Optimize Laser Welding Parameters for Different Applications

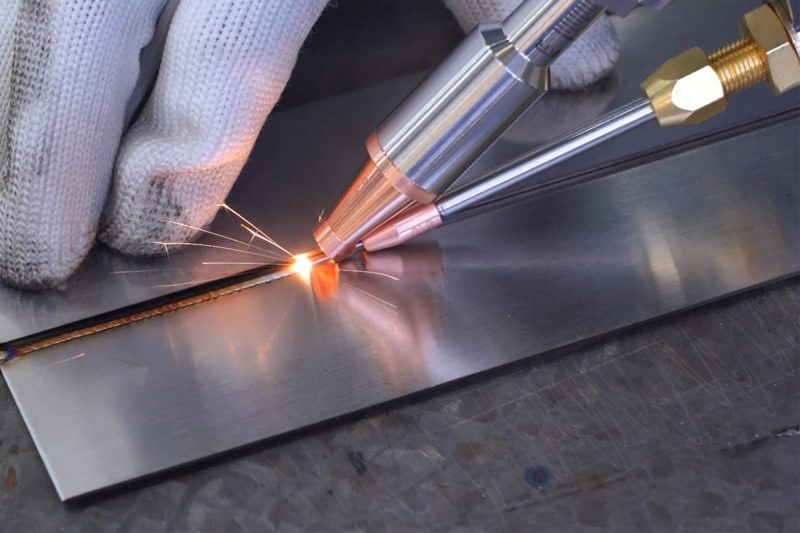

In modern manufacturing, laser welding has evolved from an advanced technology into an indispensable processing technique across numerous industrial sectors. With its high precision, high speed, low heat-affected zone, and excellent adaptability to various metallic materials, laser welding is widely used in critical industries such as automotive manufacturing, aerospace engineering, medical device production, and precision electronics manufacturing. Whether pursuing high-strength connections of structural components, upgrading production lines with automation, or strictly controlling micron-level weld seams, laser welding demonstrates technological advantages that traditional welding methods cannot match.

However, the true value of laser welding does not solely stem from the laser itself, but from the precise control and rational optimization of laser welding parameters. Core parameters such as power settings, pulse duration, pulse frequency, welding speed, and focal spot size interact and balance each other; even a slight change can determine the final result in weld quality and production efficiency. To obtain stable, reliable welding results suitable for specific industry needs, scientific and systematic optimization of these parameters is crucial.

This article will systematically introduce the fundamental parameters of laser welding, key factors influencing parameter optimization, best application strategies in different industries, and common challenges and solutions in actual production. It aims to provide manufacturing companies and engineering technicians with a directly referable guide to laser welding optimization, helping you maintain a leading edge in the ever-evolving industrial manufacturing competition.

Tartalomjegyzék

Understanding Laser Welding Parameters

In laser welding, parameter settings are crucial in determining weld morphology, penetration depth, stability, and overall weld quality. Whether it’s high-speed welding in mass production or the consistency requirements of minute weld points in precision manufacturing, the proper configuration of laser welding parameters directly impacts the final processing result. To achieve optimal welding performance, we need a comprehensive understanding of the mechanism of action of each core parameter and its interrelationships, laying the foundation for subsequent optimization and process adjustments.

Lézer teljesítmény

Laser power is a core parameter affecting penetration depth, weld pool stability, and weld strength, determining the energy density of the laser energy on the material surface. Insufficient power leads to incomplete fusion, while excessive power can cause burn-through, spatter, and weld roughness. Thick plate welding typically requires higher power, while precision welding prefers lower energy and controllable heat input.

Impulzus időtartam

Pulse duration is mainly used in pulsed laser welding; its length directly determines the energy level of a single pulse. Short pulses are suitable for micro-welding with extremely high requirements for the heat-affected zone, such as electronic components and medical device structural parts; while long pulses provide more complete melting capacity, suitable for welding thicker materials.

Pulse Frequency

Pulse frequency affects the continuity and stability of the weld. Higher frequencies result in a more uniform and continuous weld, but also increase heat input; lower frequencies are more suitable for spot welding, tack welding, or applications sensitive to heat input. In the electronics industry, frequency adjustment is often closely related to precision thermal control.

Hegesztési sebesség

Welding speed is one of the most sensitive variables in laser welding processes. Too slow a speed leads to an excessively large molten pool, an expanded heat-affected zone, and weld protrusion; too fast a speed easily results in defects such as incomplete penetration and weld separation. Different materials, thicknesses, and joint types require matching appropriate welding speeds to ensure stable weld formation.

Focus Size and Position

Focus size determines the energy density of the beam and is an important factor affecting parameters such as deep penetration welding, micro-welding, and thermal management. The smaller the focal point, the higher the energy concentration, and the greater the welding depth. Meanwhile, a shift in the focal spot position significantly alters the welding outcome: too high a position reduces penetration, while too low a position leads to burn-through. Therefore, precise control of the focal spot position is crucial for ensuring consistent laser welding.

Laser welding parameters are not isolated entities but rather interact and balance each other during the welding process. Laser power determines the energy base, pulse parameters influence the heat input pattern, and welding speed and focal spot control determine the final weld morphology. Only with a thorough understanding of the mechanisms of each parameter can the most suitable parameter combinations be determined for different materials, structures, and industrial applications, laying a solid foundation for subsequent high-quality welding and process optimization.

Factors Affecting Parameter Optimization

Laser welding process parameters are never simply a combination of “power + welding speed.” Every weld is influenced by a multitude of factors, including material properties, part geometry, welding objectives, production pace, and environmental conditions. Even seemingly minor changes, such as the thickness of the oxide layer on the material surface, fixture positioning deviations, or variations in shielding gas flow, can lead to differences in the weld. Therefore, a systematic analysis of these factors is fundamental to all welding parameter optimization work and is crucial for engineers to establish a stable and reproducible process window.

To help manufacturing companies better understand the main factors affecting process parameters, the following content will be presented from a more in-depth, detailed, and practical engineering perspective.

Anyag típusa és vastagsága

The material is the most fundamental determinant of laser welding parameters. The energy coupling ability between the laser and the material directly affects the size of the overall process window.

Absorptivity and reflectivity affect laser energy utilization efficiency

Different metals have vastly different laser absorption capabilities. High-reflectivity metals such as alumínium és réz can have reflectivity exceeding 90%, making it difficult for laser energy to effectively penetrate the material. Parameter optimization requires higher power, smaller spot size, and a narrower heat input control zone. Porosity is easily formed, requiring stricter energy density management.

Materials with better light absorption, such as rozsdamentes acél és szénacél, have higher laser utilization efficiency and stable melt pool formation. The process window is wider, allowing for greater flexibility in parameter combination selection.

Thermal conductivity affects melt pool behavior and welding stability

For high-thermal conductivity materials (such as aluminum), laser energy diffuses rapidly within the material, making it more difficult to raise the melt pool temperature. Therefore, the welding speed cannot be too fast; the focus position needs precise control; and excessive shielding gas flow may actually reduce the penetration depth.

For low-thermal-conductivity materials, excessive heat accumulation may lead to deformation, collapse, and burn-through, requiring more careful adjustment of power and speed.

Material thickness directly determines the required penetration depth and energy density

Thin plates (≤1 mm): Slightly higher power can lead to burn-through; the spot size needs to be more precisely focused; and the welding speed is often higher to quickly dissipate heat.

Thick plates (≥3 mm): Clearly require deep penetration welding mode; laser power, pulse energy, or frequency must be increased; uneven thickness will lead to unstable penetration depth. The more specialized the material, the narrower the process window; the thicker the material.

The higher the power required,the higher the thermal conductivity, the more difficult the welding.

Joint Design and Part Geometry

The structure determines the feasibility of welding. Laser welding is a high-precision process, so structural design and geometric tolerances have a significant impact.

Different joint types require completely different parameter strategies

- Butt Joint: Sensitive to the focal point position, requiring good assembly and gap control.

- Lap Joint: Prone to porosity, requiring more precise adjustment of energy density and shielding gas.

- Fillet Joint: The beam incidence angle greatly affects the penetration depth; it is more difficult when the weld geometry is irregular.

Geometric complexity affects light path, heat flow, and process stability

- Three-dimensional curved structures: The spot size changes due to curvature variations; the trajectory control system requires higher precision.

- Micro-structures: Focal size and energy concentration must be more strictly controlled; prone to thermal deformation, so speed and power must be adjusted in coordination.

- Large structures: Uneven heat input may lead to overall deformation; dynamic parameter adjustment is needed to adapt to different thermal states in different areas.

Assembly tolerances and gaps affect energy distribution

Larger gaps require more energy compensation; uneven gaps lead to inconsistent penetration depth and weld morphology; fixture stability determines weld trajectory deviation. The more complex the structure, the higher the requirements for spot control, focal length, and heat input; changes in joint type directly reconstruct the parameter combination.

Welding Quality Objectives

Different needs mean completely different parameter directions. Engineering projects have different priorities for welds, resulting in completely different parameter optimization goals.

Welding with strength as the priority (typical industries): Automotive structural parts, aerospace load-bearing components. Requires deeper penetration; higher energy density; more inclined towards deep penetration welding mode; stricter control of internal defects (porosity, cracks).

- Welding with appearance as the priority (typical industries): Consumer electronics, precision metal packaging. Control heat input to avoid metal burning or collapse; the spot position must be extremely stable; the weld surface should have a uniform and fine texture; more inclined towards low power, fast, and stable welding mode.

- Welding with consistency as the priority (typical industries): Medical devices, aerospace precision components. The parameter window needs to be narrower; extremely high equipment stability is required; each batch of processes must be traceable; and stricter requirements are placed on the environment and fixtures.

Strength focuses on penetration depth, appearance focuses on surface texture, and stability focuses on repeatability. Different projects require completely different parameter trade-offs.

Production pace and efficiency requirements

The process does not simply pursue the best, but the most suitable. Laser welding parameters also depend on the company’s production methods, not just theoretical optimality.

For mass production, speed and stability are prioritized. For example, automobile manufacturing, home appliances, and metal processing plants. Welding speed needs to be maximized; the parameter window needs to be wider to resist environmental chang es; automated equipment (robotic arms, vision systems) needs to be more closely integrated; and overall cycle time and failure rate are more important.

For small-batch, high-value-added production, quality is prioritized. For example, medical devices, aircraft engine parts, and precision electronics. Parameters are more conservative; a moderate reduction in speed is allowed to improve stability, and more attention is paid to the consistency of weld seam morphology.

For multi-specification product mixed-line production, process adaptability is prioritized. Parameter switching needs to be fast; fixtures and positioning systems must be flexible; and a comprehensive parameter library is needed to support rapid adjustments.

The larger the batch size, the more critical the production cycle; the higher the added value, the more important stability becomes.

Surface condition and production environment

Surface condition has a decisive impact on laser absorption; surface oil and grease can hinder the transmission of laser energy; oxide layers can change the absorption rate; plating materials may produce metal vapor that affects weld stability; and changes in surface roughness can lead to uneven energy distribution.

The shielding gas system affects weld quality; gas purity affects weld brightness and porosity; excessive gas flow may disrupt the molten pool; and incorrect gas flow direction will affect the discharge of metal vapor.

Environmental factors are often overlooked, but their impact is persistent. Temperature changes affect the thermal state of the laser equipment and parts; vibration can cause weld trajectory errors; and loose fixtures can cause focus shifts.

Even with perfect parameters, if the environment is unstable, the weld will be difficult to stabilize; therefore, on-site management is equally important as parameters.

Laser welding parameter optimization is a systems engineering process that depends on the synergy of various factors such as material characteristics, joint structure, welding objectives, production pace, and environmental conditions. There is no single universal parameter that applies to all projects, nor is there a fixed combination that can be applied indiscriminately. Truly successful laser welding processes are often built upon a thorough understanding of these influencing factors, gradually establishing a reproducible, scalable, and continuously optimizable process window. This, in turn, helps companies achieve higher welding quality, greater production efficiency, and more stable manufacturing performance.

Optimization Strategies for Different Applications

Laser welding applications vary across different industrial sectors; therefore, parameter optimization strategies must be tailored to the specific application scenario. For example, in the automotive industry, laser welding is widely used in car body structures, chassis components, and exhaust systems. The welding objective is not only to ensure weld strength but also to consider surface appearance and high-volume production efficiency.

Automotive parts commonly use materials such as low-carbon steel, high-strength steel, and aluminum alloys. Steel has high light absorption and a stable molten pool, making it suitable for high-speed deep penetration welding; while aluminum alloys have high reflectivity and fast heat conduction, requiring increased laser power, precise control of the focal position, and heat input to prevent porosity or hot cracking. To ensure weld consistency and surface quality, engineers typically optimize a combination of power density, welding speed, and focal diameter. Automated fixtures and vision guidance systems are also used to ensure precise matching of assembly gaps and welding trajectories, enabling high-efficiency mass production.

In the aerospace industry, laser welding is applied to high-performance materials such as titanium alloys, nickel-based alloys, and aluminum-lithium alloys. Welds must possess extremely high structural strength and meet requirements for corrosion resistance and fatigue resistance. Because these materials are highly sensitive to heat input, even slight deviations can lead to cracks or porosity, making welding parameter optimization even more critical.

High-power, ultra-stable fiber lasers are typically used, along with pulse control to reduce the heat-affected zone, ensuring uniform penetration depth and weld consistency in complex geometric structures. Multi-axis coordinated welding ensures the laser spot is perpendicular to the joint, improving weld quality. For parts with varying thickness, a zoned power adjustment strategy is employed to achieve uniform weld performance across different regions, avoiding localized overheating or insufficient penetration.

Medical device manufacturing places even more stringent demands on laser welding, primarily involving small parts, stainless steel, and titanium alloy devices, such as surgical instruments, implantable devices, or miniature pump housings. These applications require extremely high surface precision and consistency, while also demanding the smallest possible heat-affected zone to avoid material deformation or surface burns. Parameter optimisation strategies typically involve low-power, short-pulse lasers combined with miniature fixtures, precise control of the welding trajectory, and strict control of protective gas flow and purity. In the welding of thin-walled parts, multi-pass welding or repetitive pulse methods are sometimes used to ensure weld penetration depth while avoiding burn-through.

The electronics and microelectronics industries also rely on laser welding technology to process tiny structural components, such as PCB copper traces, precision connectors, or multilayer conductive elements. High thermal conductivity materials, small dimensions, and complex layouts make the weld pool very sensitive. Engineers typically choose high-power density short-pulse lasers combined with microscopic positioning systems to ensure precise weld location and consistent dimensions, while controlling weld surface smoothness and preventing oxidation. For materials with high thermal conductivity, such as copper or aluminium, preheating or superimposed pulses are sometimes used to reduce heat loss and achieve stable formation of micro-welds.

In general manufacturing and multi-purpose industries, laser welding faces a wide variety of materials, varying thicknesses, and diverse joint configurations, so parameter optimization focuses more on flexibility and adaptability. Companies typically establish detailed parameter libraries to quickly select parameter combinations based on material, thickness, and joint type, while also combining multi-mode welding strategies, such as deep penetration welding combined with pulse control, to ensure uniform welds across different thicknesses and materials. Flexible fixture designs and adjustable positioning systems can accommodate diverse parts, improving production efficiency and reducing equipment setup time.

Overall, different industries have different priorities in optimizing laser welding parameters: the automotive industry emphasizes speed, strength, and mass production; aerospace focuses on material adaptability, penetration depth, and structural strength; medical devices prioritize small size, consistency, and surface precision; the electronics and microelectronics industries emphasize high precision and electrical conductivity; and general manufacturing pursues process flexibility and multi-material compatibility.

Összegzés

Whether it’s high-speed deep penetration welding in the automotive industry or micron-level precision welding in the medical device field, the requirements for laser welding parameters vary significantly across different industries. Factors such as material type, thickness, joint design, part geometry, welding characteristics, and production efficiency demands all directly influence the selection of key parameters such as laser power, pulse frequency, focal position, and welding speed. Relying solely on empirical operation or single-parameter adjustments often makes it difficult to strike a balance between weld strength, appearance quality, and production efficiency. Therefore, systematic and scientific parameter optimization becomes a core strategy for ensuring welding quality and improving production efficiency.

In practical applications, by comprehensively analyzing material characteristics, joint design, welding objectives, and production pace, manufacturing companies can develop personalized welding processes for each product. For example, in automotive manufacturing, optimizing welding parameters can ensure body structure strength and collision safety; in the medical device industry, precise control of pulses and focal position can achieve burn-free, highly consistent welds on small parts; in electronics and microelectronics manufacturing, reasonable parameter settings can guarantee weld conductivity and dimensional accuracy while reducing defect rates and rework costs.

As a laser equipment supplier with many years of experience in the global market, AccTek Laser possesses extensive experience in laser welding applications and numerous successful engineering cases. We not only provide high-performance szálas lézeres hegesztőgépek and other equipment, but also offer comprehensive parameter optimization solutions based on customers’ different materials, part structures, and production needs. Whether it’s high-volume automotive parts welding, high-strength aerospace component processing, or precision welding of medical devices, we can customize the most suitable equipment configuration and process parameters for our customers, ensuring welding quality, improving production efficiency, and reducing processing costs.

If you are looking for a professional, reliable, and efficient laser welding solution, AccTek Laser will be your trustworthy partner. We welcome customers to lépjen kapcsolatba velünk at any time to obtain customized technical support, application examples, and detailed welding parameter recommendations, helping your company achieve optimal performance and production efficiency in the field of laser welding.

Elérhetőség

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 A zóna, Lunzhen ipari zóna, Yucheng város, Shandong tartomány.

Szerezzen lézeres megoldásokat