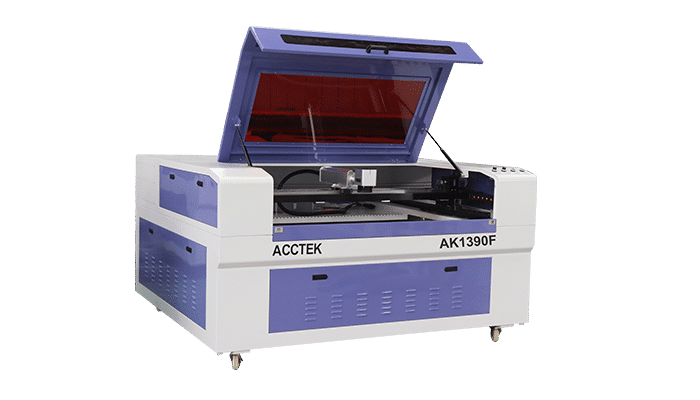

Plywood Laser Cutting Machine

Photoelectric Technology

AccTek Laser focus on designing and manufacturing photoelectric-related system. We provide accurate and exquisite processing quality with leading R&D capability.

Integration Ability & Experienced

With an experienced, completed, and elite R&D team, customized such as automated, integrated with the robot, system integration, etc. are all available.

Professional Service

AccTek Laser's laser cutting machine is a professional laser cutting machine designed and manufactured in China. Our elite engineering team provides related service support.

Equipment Features

High Power CO2 Laser Tube

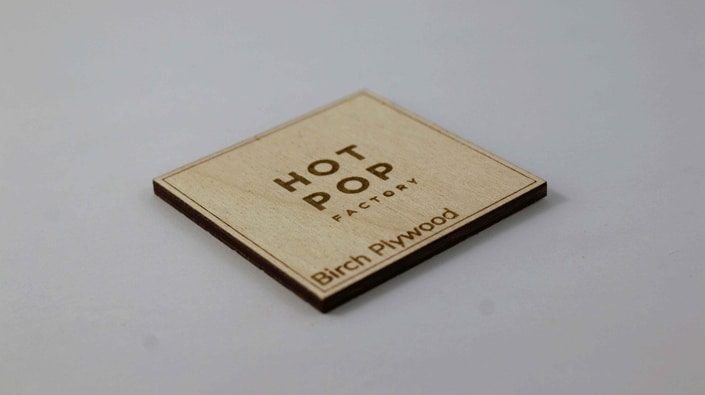

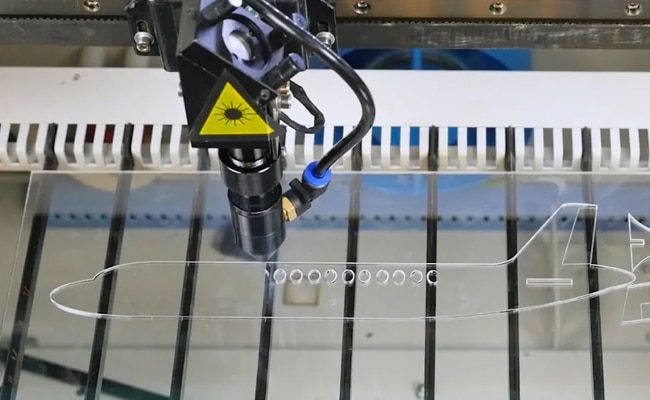

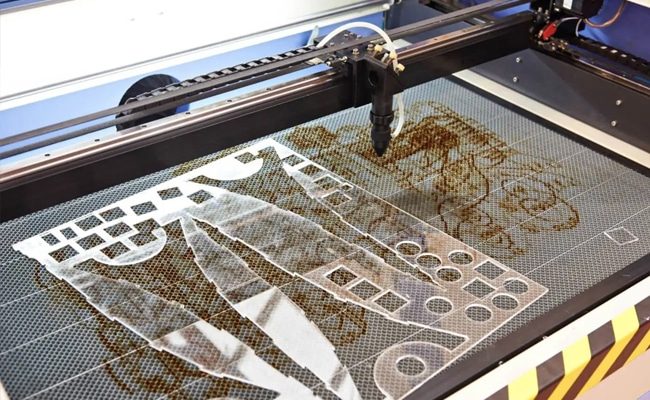

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

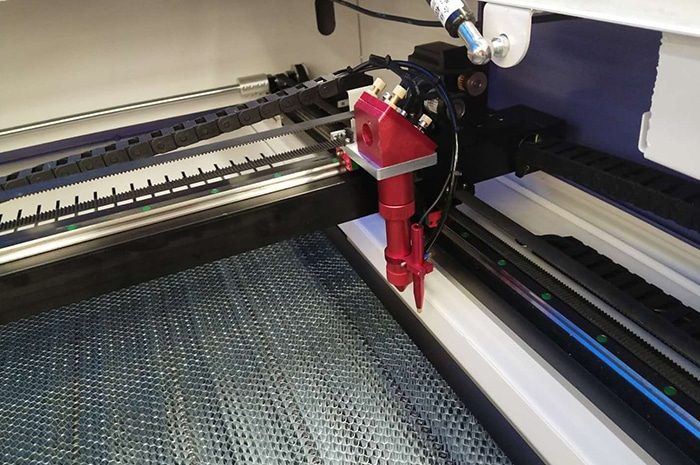

Advanced Motion System

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

High-Quality Optics

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

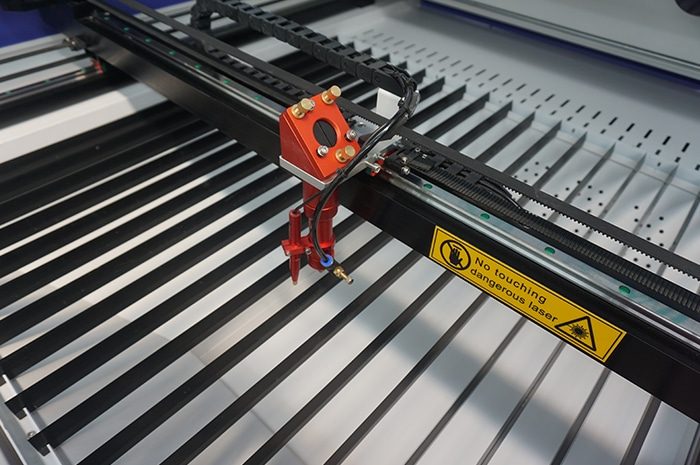

High-Precision CO2 Laser Head

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

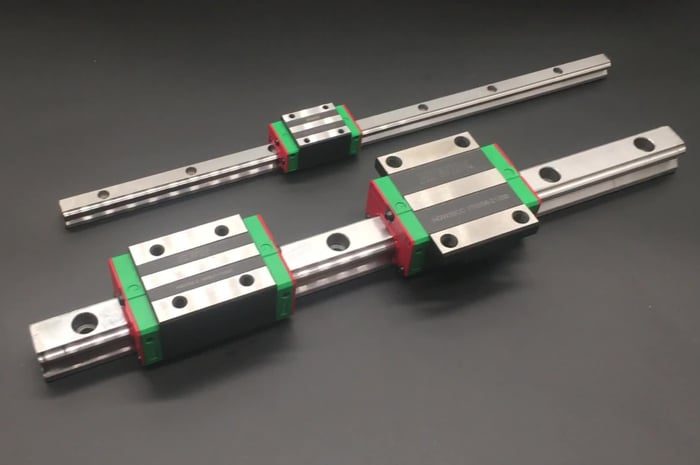

High-Precision HIWIN Rail

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

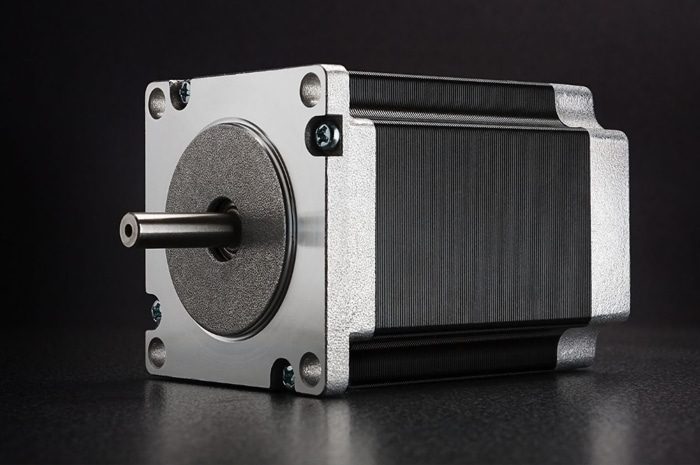

Reliable Stepper Motor

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

Technical Specifications

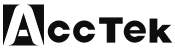

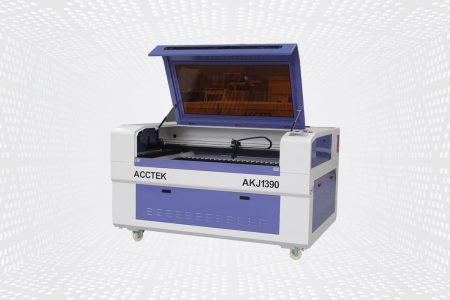

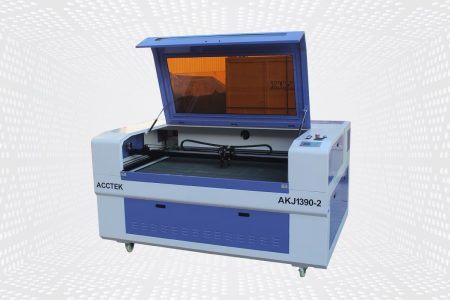

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Medium | CO2 laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000 mm/min | ||||||

| Engraving Speed | 0 - 40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water-cooling | ||||||

Laser Welding Capacity

| Laser Power | Cutting Speed | 3mm | 5mm | 10mm | 15mm |

|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 4mm/s | / | / | / |

| Optimal Cutting Speed | / | / | / | / | |

| 40W | Max Cutting Speed | 10mm/s | 5mm/s | / | / |

| Optimal Cutting Speed | 8mm/s | / | / | / | |

| 60W | Max Cutting Speed | 15mm/s | 10mm/s | 4mm/s | / |

| Optimal Cutting Speed | 12mm/s | 8mm/s | / | / | |

| 80W | Max Cutting Speed | 20mm/s | 15mm/s | 8mm/s | / |

| Optimal Cutting Speed | 18mm/s | 10mm/s | 6mm/s | / | |

| 100W | Max Cutting Speed | 25mm/s | 20mm/s | 12mm/s | 8mm/s |

| Optimal Cutting Speed | 22mm/s | 18mm/s | 10mm/s | 5mm/s | |

| 130W | Max Cutting Speed | 30mm/s | 25mm/s | 15mm/s | 11mm/s |

| Optimal Cutting Speed | 28mm/s | 22mm/s | 13mm/s | 8mm/s | |

| 150W | Max Cutting Speed | 35mm/s | 30mm/s | 20mm/s | 15mm/s |

| Optimal Cutting Speed | 33mm/s | 30mm/s | 20mm/s | 15mm/s | |

| 180W | Max Cutting Speed | 40mm/s | 35mm/s | 25mm/s | 18mm/s |

| Optimal Cutting Speed | 37mm/s | 32mm/s | 20mm/s | 15mm/s | |

| 200W | Max Cutting Speed | 50mm/s | 45mm/s | 35mm/s | 25mm/s |

| Optimal Cutting Speed | 48mm/s | 42mm/s | 30mm/s | 22mm/s |

Comparison of Different Cutting Methods

| Features | Laser Cutting | CNC Routing | Band Saw Cutting | Table Saw Cutting |

|---|---|---|---|---|

| Precision | High | High | Moderate to High | High |

| Versatility | High | High | Moderate | High |

| Cutting Speed | Fast | Moderate | Moderate | Fast |

| Intricate Shapes | Yes | Yes | Limited | No |

| Straight Cuts | Yes | Yes | Limited | Yes |

| Curved Cuts | Yes | Yes | Yes | Limited |

| Material Waste | Low | Low | Moderate | Moderate to High |

| Safety Precautions | Required | Required | Required | Required |

| Equipment Cost | High | Moderate to High | Moderate | Moderate to High |

| Setup and Calibration | Complex | Moderate | Moderate | Moderate |

| Noise Level | Low to Moderate | Moderate | Moderate to High | High |

| Edge Quality | Clean | Clean | Moderate to Good | Good |

| Heat Generation | Minimal | Moderate | Moderate to High | High |

| Accessibility to Beginners | Moderate to Difficult | Moderate | Moderate | Moderate |

Product Features

- The machine is equipped with a high-power CO2 laser generator that delivers the intense and focused laser beam needed to effectively cut plywood.

- The machine offers exceptional precision and accuracy, allowing customers to achieve complex and detailed designs with minimal cutting width and high repeatability.

- This machine can not only cut plywood but also many other materials such as acrylic, MDF, wood veneer, cardboard, etc.

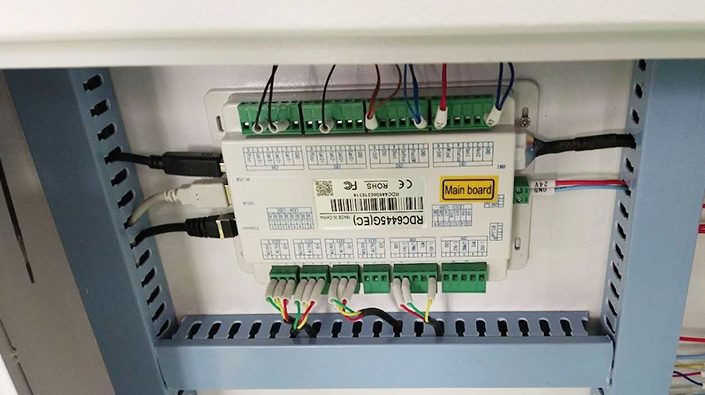

- The machine is equipped with a computer numerical control (CNC) system that allows precise programming and control of the cutting process.

- The machine is equipped with a red dot pointer, which projects visible light guidance onto the material, aiding in precise positioning and alignment of the material and cutting path.

- The machine is equipped with advanced nesting software that optimizes the design layout of materials to minimize waste and maximize material utilization.

- The machine comes with a user-friendly interface and software that makes it easy to control the machine, set parameters, and start the cutting or engraving process.

- The machine comes with a built-in diagnostic system with maintenance alerts and diagnostics to help users keep their equipment in top condition and reduce downtime.

- The machine can be integrated with popular design and CAD software for a seamless design-to-cut workflow.

- The machine offers multiple laser power options to meet different cutting requirements and material thicknesses.

Product Application

Equipment Selection

High Configuration CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With CCD Camera

CO2 Laser Cutting Machine With Electric Lift Table

Fully Enclosed CO2 Laser Cutting Machine

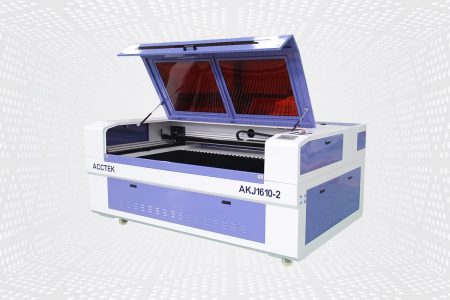

Double Head CO2 Laser Cutting Machine

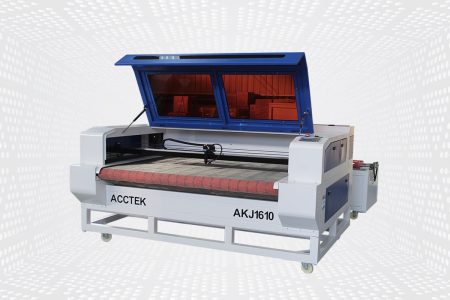

CO2 Laser Cutting Machine With Automatic Feeding Device

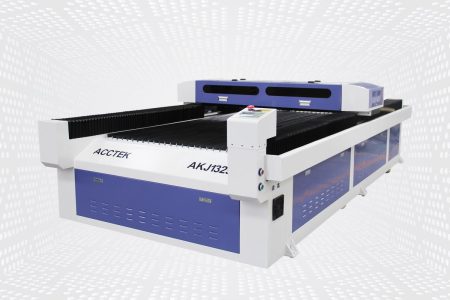

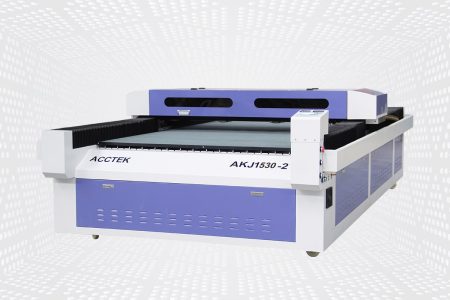

Large-Size CO2 Laser Cutting Machine

Double Head Large Size CO2 Laser Cutting Machine

Why Choose AccTek?

Impeccable Precision

Unrivaled Quality

Customized Solutions

Excellent Customer Support

Frequently Asked Questions

- Entry-level CO2 laser cutting machines: These are compact machines suitable for hobbyists, small businesses, or educational purposes. It usually has lower power (20W to 60W) and a smaller cutting area. Entry-level CO2 laser cutting machines range in price from $1,000 to $3,000 or more.

- Mid-range CO2 laser cutting machines: Mid-range CO2 laser cutting machines offer more versatility, higher power (60W to 200W), and larger cutting areas. It may include features such as autofocus and rotating attachments. Prices for mid-range machines typically start at $5,000 and can go up to $15,000 or more, depending on specifications.

- Industrial CO2 laser cutting machine: Industrial-grade CO2 laser cutting machine is designed for heavy-duty use and large-scale production. It is equipped with a high-power laser generator (above 200W) and a larger cutting area. Industrial CO2 laser cutting machines vary greatly in price, from $10,000 to hundreds of thousands of dollars or more, depending on the size and capabilities of the machine.

- Burnt edges: The heat generated during laser cutting can cause burns or charring of the edges of the cut plywood. These burnt edges may require additional finishing or sanding to achieve a polished appearance.

- Material thickness limitations: Laser cutting has a limit on the maximum thickness of plywood it can effectively cut. Thicker plywood may require more time, multiple passes, or a higher-power laser, increasing production time and cost.

- Material compatibility: The type of adhesive used in plywood may vary, and some adhesives may produce toxic fumes or residue when exposed to laser energy. Make sure the plywood is compatible with laser cutting to avoid health and safety issues.

- Material waste: Laser cutting produces waste in the form of cuts and offcuts. Effective nesting and layout planning help minimize material waste.

- Complex setup: Setting up a laser cutting machine to make precise cuts can be time-consuming and may require specialized knowledge. Achieving the desired cutting results often requires fine-tuning setup and calibration.

- Maintenance and alignment: Laser cutting machines require regular maintenance to keep them running optimally. The alignment of the laser beam, mirrors, and lenses needs to be checked and adjusted regularly to ensure accuracy.

- Smoke and odor: Laser-cutting plywood releases smoke and odor. If ventilation is not done properly, it can be unpleasant and potentially harmful, so an adequate ventilation or exhaust system is required to remove these fumes from the workspace.

- Equipment cost: Laser cutting machines can be expensive to purchase and maintain, which can be a hindrance for a small business or hobbyist.

- Material ignition: Plywood is a flammable material and there is a risk of ignition if the laser settings are not properly controlled. Safety measures such as fire protection systems and proper ventilation can help minimize this risk.

- Hardwood plywood: This type of plywood is made from hardwood veneers, such as oak, birch, or maple, and is often used to create fine furniture and cabinets. Lasers can cut on hardwood plywood, but the density of hardwood may require higher laser power and slower cutting speeds.

- Softwood plywood: Made from softwood veneers such as pine, fir, or cedar, softwood plywood is commonly used in building and structural applications. It can be laser cut, but the cutting results may vary depending on the specific softwood used.

- Marine plywood: Designed for use in wet or marine environments, marine plywood is typically made from a waterproof adhesive and high-quality wood board. While laser cutting is possible, the adhesive used in marine plywood may produce more toxic fumes when exposed to laser light.

- MDF core plywood: Plywood with a medium-density fiberboard (MDF) core is suitable for laser cutting. MDF provides a smooth, flat surface and the veneer layers can be laser cut cleanly. This type of plywood is commonly used in cabinet and furniture manufacturing.

- Plywood with a veneer finish: Plywood with a decorative veneer finish, such as walnut or cherry veneer, can be laser cut to create intricate designs and patterns while retaining the appearance of the veneer.

- Protective equipment: The laser beams used in laser cutting are very intense and can cause damage to human eyes and skin, so the operator and anyone near the laser cutting machine should wear appropriate protective equipment. This typically includes laser safety glasses and protective clothing specifically designed to block the laser wavelengths used, thereby reducing the risk of damage to the human body.

- Ventilation: Laser cutting produces smoke and potentially harmful particles, especially when cutting adhesive or certain types of plywood. Adequate ventilation or smoke extraction systems should be in place to remove these by-products from the work area, which helps maintain air quality and reduces the risk of inhaling harmful substances.

- Fire safety: Laser cutting generates intense heat and presents a risk of fire, especially when cutting combustible materials such as wood. The work area should be equipped with fire prevention and fire extinguishing systems, and flammable items should be kept away from the laser cutting machine.

- Training: Operators should receive appropriate training on the safe use of laser-cutting equipment. This includes knowing how to set up the machine, calibrate the machine, and troubleshoot problems. Inexperienced or untrained operators can pose significant safety risks.

- Material compatibility: Make sure the type of plywood used is compatible with laser cutting. Certain types of adhesives and plywood can emit harmful fumes or produce undesirable results when laser cut. It is recommended to consult the plywood manufacturer for information on the laser compatibility of the material.

- Eye and skin protection: Laser beams can be harmful to eyes and skin. Operators should avoid looking directly into the laser beam and should always wear laser-protective glasses. Additionally, skin contact with the laser beam or any reflective surface needs to be avoided.

- Machine maintenance: Regular maintenance and inspection of your laser cutting machine is essential for safety. This includes inspecting for damaged or misaligned parts, keeping laser optics clean, and ensuring all safety interlocks are functioning properly.