Double Gantry CO2 And Fiber Laser Cutting Machine

- Brand: AccTek

- Model: AKJ-F-2

- Laser Head: Raytools

- Laser Genertor: Raycus

- Servo Motor: Japanese Yaskawa

- Price Range: $16600-$40000/Set

- After Sale: 3 Years

- Lead Time: 15-17 Working Day

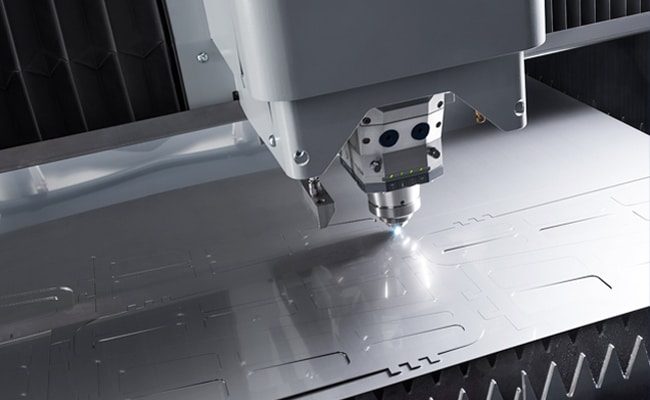

The double gantry CO2 And Fiber laser cutting machine is an advanced tool that combines the advantages of CO2 and fiber laser technology. This innovative machine combines two different types of lasers (CO2 lasers for processing non-metallic materials and fiber lasers for cutting metals) into one machine, giving manufacturers unrivaled versatility. The double gantry design allows two laser heads to operate simultaneously, resulting in faster processing and higher throughput.

AccTek has 10 years of experience in laser cutting machine production and is committed to providing professional laser solutions to global customers. As a professional manufacturer of laser cutting machines, we have designed laser cutting machines with different powers and functions to meet the needs of different customers. AccTek implements strict assembly processes and world-class brand parts to ensure high-quality laser cutting machines for customers.

| Model | AKJ1325F-2 | AKJ1530F-2 | ||

|---|---|---|---|---|

| Cutting Range | 1300*2500mm | 1500*3000mm | ||

| Control System | Au3tech | |||

| Laser Head | Au3tech | |||

| Fiber Laser Power | 1000W / 1500W / 2000W (Raycus/IPG) | |||

| CO2 Laser Power | 150W (Reci W6) | |||

| Max Cutting Speed | 35m/min | |||

| Max Speed | 50m/min | |||

| Min Line Width | 0.1mm | |||

| Power Requirements | 380V, 50/60Hz, 16A | |||

| Continuous Working Time | 24 hours | |||

| Repeat Positioning Accuracy | ±0.02mm | |||

Product Configuration

Double Gantry Design

The machine adopts a double gantry design, a CO2 laser head is installed on one gantry, and a fiber laser head is installed on the other gantry. It helps increase efficiency, improve precision, and reduce material waste, making it an excellent choice for businesses looking to enhance their manufacturing processes.

Aviation Aluminum Beam

The beam is manufactured according to the aerospace standard. Compared with the steel beam, the weight is greatly reduced, the load of the servo motor is reduced, and the inertia is reduced. After aging treatment, the beam has the characteristics of lightweight, high strength, and high running precision. The lightweight beam can ensure the fast operation of the equipment, improve the processing efficiency and ensure the processing quality at the same time.

Tube Welding Bed

The internal structure of the bed is welded by multiple rectangular tubes, and there are reinforced rectangular tubes inside the bed to enhance the strength and stability of the body. The solid body structure not only increases the stability of the guide rail but also effectively prevents the deformation of the body. The service life of the body is as long as 25 years.

Raycus Laser Generator

The Raycus laser generator not only has higher photoelectric conversion efficiency but also provides more stable optical quality to ensure a more stable and finer cutting effect.

Reci CO2 Laser Tube

The Reci CO2 laser tube is a powerful laser generator capable of producing a high-power laser beam for engraving and cutting various materials. Known for its durability and accuracy, it is also relatively easy to operate and maintain.

Au3tech Cutting Head

The A200M sheet metal cutting head was designed by the German brand A-cutter in 2018 and is mainly used for flat cutting within 2000W.

Stable and reliable, high precision, good quality, and long service life.

Delta Servo Motor

Our selection of Taiwan Delta servo motors can not only meet the high-precision positioning requirements of the laser cutting machine but also reduce maintenance and wiring costs for multi-function operations.

HIWIN Guide Rail

Using Taiwan HIWIN linear guide rail, the running speed is fast, the positioning accuracy is high, the time is longer, the engraving and cutting accuracy is improved, and the precise processing effect is ensured.

Au3tech Control System

Au3tech system is a powerful laser cutting control system designed to enhance the functionality of laser cutting machines. It offers a range of advanced features and benefits that increase user efficiency, accuracy, and overall performance.

Product Features

- The fuselage adopts a gantry structure, and the beam is integrally cast, which has higher rigidity, stability, and shock resistance.

- The high-performance laser generator and Au3tech cutting system with stable operation ensure the best cutting effect.

- The machine has a complete cooling system, lubrication system, and dust removal system to ensure stable, efficient, and long-lasting operation of the machine.

- The laser head is automatically adjusted to keep the focal length constant so that the cutting quality is more stable.

- Professional CAD/CAM automatic programming software and automatic nesting software can help save raw materials to the greatest extent.

Product Advantages

- The CO2 and fiber laser cutting machine adopts a double gantry structure, which has the advantage that it can be equipped with two independent control systems to control the fiber laser and CO2 laser respectively;

- The fiber laser cutting system is used for cutting metal materials, and the CO2 laser cutting system is used for cutting and engraving non-metal materials. One machine can be used for multiple purposes, which is more cost-effective than buying two machines separately;

Product Application

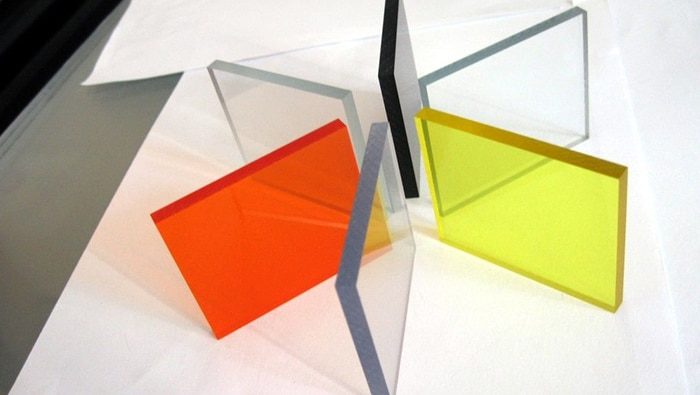

CO2 and fiber laser cutting machines can be used for cutting and engraving metal and non-metal materials. It can be used not only for cutting thin metal sheets, such as stainless steel, carbon steel, aluminum alloy, and galvanized sheet, etc. but also for cutting acrylic, wood, PVC, etc. CO2 and fiber laser cutting machines are widely used in automobiles, precision machinery, medical equipment, kitchen utensils, electronic appliances, advertising signs, elevators, electrical appliances, metal processing, and other industries.

Play Video about Cutting Samples

Play Video about Cutting Samples

Play Video about Cutting Sample

Play Video about Cutting Sample

Why Choose AccTek?

Productivity

- Advanced motion systems and one-piece frame design increase motion stability and accuracy over the full range of speeds.

- Fiber laser technology significantly increases cutting speeds while simultaneously reducing power consumption and overall operating costs.

- Ultra jump and scan cut functions minimize positioning time and maximize beam on time.

- Intelligent autofocus and automatic gas pressure control reduce setup times.

Quality

- Proven databases for a range of materials.

- Zoom head with autofocus offers automatic beam magnification of up to 4x for the best combination of speed and quality over a wide range of material thicknesses.

- Fast, clean, and more consistent perforation even in thick materials.

- The water-cooling feature adds stability to the material being processed.

Reliability

- Ruida Cutting systems deliver proven reliability.

- Fiber lasers offer maximum efficiency and reliability.

- The high-performance cutting head offers a completely dustproof beam path for long lens life and maximum reliability.

- Remote service with online diagnostics.

Get Laser Solutions

We can customize the design according to your requirements. You only need to tell us your requirements, and our engineers will provide you with turnkey solutions in the shortest possible time. Our laser equipment prices are very competitive, please contact us for a free quote. If you need other laser equipment-related services, you can also contact us.