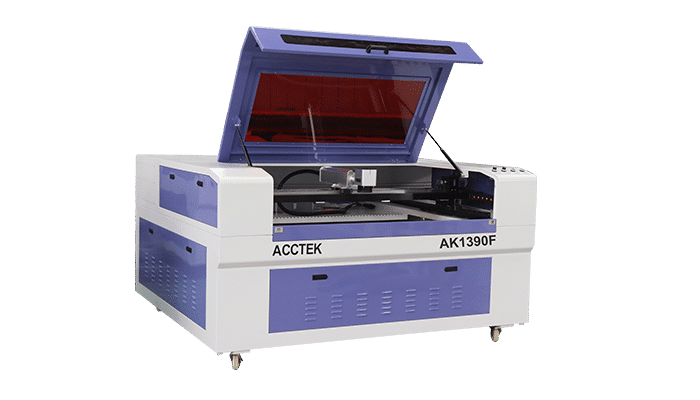

Veneer Laser Cutting Machine

Photoelectric Technology

AccTek Laser focus on designing and manufacturing photoelectric-related system. We provide accurate and exquisite processing quality with leading R&D capability.

Integration Ability & Experienced

With an experienced, completed, and elite R&D team, customized such as automated, integrated with the robot, system integration, etc. are all available.

Professional Service

AccTek Laser's laser cutting machine is a professional laser cutting machine designed and manufactured in China. Our elite engineering team provides related service support.

Equipment Features

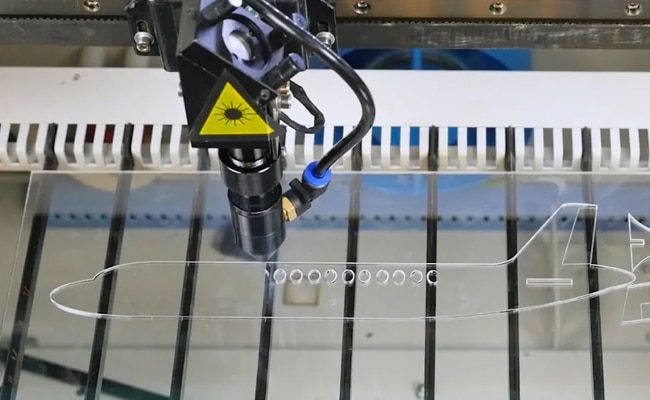

High Power CO2 Laser Tube

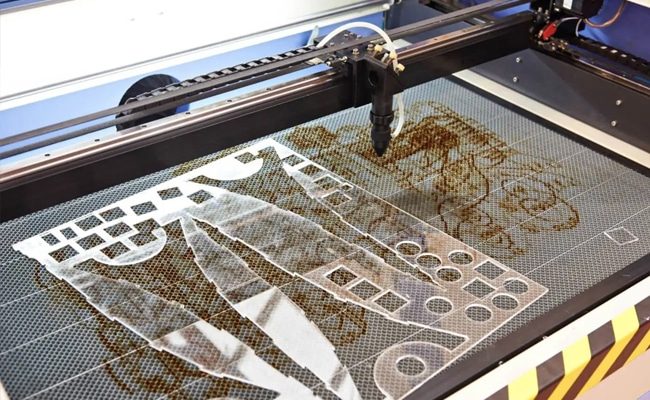

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

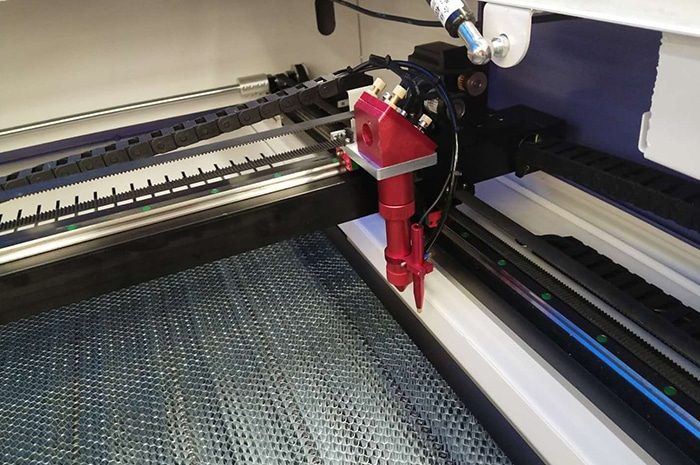

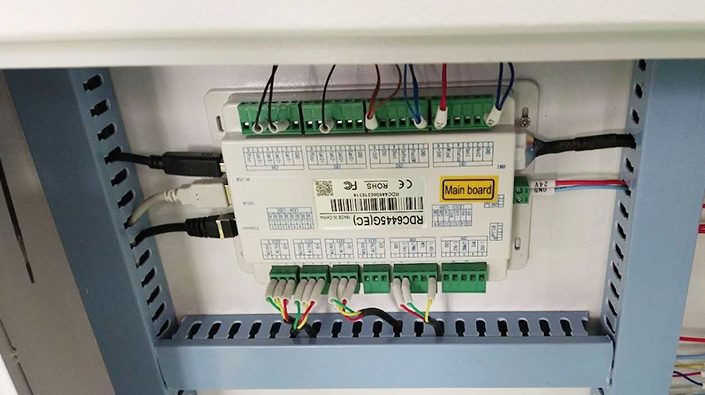

Advanced Motion System

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

High-Quality Optics

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

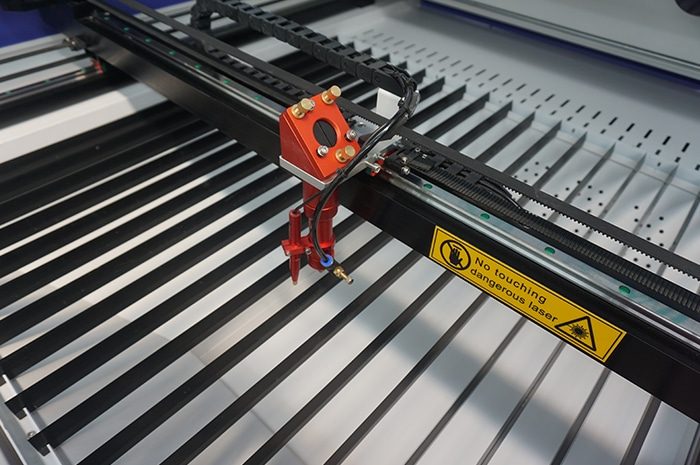

High-Precision CO2 Laser Head

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

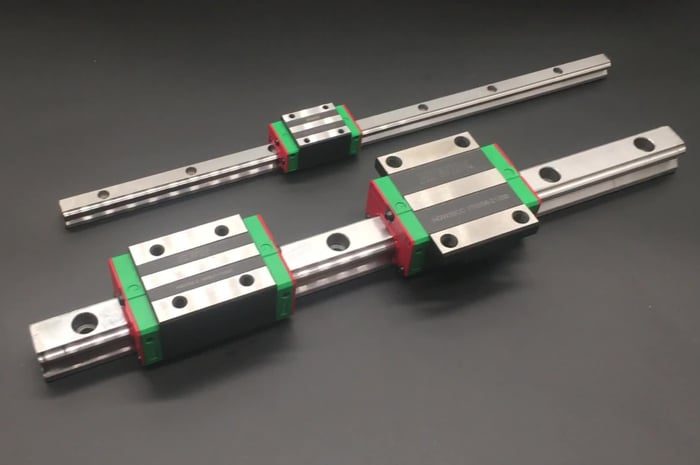

High-Precision HIWIN Rail

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

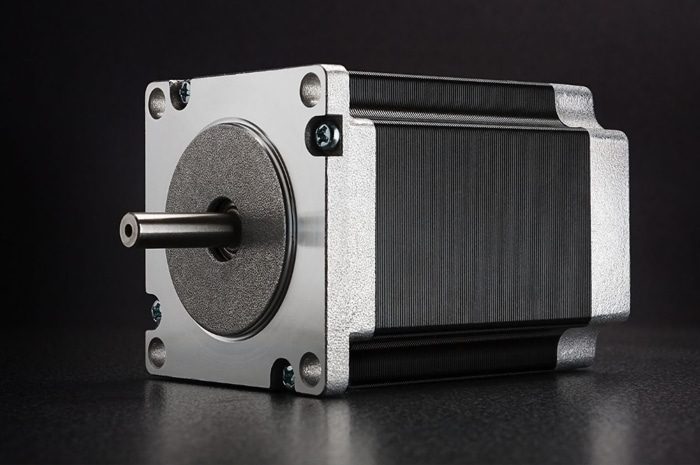

Reliable Stepper Motor

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

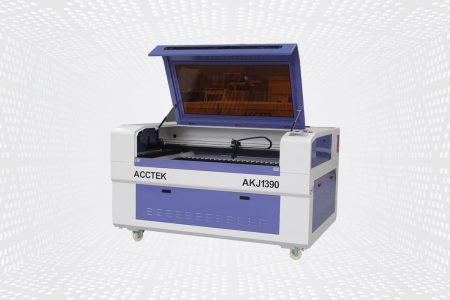

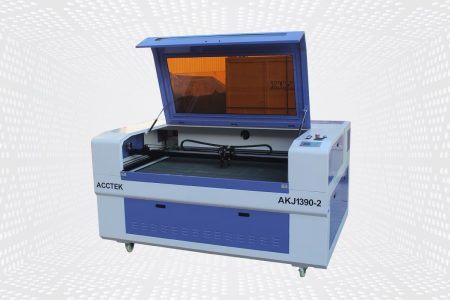

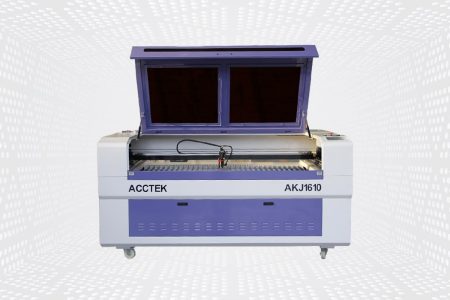

Technical Specifications

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Medium | CO2 laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000 mm/min | ||||||

| Engraving Speed | 0 - 40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water-cooling | ||||||

Laser Welding Capacity

| Laser Power | Cutting Speed | 0.5mm | 1mm | 2mm | 3mm | 5mm | 6mm |

|---|---|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 5mm/s | 3mm/s | 2mm/s | 1.5mm/s | 0.8mm/s | 0.7mm/s |

| Optimal Cutting Speed | 3mm/s | 2mm/s | 1.5mm/s | 1mm/s | 0.5mm/s | 0.4mm/s | |

| 40W | Max Cutting Speed | 8mm/s | 5mm/s | 3mm/s | 2mm/s | 1mm/s | 0.9mm/s |

| Optimal Cutting Speed | 5mm/s | 3mm/s | 2mm/s | 1.5mm/s | 0.8mm/s | 0.6mm/s | |

| 60W | Max Cutting Speed | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 1.8mm/s | 1.5mm/s |

| Optimal Cutting Speed | 8mm/s | 5mm/s | 3mm/s | 2mm/s | 1.5mm/s | 1mm/s | |

| 80W | Max Cutting Speed | 16mm/s | 10mm/s | 6mm/s | 4mm/s | 2.5mm/s | 2mm/s |

| Optimal Cutting Speed | 10mm/s | 6mm/s | 4mm/s | 2.5mm/s | 1.5mm/s | 1.2mm/s | |

| 100W | Max Cutting Speed | 20mm/s | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 2.5mm/s |

| Optimal Cutting Speed | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 2mm/s | 1.8mm/s | |

| 130W | Max Cutting Speed | 26mm/s | 16mm/s | 10mm/s | 6mm/s | 4mm/s | 3mm/s |

| Optimal Cutting Speed | 16mm/s | 10mm/s | 6mm/s | 4mm/s | 2.5mm/s | 2mm/s | |

| 150W | Max Cutting Speed | 30mm/s | 18mm/s | 12mm/s | 8mm/s | 5mm/s | 4mm/s |

| Optimal Cutting Speed | 18mm/s | 12mm/s | 8mm/s | 5mm/s | 3mm/s | 2.8mm/s | |

| 180W | Max Cutting Speed | 36mm/s | 22mm/s | 14mm/s | 10mm/s | 6mm/s | 5mm/s |

| Optimal Cutting Speed | 22mm/s | 14mm/s | 10mm/s | 6mm/s | 4mm/s | 3mm/s | |

| 200W | Max Cutting Speed | 40mm/s | 24mm/s | 16mm/s | 12mm/s | 7.5mm/s | 6mm/s |

| Optimal Cutting Speed | 24mm/s | 16mm/s | 12mm/s | 8mm/s | 5mm/s | 4mm/s |

Comparison of Different Cutting Methods

| Features | Laser Cutting | Router Cutting | Knife Cutting | Rotary Cutting |

|---|---|---|---|---|

| Precision | High precision | High precision | Moderate precision | Moderate precision |

| Cutting Speed | Fast | Variable, can be fast | Moderate | Fast |

| Material Versatility | Versatile, various materials | Versatile, various materials | Limited to veneer | Limited to veneer |

| Material Waste | Minimal | Minimal | Moderate | Moderate |

| Clean Edges | Clean, minimal | Clean | Clean | Variable |

| Intricate Cuts | Yes, intricate | Yes, intricate | Limited intricacy | Limited intricacy |

| Waste Generation | Minimal material waste | Minimal material waste | Moderate material waste | Moderate material waste |

| Charring/Burn Marks | Minimal to moderate | Minimal to none | Minimal to moderate | None |

| Heat Generation | Moderate | Variable | Minimal to moderate | Moderate |

| Maintenance | Moderate | Moderate | Low to moderate | Moderate |

| Material Thickness | Various thicknesses | Various thicknesses | Limited | Various thicknesses |

| Setup Time | Quick setup | Setup may take time | Quick setup | Setup may take time |

| Production Volume | Suitable for small to large volumes | Suitable for small to large volumes | Suitable for small volumes | Suitable for large volumes |

| Versatility | Versatile, various materials | Versatile, suitable for intricate designs | Limited to simpler shapes | Versatile, suitable for various veneer types |

Product Features

- The machine is equipped with high-quality CO2 laser generators, offering different levels of power and precision. The choice of laser generator affects the cutting capabilities of the machine.

- The machine can precisely control the laser beam, allowing the machine to have high precision and accuracy, with tolerances typically less than 0.1mm, enabling complex designs and fine details.

- The machine offers high cutting speeds and can deliver output when there are high-volume production requirements.

- The machine is equipped with an autofocus system that automatically adjusts the laser’s focus to accommodate different material thicknesses and maintain consistent cutting quality.

- This machine can cut not only a veneer, but also a variety of other materials, including acrylic, plastic, MDF, and more.

- The machine is controlled by computer software that is compatible with industry-standard design software such as AutoCAD or CorelDRAW and features user-friendly software for creating and importing designs.

- The machine is equipped with a computer numerical control (CNC) system that allows users to program and control the cutting process, including setting cutting parameters, specifying shapes, and managing production runs.

- The machine is equipped with an efficient cooling system that helps maintain the optimal temperature of the laser generator, ensuring consistent performance and extending the life of the laser components.

- The machine can customize the effective cutting area according to specific requirements, and we can also equip you with grids or slats to support the material and allow efficient laser cutting.

- The machine is equipped with a red dot pointer to help users preview the cutting path before starting the actual cutting process, ensuring proper alignment and positioning.

Product Application

Equipment Selection

High Configuration CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With CCD Camera

CO2 Laser Cutting Machine With Electric Lift Table

Fully Enclosed CO2 Laser Cutting Machine

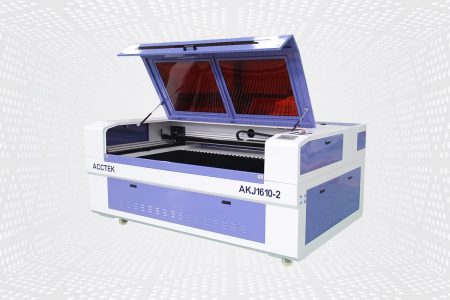

Double Head CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With Automatic Feeding Device

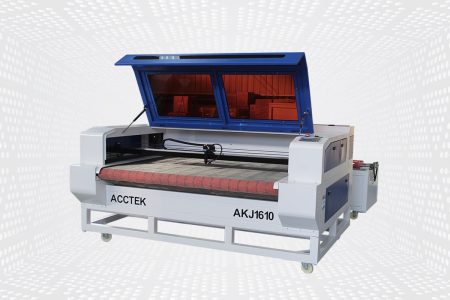

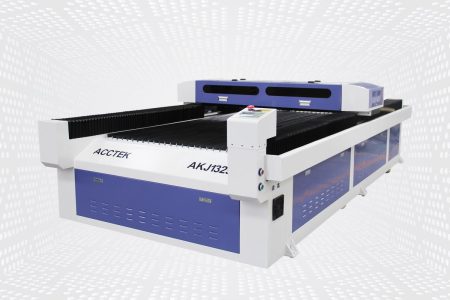

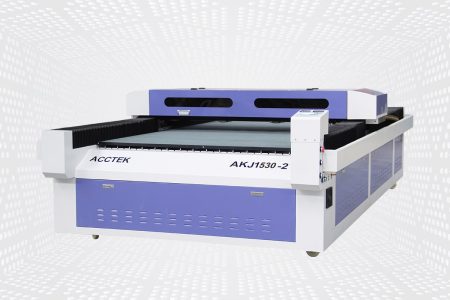

Large-Size CO2 Laser Cutting Machine

Double Head Large Size CO2 Laser Cutting Machine

Why Choose AccTek?

Impeccable Precision

Unrivaled Quality

Customized Solutions

Excellent Customer Support

Frequently Asked Questions

- Wavelength compatibility: The wavelength of the CO2 laser can be highly absorbed by wood, making it effective in cleaning and cutting wood veneers efficiently. This absorbency allows for precise cuts with minimal carbonization or burning.

- Versatility: CO2 laser generators are versatile and can handle various types of veneers, including different wood species and wood composites. It is also capable of cutting other materials, making it suitable for a wide range of applications.

- Edge quality: CO2 laser generators typically produce high-quality edges with minimal charring or burning, resulting in a clean and polished surface required for many veneer applications.

- Power range: CO2 laser generators are available in various power levels, and you can choose the appropriate wattage based on the thickness of the veneer and the required cutting speed. Lower-wattage CO2 laser generators are suitable for thinner veneers, while higher-wattage laser generators can handle thicker veneers and provide faster cutting speeds.

- Control and precision: CO2 laser generators precisely control the cutting process, allowing for complex and detailed cuts. This precision is critical when working with thin veneers to create custom designs and patterns.

- Maintenance: While the CO2 laser generator may require some maintenance due to its optical components and gas circulation system, it is mature and widely used in the industry, so support and maintenance are readily available.

- Scorching: Laser cutting generates heat that may cause veneer edges to scorch or burn, especially when working with certain types of wood. This may require additional sanding or finishing to achieve the desired look.

- Equipment cost: Laser cutting machines, especially high-quality laser cutting machines, can be expensive to purchase and maintain. The initial investment includes the cost of the machine itself, ventilation and exhaust systems, and safety measures. Maintenance costs, including the replacement of laser tubes and optics, also increase over time.

- Material limitations: Laser cutting is most effective with materials that effectively absorb laser wavelengths. While wood veneer is generally a good fit, certain exotic or highly reflective wood species may not cut as cleanly.

- Limited thickness: Laser cutting is most effective on thin to medium-thickness veneers. If you need to cut very thick veneer, you may need specialized equipment or alternative cutting methods.

- Maintenance: laser cutting machines require regular maintenance and cleaning to ensure optimal performance. This includes cleaning lenses and mirrors, checking gas levels, and calibrating the machine.

- Complexity: Laser-cutting machines can have complex setups and require a certain level of expertise to operate effectively, which may require a learning curve and familiarity with the machine’s software and settings.

- Material waste: While laser cutting minimizes material waste compared to traditional methods, some waste may still occur, especially when cutting complex shapes or designs.

- Fire hazard: Laser cutting produces sparks and heat, which can create a fire hazard if not managed properly. Adequate safety measures and fire prevention precautions are crucial.

- Safety precautions: Operating a laser cutting machine requires strict safety precautions. Laser beams can be harmful to the eyes, and the cutting process can produce smoke and particulate matter, posing health risks. Proper safety measures, including eye protection, ventilation, and smoke extraction, help keep operators safe.

- Ventilation and fume extraction: When laser cutting veneer, proper ventilation, and fume extraction can help remove potentially harmful smoke and particulate matter generated during the process. Establishing and maintaining an effective ventilation system is critical.

- Design limitations: While laser cutting offers high precision, there are still limitations in design complexity, especially when cutting very complex or fine details.

- Noise: Laser cutting machines produce noise and may require soundproofing or noise reduction measures in the workplace.

- Energy consumption: Laser cutting machines require electricity to operate. In terms of energy consumption, the environmental impact of laser cutting depends on the source of electricity. If the electricity is generated from renewable energy sources such as wind or solar, the environmental footprint is reduced. Using energy-efficient equipment also helps minimize energy consumption.

- Emissions: Laser cutting produces emissions in the form of smoke and gases, especially when cutting materials such as wood veneer. These emissions may contain particulate matter and volatile organic compounds (VOCs), which may have environmental and health effects. Proper ventilation and smoke extraction systems help remove and filter these emissions.

- Material waste: While laser cutting minimizes material waste compared to other cutting methods, there is still some waste of scraps and unused materials. However, waste management and disposal of offcuts and waste materials should be handled responsibly to minimize environmental impact.

- Resource use: The production and maintenance of laser cutting machines involves the consumption of resources and may have an impact on the environment. This includes the manufacturing and disposal of laser components. Proper maintenance and responsible disposal practices can mitigate these effects.

- Chemical treatment: Some veneers are chemically treated or bonded with adhesives that may contain volatile organic compounds (VOCs). Environmental impact can be reduced by choosing veneers with low-VOC adhesives.

- Material sourcing: The source of the veneer material itself can also impact environmental impact. Using veneers from sustainably managed forests or certified sources helps reduce the overall environmental footprint of the final product.

- Fire hazard: Laser cutting generates heat, which can present a fire risk if not properly controlled, especially when cutting flammable materials such as veneer. Appropriate fire protection measures should be taken to mitigate this risk.

- Recycling and waste disposal: The disposal of scrap materials (such as offcuts or used laser components) should be managed responsibly. Recycling or repurposing veneer offcuts and scraps can minimize your environmental impact.

- Use energy-saving laser-cutting equipment.

- Consider using veneers that come from sustainably managed forests or are certified by organizations like the Forest Stewardship Council (FSC).

- Implement effective smoke extraction and filtration systems to minimize emissions.

- Properly manage waste through recycling or responsible disposal.

- Use renewable energy wherever possible.

- Choose a veneer adhesive with low VOC content.

- Ensure your laser cutting machine is properly maintained and calibrated to maximize its efficiency.

- Eye protection: The laser beam used in laser cutting can be harmful to the eyes. The operator and anyone near the laser cutting area should always wear laser safety glasses or goggles to prevent accidental exposure.

- Ventilation and smoke evacuation: Laser cutting produces smoke and particles, some of which emissions may be harmful if inhaled. Adequate ventilation and smoke extraction systems must be in place to eliminate potentially harmful emissions from the work area. Proper filtration helps ensure the removal of particles and gases.

- Fire safety: Wooden veneer is flammable and laser cutting generates heat. If the cutting process is not controlled properly, there is a risk of fire. Have a fire extinguisher or fire suppression system nearby and ensure operators are trained in fire safety procedures.

- Machine maintenance: Regular maintenance of your laser cutting equipment helps ensure that it operates safely and efficiently. Maintenance should be performed by trained technicians in accordance with manufacturer guidelines, as properly maintained equipment is less likely to malfunction or create a safety hazard.

- Material compatibility: Certain materials used in veneers, such as adhesives or coatings, may emit harmful fumes when exposed to laser light. Make sure the material you are cutting is compatible with laser cutting and does not pose a health risk.

- Training: Operators should receive comprehensive training on the safe operation of laser cutting machines. They should know how to set up the machine, adjust settings, and respond to emergencies.

- Personal protective equipment (PPE): In addition to laser safety glasses, operators should wear appropriate personal protective equipment, including gloves and clothing, to protect against laser radiation, sparks, and potential fires.

- Emergency procedures: Clear emergency procedures should be established and all personnel should be familiar with these procedures. This includes knowing how to shut down the machine in an emergency, such as a fire or breakdown.

- Material handling: Proper material handling procedures should be in place to prevent injuries, this includes safely loading and unloading veneers and securing them during cutting.

- Safety standards: Make sure the laser cutting machine and its operation comply with relevant safety standards and regulations in your region.