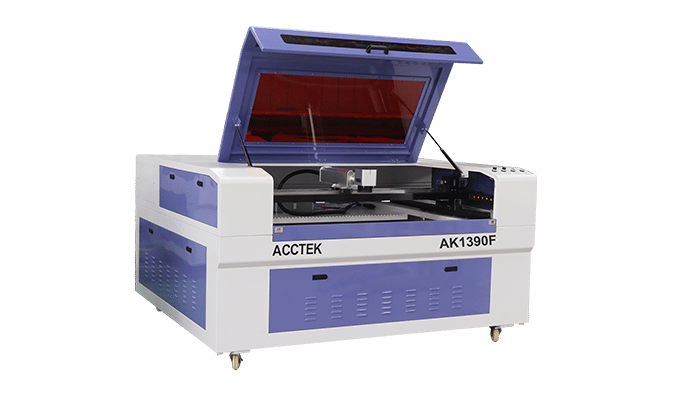

Acrylic Laser Cutting Machine

Photoelectric Technology

AccTek Laser focus on designing and manufacturing photoelectric-related system. We provide accurate and exquisite processing quality with leading R&D capability.

Integration Ability & Experienced

With an experienced, completed, and elite R&D team, customized such as automated, integrated with the robot, system integration, etc. are all available.

Professional Service

AccTek Laser's laser cutting machine is a professional laser cutting machine designed and manufactured in China. Our elite engineering team provides related service support.

Equipment Features

High Power CO2 Laser Tube

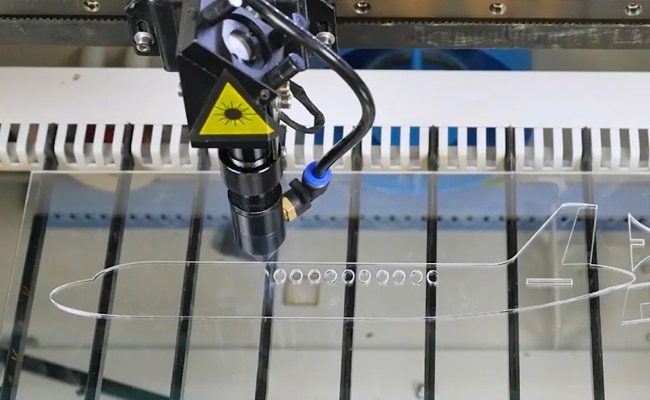

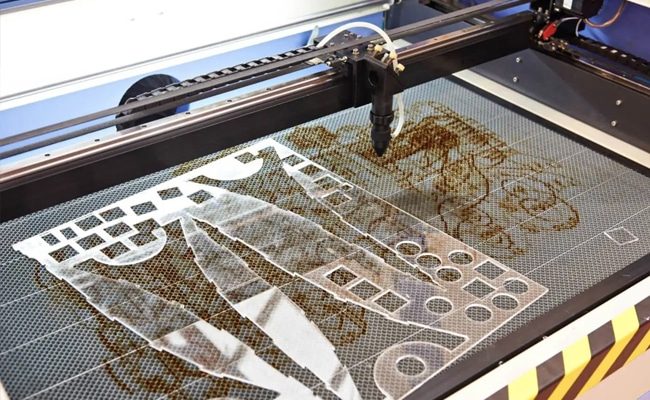

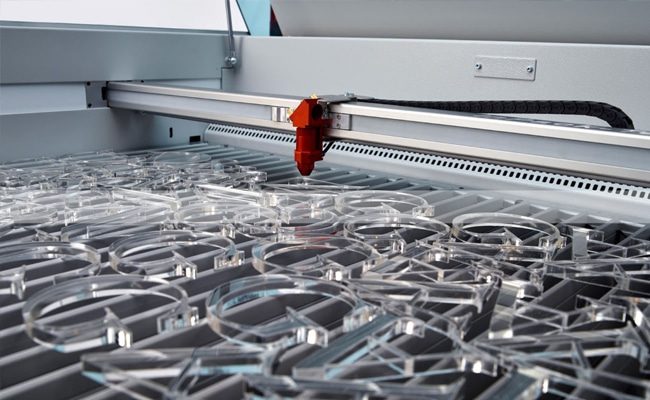

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

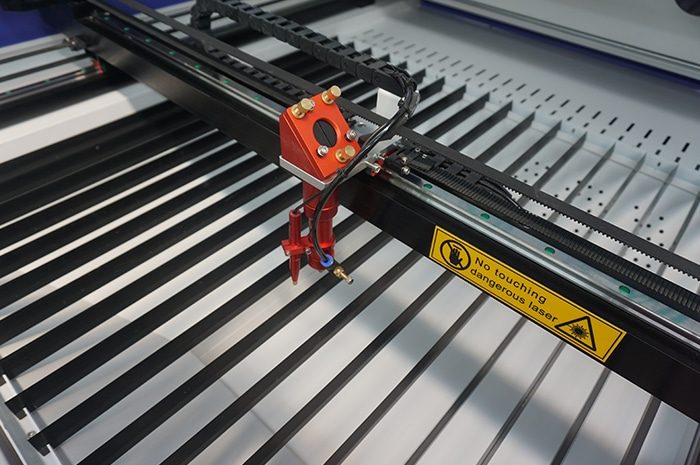

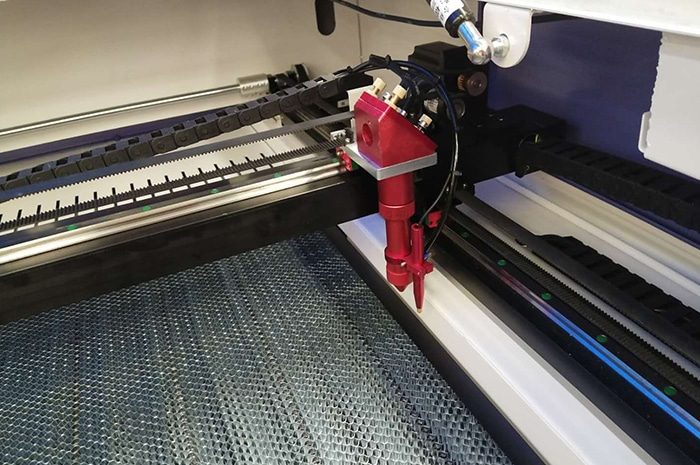

Advanced Motion System

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

High-Quality Optics

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

High-Precision CO2 Laser Head

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

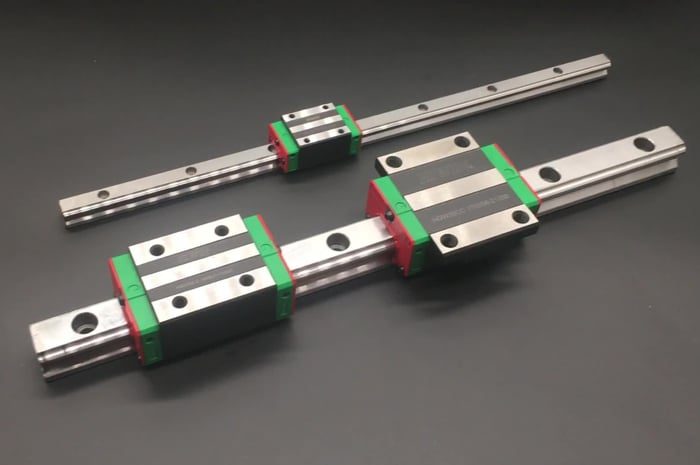

High-Precision HIWIN Rail

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

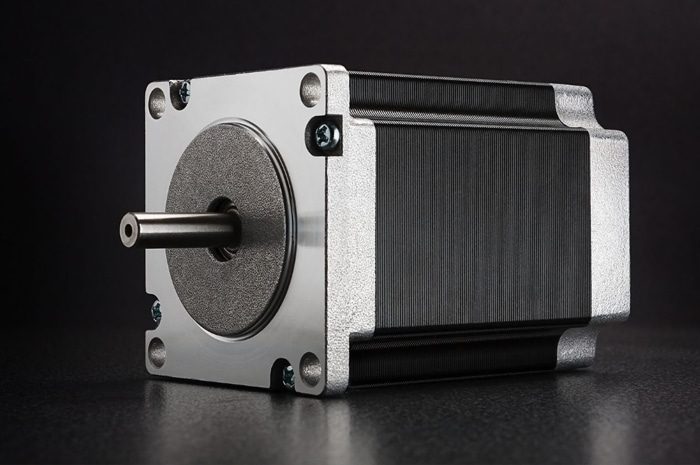

Reliable Stepper Motor

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

Technical Specifications

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Medium | Fiber laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000 mm/min | ||||||

| Engraving Speed | 0 - 40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water-cooling | ||||||

Laser Welding Capacity

| Laser Power | Cutting Speed | 3mm | 5mm | 8mm | 10mm | 15mm | 20mm | 25mm | 30mm | 35mm | 40mm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 8mm/s | 4mm/s | 1mm/s | / | / | / | / | / | / | / |

| Optimal Cutting Speed | 5mm/s | 2mm/s | / | / | / | / | / | / | / | / | |

| 40W | Max Cutting Speed | 15mm/s | 8mm/s | 4mm/s | 3mm/s | / | / | / | / | / | / |

| Optimal Cutting Speed | 10mm/s | 5mm/s | 2mm/s | / | / | / | / | / | / | / | |

| 60W | Max Cutting Speed | 20mm/s | 10mm/s | 5mm/s | 4mm/s | 2mm/s | 1mm/s | / | / | / | / |

| Optimal Cutting Speed | 15mm/s | 7mm/s | 3mm/s | 2mm/s | 0.8mm/s | 0.3mm/s | / | / | / | / | |

| 80W | Max Cutting Speed | 25mm/s | 12mm/s | 9mm/s | 6mm/s | 3mm/s | 1.5mm/s | 0.5mm/s | / | / | / |

| Optimal Cutting Speed | 20mm/s | 8mm/s | 5mm/s | 3mm/s | 1.5mm/s | 0.5mm/s | 0.2mm.s | / | / | / | |

| 100W | Max Cutting Speed | 30mm/s | 15mm/s | 10mm/s | 7mm/s | 4mm/s | 2mm/s | 0.8mm/s | 0.3mm/s | / | / |

| Optimal Cutting Speed | 25mm/s | 10mm/s | 6mm/s | 4mm/s | 2mm/s | 0.7mm/s | 0.3mm/s | / | / | / | |

| 130W | Max Cutting Speed | 35mm/s | 17mm/s | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 1mm/s | 0.5mm/s | 0.2mm/s | / |

| Optimal Cutting Speed | 30mm/s | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 1mm/s | 0.4mm/s | 0.3mm/s | / | / | |

| 150W | Max Cutting Speed | 40mm/s | 21mm/s | 15mm/s | 11mm/s | 7mm/s | 4mm/s | 1.8mm/s | 0.8mm/s | 0.4mm/s | 0.1mm/s |

| Optimal Cutting Speed | 35mm/s | 15mm/s | 10mm/s | 7mm/s | 4mm/s | 1.5mm/s | 0.8mm/s | 0.5mm/s | 0.1mm/s | / | |

| 180W | Max Cutting Speed | 45mm/s | 25mm/s | 18mm/s | 16mm/s | 9mm/s | 5mm/s | 2.5mm/s | 1.3mm/s | 0.6mm/s | 0.2mm/s |

| Optimal Cutting Speed | 40mm/s | 18mm/s | 12mm/s | 10mm/s | 6mm/s | 2mm/s | 1.2mm/s | 0.8mm/s | 0.3mm/s | 0.1mm/s | |

| 200W | Max Cutting Speed | 55mm/s | 30mm/s | 25mm/s | 20mm/s | 11mm/s | 7mm/s | 5mm/s | 3mm/s | 1mm/s | 0.5mm/s |

| Optimal Cutting Speed | 45mm/s | 25mm/s | 15mm/s | 13mm/s | 8mm/s | 4mm/s | 3mm/s | 1.5mm/s | 0.7mm/s | 0.3mm/s |

Comparison of Different Cutting Methods

| Cutting Process | Laser Cutting | CNC Routing | Saw Cutting | Ultrasonic Cutting |

|---|---|---|---|---|

| Precision And Accuracy | High | Good | Moderate | High |

| Cutting Speed | High | Moderate | Low | Moderate |

| Material Thickness | Thin to Medium | Thin to Thick | Thick | Thin to Medium |

| Heat Affected Zone | Minimal | Minimal | Moderate | Minimal |

| Cutting Edge Quality | Smooth and Polished | Smooth | Rough | Smooth and Precise |

| Material Waste | Minimal | Moderate | High | Minimal |

| Complexity | Suitable for Intricate Designs | Suitable for Complex Designs | Simple Cuts Only | Suitable for Complex Designs |

| Versatility | Versatile | Versatile | Limited Applications | Limited Applications |

| Noise | Low | Moderate | High | Low |

| Equipment Cost | High | High | Low | High |

| Operating Cost | Moderate to High | Moderate to High | Low | Moderate to High |

| Safety Considerations | Eye Protection | Eye Protection | Safety Gear | Eye Protection |

| Post-Processing Required | Rarely | Sometimes | Often | Rarely |

| Handling Complex Designs | Yes | No | No | Yes |

Product Features

- The machine is equipped with a high-quality CO2 laser generator, which is very suitable for cutting acrylic materials.

- The machine can cut acrylic material quickly, which increases productivity.

- The machine provides excellent cutting precision and accuracy, ensuring clean and smooth cuts with minimal material waste.

- The machine can handle acrylic sheets of various thicknesses and can also cut other materials such as wood, plastic, and some metals.

- The laser beam does not physically touch the material, minimizing the risk of material damage or contamination.

- The machine has autofocus and height adjustment functions, which can get the best cutting performance on different thicknesses of acrylic.

- An intuitive control panel or user interface allows the operator to set cutting parameters, adjust laser power, and control machine motion.

- The machine can be integrated with various design software to realize the seamless transfer of cutting designs.

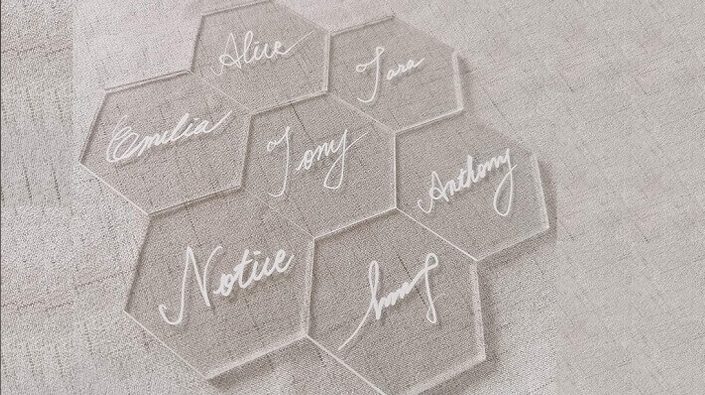

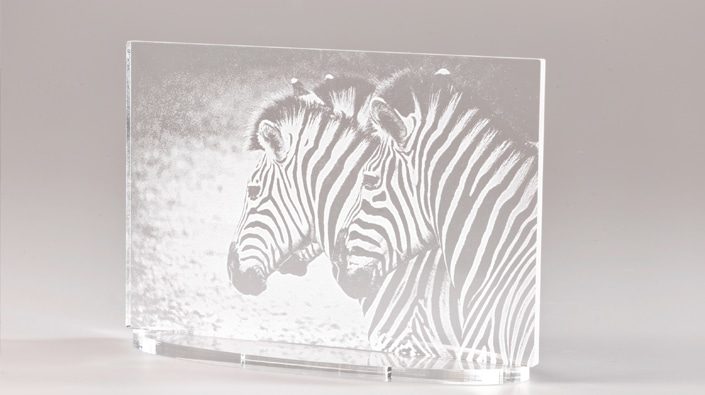

Product Application

Equipment Selection

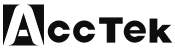

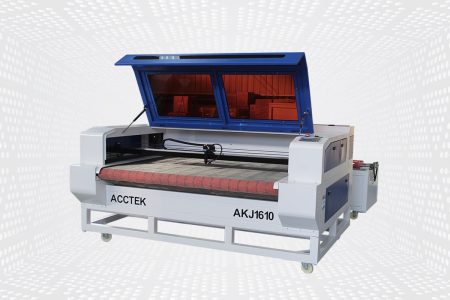

High Configuration CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With CCD Camera

CO2 Laser Cutting Machine With Electric Lift Table

Fully Enclosed CO2 Laser Cutting Machine

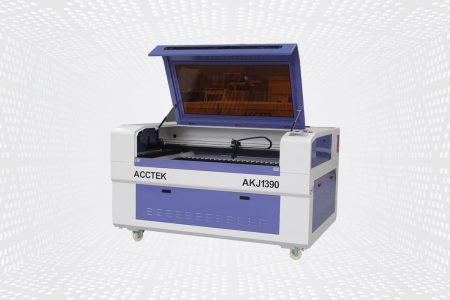

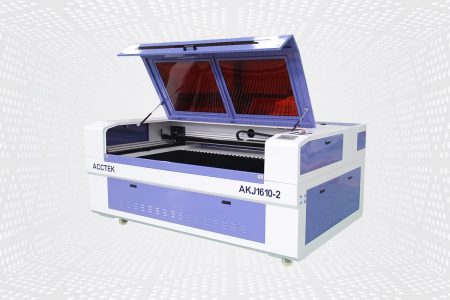

Double Head CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With Automatic Feeding Device

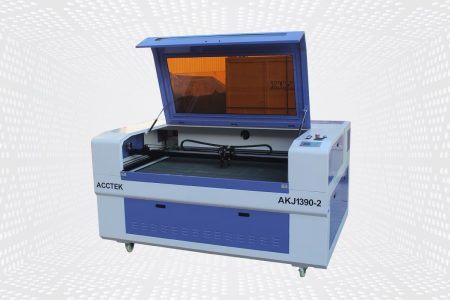

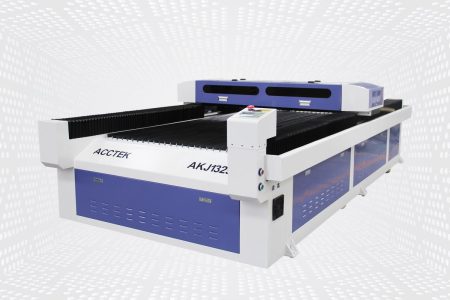

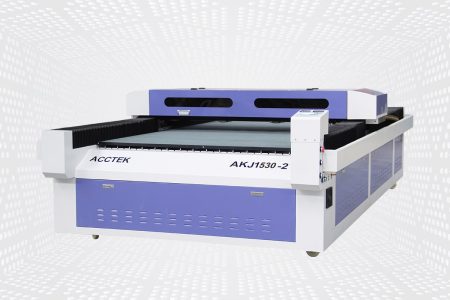

Large-Size CO2 Laser Cutting Machine

Double Head Large Size CO2 Laser Cutting Machine

Why Choose AccTek?

Impeccable Precision

Unrivaled Quality

Customized Solutions

Excellent Customer Support

Frequently Asked Questions

Yes, laser-cutting machines can cut acrylic. In fact, laser cutting is one of the most popular methods of cutting acrylic sheets and other materials. Also known as plexiglass or PMMA (polymethyl methacrylate), acrylic has properties ideal for laser cutting.

The laser cutting process works by using a high-powered laser beam to melt, burn or vaporize material along the cutting path. A focused laser beam delivers a large amount of energy to a small area, allowing it to cut acrylic with high precision and a minimal heat-affected zone. By adjusting the power, speed, and focus of the laser, different cutting depths and edge finishes can be obtained.

The reason to cut acrylic with a laser cutting machine is that it provides clean, smooth edges without the need for additional finishing processes. The cut edges are polished, perfect for projects that require a high-quality finish. Additionally, laser cutting can achieve intricate and detailed designs on acrylic, making it a popular choice for custom signage, displays, and artistic creations.

When using an acrylic laser cutting machine, the settings must be adjusted correctly to ensure a clean cut. Laser power, speed, and focus should be optimized according to the thickness and type of acrylic used. Fumes and potentially hazardous particles are released during laser cutting and proper ventilation and safety measures should be taken.

The price of an acrylic laser cutting machine will vary widely, depending on several factors such as the brand of the machine, power, size, features, and country of purchase. In general, smaller and lower-powered laser cutting machines designed for hobbyists or small businesses can be more affordable, while larger and higher-powered industrial-grade machines can be expensive.

A basic entry-level desktop laser-cutting machine for a hobbyist or small business can cost between $1,000 and $3,000. These machines usually have lower power (such as 40W to 60W) and a smaller cutting area.

Larger, more powerful industrial-grade laser cutting machines with larger cut sizes and higher laser power (such as 100W to 200W) can cost anywhere from $4,000 to $8,000 or more. Prices can be higher for professional and high-end models with advanced features.

These price ranges are rough estimates and will vary by region, specific seller, and other factors. Additionally, factors such as shipping costs, taxes, and optional add-ons can affect the final price of a machine.

If you are planning to buy acrylic laser cutting machine, you can contact us. Our engineers will provide you with specific quotations according to your requirements and budget, and we will also provide you with comprehensive after-sales support, warranty, and training services. Looking forward to working with you!

- Cast Acrylic: This is the most common type of acrylic used for laser cutting, it offers excellent laser cutting properties and is available in a variety of colors, thicknesses, and finishes. Cast acrylic is made by pouring liquid acrylic into a mold and allowing it to cool and solidify, resulting in a high-quality, bubble-free material.

- Extruded Acrylic: Extruded acrylic is manufactured using an extrusion process, which may contain more impurities than cast acrylic. While it’s still suitable for laser cutting, the cut edges may not be as smooth as cast acrylic.

- Colored And Clear Acrylic: Acrylic sheets are available in a variety of colors and transparencies. Both colored and clear acrylic can be laser cut, but laser power and cutting speed settings may need to be adjusted for specific colors or levels of transparency.

- Frosted/Matte Acrylic: Frosted or matte acrylic has a textured surface that diffuses light and creates a soft, diffuse look. Laser cutting can be used to etch intricate patterns into frosted acrylic surfaces, creating a beautiful frosted effect.

- Mirrored Acrylic: Mirrored acrylic has a reflective surface and can be laser-cut to create unique designs and decorations. The mirror layer is laser cut to reveal the clear acrylic underneath while retaining the mirror effect around the cut edges.

- Fluorescent Acrylic: These acrylic sheets contain additives that make them glow under ultraviolet (UV) light. Cutting this material with a laser can create eye-catching and unique designs.

- Thin Acrylic Sheets: For acrylic sheets between 1 and 3mm thick, a laser cutting machine with a power of about 30 to 60 watts is usually sufficient for clean, efficient cuts.

- Medium-Thickness Acrylic Sheets: For acrylic sheets between 4 and 8mm thick, a laser cutting machine with a power of 60 to 120 watts should be sufficient for most cutting tasks.

- Thick Acrylic Sheets: For thicker acrylic sheets with a thickness of 8mm and above, a laser cutting machine with a power of 120 to 200 watts is usually required to effectively cut the material.

- Edge Quality: Acrylic is sensitive to heat, and the edges of the acrylic cut with a laser can sometimes appear melted, rough, or uneven, more noticeable when cutting thicker acrylic sheets or when using a high-powered laser generator. Additional post-processing may be required to achieve a smoother surface quality.

- Toxic Fumes: Potentially harmful fumes or gases such as acrylic acid, hydrogen cyanide, and other volatile organic compounds (VOCs) are released when lasers are used to cut acrylic. Inhalation of these fumes may be irritating or toxic, so proper ventilation and safety measures are required to protect the operator and others nearby.

- Material Thickness Limitations: Laser cutting has its limitations when it comes to the thickness of acrylic sheets. Thicker acrylic may require multiple cuts, which slows down the cutting process and results in less precise cuts.

- Risk of Cracking And Warping: If the laser cutting settings are not adjusted properly, or if the acrylic sheet is of poor quality, there is a risk of material cracking or warping during the cutting process. This can result in wasted material and increase production costs.

- Equipment And Maintenance Costs: Laser-cutting machines can be expensive to purchase and maintain. It requires regular maintenance to ensure optimum performance and longevity, which adds to overall operating costs.

- Limited Cutting Speed: Acrylic can be cut relatively quickly with a laser, but it may still take more time to achieve a precise, clean cut than other materials. This can affect productivity, especially for large projects.

- Material Limitations: While acrylic is generally excellent for laser cutting, not all acrylic types are. Some types of acrylic may produce fumes when cutting, while others may not produce clean edges or may melt too easily.

- Optimal Power and Speed Settings: Adjust laser power and cutting speed to find the right balance for your specific acrylic material. Lower power settings or higher cutting speeds help reduce the heat generated during the cut, thereby minimizing burn marks.

- Test Cut: Before running the whole project, make a test cut of the acrylic scrap. Experiment with various power and speed combinations to find the best laser setting that provides a clean cut without overburning.

- Maintain Proper Ventilation: Make sure the laser cutting area is well-ventilated to remove the fumes and heat generated during the cutting process. Proper ventilation helps reduce the chance of sediment settling back onto the material and causing burn marks.

- Using Air Assist: When cutting acrylic with a laser beam, use an air assist system to blow compressed air or gas (usually nitrogen) around the laser beam. This helps clear fumes, debris, and heat from the cutting area, preventing over-melting and reducing the chance of burn marks.

- Focusing The Laser Properly: It is necessary to ensure that the laser beam is properly focused on the acrylic surface. A well-focused beam provides cleaner, more precise cuts, reducing the potential for over-melting and burn marks.

- Use Masking Tape or Protective Film: Applying masking tape or protective film to the surface of the acrylic before cutting will help prevent burn marks and protect the material from any residual smoke or debris.

- Clean Optics: The optics of a laser cutter, including lenses and mirrors, need to be cleaned regularly, as dirt or debris can affect the performance of the beam and cause uneven cuts.

- Choose High-Quality Acrylic: The quality and formulation of the acrylic can affect the severity of burn marks. Choose high-quality acrylic sheets designed for laser cutting to minimize the chance of discoloration or burning.