Guia completo para selecionar os parâmetros corretos de limpeza a laser

Laser cleaning technology, thanks to its high precision, non-contact nature, and environmental friendliness, is being widely adopted in industries such as metal processing, mold maintenance, cultural relic restoration, and electronics manufacturing. This technology uses a laser beam to selectively remove surface contaminants without damaging the substrate, avoiding the secondary contamination or substrate damage that can occur with traditional chemical cleaning or mechanical polishing. Common applications include pre- and post-weld treatment of metals, removal of mold release residue, cleaning oxide layers from cultural relic surfaces, and high-precision decontamination of electronic components.

In terms of technical implementation, pulsed laser cleaning, laser rust removal, and laser surface preparation are the three main methods. Pulsed laser cleaning is suitable for precision cleaning, laser rust removal specifically targets metal corrosion, and laser surface preparation optimizes the substrate surface condition and enhances coating or bonding properties. Key parameters such as laser wavelength (1064nm or 532nm), pulse energy, repetition rate, and scanning speed must be optimized based on the material type (e.g., steel, aluminum, composites) and contaminant characteristics (e.g., rust, paint, carbon deposits) to ensure cleaning efficiency and quality. With the increasing environmental protection requirements and the upgrading of the manufacturing industry, laser cleaning technology is expected to replace traditional cleaning methods in more fields.

Índice

Introduction to Laser Cleaning Parameters

In the application of máquinas de limpeza a laser, the following core parameters are key factors that determine cleaning efficiency, surface quality, and overall process stability:

Comprimento de onda

Wavelength is the basic parameter for the interaction between the laser and the material being cleaned, and it directly affects the absorption efficiency of the laser beam.

- Common industrial laser cleaning machines use a 1064nm wavelength (fiber laser), suitable for most metal surface treatments, such as steel, stainless steel, and aluminum alloys. They offer strong penetration and concentrated energy.

- 355nm (UV laser) is suitable for high-precision, low-heat-impact cleaning tasks, such as semiconductors, precision electronic components, and cultural relic preservation. Its short wavelength and high photon energy enable material removal with low heat input.

The choice of different wavelengths should be determined according to the substrate absorption curve and the characteristics of the pollutants to achieve the best cleaning effect.

Duração do pulso

Pulse duration refers to the length of time that the laser pulse energy acts on the target surface, usually measured in nanoseconds (ns), picoseconds (ps), or femtoseconds (fs).

- Nanosecond pulses are suitable for removing common contaminants such as oxide layers, oil stains, and rust.

- Picosecond and femtosecond pulses are ultrashort lasers that enable “cold processing,” minimizing the heat-affected zone and making them suitable for surface treatment of precision parts and sensitive materials.

Shorter pulse durations generally increase removal accuracy and reduce the risk of material damage.

Energia de pulso

Pulse energy refers to the amount of energy released by each laser pulse, which directly affects the stripping efficiency and cleaning speed of pollutants.

- High pulse energy is suitable for the rapid removal of stubborn rust or thick coatings, but care must be taken to avoid overheating the substrate or melting the surface.

- Low pulse energy is more suitable for delicate machining tasks that require preserving surface structure.

In practical applications, the pulse energy needs to be adjusted according to the adhesion and thickness of the pollutants.

Taxa de repetição de pulso

The pulse repetition rate is the number of laser pulses emitted per unit time, usually expressed in kHz.

- Higher repetition rates increase cleaning speed but may increase the risk of heat buildup.

- Lower repetition rates help control heat input and are suitable for precision cleaning.

Properly setting the pulse repetition rate can strike a balance between efficiency and thermal effects.

Tamanho do ponto

The spot size determines the reach and energy density of the laser beam on the surface.

- Smaller spot sizes help concentrate energy and improve removal accuracy, making them suitable for detailed cleaning.

- Larger spot sizes cover a larger area and improve overall efficiency, but energy density is reduced, and you may need to increase power to compensate.

When cleaning curved or irregular surfaces, flexible adjustment of the spot size is particularly important.

Scanning Pattern

The scanning pattern is the path of the laser beam across the surface being cleaned. Common patterns include linear scanning, cross scanning, spiral scanning, etc.

- Linear scanning is suitable for regular, flat surfaces.

- Cross-scanning improves coverage uniformity and reduces missed areas.

- Spiral scanning is more suitable for round or irregularly shaped workpieces.

Scientifically selecting and adjusting the scanning mode can ensure cleaning uniformity and reduce the necessity of secondary processing.

A comprehensive understanding of parameters such as wavelength, pulse duration, pulse energy, pulse repetition rate, spot size, and scanning pattern is the first step in optimizing laser cleaning solutions. The combination of these parameters in different application scenarios directly determines cleaning performance, processing speed, and surface integrity. Choosing the right parameters not only improves efficiency but also extends equipment life and reduces operating costs.

Key Considerations for Selecting Laser Cleaning Parameters

When setting laser cleaning parameters, blindly adjusting them can waste time and even damage the workpiece. A more effective approach is to first determine a reasonable range based on the workpiece material and cleaning objectives, and then gradually optimize. The following four aspects are key factors to evaluate when selecting a fiber laser cleaning solution:

Compatibilidade de materiais

Different materials exhibit significant variations in their absorption and thermal conductivity at laser wavelengths. For example, copper and aluminum have high reflectivity and poor cleaning efficiency under 1064nm fiber laser cleaning, while stainless steel and carbon steel absorb this wavelength well. Non-metallic materials such as plastic and stone may carbonize or melt due to excessively long pulse durations. Substrate characteristics determine the range of wavelength, pulse energy, and spot size.

Características do Contaminante

The type and thickness of contaminants directly influence the selection of cleaning parameters. Light, thin oil stains can be removed with multiple scans at low pulse energy, while thick rust or oxide layers require higher energy densities or slower scan speeds. For coatings, their chemical composition must also be considered, as some materials release harmful gases during laser cleaning, necessitating exhaust ventilation. Accurately identifying contaminants accelerates parameter optimization, improves laser cleaning efficiency, and ensures safety.

Surface Sensitivity

Artifacts, precision molds, optical components, and other components are extremely sensitive to heat. These applications often utilize ultrashort pulse durations (picosecond or femtosecond lasers) and reduced energy density to avoid altering surface roughness or functional properties. In practice, small-scale trials are often necessary, followed by gradual expansion of the cleaning area. For sensitive surfaces, low-energy and short pulse strategies should be prioritized to ensure that laser cleaning parameters do not damage the substrate.

Cleaning Requirements

Different applications have different goals. For cosmetic restoration, visual cleanliness is sufficient; for subsequent painting, welding, or coating, ensuring a completely residue-free surface is crucial. These requirements determine the settings for pulse energy, pulse repetition rate, and scanning pattern. Clarifying the cleaning goal is the key to adjusting laser cleaning parameters.

When selecting appropriate fiber laser cleaning parameters, one should first evaluate material properties, contaminant type, surface sensitivity, and the ultimate cleaning goal. These four factors can help users quickly determine the appropriate ranges for key parameters such as pulse energy, pulse duration, and spot size, thereby improving first-time success rates, reducing unnecessary trial and error, and finding the optimal balance between efficiency and safety.

Select appropriate laser cleaning parameters

In practical applications, the effectiveness of laser cleaning often depends on the comprehensive matching of multiple core parameters. A scientific parameter selection process can not only improve cleaning efficiency but also avoid surface damage. The following steps can be used as a reference:

Understand Material Properties

A material’s optical and thermal properties directly determine its response to lasers. For example, copper and aluminum have high reflectivity and low energy efficiency when using 1064nm fiber laser cleaning, while steel absorbs this wavelength better, making cleaning more efficient. Non-metallic materials, such as plastics or stone, may carbonize or thermally crack at excessively high pulse energies. Therefore, before beginning, it’s crucial to clearly define the material’s reflectivity, thermal conductivity, and melting point as a basis for parameter setting.

Realize testes de materiais

Theoretical analysis is only the first step; actual results must be verified through small-area testing. During testing, the pulse duration, energy density, and spot size can be gradually adjusted, and the color change, surface roughness, and presence of melting marks in the cleaned area can be observed. By recording the results under different parameters, the optimal parameter range can be quickly narrowed down, reducing the cost of blind trial and error.

Consider Contaminant Characteristics

The type, thickness, and adhesion of the contaminant determine the cleaning strategy. Light oil or dust can be removed with multiple low-energy scans; thick rust, oxide layers, or industrial coatings, on the other hand, typically require higher pulse energies and slower scanning speeds to ensure thorough removal. The composition of the contaminant should also be considered. Some coatings may release hazardous fumes during cleaning, requiring ventilation and protective equipment.

Balance Efficiency and Surface Integrity

The goal of laser cleaning is not only to remove contaminants but also to protect the substrate itself. Excessive energy or slow scanning speeds can easily lead to surface overheating, melting, or increased roughness, compromising workpiece performance. For example, when cleaning molds, optical components, or artifacts, surface integrity is often more important than cleaning speed. Therefore, performance should be constantly monitored during operation to strike the right balance between efficiency and safety.

Optimize Parameter Combination

Adjusting a single parameter doesn’t guarantee optimal results; a comprehensive approach is often necessary. For example, when cleaning thick rust layers, increasing the pulse repetition rate can improve efficiency, but excessive energy can also cause surface burns. In this case, appropriately adjusting the scanning speed and spot size can disperse the energy, achieving a win-win situation for both cleanliness and surface quality.

Adapt to Surface Geometry

For flat workpieces, a regular scan is sufficient; however, for complex curved surfaces, pipes, or grooves, a flexible scanning path is required to ensure uniform energy distribution. If the surface has fine structures, it is necessary to reduce the spot size or increase the overlap rate to avoid uneven cleaning or omissions.

Selecting the right laser cleaning parameters isn’t a one-time, fixed process; it’s a dynamic cycle of adjustment and verification. By first understanding the characteristics of the material and contaminants, combined with small-area testing and parameter optimization, the first-time success rate can be significantly improved. The ultimate goal is to achieve a “clean and safe” cleaning result, ensuring that the workpiece meets ideal standards in appearance, function, and subsequent processing.

Best Practices for Laser Cleaning Parameter Optimization

In practice, laser cleaning effectiveness isn’t achieved overnight; rather, it’s achieved through continuous parameter adjustment and optimization. A scientific debugging process not only improves cleaning efficiency but also ensures substrate safety and extends equipment life. The following five practical experiences offer valuable insights:

Start with Conservative Settings: For initial testing, begin with low pulse energy and moderate scanning speed. This is to avoid irreversible damage to the workpiece, such as ablation, melting, or color change, caused by excessive energy. Subsequently, gradually increase the energy or decrease the scanning speed to find the balance between removing contaminants and maintaining surface integrity.

Monitor Surface Condition: Changes during laser cleaning are often subtle and not immediately discernible to the naked eye. Using a microscope, high-definition camera, or 3D surface inspection instrument, the surface condition after cleaning can be observed in real time to determine if there are microcracks, increased roughness, or localized melting. Regular monitoring allows for timely parameter adjustments to ensure consistent quality across the entire workpiece surface.

Conduct iterative testing: Parameter optimization is a gradual process that cannot be completed in one go. Multiple rounds of fine-tuning of the pulse repetition rate, spot overlap, and scanning pattern are typically required. Each adjustment should be limited, and the relationship between parameters and cleaning results should be recorded to identify patterns and develop the optimal parameter combination for the material and contaminant.

Ensure safety precautions: Lasers are high-energy light sources that can affect not only the workpiece but also the operator. During parameter optimization, strictly adhere to international laser safety standards (such as the protection requirements for Class 4 laser equipment). Wear standard goggles and use a protective shield or enclosed work chamber. Also, be aware that vaporization or stripping of contaminants can release dust and hazardous gases, making a good exhaust system essential.

Consult with Experts: Even with extensive experimental experience, it’s still recommended to seek technical support from the equipment manufacturer when faced with complex workpieces and special applications. For example, AccTek Laser’s engineering team has accumulated extensive practical experience in various application scenarios and can provide customers with more precise parameter recommendations and process optimization solutions. This not only shortens commissioning cycles but also helps users avoid equipment wear and workpiece failure caused by improper parameter settings.

Optimizing laser cleaning parameters is a dynamic, iterative process that requires continuous testing and revision under the premise of safety. By starting conservatively, monitoring in real time, and gradually optimizing, combined with scientific safety precautions and expert guidance, users can ensure cleaning quality while extending equipment life and reducing long-term operating costs.

Applications of Optimized Laser Cleaning Parameters

Optimized laser cleaning processes go beyond simply removing dirt faster. By leveraging appropriate wavelength, pulse energy, and scanning strategies, they enable precise control of diverse operating conditions, improving process reliability and yield across multiple industries. The following lists several typical applications that often benefit from these technologies and explains why parameter optimization is crucial.

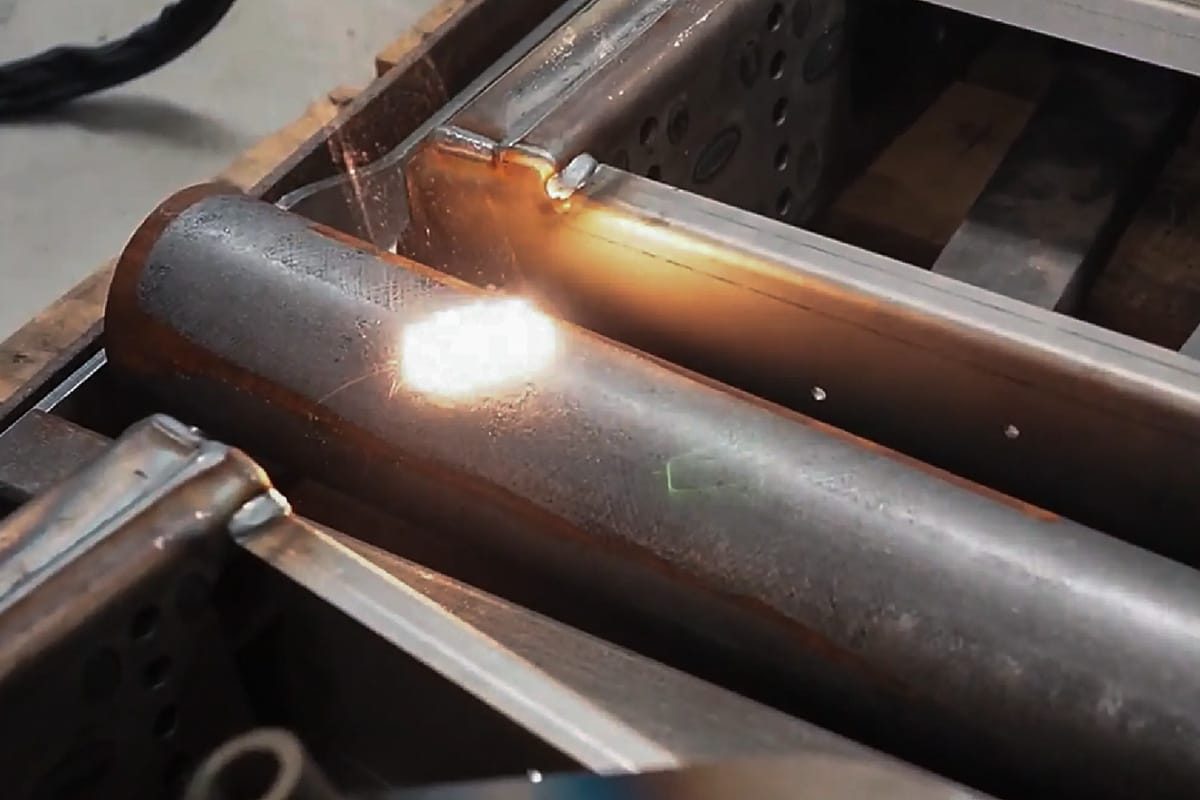

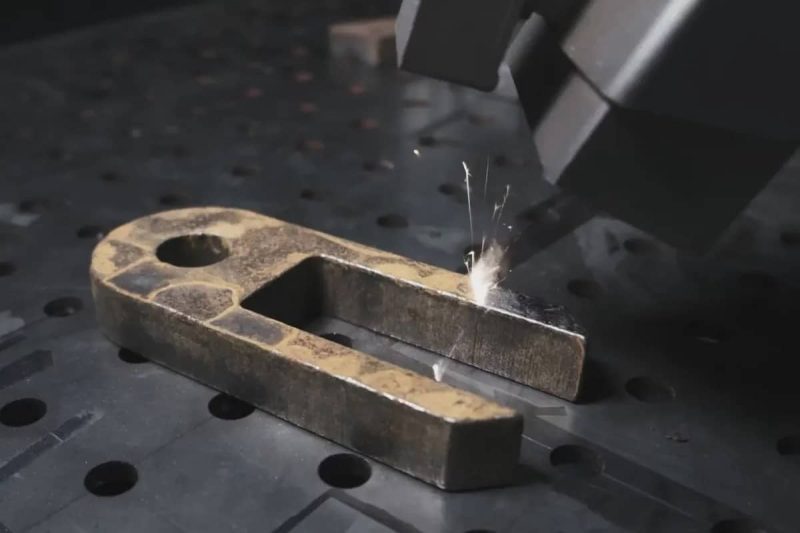

Industrial Cleaning and Surface Preparation

Optimized laser cleaning parameters achieve stable and repeatable cleaning results in industrial applications such as mold maintenance, weld pretreatment, and rust and coating removal on pipes and structural components. For high-value workpieces like molds, appropriately reducing energy density and increasing overlap can remove rust and residue while maintaining cavity dimensions and surface finish. For weld pretreatment, controlling pulse energy and spot size can create a more uniform metal surface, improving weld adhesion and weld quality. Overall, parameter optimization directly impacts process efficiency, rework rate, and mold life.

Cultural heritage and cultural relics protection

Cultural relic cleaning emphasizes “removing contaminants without removing the material.” This type of work is extremely sensitive to heat input and micro-damage. Using ultrashort pulses or multiple low-energy sweeps, coupled with fine-tuning of the pulse duration and scanning pattern, can remove surface deposits and carbides without damaging the original material or surface pigment. Parameter optimization in this application not only prevents micro-damage invisible to the naked eye but also ensures the reversibility and recordability of restoration work, which is particularly important for professional restoration teams.

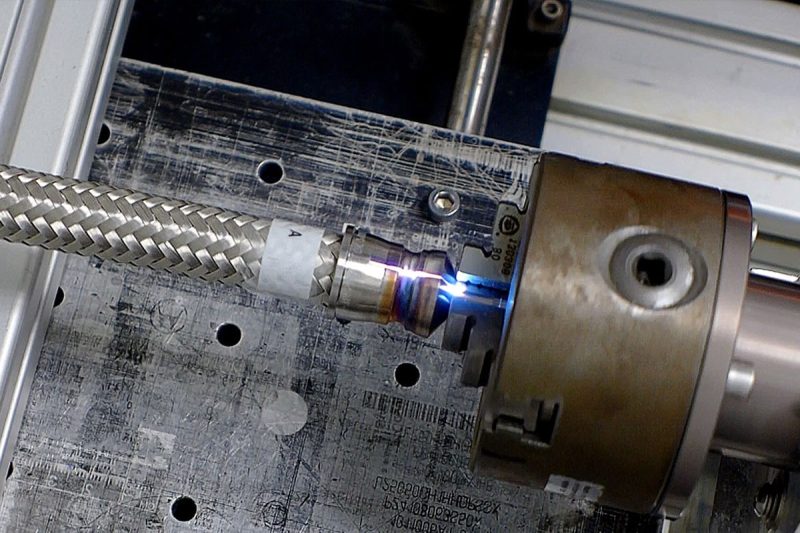

Electronics Manufacturing and Refurbishment

Cleaning electronic components, printed circuit boards (PCBs), and precision connectors requires the removal of oxides and solder residues without affecting conductivity or microstructures. By precisely controlling pulse energy, pulse repetition rate, and spot size, optimized laser cleaning achieves highly selective decontamination—removing oxide layers or flux residues while preserving the form and function of pads and pins, reducing subsequent rework rates and improving device yields.

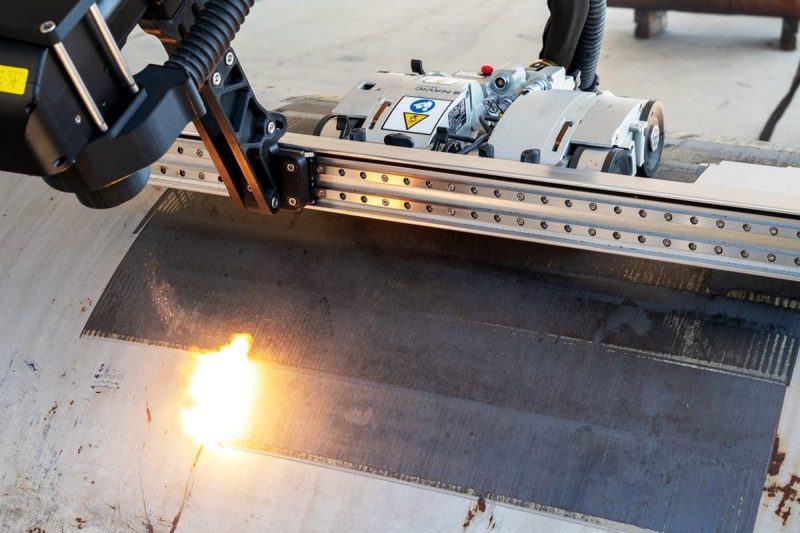

Automotive, aviation and heavy industry maintenance

Surface cleaning or coating preparation for engine components, blades, gears, and other structural parts often involves thick rust, impurity deposits, or old coatings. A suitable parameter combination (such as high-energy, short pulses combined with segmented scanning) can rapidly remove thick contamination while simultaneously avoiding heat buildup and substrate annealing through zoned monitoring. Parameter optimization can shorten maintenance downtime and reduce errors and safety risks associated with manual handling.

Precision refurbishment and surface functionalization

In part refurbishment, surface roughening (in preparation for coating or bonding), and laser surface modification, fine-tuning parameters determine the final surface roughness, surface chemistry, and bonding properties. The correct scanning speed and overlap settings enable simultaneous cleaning and surface roughening, providing controlled surface conditions for subsequent processing steps (coating, bonding, thermal spraying, etc.).

Different cleaning tasks require different laser cleaning parameters (such as wavelength, pulse energy, pulse duration, repetition rate, spot size, and scanning pattern). Only through systematic testing and parameter optimization can we find the optimal balance between cleaning performance, processing speed, and surface integrity, significantly improving overall process quality and economic efficiency. If you require parameter recommendations or sample testing for specific application conditions, we provide process support and testing services based on on-site material and contaminant characterization to help you quickly implement optimized results.

Resumir

Laser cleaning is an efficient, controllable, and environmentally friendly surface treatment technology. However, fully realizing its benefits depends on correctly selecting and optimizing laser cleaning parameters. By understanding the various parameters, clarifying application requirements, and following a scientific debugging method, you can achieve efficient and safe cleaning results. At Laser AccTek, we not only provide advanced máquinas de limpeza a laser pulsado, but also provide customized parameter recommendations and testing support to help you achieve optimal results in your application. If you are looking for a laser cleaning solution suitable for your business, please Contate-nos for more details.

Informações de contato

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zona A, Zona Industrial de Lunzhen, Cidade de Yucheng, Província de Shandong.

Obtenha soluções a laser