In che modo la saldatura laser influisce sulla zona termicamente alterata (ZTA)?

In modern metal joining technology, laser welding has become a key process in industries such as automotive, aerospace, precision instruments, and medical devices due to its high energy density, weld seam precision, and potential for automation. Compared to traditional arc welding or resistance welding, saldatrici laser offer smaller weld seams, reduced distortion, and higher efficiency. However, this process also affects the base metal surrounding the weld, an area known as the heat-affected zone (HAZ).

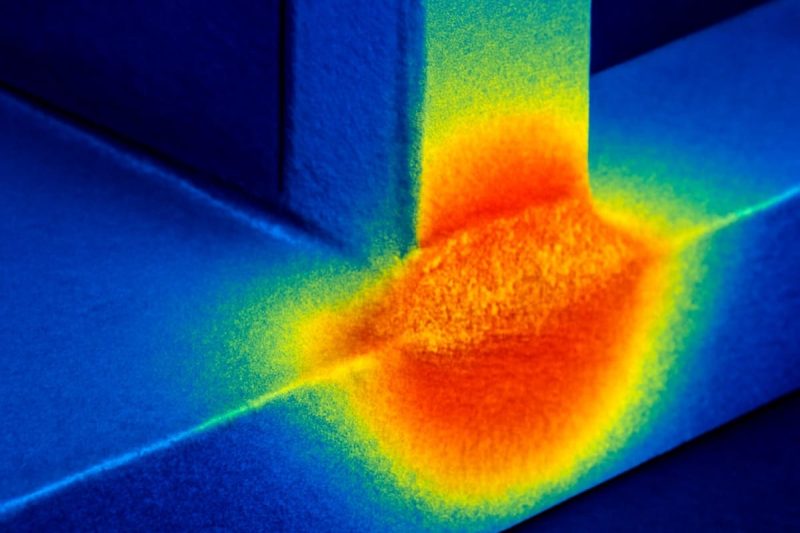

The HAZ is a crucial concept in welding research and practical applications. It is not part of the molten pool, but rather a region near the weld where the microstructure and properties change due to the welding thermal cycle. Although the HAZ does not melt, its metallurgical structure, hardness, and strength often undergo significant changes, directly impacting the overall reliability of the weld joint.

For welding processes using laser generators, the morphology and properties of the HAZ differ significantly from those of traditional welding methods. While laser welding utilizes concentrated energy and extremely rapid heating and cooling rates, the HAZ is typically smaller, but the internal microstructural changes are still significant. This article will analyze in detail the impact mechanism, main characteristics, control factors, and mitigation strategies of laser welding on HAZ, providing scientific guidance for manufacturing companies in the application of laser welding.

Sommario

Heat-Affected Zone (HAZ) Basics

The heat-affected zone (HAZ) is one of the most sensitive and complex areas in a weld joint. Although the base metal in this area is not fully melted, the weld heat significantly alters the metal’s microstructure and mechanical properties. Understanding the basic concepts, metallurgical changes, and influencing factors of the HAZ is crucial for understanding metal behavior during laser welding and optimizing weld quality. This section systematically introduces the definition and location of the HAZ, its metallurgical characteristics, and the factors influencing its properties, laying the foundation for a detailed analysis of the specific characteristics of the HAZ in laser welding.

Definition and Location

The heat-affected zone (HAZ) is the region of the base metal located outside the fusion line during welding. Here, although the metal has not yet reached its melting point, its temperature has increased significantly, and during cooling, it undergoes varying degrees of microstructural changes. In other words, the HAZ is a typical “heated but not melted” zone.

The extent of the HAZ depends on the welding heat input, welding method, and the thermophysical properties of the base metal. For example, in conventional arc welding, the HAZ can be wide due to the high heat input. In contrast, in laser welding, the heat-affected zone (HAZ) is often narrower due to the highly concentrated heat output from the laser generator, resulting in relatively limited microstructural changes. This is one of the key advantages of laser welding over conventional welding methods.

Metallurgical Changes in the HAZ

The welding thermal cycle profoundly affects the microstructure and properties of the base metal. Within the HAZ, the temperature varies, and it can be divided into several typical zones, each characterized by specific metallurgical changes:

- Grain Growth Zone (Coarse-Grained Zone): This high-temperature region near the fusion line reaches temperatures exceeding 1100–1350℃. The metal grains grow significantly, resulting in decreased toughness and weakened impact properties. The coarse-grained zone is often considered the most vulnerable portion of the HAZ.

- Partially Recrystallized Zone (Fine-Grained Zone): The temperature is slightly lower than the coarse-grained zone, typically between 900–1100℃. The grains here undergo recrystallization, resulting in a relatively uniform microstructure and excellent mechanical properties, sometimes even superior to those of the base metal.

- Phase Transformation Zone: For steel, austenitization occurs between 800–900℃. During cooling, austenite may transform into structures such as martensite, bainite, or pearlite. Fast cooling rates tend to form hard and brittle martensite, increasing crack susceptibility; slower cooling may result in pearlite or ferrite, which exhibits improved ductility and toughness.

- Partial Phase Transformation and Precipitation Zone: In the temperature range of 500–700℃, carbides or other precipitates of certain alloying elements may dissolve or reprecipitate. For example, chromium carbide precipitation may occur in stainless steel within this range, increasing susceptibility to intergranular corrosion.

- Residual Stress Formation: Due to the sharp temperature gradient and the resulting asynchrony between thermal expansion and contraction, residual stresses are easily generated in the HAZ. These stresses can reduce the fatigue life of the joint and cause cold cracking or stress corrosion cracking.

These metallurgical changes make the HAZ a “weak link” in the weld joint, requiring special attention during process design.

Factors Affecting HAZ Properties

The properties of the heat-affected zone (HAZ) are not fixed but are influenced by a variety of factors. These include:

The chemical composition and metallurgical properties of the base metal: Steels with high carbon content are more likely to form hard and brittle martensite during welding, resulting in increased crack susceptibility. Differences in the thermophysical properties of low-alloy steels, stainless steels, or aluminum alloys also determine the microstructure and properties of the HAZ.

Welding heat input and distribution: Greater heat input leads to a wider HAZ and a more pronounced coarse-grained zone. Lower heat input reduces the range of microstructure variation but may increase the risk of cold cracking.

Heating and cooling rates: Fast cooling rates tend to produce hard and brittle structures, such as martensite; slow cooling rates lead to excessive grain growth and reduced toughness. Therefore, a balance must be struck between the two.

Welding process parameters: Laser generator power, welding speed, spot diameter, and focal position all directly affect heat distribution and HAZ width. Laser welding offers the advantage of concentrated heat and high energy density, effectively reducing the HAZ area.

Joint Design and Assembly: Different joint configurations (butt, lap, fillet) and assembly gaps alter the local thermal cycle, thereby affecting the microstructure distribution of the HAZ. For example, excessive gaps can lead to abnormal heat conduction and increase the risk of defects.

Although the heat-affected zone (HAZ) remains unmelted, it undergoes complex microstructural evolution and property changes due to the welding thermal cycle. Its characteristics are influenced by multiple factors, including the base material, welding process parameters, and joint configuration. Understanding the definition of the HAZ, its metallurgical mechanisms, and influencing factors is crucial to mastering welding metallurgy and fundamental to ensuring the quality and reliability of laser welding. By properly controlling process parameters, particularly leveraging the high energy density of laser generators, the adverse effects of the HAZ can be effectively minimized, resulting in more stable weld joint quality for the manufacturing industry.

Characteristics of the HAZ in Laser Welding

Compared to traditional welding methods such as arc welding and tungsten inert gas welding, the welding heat source output by a laser generator offers the advantages of high energy density, concentrated heat input, and short exposure time. This results in significantly different characteristics of the heat-affected zone (HAZ) during laser welding in terms of size, microstructure, and properties. Understanding these characteristics can help the manufacturing industry better leverage the unique advantages of laser welding, improve joint quality, and minimize adverse metallurgical effects.

Dimensions and Geometry

One of the greatest advantages of laser welding is its highly concentrated heat input. Because the laser generator can focus energy into an extremely small spot, the heating width applied to the base material is significantly reduced. Unlike the more diffuse heat source and wide heat transfer path of traditional arc welding, the HAZ produced by laser welding typically exhibits the following characteristics:

Narrower Width: While the HAZ of traditional arc welding is often on the order of several millimeters or even centimeters, the HAZ produced by laser welding can typically be reduced to on the order of 0.1–0.5 mm. This narrow heat exposure range means that the original microstructure of the base material remains largely unchanged.

Elongated Morphology: Due to the small laser spot size and high energy density, the heat distribution in the weld joint is deeper and more concentrated, resulting in a HAZ geometry that typically exhibits a “needle-like” or “elongated” shape with a large depth and extremely narrow width.

Reducing the Scope of Microstructural Damage: A narrow HAZ effectively minimizes the area of base material degradation, which is particularly beneficial for heat-sensitive materials such as high-strength steel and titanium alloys.

This characteristic not only ensures a smooth transition between the weld and the base material but also significantly reduces the risk of cracking caused by grain coarsening or stress concentration.

Microstructural Changes

Although the laser-welded HAZ is very small, it still undergoes complex microstructural transformations. Based on the temperature distribution, the HAZ can be divided into several typical regions:

Coarse-Grained Zone: The region near the fusion line has the highest temperature. The grains grow significantly at high temperatures, resulting in a decrease in toughness. This region is typically the most vulnerable in the HAZ.

Fine-Grained Zone: Slightly away from the molten pool, the temperature reaches the recrystallization conditions but does not reach excessive growth, resulting in a uniform and fine-grained structure. Compared to the coarse-grained zone, the fine-grained zone often exhibits higher strength and toughness, making it the relatively better-performing portion of the HAZ.

Tempering Zone: In the lower temperature region (approximately 450–650℃), some hard and brittle structures may undergo tempering transformation, forming tempered bainite or tempered martensite. This structure can improve toughness and reduce crack susceptibility to a certain extent.

Martensitic Characteristics: For high-strength steels and some stainless steels, when the welding cooling rate is extremely rapid, a hard and brittle martensitic structure may form in the HAZ. This significantly increases hardness, but also reduces joint toughness and increases the risk of cracking.

Notably, because the cooling rate in laser welding is much higher than that in arc welding, the tendency to martensitize in the HAZ is more pronounced. Therefore, properly controlling the cooling rate and post-weld heat treatment is particularly critical in welding high-strength steels and alloy steels.

Mechanical Properties

The mechanical properties of the heat-affected zone (HAZ) of laser welds exhibit a gradient, with different areas exhibiting varying degrees of hardness, strength, and toughness:

Hardness Variation: Rapid cooling conditions favor the formation of high-hardness martensite or fine microstructures within the HAZ, significantly increasing local hardness. This can be advantageous for certain applications requiring high wear resistance, but it also introduces crack susceptibility.

Toughness Decrease: The presence of coarse-grained regions and the formation of martensite reduce local toughness and impact resistance. This is a key area of concern for the reliability of laser welded joints.

Residual Stress and Fatigue Performance: Due to the rapid cooling rate and large temperature gradients associated with laser welding, tensile stresses are likely to form within the HAZ. These residual stresses can reduce fatigue life and increase the risk of stress corrosion cracking during service. This adverse effect can be mitigated by properly adjusting welding parameters and post-processing.

Overall, the laser-welded HAZ exhibits a distinct gradient in hardness, strength, and toughness, requiring a combination of material properties and process optimization to fully realize its advantages.

Compared to traditional welding methods, the heat-affected zone (HAZ) in laser welding exhibits narrower dimensions, more distinct microstructure evolution, and more complex property variations. This difference stems primarily from the high energy density and short exposure time provided by the laser generator. While a smaller HAZ means less damage to the base material, it can still contain unfavorable factors such as a hard and brittle structure, grain coarsening, and residual stresses. Therefore, understanding the characteristics of the HAZ in laser welding and optimizing it through appropriate process control and material selection is key to ensuring high-quality and long-lasting weld joints.

Factors Affecting the HAZ in Laser Welding

During laser welding, the size, structure, and properties of the heat-affected zone (HAZ) depend not only on the high energy density of the laser generator but also on the combined influence of the material’s inherent properties and process parameters. Different metal materials, laser power, and welding speed, beam focusing conditions, and joint configuration all alter the thermal cycle, thereby determining the extent and quality of the HAZ. This section systematically analyzes these key factors to help understand how to minimize the adverse effects of the HAZ through optimal control.

Proprietà dei materiali

The chemical composition and metallurgical properties of the base metal are the primary factors affecting the HAZ.

Steel: High-carbon steel cools rapidly during welding, easily forming martensite in the HAZ, resulting in increased hardness and decreased toughness. Low-carbon steel exhibits less structural change and a relatively lower HAZ risk.

Stainless steel: The thermal cycle during welding may induce the precipitation of chromium carbides, increasing susceptibility to intergranular corrosion. Austenitic stainless steel, due to its low thermal conductivity, has a relatively narrower HAZ, but also carries a higher risk of residual stress.

Aluminum alloys: Due to their high thermal conductivity, heat diffusion is rapid during welding, resulting in a wider HAZ than steel. Dissolution and coarsening of the precipitation-strengthening phases are also more likely, weakening mechanical properties.

Titanium alloys: Sensitive to impurities such as oxygen and hydrogen, the HAZ is prone to grain coarsening. Improper protection can lead to decreased strength and toughness.

Thermophysical properties of different materials, such as thermal conductivity, specific heat capacity, and coefficient of expansion, directly determine the size and microstructural changes of the HAZ.

Potenza laser

The output power of the laser generator directly determines the heat input during the welding process.

High power: High heat input leads to a deeper weld pool, which increases the HAZ area. Excessive power can also lead to severe grain coarsening.

Low power: Insufficient heat input leads to insufficient weld penetration, potentially resulting in incomplete weld penetration, but the HAZ area is smaller, and microstructural changes are minimal.

Power stability: Unstable laser output can cause temperature fluctuations in the weld joint, leading to uneven HAZ structure.

Appropriate power selection can minimize the HAZ area while ensuring weld penetration and strength.

Velocità di saldatura

Welding speed determines the distribution of heat input per unit time and plays a key role in the width and microstructural evolution of the HAZ.

High-speed welding: Low heat input, rapid cooling, and a narrow HAZ are common, but hard and brittle structures such as martensite are more likely to form.

Low-speed welding: Increased heat input widens the HAZ, potentially leading to excessive grain growth and reduced toughness.

Moderate speed strikes a balance between reducing HAZ width and avoiding excessive hardening.

Both excessively fast and slow welding speeds can pose risks; the optimal speed should be determined based on a comprehensive consideration of material properties and process requirements.

Beam Focus and Diameter

The focusing conditions of the laser beam determine the energy density distribution, which in turn affects the HAZ morphology.

Small spot diameter: High energy density results in a deep and narrow weld, a smaller HAZ, but rapid cooling and an increased risk of cracking.

Large spot diameter: More uniform heat distribution, a wider HAZ, and more pronounced microstructural changes are common, but crack susceptibility is reduced.

Focus Position: If the focus is located on or above the workpiece surface, heat is concentrated on the surface, potentially resulting in insufficient penetration. If the focus is located within the material, energy utilization is higher, but the HAZ depth may increase.

By adjusting the spot diameter and focus position, an optimal balance can be achieved between weld formation and HAZ control.

Joint Design and Geometry

The weld joint form and assembly conditions have a direct impact on heat conduction and stress distribution.

Joint Form: Butt welds, lap welds, and fillet welds vary in HAZ size and shape due to different heat flow paths.

Assembly Clearance: Excessive clearance can lead to abnormal heat input distribution, expanding the HAZ, and potentially causing porosity or incomplete weld penetration.

Thickness and Geometry: Thick plates have poor thermal conductivity, resulting in a wider HAZ; thin plates have a relatively smaller HAZ due to faster heat dissipation.

Proper joint design and assembly accuracy are crucial prerequisites for controlling HAZ shape and performance.

The heat-affected zone (HAZ) in laser welding isn’t determined by a single factor it’s the result of multiple factors, including material properties, laser power, welding speed, beam focusing conditions, and joint geometry. Optimizing these process parameters can effectively reduce the HAZ, avoid the formation of hard and brittle structures, and lower residual stresses, thereby improving the overall performance of the welded joint. This is a key reason why laser welding is widely used in precision manufacturing and high-performance structural parts processing.

Mitigation Strategies for HAZ Effects

Although the heat-affected zone (HAZ) is relatively narrow during laser welding, its potential adverse effects cannot be ignored, such as the formation of a hard and brittle structure, grain coarsening, and residual stress accumulation. To achieve stable weld joints, a series of control and mitigation measures is typically implemented in engineering practice. These measures primarily include optimizing laser parameters, pre- and post-weld heat treatment, and comprehensive consideration of joint design and process methods.

Ottimizzazione dei parametri laser

As a highly concentrated heat source, the laser’s energy input characteristics determine the size and properties of the HAZ. Properly controlling welding parameters can significantly improve weld quality:

Power Control: Excessive laser power leads to an excessively large molten pool and an increased HAZ extent; insufficient power can result in incomplete penetration or porosity. Selecting the appropriate power ensures weld formation while minimizing heat diffusion.

Welding Speed: Faster welding speeds help reduce the HAZ, but excessively fast speeds reduce weld penetration. A balance must be struck between weld quality and HAZ extent.

Spot Size: A small spot size increases energy density and enhances localized heating, but can also lead to excessive cooling rates. Moderately increasing the spot diameter can disperse heat and prevent microstructure hardening.

Pulse Parameters: For pulsed laser welding, the combination of pulse width, frequency, and peak power determines the thermal cycle pattern. Optimizing these parameters can effectively reduce stress concentration and control microstructural transformation.

In general, the goal of parameter optimization is to minimize heat input while ensuring weld strength and density, thereby avoiding the formation of large areas of brittle microstructure in the HAZ.

Pre- and Post-Weld Heat Treatment

Heat treatment is a traditional method for mitigating the adverse effects of the HAZ and is also applicable in laser welding:

Pre-weld Preheating: Applicable to easily hardened materials (such as high-strength steel), preheating the base metal to an appropriate temperature before welding slows the cooling rate and reduces the likelihood of martensite formation.

Post-weld Heat Treatment: Common methods include tempering, annealing, and normalizing. Tempering reduces hardness and improves ductility; annealing helps refine grains and eliminate residual stresses; and for certain heat-resistant alloys, normalizing further stabilizes the microstructure.

Localized Heat Treatment: When deformation control or localized performance needs to be maintained, localized heating and cooling techniques can be used to strengthen or relieve specific areas.

These heat treatment measures not only improve the microstructure and properties of the HAZ but also enhance the long-term stability of the weld joint.

Combined Design and Process Considerations

In addition to process control within the welding process itself, the proper coordination of joint design with other process methods is also an important way to reduce HAZ risks:

Joint Design Optimization: Proper design of the groove angle and assembly gap can improve the laser beam’s incident conditions and energy distribution, thereby avoiding localized overheating.

Material Selection: Using low-carbon, low-alloy materials or specialized welding materials can reduce the tendency of the heat-affected zone (HAZ) to harden.

Hybrid Welding Technology: In recent years, laser-arc hybrid welding has become widely used. This method utilizes the high energy density of the laser and the excellent weld pool control of the arc to optimize the thermal cycle, further reducing the HAZ area and improving the weld profile.

Cooling Method Control: By selecting appropriate fixtures, heat dissipation methods, or auxiliary cooling gases, temperature gradients can be adjusted to reduce stress concentrations.

Overall, while the HAZ (Highly Ambient Zone) in laser welding is narrower than that produced by conventional processes, changes in its microstructure and properties can still affect the weld joint. By adjusting process parameters, preheating and post-weld heat treatment, and integrating joint design with composite processes, the adverse effects of the HAZ can be effectively mitigated, resulting in weld joints with superior performance and high reliability. In practical applications, these measures often require targeted selection and optimization based on specific material and product requirements.

Riepilogo

The heat-affected zone (HAZ) is a key component in assessing weld joint quality. While laser welding typically creates a smaller HAZ than traditional welding methods, potential issues such as grain coarsening, phase transformation, and residual stresses still exist. By properly selecting laser power, welding speed, spot parameters, and joint design, supplemented by preheating and post-weld heat treatment, HAZ characteristics can be significantly improved, thereby enhancing the reliability and life of the welded joint.

For manufacturers striving for high precision, efficiency, and reliability, laser welding is not only an advanced process but also a vital tool for driving industrial upgrading. As a professional laser welding solutions provider, Laser AccTek offers comprehensive technical support and equipment solutions to help you achieve high-quality welds while minimizing the negative effects of the HAZ. If you are looking for suitable laser welding equipment or would like to optimize your existing production processes, please feel free to Contattaci.

Informazioni sui contatti

- [email protected]

- [email protected]

- +86-19963414011

- N. 3 Zona A, zona industriale di Lunzhen, città di Yucheng, provincia di Shandong.

Ottieni soluzioni laser