Laser labeling: General choice for small and large projects

In modern manufacturing, laser marking technology has received widespread attention due to its efficient and precise marking method. However, there may be some differences in the application of laser marking for projects of different sizes and needs. Can laser marking be used on both small and large projects? Let’s explore it together.

There are different characteristics in the operation process of small projects and large projects, so the requirements for laser marking technology are also different. This article will explore common options for laser marking in small and large projects, including the fundamentals of laser marking technology, laser marking applications for laser marking in small and large projects, and the factors that influence common options for laser marking in various projects. , analyze its applicability, advantages, and application considerations in different projects.

Basic principles of laser marking technology

Laser marking technology is a marking method that uses a laser beam to etch, melt, or color the surface of a workpiece. Its basic principle can be briefly described as follows:

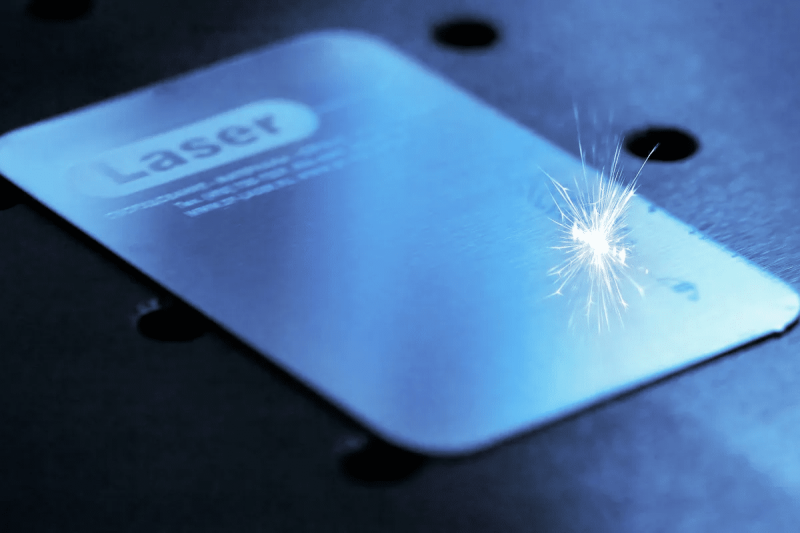

- Laser emission: The laser marking system uses a laser generator to generate a high-energy, high-monochromatic laser beam.

- Beam focusing: Focusing the laser beam into a small diameter spot through a lens system or mirror so that it can act precisely on the workpiece surface.

- Energy effect: The focused laser beam instantly acts on the surface of the workpiece, and its energy will cause local heating, evaporation, or melting of the material.

- Material interaction: Under the action of the laser beam, materials can undergo various reactions, including surface oxidation, vaporization, melting, etc., to form marks or scratches.

- Marking control: By controlling parameters such as the position, power, and action time of the laser beam, precise control of the marking pattern, depth, and quality is achieved.

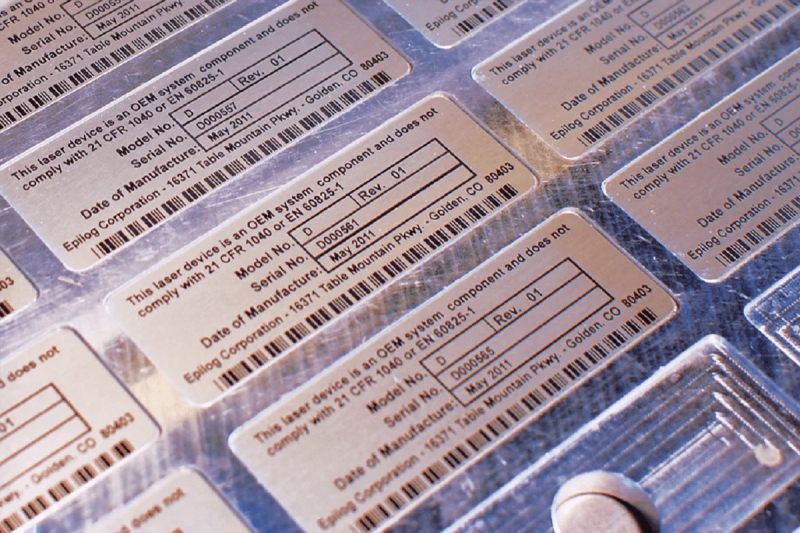

- Mark formation: After the action of the laser beam, corresponding marks are formed on the surface of the workpiece, which can be text, patterns, barcodes, etc.

In general, laser marking technology achieves the process of finely marking the surface of the workpiece by controlling the energy and mode of action of the laser beam. Its high precision and non-contact characteristics make it widely used in industrial production.

Laser marking applications in small projects

In small projects, laser marking technology has a wide range of application prospects. Its flexibility, precision, and efficiency make it an ideal choice for many small projects. Here are some examples of laser marking applications on small projects:

- Handicraft production: Small handicraft manufacturers often use laser marking technology to add branding, manufacturer information, or decorative patterns to their products. For example, in jewelry making, laser marking can engrave brand names or textures on metal surfaces to add uniqueness and beauty to the product.

- Personalized gift customization: Small gift customization shops can use laser marking technology to customize personalized gifts for customers, such as wooden or metal products engraved with names, dates, or specific patterns. This customized service not only meets the individual needs of customers but also brings additional revenue to small businesses.

- Electronic product marking: Small electronics manufacturers can use laser marking technology to mark model numbers, serial numbers, or company logos on the surface of their products. Compared to traditional stickers or jet-printed markings, laser marking is more durable and does not affect the appearance of the product.

- Model making: In small model making, laser marking can be used to carve model details and mark parts. For example, in the production of model aircraft, laser marking can accurately mark the airline logo on the wing or the registration number of the aircraft.

- Art creation: Some artists and creative workers use laser marking technology to engrave patterns, text, or complex textures on artwork. This innovative application not only adds a unique visual effect to works of art but also demonstrates the potential of laser marking technology in the field of art.

In short, laser marking technology has a variety of creative and practical applications in small projects. These applications can give full play to its unique advantages and bring more development opportunities to small businesses.

Laser marking applications in large projects

In large-scale projects, laser marking technology also has a wide range of applications. Its high efficiency, high precision, and reliability make it an indispensable tool in many large-scale projects. The following are examples of laser marking applications in large projects:

- Automobile manufacturing industry: In the automobile manufacturing process, laser marking technology is widely used to mark parts, bodies, or vehicle logos. For example, laser marking can be used to engrave engine numbers, vehicle identification numbers (VIN), production dates, and other key information to achieve vehicle traceability, anti-counterfeiting, and management.

- Aerospace: The manufacturing and assembly of large aircraft and spacecraft requires high-precision marking and marking. Laser marking technology can be used to mark part numbers, serial numbers, production batches, and other key information on aerospace parts to ensure traceability and quality control of parts.

- Engineering construction projects: In large-scale construction projects and infrastructure projects, laser marking technology can be used to mark the location, size, and other important information on the surface of construction materials to help construction personnel accurately install and position materials.

- Electronics manufacturing: Large electronics manufacturers can use laser marking technology to mark model numbers, dates, and batch information on electronic components. Such marking not only improves product traceability but also provides necessary information during assembly and repair processes.

- Metal processing industry: Large metal processing plants usually use laser marking technology to mark patterns, text, or trademarks on metal surfaces. This marking method has high precision and durability and is suitable for marking and anti-counterfeiting of metal parts.

To sum up, laser marking technology has many important applications in large-scale projects, and these advantages of laser marking technology can also help companies improve production efficiency, product quality, and management levels. Therefore, laser marking technology has become one of the indispensable key technologies in many large-scale projects.

Common selection factors for laser marking in small and large projects

Laser marking technology has a wide range of applications in both small and large projects, but there are a range of factors to consider when choosing whether to use this technology. The following are common selection factors for laser marking in both small and large projects:

Performance requirements

- Accuracy requirements: Different projects have different requirements for marking accuracy. Some projects may require very high precision, such as the marking of micro-electronic components, while other projects may have relatively low accuracy requirements, such as the marking of general industrial products.

- Speed requirement: Production efficiency is one of the important factors in selecting laser marking technology for the project. Some projects require high-speed production, while other projects are more focused on mark quality and finesse and therefore require slower mark speeds.

Material adaptability

- Material type: Different types of materials are used in different projects, and the laser marking system needs to be able to adapt to these different materials, including metal, plastic, glass, ceramics, etc. Therefore, when choosing a laser marking system, you need to ensure that it can effectively mark the required materials.

- Surface treatment requirements: Some special materials may require special surface treatment before laser marking to ensure the quality and accuracy of the mark. When selecting a laser marking system, you need to consider the surface treatment requirements of the material and the system’s ability to adapt to this.

Cost considerations

- Equipment costs: Small projects may be limited by equipment costs, so consider whether the price of laser marking equipment fits your budget.

- Operating costs: including energy consumption, maintenance costs, consumable costs, etc. For large projects, long-term operating costs can become an important consideration.

Technical support and service

- After-sales service: The after-sales service provided by the supplier is very important for the continued operation of the project. Including services such as equipment maintenance, technical support, and training.

- Technology updates: Laser marking technology is constantly developing, and whether it is convenient to choose a supplier to provide technology updates and upgrade services also needs to be considered.

Project cycle and production scale

- Project cycle: Some projects may need to come online quickly, requiring rapid deployment and integration of laser marking technology. While other projects may have a longer timeline, allowing for a more in-depth evaluation of technology and vendors.

- Production scale: The size of the production scale will directly affect the configuration and investment of the laser marking system. Large-scale projects need to consider the production capacity and stability of the laser marking system to meet the needs of mass production.

In conclusion, whether it is a small or large project, there are several factors to consider when choosing to use laser marking technology. A comprehensive analysis of the project’s needs, budget, and technical capabilities, and the selection of suitable laser marking equipment and suppliers will contribute to the smooth progress and successful implementation of the project.

Summarize

When exploring the universal options for laser marking in both small and large projects, we found that laser marking technology has a wide range of applicability, and can play its unique advantages whether it is for small-scale handicraft production or large-scale automobile manufacturing projects. Therefore, laser compliance technology has a wide range of application prospects. Whether it is a small or large project, you can find a solution that suits your needs.

With the continuous development of laser technology and the continuous expansion of application scenarios, we believe that laser marking technology will play an increasingly important role in industrial production, bringing more possibilities and opportunities to all walks of life. For those seeking the pinnacle of laser marking technology, AccTek Laser is ready to help. Whether it’s learning about the depths our machines can reach or purchasing a machine for your business, our team is dedicated to guiding you every step of the way. Contact us today to explore the huge potential of laser marking and experience the difference AccTek Laser can bring.

Contact information

- Email:[email protected]

- Skype:[email protected]

- Wechat: +86-19963414011

Address to send the proofing materials

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Related Blog