Do Fiber Laser Generators Lose Power over Time?

Fiber laser generators are widely used in industrial manufacturing due to their high efficiency, precision, and stability. However, many users are concerned about a key question: Will the power of a fiber laser generator decrease over time? The answer is yes, but this process can be controlled and delayed through proper maintenance and management. This article will explore the working principle of fiber laser generators, factors that affect power output, and how to effectively mitigate power loss to help companies optimize equipment life and improve production efficiency.

Sommario

Working principle and advantages of fiber laser generator

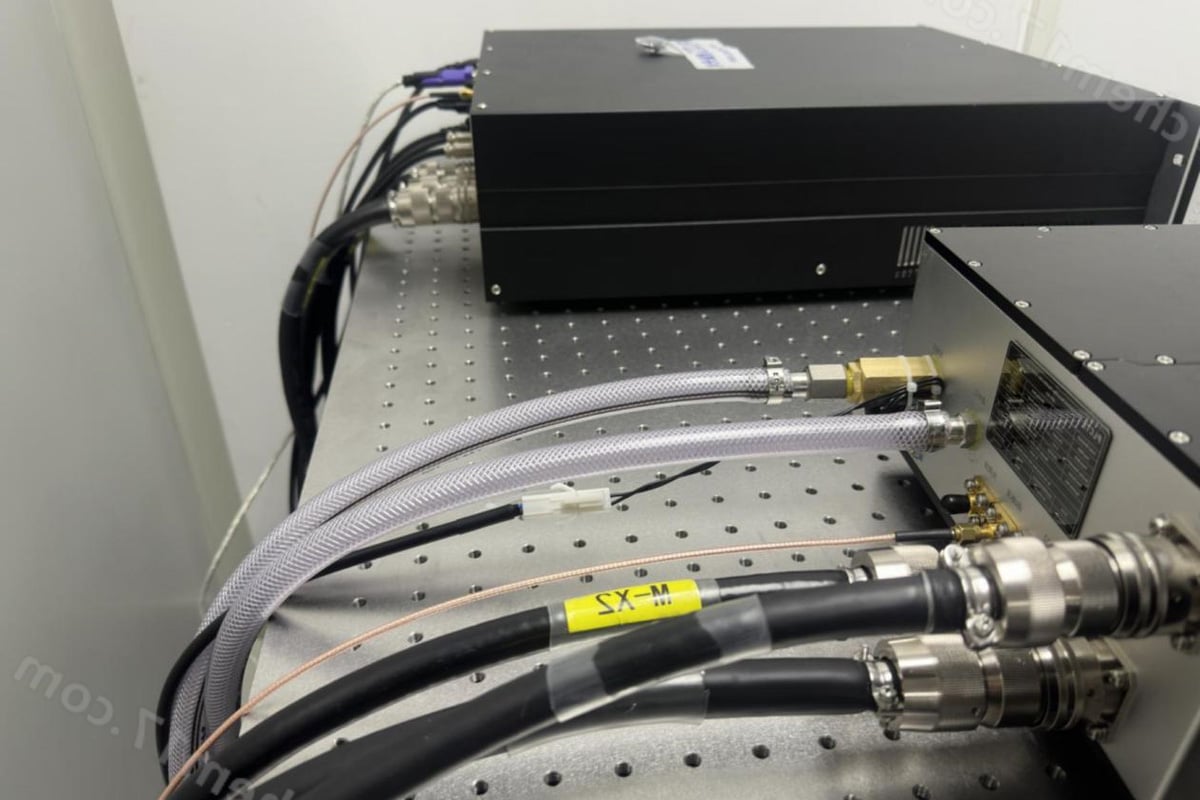

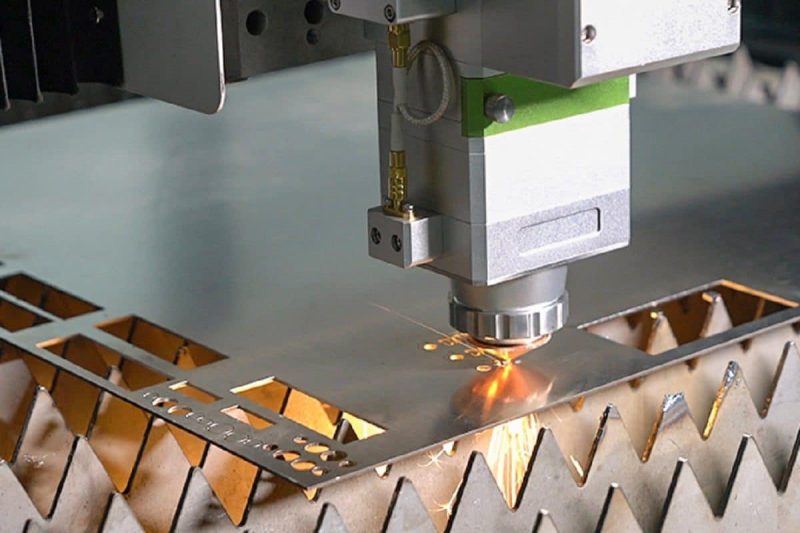

A fiber laser generator is a device that uses rare earth elements (such as ytterbium-doped fiber) as a gain medium and generates a high-intensity laser beam through optical pumping. Compared with traditional CO2 laser generators, it has higher energy efficiency, a more stable structure, and wider application fields, and it has been widely used in industries such as metal cutting, welding, marking, and cleaning.

The core advantages of fiber laser generator

- High photoelectric conversion efficiency: The photoelectric conversion efficiency of the fiber laser generator can reach 30%-50%, which is much higher than that of the CO2 laser generator (about 10%-15%). It not only reduces energy consumption, but also reduces long-term operating costs, making it an energy-saving and efficient industrial choice.

- Stability and durability: The all-solid-state fiber structure is adopted, and there is no need for complex optical path adjustment, which reduces the wear of mechanical parts, ensures long-term stable operation of the equipment, and greatly reduces the maintenance requirements.

- High precision and consistency: With excellent beam quality and extremely small focal size, it can achieve more sophisticated cutting, welding and marking processes, ensure the consistency of processing quality, and is particularly suitable for high-precision manufacturing fields.

- Low maintenance requirements: The fiber laser generator has no easily consumable reflectors or gas media, and does not require frequent replacement of optical components, which reduces maintenance costs and increases the service life of the equipment.

- Wide range of material adaptability: It is suitable for the processing of various metal materials such as acciaio inossidabile, acciaio al carbonio, lega di alluminio, rame, etc., meeting the production needs of multiple industries and improving processing flexibility.

Although fiber laser generators have many advantages, their power may still decrease during long-term use due to environmental factors, component aging, etc. Therefore, regular maintenance, optimization of the use environment, and correct operation of the equipment are essential to extend the service life of the fiber laser generator.

Main factors affecting the power output of fiber laser generator

Although fiber laser generators are widely used for their high efficiency, stability, and low maintenance, their power output may still be affected by many factors during long-term operation. Understanding these factors and taking corresponding preventive measures can help extend the life of the equipment and maintain efficient operation. The following are the main reasons that affect the power output of fiber laser generators:

Thermal degradation

When operating at high power for a long time, the gain medium of the fiber laser generator will be affected by heat accumulation, resulting in a gradual decrease in laser conversion efficiency. This thermal degradation effect will not only weaken the laser output power but may also affect the beam quality and reduce processing accuracy. In addition, if the heat cannot be dissipated in time, it may also accelerate the loss of fiber materials and further shorten the service life of the equipment.

Degradation of optical components

The key optical components inside the fiber laser generator (such as reflectors, lenses, fiber couplers, etc.) may degrade in performance during long-term use due to dust accumulation, contaminant adhesion, or long-term high-intensity laser irradiation. Contamination of optical components will reduce light transmittance and may cause scattering losses, which will directly affect power output. In addition, the coating layer of the mirror or lens may also be gradually damaged due to long-term light exposure or external environmental factors, which will reduce the transmission and focusing ability of the laser beam.

Electronic component aging

Electronic components such as the power module, drive circuit, and control system of the laser generator will gradually age during long-term operation, resulting in current fluctuations or an unstable power supply. This may directly affect the output power of the laser and even cause short-term power fluctuations, affecting the processing quality. The aging speed of electronic components is usually affected by the operating temperature, humidity, and load conditions, so it is necessary to regularly detect and replace aging components to maintain the stability of the system.

Reduced cooling system efficiency

Fiber laser generators rely on an efficient cooling system to maintain temperature stability to ensure the stability of laser output. However, if the cooling system is not properly maintained, such as the coolant has not been replaced for a long time, the radiator is blocked, the circulation pump efficiency is reduced, etc., it will lead to poor heat dissipation of the equipment, which will cause the temperature to rise and affect the power stability. Especially for equipment operating in a high temperature environment, the performance degradation of the cooling system may aggravate power loss and even cause equipment failure.

Maintenance and Cleaning Practices

Good maintenance and cleaning habits are essential to maintaining the power output of a fiber laser generator. If the optical components are not cleaned regularly, dust and dirt will affect the transmittance of the laser and cause the output power to drop. In addition, the fiber connector is also an important part of laser transmission. Regularly checking its cleanliness can effectively reduce power loss and improve the overall performance of the laser generator.

Environmental factors (temperature, humidity, etc.)

Fiber laser generators are sensitive to external environmental conditions, such as:

- High temperature environment: accelerates the aging of electronic components and may affect the efficiency of the cooling system, thereby affecting the power output.

- High humidity environment: This may cause condensation on the surface of optical components, affecting beam transmission and reducing output power.

- Dust and pollutants in the air: These may adhere to optical components and electronic components, accelerate equipment aging, and reduce beam quality.

The power output of a fiber laser generator is affected by many factors, including thermal degradation, degradation of optical components, aging of electronic components, reduced cooling system efficiency, maintenance habits, and environmental conditions. To maintain the best performance of the equipment, companies should implement a scientific maintenance plan, regularly clean optical components, check the operation of the cooling system, and optimize the use environment. These measures can not only effectively reduce power loss but also extend the service life of the equipment and improve production efficiency.

Power Loss Mitigation Strategies

To minimize the power loss of fiber laser generators and ensure the long-term stable operation of the equipment, enterprises need to take a series of effective maintenance and management measures. This can not only improve production efficiency but also reduce operating costs and extend the service life of the equipment. The following strategies can help optimize the performance of fiber laser generators and ensure their stable output in various industrial applications.

Invest in high-quality parts and equipment

High-quality core components are the basis for ensuring the long-term stable operation of fiber laser generators. When purchasing equipment, companies should give priority to laser generators, optical components, and power modules from well-known brands to reduce power loss and failure rates caused by low-quality components. In addition, the quality of the cooling system is also crucial. The use of water-cooling or air-cooling systems that meet industrial standards can effectively reduce the heat load of the equipment and prevent power output from being affected by unstable temperatures. Although the initial investment in high-quality equipment is higher, from a long-term operation perspective, it can significantly reduce maintenance costs and improve overall production efficiency.

Implement a proactive maintenance program

Preventive maintenance is an important means to reduce power loss. Regular maintenance and inspection of equipment can detect potential problems in a timely manner and avoid performance degradation due to long-term accumulated faults.

- Clean optical components regularly: Key optical components such as lenses, fiber couplers, and reflectors are susceptible to dust, oil, and contaminants, which reduce the transmittance of the beam. Therefore, special cleaning tools and a dust-free environment are required for maintenance to reduce optical losses.

- Monitor the power output curve: Establishing the power curve of the laser generator and regularly recording the power changes can help technicians identify abnormalities in time and prevent sudden failures.

- Maintain the cooling system: The cooling system is an important guarantee to ensure the stable operation of the fiber laser generator. The coolant should be replaced regularly, the water circulation system should be cleaned, and the heat dissipation device should be checked for normal operation to ensure that the laser generator can maintain the optimal operating temperature.

Monitor environmental conditions and implement appropriate controls

The working environment of the fiber laser generator will directly affect its power output and stability, so measures need to be taken to optimize the operating environment:

- Control temperature and humidity: Too high or too low a temperature may affect the performance of electronic and optical components. Excessive humidity will cause condensation on optical components and affect light transmittance. It is recommended to operate the laser generator in a constant temperature and humidity environment to avoid unnecessary losses caused by extreme temperature or humidity.

- Reduce dust and pollutants: In dusty environments such as metal processing workshops, it is recommended to use an air filtration system or a dust-free operating table to reduce dust contamination of optical components and prevent power attenuation caused by pollutant accumulation.

Train employees on proper operating and maintenance procedures

The stability of the equipment depends not only on the hardware quality and maintenance plan but also on the operator’s usage habits. Enterprises should formulate detailed training plans to improve employees’ awareness of laser generator operation and maintenance to reduce equipment damage caused by misoperation:

- Correctly operate the equipment: Ensure that the operator is proficient in the use of the laser generator, including correct startup, power adjustment, mode switching, etc., to avoid excessive equipment load or damage to optical components due to misoperation.

- Master basic maintenance skills: Train technicians to understand the cleaning methods of optical components, the cooling system maintenance process, and power monitoring techniques so that they can quickly take countermeasures when the equipment has minor abnormalities and reduce the impact of equipment failures.

The power loss of fiber laser generators is an issue that cannot be ignored, but through reasonable management and maintenance strategies, the risk of power drop can be effectively reduced to ensure long-term stable operation of the equipment. Enterprises should invest in high-quality equipment, establish regular maintenance plans, optimize the operating environment, and strengthen employee training to improve the overall reliability and service life of the equipment. Through these measures, not only can maintenance costs be reduced, but production efficiency can also be significantly improved, making the fiber laser technology play the greatest value in industrial applications.

Riassumere

The high efficiency and stability of fiber laser generators in industrial production are unquestionable, but their power may gradually decrease over time. Through reasonable maintenance measures, high-quality equipment selection, and an optimized operating environment, power loss can be effectively slowed down to ensure long-term stable operation of the equipment.

As a professional laser equipment manufacturer, Laser AccTek provides high-quality fiber laser cutting machines, welding machines, and cleaning machines, using advanced cooling systems and durable optical components to ensure that the equipment maintains stable power output during long-term operation. If you want to learn more about the optimization solutions for fiber laser equipment, please Contattaci!

Informazioni sui contatti

- [email protected]

- [email protected]

- +86-19963414011

- N. 3 Zona A, zona industriale di Lunzhen, città di Yucheng, provincia di Shandong.

Ottieni soluzioni laser