to help readers understand the core role of focusing optics in laser welding.

Tartalomjegyzék

The basic principle of laser focusing

Laser focusing isn’t just about converging the beam to a single point; it determines how the energy is distributed across the workpiece surface, directly impacting penetration, weld shape, heat-affected zone, and process stability. In fiber laser welding, the design and control of focusing optics (laser welding optics) are key to achieving high-quality welds.

Relationship between spot size and energy density

The smaller the focused spot diameter, the more concentrated the energy per unit area, resulting in higher penetration and heating efficiency. Conversely, a larger spot size results in a more dispersed energy distribution, typically producing a wider but shallower melt pool. Therefore, depending on the process goal (deep penetration or surface fusion), it is necessary to select the appropriate focusing optical configuration to control the spot size.

Depth of focus and processing tolerance

Depth of focus refers to the range of allowable focal deviation in space. Smaller spot sizes typically result in shorter depths of focus, which in turn increases requirements for workpiece surface height, fixture accuracy, and positioning. For welds involving thick plates or deep penetration, a shorter depth of focus can result in higher energy density, but workpiece position consistency must be maintained throughout the process. For applications with large assembly tolerances, it may be necessary to sacrifice some spot concentration for a greater depth of focus tolerance.

Effect of focusing on welding mode

Focusing characteristics determine whether welding is primarily conducted or keyhole-based. A more dispersed focus typically produces a shallow weld pool dominated by conduction, resulting in a flat weld and a wide heat-affected zone. Highly concentrated focus, on the other hand, more easily creates deep, narrow keyhole welds in the material, enabling greater penetration depth but requiring higher parameter control and process stability. Choosing the appropriate focusing strategy depends on the material, plate thickness, and production objectives.

Common physical factors affecting focus stability

A variety of practical factors can cause focus drift or spot distortion. These include changes in the optical properties of heated optical components (thermal lensing), thermal expansion or vibration of the mechanical mount and lens barrel, ambient air turbulence, and contamination of optical surfaces. These factors can impair the consistency of laser welding optics, impacting weld repeatability and yield.

Practical means of controlling and improving focusing performance

Common methods include: using a beam expander in the optical path to increase the incident beam diameter, thereby better controlling the focusing effect; selecting high-quality, short-focal-length or dedicated focusing lenses to achieve the desired beam spot; incorporating autofocus or real-time monitoring equipment (such as visual sensors, melt pool monitoring, or online power monitoring) into the system to automatically compensate for focus drift; and improving beam quality (reducing beam divergence and distortion) to achieve near-ideal focusing performance. Rigid fixtures and constant temperature control are also often used on-site to reduce external interference.

Focusing plays a core role as an “energy distributor” in laser welding: spot size, focal depth, and focus stability collectively determine weld penetration depth, weld morphology, and process tolerances. Understanding these qualitative relationships and implementing targeted control measures (such as improving optical design, using autofocus and real-time monitoring, and enhancing environmental and mechanical stability) are key to improving fiber laser welding quality and production stability.

Components of the focusing optical system

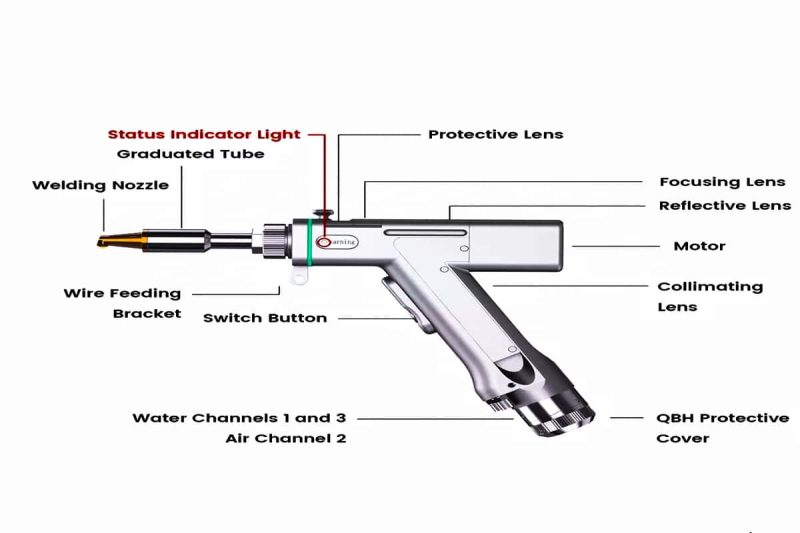

The focusing optics system consists of several key components that work together to control, transmit, and ultimately precisely focus the laser energy at the welding location. A complete and high-performance laser welding optics solution must ensure efficient energy transfer while also balancing long-term stability and field maintainability.

Laser Light Source: The light source is the energy source for the system. High-power fiber laser generators are typically used in fiber laser welding. Fiber laser generators offer stable output and high beam quality, maintaining excellent energy distribution over long transmission paths. This provides a reliable foundation for back-end collimation and focusing. When selecting a light source, consider output power, beam quality (for final spot control), and compatibility with fiber coupling.

Collimation and beam shaping components: The optical beam emerging from an optical fiber often exhibits a certain degree of divergence. Collimation components are responsible for converting this divergence into a nearly parallel beam. Simultaneously, beam shapers or expanders adjust the incident diameter and energy distribution according to process requirements (for example, toward a more uniform spot distribution or a specific shape) to achieve the desired energy density and melt pool shape during focusing. High-quality collimation and shaping components significantly reduce transmission loss and wavefront distortion, and are essential for achieving stable focusing.

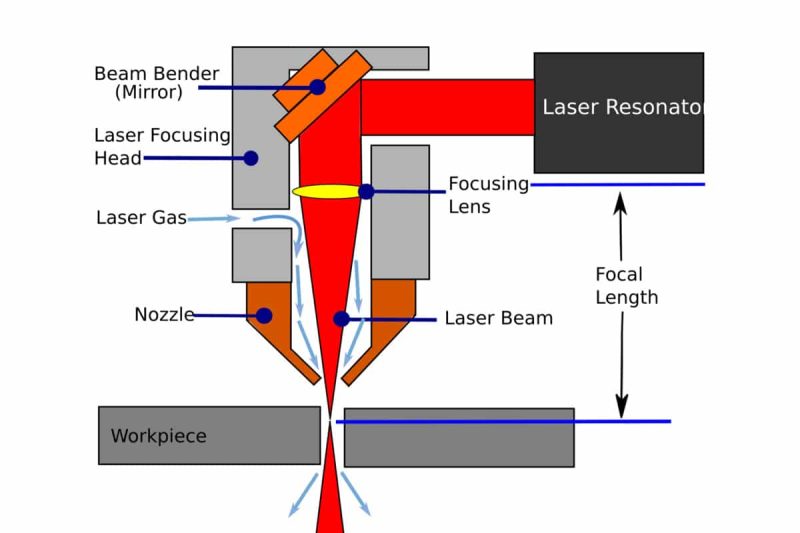

Focusing optics: The focusing component is the core unit that determines the spot size, focal depth, and power tolerance. It includes a focusing lens with a fixed focal length or variable focus, a focusing head, and scanning optics for trajectory processing (such as a mirror scanning system). The material, coating, and structure of the focusing lens must be able to withstand high power density and reduce absorption to ensure transmittance and long-term reliability. Different focusing schemes correspond to different welding modes (for example, a smaller spot for deep penetration and a larger spot for wide and shallow welds). Therefore, the selection of focusing components has a significant impact on the process window.

Beam delivery system: This system is responsible for safely and efficiently delivering laser light from the source to the workstation. Common components include fiber optic connectors, reflectors, extension tubes, and precision mounts. A superior beam delivery path maximizes wavefront quality, minimizes reflection and scattering losses, and facilitates on-site adjustments. The delivery system’s mechanical rigidity, alignment mechanisms, and interface reliability are directly related to repeatable positioning accuracy during production.

The aforementioned components—the light source, collimation and shaping, focusing unit, and transmission path—collectively constitute an efficient and reliable focusing optical system. Any performance degradation in any component will affect the final focusing effect and weld quality. Therefore, comprehensive considerations, including overall integrity and on-site maintenance, are crucial during design and selection.

Working principle of focusing optical system

Focusing optics play a crucial role in laser welding, determining whether laser energy can be effectively and accurately delivered to the workpiece surface. The entire process involves not only laser generation and transmission, but also multiple steps such as collimation, focusing, and alignment. Each step directly affects the energy density and weld quality of the weld. Understanding the working principles of laser welding optics can help optimize process parameters and ensure stable welding results.

Beam generation and collimation

The operation of a focusing optical system begins with beam generation. A high-power fiber laser generator releases a powerful laser beam through an output optical fiber, typically exhibiting a Gaussian distribution with a certain degree of divergence. Without processing, the beam rapidly diffuses during transmission, reducing its energy density and making it difficult to achieve the precision and intensity required for welding. Therefore, the system is equipped with collimating optical devices, such as collimating lenses, beam expanders, or collimating lenses to convert the diverging beam into a nearly parallel beam. This step not only reduces energy loss and wavefront distortion in the optical path but also provides stable incident light conditions for subsequent focusing, laying the foundation for efficient laser welding optics.

Beam focusing

When a parallel light beam enters a focusing lens or focusing lens, the beam is converged to the focal length of the lens, forming a tiny spot with extremely high energy density. The size and shape of the focused spot depend on the focal length of the lens, the object distance, and the beam quality. By precisely adjusting the position of the lens or focusing head, the focal position and spot size can be effectively changed to suit different welding process requirements. For example, deep penetration welding generally requires a smaller spot and higher power density, while surface heat treatment or spot welding may require a larger spot for uniform heating. A high-quality focusing process ensures that the laser energy is concentrated in the welding area, improving penetration depth and weld strength.

Beam alignment

Alignment is essential to ensure that the focus falls precisely on the target position of the welded workpiece. Modern laser welding systems typically employ adjustable optical platforms, servo motor drive components, or high-precision mechanical positioning devices to fine-tune the beam direction and focus position. In automated production, focusing optical systems are often equipped with auxiliary monitoring equipment, such as industrial cameras, laser rangefinders, or molten pool visual monitoring systems, to track in real time whether the focus is aligned with the weld path. This dynamic monitoring and feedback mechanism can quickly correct focus offsets when there are deformations or positional errors in the workpiece, ensuring continuity and high consistency during the welding process.

From beam generation and alignment to final focusing and alignment, every step determines whether the laser can stably and efficiently impact the weld surface. Only when the light source, collimation, focusing, and alignment work in tandem can a stable focus with high energy density be achieved, enabling rapid metal melting and a strong connection. This operating principle is the core of laser welding optics and the technological foundation for achieving high-quality laser welding processes.

Factors affecting optical system performance

The efficient and stable operation of focusing optics in laser welding is influenced by a variety of factors. These factors not only determine whether the laser energy can be effectively concentrated at the weld point but also directly affect the weld depth, shape, and consistency. To better understand the operating principles of laser welding optics, we can analyze them from several perspectives, including beam characteristics, system stability, material properties, and the external environment.

Beam quality and power density

Beam quality is a crucial parameter for determining whether a laser can be effectively focused. Higher beam quality means the laser energy maintains a smaller divergence angle during transmission and focusing, ultimately forming a smaller, more stable spot at the focal point. A smaller spot size results in a higher power density, allowing the metal to be heated and melted more quickly, significantly improving welding efficiency and weld strength. Conversely, poor beam quality results in a larger focused spot size and insufficient energy density, potentially leading to insufficient penetration or uneven welds.

System stability and accuracy

The stability and accuracy of the optical system directly impact weld consistency. Fluctuations in laser power output, minor optical component jitter, or focus drift can all degrade weld quality. Lack of stability during prolonged or high-intensity operation can lead to weld defects such as cracks, porosity, or incomplete penetration. Therefore, focusing optical systems require high-precision optical mounting and alignment devices, combined with advanced cooling and thermal compensation measures, to ensure accurate and stable focus throughout the welding process.

Anyagtulajdonságok

Different materials have significant differences in their ability to absorb laser light. For highly reflective materials, such as copper and aluminum, laser energy is easily reflected, resulting in insufficient absorption. This not only affects welding efficiency but can also return reflected laser light to optical components, damaging lenses or mirrors. To address this issue, optical systems typically employ special optical coatings, anti-reflection designs, or appropriate wavelength matching to improve the material’s absorption efficiency. Furthermore, the material’s thermal conductivity and melting point can affect the energy distribution at the welding focus, altering the molten pool morphology and welding quality.

Környezeti tényezők

The impact of the external environment on optical system performance is also crucial. Dust particles in the air can deposit on optical surfaces, causing energy loss or focus shift. Temperature fluctuations can cause thermal expansion of optical components, resulting in slight shifts in the focus position. Air turbulence can even alter the beam propagation path, causing uneven energy distribution. To mitigate these issues, many high-end laser welding systems employ sealed protection, constant temperature control, or auxiliary shielding gases to maintain stable performance.

Overall, beam quality and power density, system stability and accuracy, material properties, and environmental conditions are all crucial factors influencing the performance of focusing optical systems. Only when these factors are properly controlled and optimized can the laser energy be fully utilized, ensuring stable, efficient, and high-quality welding results.

Optimization and Adjustment

In the actual laser welding process, the focusing optics system is not static. Different welding materials, thicknesses, and process requirements all pose new challenges to laser focusing. Therefore, to ensure the optimal performance of the laser welding optics, the system requires continuous optimization and fine-tuning.

Optical component alignment

Precise alignment of optical components is essential for ensuring stable beam transmission. This typically requires the use of laser collimators, alignment plates, or CCD monitoring devices to monitor the optical path. The position and angle of lenses, reflectors, and fiber optic connectors are then individually adjusted to ensure the laser beam propagates along the ideal optical path. Even the slightest misalignment of optical components can result in abnormal spot shape, energy loss, and even focus drift. Therefore, alignment must be performed not only during installation and commissioning but also regularly as part of routine maintenance.

Fókusz beállítása

Workpieces of varying thicknesses and materials require different focal positions and spot sizes. For example, welding thin plates requires a smaller spot size for finer welds, while welding thicker plates requires a deeper focus to increase penetration. By adjusting the position of the focusing lens, the focal depth and spot diameter can be flexibly varied to match process requirements. Some high-end systems also feature an automatic focus adjustment module, enabling rapid switching via software, significantly improving production efficiency and adaptability.

Real-time monitoring technology

With the development of intelligent manufacturing, more and more laser welding equipment is incorporating real-time monitoring technology. Common methods include high-speed camera monitoring, optical sensor detection, and online melt pool analysis. These technologies provide real-time feedback on the laser spot position, melt pool shape, and energy distribution during the welding process. When the system detects focus deviation or welding anomalies, it can promptly issue an alarm or even automatically adjust parameters to prevent defects. Real-time monitoring not only improves welding reliability but also ensures the automation and intelligentization of production.

By precisely aligning optical components, adjusting the focus position, and leveraging real-time monitoring technology, the focusing optical system maintains greater stability and flexibility, better adapting to diverse welding conditions. Optimization and adjustment not only enhance the overall performance of laser welding optics but also provide a solid foundation for a high-quality, controllable welding process.

Kihívások és szempontok

While focusing optics play a central role in laser welding, practical applications still present a range of challenges. These challenges arise not only from the long-term operation of the equipment itself but also from external environmental and safety factors. Failure to properly address these issues can negatively impact the stability of the laser welding optics and weld quality. Therefore, understanding these issues and taking preventative measures is crucial to ensuring reliable system operation.

Berendezések karbantartása

During extended operation, optical components of laser equipment inevitably accumulate dust and oil or oxidize due to high temperatures. These conditions reduce light transmittance and beam transmission efficiency. If left untreated, these conditions can lead to beam distortion or even damage. Therefore, regular inspection and replacement of lenses, reflectors, and fiber optic connectors is essential for maintaining long-term system stability.

Optical component cleaning

During the welding process, flying metal particles and smoke can easily contaminate optical lenses and mirror surfaces. This contamination not only affects beam focus but can also cause irreversible damage to the lens due to the high-energy laser. To prevent this, protective windows, air blowing systems, or isolation devices are often used to protect optical components. Furthermore, cleaning with a dust-free cloth and specialized solvents is essential to avoid scratching the lens and ensure a clear optical path.

Környezeti hatás

Focusing optical systems are highly sensitive to their operating environment. Temperature fluctuations can cause optical components to expand or contract, shifting the focal position. Mechanical vibrations can cause optical path deviation or focal jitter, severely impacting welding stability. Therefore, it’s best to operate the equipment in a constant-temperature, low-vibration environment and equip it with anti-vibration structures or temperature control systems to minimize external interference with focusing.

Safety considerations

High-power lasers have extremely high energy densities, posing potential risks to the operator and environmental safety. Necessary protective measures must be implemented during system design and operation. For example, laser shields, emergency stop buttons, and the requirement that operators wear standard laser safety glasses are essential. These safety features are not only required by law and industry regulations, but are also fundamental to ensuring the safety of both personnel and equipment.

In summary, focusing optical systems inevitably face challenges in practical applications, including maintenance, cleaning, environmental, and safety. Regular maintenance, effective protective measures, and strict adherence to operating procedures can minimize risks and ensure the long-term stability, efficiency, and safety of laser welding optics.

Összesít

The focusing optical system of a szál lézeres hegesztőgép has a decisive influence on welding performance. Precise and stable focusing allows for more concentrated heat input during welding, thereby improving weld quality, penetration depth, and processing efficiency. As a leading company in laser welding optics, AccTek Laser leverages continuous innovation and expertise to continuously optimize the design of focusing optical systems, ensuring optimal performance in a variety of complex welding scenarios. Looking ahead, with the continuous advancement of optical technology and intelligent control, focusing optical systems will bring greater flexibility and advantages to laser welding, thereby driving the development of the manufacturing industry.

Elérhetőség

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 A zóna, Lunzhen ipari zóna, Yucheng város, Shandong tartomány.

Szerezzen lézeres megoldásokat