1500W Laser Welding Machine

Photoelectric Technology

AccTek Laser focus on designing and manufacturing photoelectric-related system. We provide accurate and exquisite processing quality with leading R&D capability.

Integration Ability & Experienced

With an experienced, completed, and elite R&D team, customized such as automated, integrated with the robot, system integration, etc. are all available.

Professional Service

AccTek Laser's laser welding machine is a professional laser welding machine designed and manufactured in China. Our elite engineering team provides related service support.

Equipment Features

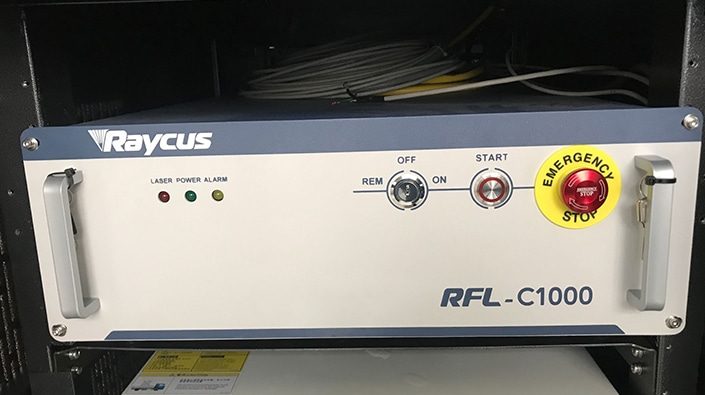

Famous Laser Generator

Using well-known brand laser generators (Raycus / JPT / Reci / Max / IPG), a high photoelectric conversion rate ensures the laser power and makes the welding effect better. AccTek can design different configurations to meet customer needs.

Industrial Water Chiller

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the welding machine to provide consistent welding quality and helping to improve the overall quality of the weld itself. It can also increase welding output by reducing the downtime of fiber laser welding machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser welding machine.

Laser Welding Gun

The laser welding gun is ergonomically designed, light in shape, comfortable to hold, and easy to control and operate. The hand-held welding gun is easy to hold and can be operated at any angle, making welding more convenient and flexible.

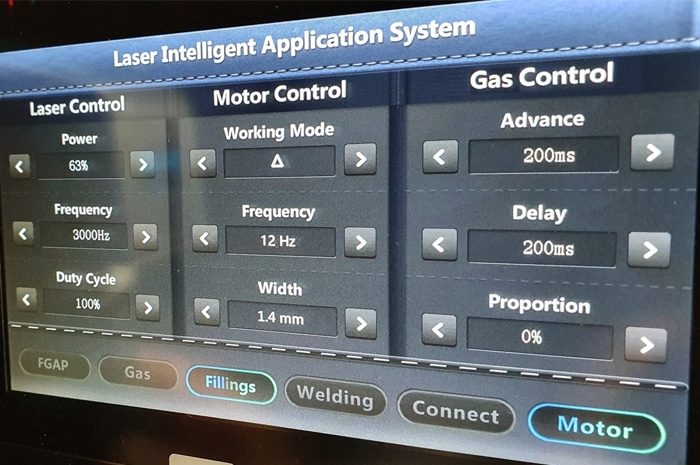

Interactive Touch Screen Control System

AccTek provides high-performance, intuitive, and easy-to-use operating systems. It expands the tolerance range and weld width of machined parts and provides better weld formation results. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

Technical Specifications

| Model | AKH-1000 | AKH-1500 | AKH-2000 | AKH-3000 |

|---|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber laser | |||

| Range of Adjustable Power | 1-100% | |||

| Laser Wavelength | 1064nm | |||

| Way of Workinging | Continuous/Modulation | |||

| Speed Range | 0-120mm/s | |||

| Repeat Precision | ±0.01mm | |||

| Welding Gap Requirements | ≤0.5mm | |||

| Cooling Water | Industrial thermostatic water tank | |||

Laser Welding Capacity

| Material Type | Welding Form | Thickness (mm) | Laser Power (W) | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|---|

| Carbon Steel (Q235B) | Butt Welding | 0.5 | 1500 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1500 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1500 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 1500 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 1500 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 1500 | 15~20 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Stainless Steel (SUS304) | Butt Welding | 0.5 | 1500 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1500 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1500 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 1500 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 1500 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 1500 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Brass | Butt Welding | 0.5 | 1500 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1500 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1500 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 1500 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 1500 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1500 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1500 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 1500 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 1500 | 10~20 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 1500 | 60~65 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1500 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1500 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 1500 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Copper | Butt Welding | 0.5 | 1500 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

- In the welding data, the core diameter of the 1500W laser output fiber is 50 microns.

- The welding data adopts a Raytools welding head (swing welding head is used for copper welding), and the optical ratio is 100/200 (collimator/focus lens focal length).

- Welding shielding gas: Argon (purity 99.99%).

- Due to the differences in equipment configuration and welding process used by different customers, this data is for reference only.

Product Features

- The operation is simple and easy to learn, and the weld seam is not deformed.

- The laser output is stable, ensuring the consistency of the weld.

- High power density after laser focusing.

- The welding seam is smooth and beautiful, the welding workpiece will not be deformed, and the welding is firm without a subsequent grinding process, saving time and cost.

- 360-degree micro-welding without dead angle. After the laser beam is focused, a small spot can be obtained, which can be precisely positioned and used for the welding of small and small workpieces and can realize mass production.

- The welding speed is fast and the operation is simple, which is 2-10 times faster than the traditional welding speed.

- Long service life, providing a safer and more environmentally friendly welding method.

- High energy density, low heat input, small thermal deformation, narrow and deep melting zone, and heat-affected zone.

- The cooling speed is fast, the fine weld structure can be welded, and the joint performance is good.

- Compared with the contact welding method, laser welding saves electrodes, reduces daily maintenance costs, and greatly improves production efficiency.

- The welding seam is thin, the penetration depth is large, the taper is small, the precision is high, and the appearance is smooth and beautiful.

- No consumables, small size, flexible processing, low operation, and maintenance costs.

Product Application

Frequently Asked Questions

- Power Consumption: Power consumption refers to the power consumption of the laser welding machine when it is running at full power. For example, the power consumption of a 1500-watt laser welding machine is about 4500-7500 watts per hour, because the photoelectric conversion rate is not 100%. This power consumption refers to the energy requirements of the laser generator and does not take into account additional systems such as cooling systems or auxiliary equipment. It is important to note that laser welding machines may have different power consumption levels in standby or idle mode, which may be much lower.

- Duty Cycle: Duty cycle refers to the amount of time a laser welding machine can run continuously before requiring a cooler. Laser welding machines usually have a specified duty cycle ranging from 10% to 100%. For example, a machine with a 50% duty cycle can run at full power for 30 minutes and then require a 30-minute cool-down period. The duty cycle affects effective power consumption and operating costs because the machine may not be able to run at full power continuously.

- Operating Costs: The operating costs of a laser welding machine should include electricity costs. Electricity bills can be estimated by calculating power consumption and multiplying it by the cost of idle hours (kWh) charged by the utility provider. It is worth noting, however, that laser welding machines typically operate for a short period of time on a single weld, so overall power costs may be relatively low compared to other industrial equipment.

- Maintenance And Consumables: Laser welding machines may require periodic maintenance such as cleaning or replacing optics, cooling systems, or gas supplies (if applicable). These maintenance and consumable costs should be factored into overall operating costs.

- Stainless Steel: Laser welding is commonly used to weld stainless steel. It can be used to weld different grades of stainless steel, such as austenitic. Ferritic and martensitic stainless steels.

- Carbon Steel: Laser welding can be used to weld carbon steels, both mild and high carbon.

- Aluminum: Laser welding can be used to weld aluminum and its alloys. But aluminum requires special consideration due to its high reflectivity, thermal conductivity, and tendency to create porosity. Additional measures, such as using a laser beam with a higher absorption wavelength or using filler materials, may be required to achieve effective aluminum welding.

- Copper And Copper Alloys: Laser welding can be used to weld copper and copper alloys. Copper has high thermal conductivity, which can create challenges for laser welding. Using a high-powered laser generator and proper thermal management techniques can help achieve successful brazing.

- Titanium: Laser welding can be used to join titanium and its alloys. The high energy density and precise control offered by laser welding make it an effective method for welding this challenging material. Titanium is commonly used in aerospace and medical applications that require high-strength, lightweight materials.

- Nickel And Nickel Alloys: Laser welding can be used to weld nickel-based alloys commonly used in high-temperature and corrosive environments, such as Inconel and Hastelloy. These alloys are commonly used in industries such as aerospace, chemical processing, and power generation.

- Precious Metals: Laser welding can be used to weld precious metals such as gold, silver, and platinum. It is commonly used in jewelry-making and dental applications.

- Laser Safety Standards: Laser welding machines are often required to comply with laser safety standards to ensure safe operation and use of laser technology. These standards ensure that machines meet specific safety requirements to protect operators and bystanders from potential hazards associated with laser radiation. Examples of laser safety standards include the International Electrotechnical Commission (IEC) 60825 series, which provides guidance for the classification, labeling, and safety precautions of laser products.

- Electrical Safety: Laser welding machines also need to comply with electrical safety standards to ensure safe operation and prevent electrical hazards. These standards may include provisions for electrical systems, grounding, insulation, and protection against electrical hazards. Specific standards may vary by country, such as UL (Underwriters Laboratories) standards in the United States or CE (Conformité Européene) marking in the European Union.

- Industry-Specific Standards: Depending on the industry or application in which the laser welding machine is used, additional standards or certifications may need to be met. For example, in the automotive or aerospace industries, specific quality standards or industry-specific certifications may be required to ensure compliance with industry-specific requirements.

- Demonstration of Quality Management: Manufacturers of laser welding machines may choose to implement a quality management system, such as ISO 9001, to demonstrate their commitment to producing high-quality products and ensuring consistent performance.

- Power Output: The machine is capable of emitting a laser beam with a power output of 1500 watts, providing enough energy for welding various materials. The laser power output determines the intensity and depth of the laser beam used for welding.

- Control System: Laser welding machines are equipped with a control system that allows the operator to adjust welding parameters such as power output, pulse duration, laser beam shape, and welding speed. These controls allow customization and optimization of welding processes for specific applications and welding materials.

- Beam Delivery System: The laser beam is delivered from the laser generator to the workpiece through the beam delivery system. A beam delivery system typically includes beam-shaping optics, focusing lenses, and mirrors. The beam delivery system ensures precise control and manipulation of the laser beam.

- Welding Modes: Laser welding machines often offer different welding modes, such as continuous wave (CW) or pulsed. CW mode provides a continuous laser beam for continuous welding, while pulsed mode delivers laser energy in pulses, providing precise control and minimizing heat input.

- Cooling System: Laser welding machines typically have a cooling system to manage the heat generated during operation and maintain optimum performance. This may involve the use of water or other cooling methods to keep the laser generator and other components at a steady temperature.

- Laser Welding Gun: The machine has a laser welding gun that focuses the laser beam onto the workpiece. There may be adjustable parameters on the laser gun, such as focal length, spot size, and beam shape, allowing control over welding characteristics.

- Precision And Accuracy: Laser welding machines typically feature high precision and accuracy, allowing precise control of the welding process. This is critical to achieving high-quality welds, especially in applications that require fine details or tight tolerances.

- Automation And Integration: Laser welding machines can be integrated into automated production lines or robotic systems, enabling high-speed and precise welding operations. Automation allows for a repeatable and efficient welding process, increasing productivity and efficiency in industrial applications, and making it suitable for high-volume production or complex welding applications.

- Spot Weld: A spot weld design joins two or more metal parts by creating localized welds. A laser beam is focused on a small area, rapidly heating and melting the material to create a solder joint. Spot welding is often used in applications that require precise and localized welding, such as in the automotive or electronics industries.

- Seam Welding: The seam welding design moves a laser beam along the seam between two workpieces, creating a continuous weld. A laser beam travels along the joint, melting and fusing the materials together. Seam welding is often used in applications requiring a leak-proof or hermetic seal, such as the manufacture of tubes, pipes, or containers.

- Continuous Welding: Continuous welding is also known as wire welding or trajectory welding. The laser beam moves continuously along the welding path (straight or curved) without interruption to form a tangentially continuous weld joint. The technology is suitable for joining larger or more complex components, such as structural applications or manufacturing components with complex geometries.

- Regular Cleaning: Laser optics, including lenses and mirrors, should be kept clean and free of dust, debris, and contaminants. This may require careful cleaning and shrinkage of optics to maintain beam quality and prevent performance degradation. Proper cleaning methods recommended by the manufacturer are recommended.

- Cooling System Maintenance: If the laser welding machine uses a water-cooled system, regular maintenance is required to ensure proper water flow, monitor coolant production, and prevent scale or impurities from building up. It is recommended to follow the manufacturer’s cooling system maintenance guidelines, clean or replace the filter as needed, and monitor the coolant level when appropriate.

- Alignment And Calibration: Laser welding machines may require regular alignment and calibration to ensure accurate beam delivery and welding performance. This may be designed to check and adjust the alignment of optics, verify focus position, and calibrate control systems. It is recommended to consult the manufacturer’s guidelines or seek professional assistance for proper calibration and alignment procedures.

- Replacing Consumables: Certain components in a laser welding machine, such as the shielding gas nozzle or laser diodes, may have a limited lifespan and need to be replaced periodically. Monitor the condition of consumables and replace them as needed to maintain optimum welding performance.

- Gas Supply: If the laser welding machine uses auxiliary gas, then it is necessary to ensure a continuous and clean supply of the gas used. Monitor gas pressure and quality to avoid interruptions or impact on weld quality.

- Power And Electrical Components: Check the power and electrical connections for any signs of damage or wear. Ensure proper grounding and resolve any electrical issues promptly.

- Safety Inspections: Periodically inspect and test machine safety features, such as interlocks and emergency stop buttons, to ensure they function properly and provide adequate protection for operators and personnel.

- Routine Inspections: Perform routine inspections of machine components, including laser generators, beam delivery systems, and work holding, for any signs of wear, damage, or misalignment.

- Professional Service: If your machine experiences performance problems or malfunctions, it may require professional service or repair by a trained technician. Follow the manufacturer’s guidelines for assistance by contacting their service department or an authorized service provider who has the expertise to diagnose and resolve specific problems associated with your laser welding machine.