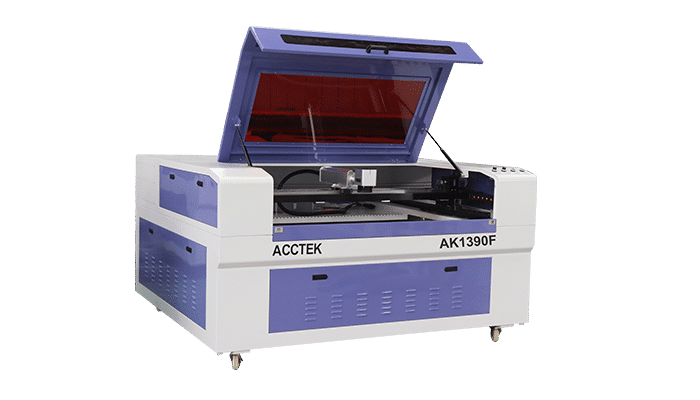

MDF Laser Cutting Machine

Photoelectric Technology

AccTek Laser focus on designing and manufacturing photoelectric-related system. We provide accurate and exquisite processing quality with leading R&D capability.

Integration Ability & Experienced

With an experienced, completed, and elite R&D team, customized such as automated, integrated with the robot, system integration, etc. are all available.

Professional Service

AccTek Laser's laser cutting machine is a professional laser cutting machine designed and manufactured in China. Our elite engineering team provides related service support.

Equipment Features

High Power CO2 Laser Tube

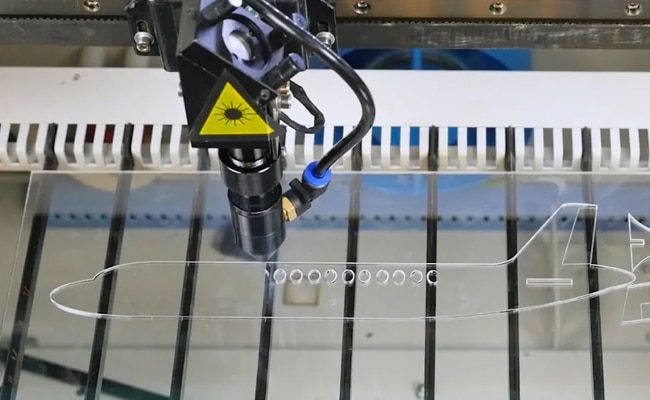

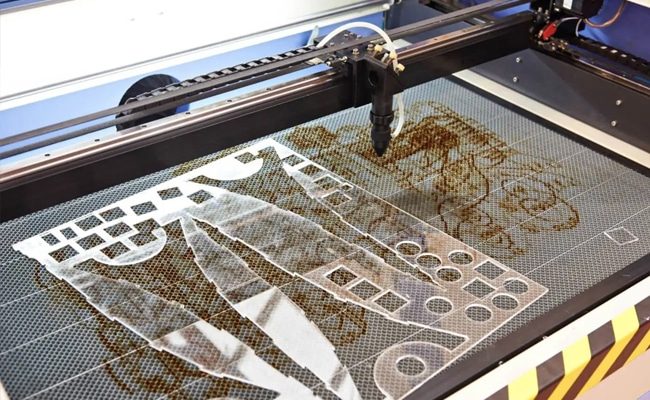

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

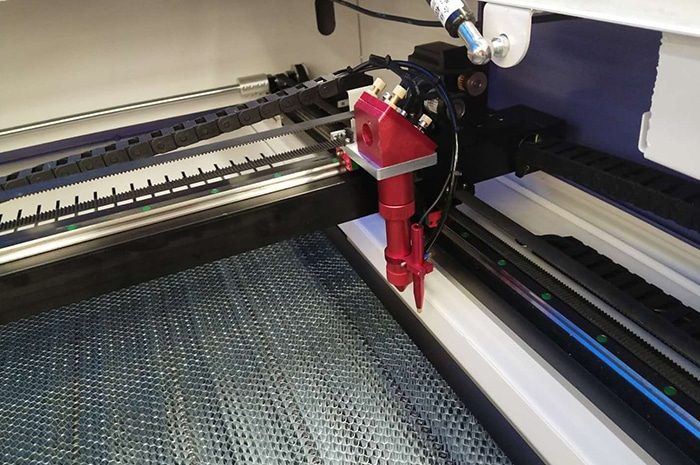

Advanced Motion System

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

High-Quality Optics

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

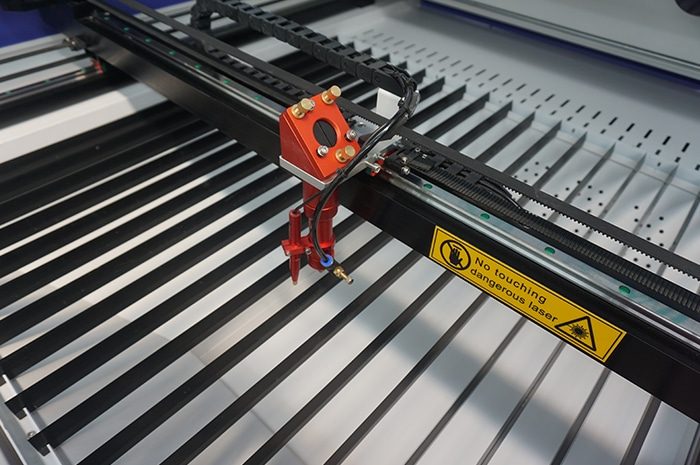

High-Precision CO2 Laser Head

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

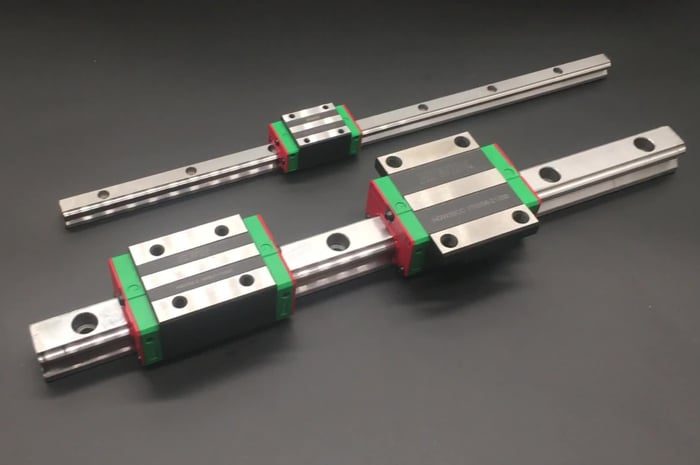

High-Precision HIWIN Rail

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

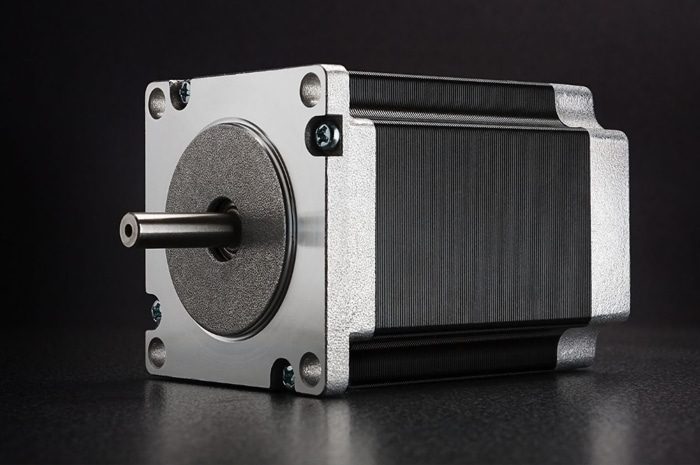

Reliable Stepper Motor

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

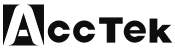

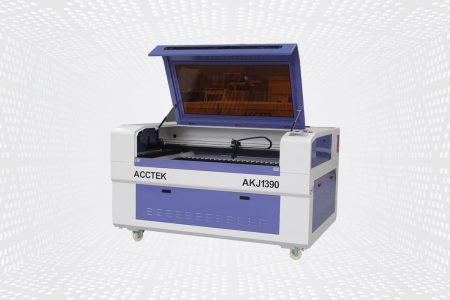

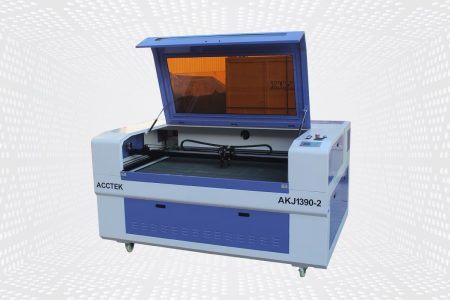

Technical Specifications

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Medium | CO2 laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000 mm/min | ||||||

| Engraving Speed | 0 - 40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water-cooling | ||||||

Laser Welding Capacity

| Laser Power | Cutting Speed | 3mm | 5mm | 8mm | 10mm | 15mm | 20mm |

|---|---|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 5mm/s | 2mm/s | / | / | / | / |

| Optimal Cutting Speed | 3.5mm/s | / | / | / | / | / | |

| 40W | Max Cutting Speed | 10mm/s | 5mm/s | 2mm/s | / | / | / |

| Optimal Cutting Speed | 8mm/s | 3.5mm/s | / | / | / | / | |

| 60W | Max Cutting Speed | 15mm/s | 10mm/s | 5mm/s | 2mm/s | / | / |

| Optimal Cutting Speed | 12mm/s | 8mm/s | 3.5mm/s | / | / | / | |

| 80W | Max Cutting Speed | 20mm/s | 13mm/s | 10mm/s | 5mm/s | / | / |

| Optimal Cutting Speed | 15mm/s | 10mm/s | 8mm/s | 3.5mm/s | / | / | |

| 100W | Max Cutting Speed | 23mm/s | 15mm/s | 13mm/s | 8mm/s | 2.5mm/s | / |

| Optimal Cutting Speed | 18mm/s | 13mm/s | 10mm/s | 5mm/s | / | / | |

| 130W | Max Cutting Speed | 25mm/s | 18mm/s | 13mm/s | 9mm/s | 4mm/s | / |

| Optimal Cutting Speed | 20mm/s | 15mm/s | 10mm/s | 6.5mm/s | 3mm/s | / | |

| 150W | Max Cutting Speed | 30mm/s | 21mm/s | 15mm/s | 12mm/s | 7mm/s | 4mm/s |

| Optimal Cutting Speed | 25mm/s | 18mm/s | 13mm/s | 9mm/s | 5.5mm/s | / | |

| 180W | Max Cutting Speed | 33mm/s | 25mm/s | 18mm/s | 14mm/s | 9mm/s | 5mm/s |

| Optimal Cutting Speed | 28mm/s | 21mm/s | 15mm/s | 11mm/s | 7mm/s | 4mm/s | |

| 200W | Max Cutting Speed | 40mm/s | 30mm/s | 25mm/s | 18mm/s | 12mm/s | 8mm/s |

| Optimal Cutting Speed | 35mm/s | 25mm/s | 20mm/s | 15mm/s | 10mm/s | 7mm/s |

Comparison of Different Cutting Methods

| Features | Router Cutting | CNC Routing | Miter Saw Cutting | Hand Tool Cutting |

|---|---|---|---|---|

| Precise Cuts | Yes | Yes | Yes | No |

| Intricate Designs | Yes | Yes | No | No |

| Minimal Material Waste | Yes | Depends on Routing | No | No |

| Suitable for Angled Cuts | No | No | Yes | No |

| Automation | Yes | Yes | No | No |

| Skill Required | Moderate | Moderate | Moderate | High |

Product Features

- This machine has a high-quality CO2 laser generator, suitable for cutting and engraving MDF. In addition, CO2 laser generators are available in various power ratings, with higher-power laser generators providing faster cutting speeds and the ability to cut thicker MDF.

- The machine has high precision and accuracy and can create complex designs and delicate details on MDF.

- The machine can be equipped with different bed sizes according to needs to adapt to different plate sizes.

- The machine features user-friendly and versatile control software that allows easy import of design files, setting cutting parameters and adjusting settings.

- The machine is compatible with industry-standard design software such as AutoCAD, CorelDRAW, or Adobe Illustrator, making it easy to import designs into the machine.

- The machine is equipped with a red dot pointer that helps users accurately position the laser on the material before cutting or engraving.

- This machine is not only capable of cutting MDF but also other materials such as acrylic, plywood, leather, cardboard, etc.

- The machine is equipped with a cooling system that prevents the laser generator from overheating during prolonged use.

- The machine can control cutting speed and power settings as needed to meet efficient cutting of different MDF thicknesses and designs.

- The machine offers an automatic nesting feature that optimizes the cutting path to minimize waste.

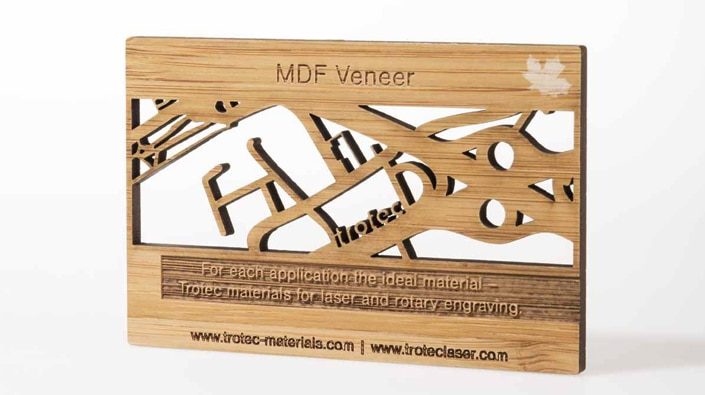

Product Application

Equipment Selection

High Configuration CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With CCD Camera

CO2 Laser Cutting Machine With Electric Lift Table

Fully Enclosed CO2 Laser Cutting Machine

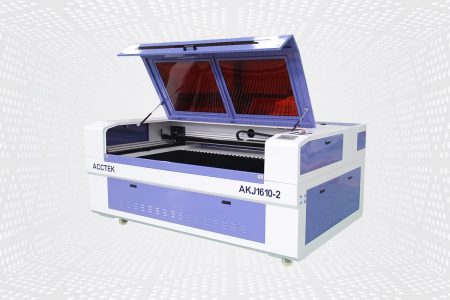

Double Head CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With Automatic Feeding Device

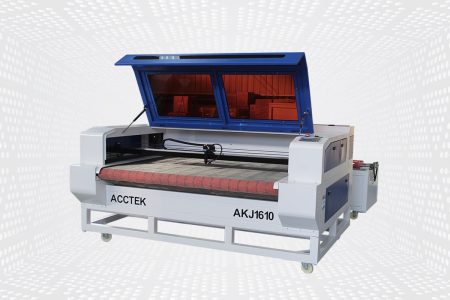

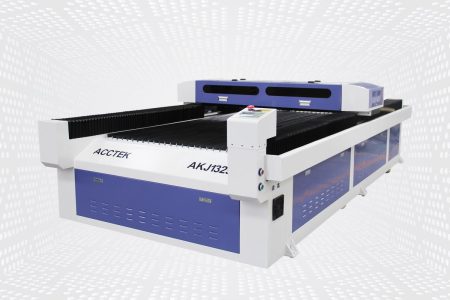

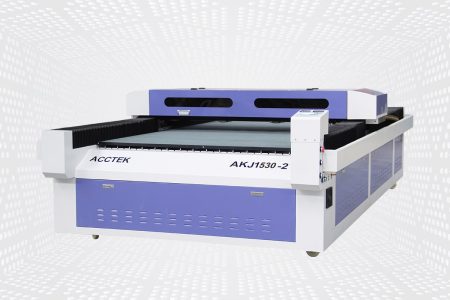

Large-Size CO2 Laser Cutting Machine

Double Head Large Size CO2 Laser Cutting Machine

Why Choose AccTek?

Impeccable Precision

Unrivaled Quality

Customized Solutions

Excellent Customer Support

Frequently Asked Questions

- Low-power CO2 laser cutting machines (under 100 watts): Low-power CO2 laser cutting machines are generally suitable for cutting thinner MDF sheets, usually up to about 6 to 8 mm (about 1/4 inch) thick. While they can cut thicker MDF, the process may be slower and the cut quality may not be optimal.

- Medium-power CO2 laser cutting machines (100 to 150 Watts): Medium-power CO2 laser cutting machines can handle thicker MDF, typically up to about 12 to 15 mm (about 1/2 inch). They provide higher cutting speed and quality compared to lower-power lasers.

- High-power CO2 laser cutting machine (150 watts and above): High-power CO2 laser generators can cut thicker MDF sheets, usually up to 25 mm (about 1 inch) or more. These laser generators offer faster cutting speeds and the ability to cut thicker materials efficiently.

- MDF (medium-density fiberboard):

- Cutting precision: MDF is known for its uniform density and smooth surface, which makes it ideal for laser cutting. Consistent material properties allow for precise, clean cuts.

- Edge quality: Laser-cutting MDF typically produces clean, smooth edges with minimal charring, making it ideal for projects where edge quality is critical.

- Intricate designs: MDF is ideal for intricate and detailed designs as the smooth surface allows for fine engravings and intricate patterns with high precision.

- Minimal warping: Compared to plywood, MDF is relatively stable and less prone to warping, which is important for maintaining cutting accuracy.

- Paintability: MDF readily accepts paints and finishes, allowing for a variety of customization options after cutting.

- Plywood:

- Natural aesthetics: Plywood retains the natural wood grain and appearance, making it a good choice for projects that require a wood or rustic look.

- Strength and durability: Plywood is generally stronger and more durable than MDF, which is beneficial for structural or load-bearing applications.

- Layered structure: The layered structure of plywood can add unique visual texture and depth to laser-cut designs, making them beautiful and elegant.

- Burn marks: Plywood is more likely to develop visible burn marks around the cut edges, which may require additional finishing or sanding.

- Quality varies: The quality of plywood varies widely, and lower-quality plywood may have voids or defects that interfere with the laser-cutting process.

- Laser power: Laser power settings will depend on your laser cutting machine and material thickness. Start with lower power and higher speed settings and gradually adjust them to achieve the desired results.

- Cutting speed: Adjust the cutting speed according to material thickness and laser power. Thinner MDF is suitable for faster speeds, while thicker materials may require slower speeds.

- Material selection: Make sure the MDF you use is suitable for laser cutting, as different compositions and densities can affect cutting results.

- Focus: Proper focus helps achieve clean and precise cuts. The focus of the laser needs to be adjusted to match the thickness of the MDF sheet.

- Masking or taping: Using masking tape or self-adhesive paper on the surface of MDF can help reduce charring and protect the surface of the material.

- Optimized cutting path: Optimize cutting path to minimize cutting time and reduce wear and tear on the machine.

- Test cuts: Before starting a project, make test cuts on a small piece of MDF using various power, speed, and focus settings to determine the best parameters for your specific machine and material. This helps prevent material waste and ensures the required cut quality.

- Emissions of hazardous smoke: When using a laser to cut or engrave MDF, harmful smoke and airborne particles are released into the air. These emissions often contain wood chips, resins, and other by-products of the laser cutting process. Breathing these fumes can be harmful to your health, causing respiratory problems and eye irritation.

- Fire hazard: MDF is a highly flammable material, and the laser-cutting process generates significant amounts of heat. If the laser is not set up correctly or the cutting process is not closely monitored, ignition and fire hazards can result.

- Eye and skin hazards: The laser beam used during laser cutting can be harmful to the eyes and skin. Direct exposure to the laser beam or even reflections from materials can cause eye injuries and skin burns. Operators must wear appropriate laser goggles and protective clothing.

- Burnt material: Laser cutting MDF can cause burnt edges, especially if the laser settings are too high or the material is of poor quality. While this may not pose a safety risk, it can affect the quality of the finished product.

- Chemical exposure: Some MDF products may contain adhesives that release harmful chemicals when exposed to high temperatures, potentially resulting in chemical exposure risks.

- Noise: Operation of a laser cutting machine may produce noise levels that exceed safe limits. Without proper hearing protection, prolonged exposure to loud noise can cause hearing damage.

- Provide appropriate ventilation and exhaust systems.

- Use appropriate personal protective equipment (PPE), including laser goggles.

- Calibrate and maintain your laser cutter according to the manufacturer’s recommendations.

- Make sure your workspace is organized, well-lit, and free of flammable materials.

- Implement fire suppression systems and emergency shutdown procedures.

- Train operators on safe laser-cutting practices.

- Follow material safety data sheet (MSDS) guidelines for MDF materials.

- Regularly inspect and maintain laser cutting equipment.

- Material emissions: Laser-cutting MDF can release potentially harmful emissions, which may contain chemicals such as formaldehyde and other volatile organic compounds (VOCs). Proper ventilation and exhaust systems can help mitigate these health hazards.

- Edge burnt: Laser cutting may leave burn marks or discoloration on the cut edges, which is especially noticeable on light-colored or unpainted MDF surfaces. This may require additional finishing or sanding to remove or hide marks.

- Material thickness limitations: Laser cutting is generally most effective on thinner MDF materials. Cutting thicker MDF can be challenging due to the increased cutting time and the potential for greater heat build-up, which can lead to more severe discoloration and scorching.

- Material warping: The intense heat generated by the laser can cause MDF to warp, especially if the material is not properly secured during the cutting process. This can lead to inaccurate cuts and affect the quality of the final product.

- Design limitations: While laser cutting is highly accurate, it can be challenging to accurately execute complex designs, especially on thick MDF. More time and expertise may be required to achieve complex cuts.

- Equipment cost: Laser-cutting machines can be expensive to purchase and maintain. They require regular repairs and maintenance to ensure they function properly, which increases the overall cost of using the technology.

- Limited material compatibility: Laser cutting is not suitable for all types of MDF. Some MDF boards are manufactured using adhesives or coatings that can produce harmful fumes or damage laser-cutting equipment when cutting. It is recommended to use MDF specifically designed for laser cutting.