What Are the Considerations for Laser Welding in Terms of Weld Penetration and Depth-to-Width Ratio?

Laser welding machines, with their high precision, high efficiency, and minimal heat-affected zone, are becoming an indispensable tool in modern manufacturing. Compared to traditional welding methods, laser welding precisely focuses a high-energy-density beam on the material surface, instantly heating and melting the material locally, resulting in stable, strong, and aesthetically pleasing welds. This process not only significantly improves welding speed and productivity but also minimizes material deformation and the need for subsequent processing.

In the entire welding process, two key factors determine weld quality and performance: weld penetration (the depth to which the base material is completely melted and fused) and aspect ratio (the ratio between weld depth and width). These factors directly impact joint strength, weld uniformity, and the long-term reliability of the product. In other words, insufficient weld penetration may prevent the joint from withstanding stress, while an improperly controlled aspect ratio can easily lead to cracks or surface defects.

Therefore, when analyzing and optimizing laser welding processes, weld penetration and aspect ratio are not only key indicators of weld quality but also fundamental to ensuring that the final product meets high strength, stability, and aesthetic requirements. This article will systematically explore the main factors affecting these two parameters and deeply analyze how to achieve ideal welding effects through scientific regulation.

Índice

Understanding Weld Penetration and Aspect Ratio

In laser welding, weld penetration and depth-to-width ratio are crucial technical indicators for measuring weld quality and stability. They not only determine whether the weld achieves complete penetration and a strong bond, but also directly impact the weld’s mechanical properties and service life. Understanding the definitions and significance of these two parameters is fundamental to understanding the laser welding process.

Definition of weld penetration

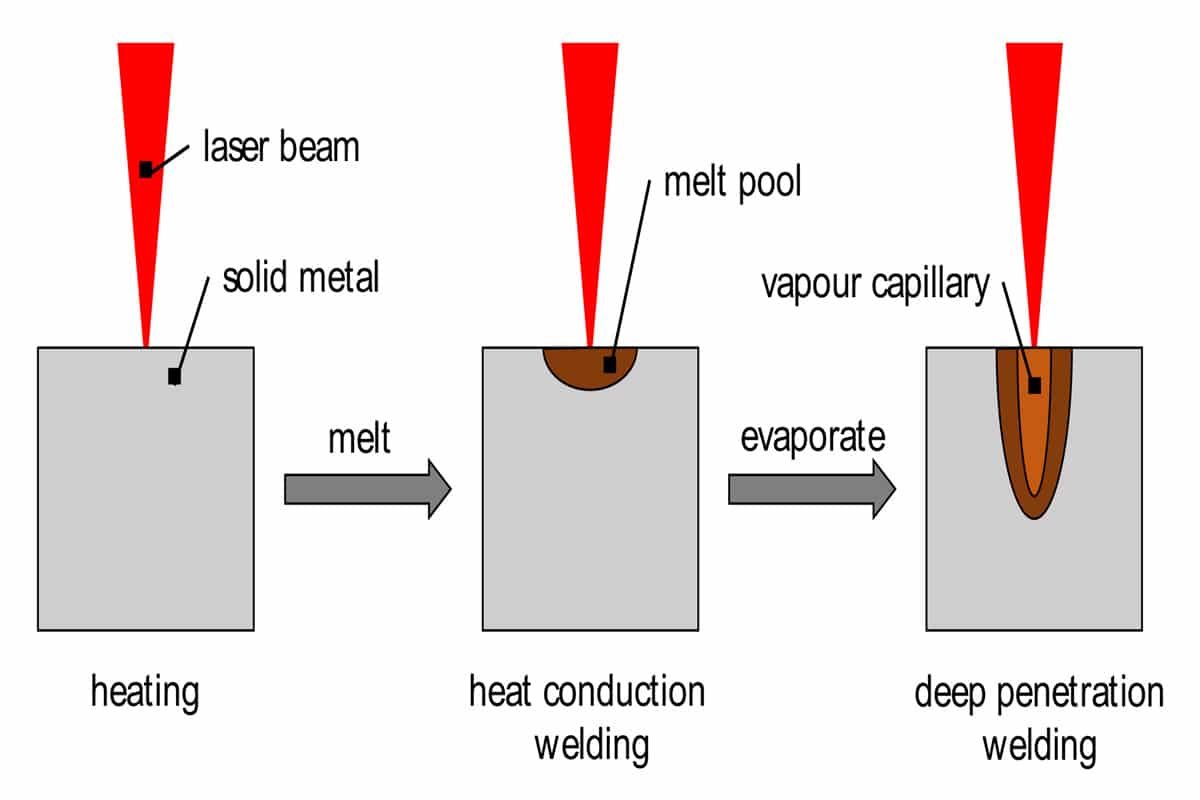

Weld penetration refers to the depth of molten metal below the surface of the parent material and reflects the extent of the laser energy’s effect within the material. Typically, at low power densities, laser welding exhibits conduction-type characteristics, with heat primarily diffusing through conduction, resulting in shallow, wide welds. At high power densities, the laser forms small steam pores in the metal, creating deep-penetration welds with deep, narrow welds and significantly enhanced penetration.

Definition of aspect ratio

The aspect ratio is the ratio of weld depth to width (depth/width), which characterizes weld geometry and energy utilization. A high aspect ratio (>1) results in a deep, narrow weld, often seen in deep penetration welding and suitable for applications requiring high penetration. A low aspect ratio (<1) results in a shallow, wide weld, often seen in conduction welding and suitable for applications requiring high weld appearance and surface smoothness.

Importance of Depth of Penetration and Aspect Ratio

These two indicators play a decisive role in welding quality:

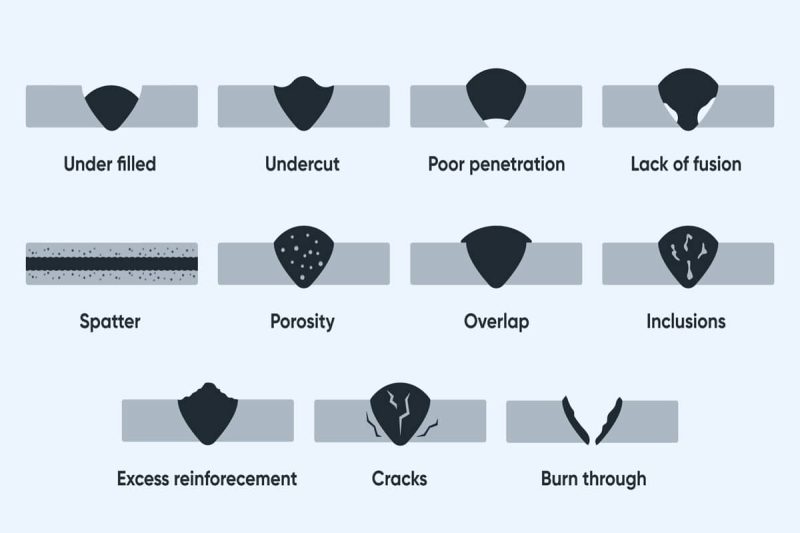

Penetration: Sufficient penetration ensures complete fusion of the joint, avoiding incomplete penetration, cold welds, or root defects, thereby ensuring weld strength. Deep-to-width ratio: The depth-to-width ratio of a weld affects its internal stress distribution.

- A low aspect ratio can lead to surface cracking in the weld and reduced fatigue life.

- A high aspect ratio can lead to central cracking or high residual stress in the weld, compromising overall stability.

A reasonable balance between weld penetration depth and depth-to-width ratio is the key to achieving efficient application of máquinas de solda a laser and ensuring weld quality.

In summary, weld penetration and aspect ratio are the most critical geometric parameters in the laser welding process. They not only determine the weld’s morphological characteristics but also profoundly influence its mechanical properties and durability. By properly controlling penetration and aspect ratio, manufacturers can achieve weld joints that combine strength, reliability, and aesthetics, laying a solid foundation for subsequent high-performance product manufacturing.

Factors affecting weld penetration

When using a laser welding machine, weld penetration is a key parameter that determines weld strength and complete penetration. This depth of penetration depends not only on the performance of the laser machine itself but also on factors such as material properties and joint design. A thorough understanding of these factors can help you more precisely control the welding process and achieve ideal results in practical applications.

Parâmetros do laser

- Laser power: Higher power inputs more energy into the material, generally increasing penetration. However, excessive power can cause spatter or weld defects, so a balance must be struck between intensity and stability.

- Focal position: When the laser beam is precisely focused on the weld area, energy density is highest and penetration is greatest. A misaligned focus causes energy dispersion, reducing penetration.

- Spot size: A smaller spot size results in more concentrated energy and deeper penetration. However, a larger spot size results in a more diffuse energy distribution, significantly reducing penetration.

Propriedades dos materiais

- Material Type: Different metals have significantly different laser absorption rates. For example, steel generally achieves thorough penetration more easily, while highly reflective metals like alumínio e cobre reflect a significant amount of laser energy, resulting in insufficient penetration. This requires increasing the power or using a specialized laser wavelength.

- Thermal Conductivity: Materials with high thermal conductivity dissipate heat rapidly, reducing penetration. These materials often require a lower welding speed or increased power density to ensure adequate penetration.

- Material Thickness: Thick plate materials require higher energy input to achieve complete penetration, while thin plates are easier to penetrate. Avoiding overmelting or burn-through presents a challenge in process control.

Projeto e montagem de juntas

- Joint geometry: Different joint configurations significantly impact laser energy transfer efficiency. For example, a V-groove can guide the weld pool deeper, but also requires more filler material. Overlap joints can disperse energy and increase the risk of incomplete fusion.

- Joint gap: Ideally, welding requires a tight fit. Excessive gaps can cause energy loss, resulting in insufficient penetration and even porosity and weld defects.

- Assembly precision: High-precision assembly not only reduces energy loss but also ensures uniformity and consistency of the weld.

Generally speaking, weld penetration is influenced by a combination of laser parameters, material properties, and joint design. To achieve ideal penetration, precise adjustments must be made to power, focus, and spot control, while optimizing them based on material properties and joint assembly. Only in this way can laser welding fully realize its advantages and ensure excellent weld strength and reliability.

Factors Affecting Aspect Ratio

In laser welding, the aspect ratio is a crucial metric for evaluating weld geometry. It not only impacts the weld’s overall appearance and aesthetics, but also directly influences the stress distribution and long-term stability of the weld joint. Excessively high or low aspect ratios can lead to various welding defects. Therefore, properly controlling the aspect ratio is crucial for improving weld quality when using a laser welding machine.

Parâmetros do laser

- Focus Position: When a laser beam is highly focused, the energy density is concentrated in a narrow area, typically resulting in a deep, narrow weld with a high aspect ratio. If the focus is offset or not accurately aligned with the workpiece, the energy will diffuse, resulting in a shallow, wide weld.

- Spot Size: A small spot size results in higher energy density, which results in a larger aspect ratio. A larger spot size, on the other hand, results in a more even energy distribution, a wider weld, and a lower aspect ratio.

- Power Distribution: A uniform Gaussian beam favors wider welds, while annular or special beam distributions can extend weld width without compromising penetration. Modern beam shaping techniques or laser wobbling processes allow for flexible adjustment of the aspect ratio to meet diverse process requirements.

Propriedades dos materiais

- Material Type: Different metals have significantly different absorption rates for laser energy. For example, carbon steel and stainless steel absorb laser energy more efficiently, resulting in deeper welds. Highly reflective materials like aluminum and copper, on the other hand, tend to produce wider, shallower welds.

- Surface Condition: A clean, oxide-free surface absorbs laser energy more efficiently, creating a wider aspect ratio. Oxides, oil, or impurities on the surface can cause energy reflection or scattering, reducing penetration and resulting in shallower, wider welds, impacting weld consistency.

Welding speed and direction

- Welding speed: Welding speed directly determines heat input. A slower speed means heat retention time, increasing penetration, and improving the aspect ratio. Conversely, a faster welding speed reduces penetration, resulting in a shallower weld and a lower aspect ratio.

- Direction and Method: Straight welding results in a narrow weld and a higher aspect ratio. Welding with oscillation or multi-pass welding effectively increases weld width, thereby reducing the aspect ratio and creating a smoother, more aesthetically pleasing weld.

Generally speaking, the aspect ratio is significantly affected by three factors: laser parameters, material properties, and welding speed and method. If the aspect ratio is too high, central cracks may form in the weld; if the aspect ratio is too low, surface cracks or fatigue performance degradation may occur. Therefore, in practical applications, companies need to flexibly adjust laser power, focal position, spot size, and welding speed according to different workpieces and materials to achieve the optimal balance between weld strength, aesthetics, and stability.

The importance of optimizing weld penetration and depth-to-width ratio

In production practice, weld geometry not only impacts short-term assembly pass rates but also determines long-term structural safety and service life. For companies using laser welding machines, optimizing weld penetration and depth-to-width ratio is essential for ensuring weld strength and reliability, while also reducing post-processing costs and improving product appearance and market competitiveness. This section will detail the specific impacts of these two factors on weld quality and appearance, and identify common optimization strategies.

Welding quality and mechanical properties

- Load-bearing capacity and strength: Sufficient weld penetration ensures a complete metallurgical bond between the weld and the parent material, avoiding failure modes such as incomplete penetration or cold welds, thereby ensuring the static load strength and load-bearing capacity of the joint.

- Fatigue performance and crack resistance: The aspect ratio affects the stress gradient within the weld and the defect sensitivity of the weld joint. Generally speaking, a reasonable aspect ratio helps distribute stress concentrations over a larger volume, reducing the stress concentration factor and thus improving fatigue life. However, excessively low or high aspect ratios can increase the susceptibility of the weld to crack initiation under cyclic loading.

- Residual stress and deformation control: Deep and narrow welds or shallow and wide welds generate thermal cycling and cooling gradients in different ways, affecting the residual stress distribution and workpiece deformation. By controlling the depth of penetration and aspect ratio, the heat-affected zone can be reduced, deformation can be minimized, and assembly rework and subsequent corrective steps can be reduced. Sealing and corrosion resistance: For joints that require airtight or liquid-tight performance (such as pressure vessels and pipeline connections), appropriate penetration depth can avoid leakage risks caused by incomplete root welding; at the same time, uniform weld morphology is also conducive to the adhesion of coatings or anti-corrosion treatments, thereby improving service life.

Aesthetics and surface finish

- Weld Appearance: Laser welding machines are renowned for their narrow, smooth weld appearance. Their excellent depth-to-width ratio produces smooth welds with minimal ridges, reducing the need for manual grinding or leveling.

- Spatter and Defect Control: Excessive penetration or keyhole instability can cause surface defects such as spatter, porosity, or depressions; insufficient penetration can result in depressions, incomplete penetration, or an irregular weld profile. By optimizing parameters to stabilize the weld pool, the incidence of surface defects can be significantly reduced.

- Post-Processing and Cost Savings: When weld morphology is controlled (with an appropriate depth-to-width ratio and moderate weld ridge), the need for subsequent grinding, polishing, or touch-up welding is significantly reduced, thereby reducing labor costs and production cycle time, and improving product consistency.

In summary, optimizing weld penetration and depth-to-width ratio isn’t just about improving a single metric; it involves systematic process adjustments to achieve a balance between strength, fatigue performance, deformation control, and surface aesthetics. For manufacturers using laser welding machines, scientifically controlling these two key parameters not only ensures weld reliability but also significantly reduces post-processing costs and enhances product competitiveness.

Desafios e Soluções

In actual production, even with advanced laser welding machines, challenges that affect weld quality are inevitable. This is particularly true when controlling weld penetration and aspect ratio. Minor changes in the external environment, material differences, and process conditions can all lead to various weld defects. Therefore, recognizing these issues and developing appropriate solutions is crucial to ensuring weld stability and consistency.

Common Challenges

During the production process, weld penetration and depth-to-width ratio are easily affected by the following factors:

- Laser power fluctuations: This can lead to an unstable melt pool and uneven penetration depth.

- Material variations: Highly reflective or highly thermally conductive metals (such as aluminum and copper) are difficult to penetrate, while ultra-thin materials can easily burn through.

- Inadequate assembly precision: Excessive gaps or misalignment can reduce energy utilization, resulting in incomplete fusion or weld defects.

- Environmental interference: Spatter, porosity, and surface oxidation are often caused by improper shielding gas control or an unstable melt pool.

Solução

To address these challenges, the following measures can be taken:

- Enhance pretreatment: Clean oxide layers, oil stains, and rust to improve laser energy absorption.

- Optimize shielding gas: Rationally control the flow rate and spray pattern to avoid plasma interference and reduce surface oxidation.

- Improve assembly accuracy: Use high-precision fixtures to ensure tight joints and reduce the risk of welding defects.

- Optimize beam control: Improve weld pool stability and weld formation through beam oscillation or dual-beam shaping.

- Apply intelligent monitoring: Introduce real-time monitoring and adaptive control systems to dynamically adjust welding parameters based on actual conditions, ensuring consistent welding quality.

Overall, while controlling weld penetration and aspect ratio presents challenges, the welding defect rate can be significantly reduced through appropriate process optimization and auxiliary measures. For companies, the key lies in controlling the entire chain of “material preparation – process execution – quality monitoring” to improve the overall reliability and consistency of laser welding.

Resumir

Weld penetration and aspect ratio are core metrics for measuring weld quality in laser welding. They not only determine the strength and reliability of the weld joint but also directly impact its durability and appearance. Sufficient penetration ensures complete penetration of the base metal, resulting in higher joint strength and fatigue resistance. A reasonable aspect ratio helps the weld withstand external stresses, preventing defects such as cracks and porosity, while also ensuring a smoother weld profile and a more aesthetically pleasing appearance. Therefore, mastering and optimizing these two parameters is crucial for modern manufacturers to improve product performance and appearance.

In practice, controlling penetration and aspect ratio requires comprehensive consideration of multiple process parameters. Laser power, focal position, and spot size are the most direct influencing factors: higher power results in greater penetration; a more precise focus results in more concentrated energy; and a smaller spot size results in greater weld depth and stability. Furthermore, welding speed plays a key role. Slower speeds allow for longer heat retention, promoting deeper penetration. However, faster speeds can result in shallower welds or even incomplete penetration. At the same time, joint design and assembly methods are also crucial. Excessive joint gaps or improper joint geometry can impair heat transfer, altering the weld’s aspect ratio and overall appearance.

By comprehensively managing these key factors, it’s possible to maintain both mechanical properties and aesthetics. For example, in applications requiring high strength and durability, the focus should be on increasing penetration while maintaining a reasonable aspect ratio. Where aesthetically pleasing welds are crucial, surface flatness and smoothness should be considered. Ultimately, optimizing weld penetration and aspect ratio can help manufacturers achieve welds that are both durable and aesthetically pleasing, laying the foundation for their products to stand out in the market.

Obtenha soluções a laser

As a professional laser solutions provider, Laser AccTek is committed to providing customers with efficient and reliable laser welding machines and comprehensive technical support. We understand the importance of weld penetration and aspect ratio in weld quality. Therefore, we continuously optimize equipment performance and process solutions to help companies precisely control key welding parameters for diverse materials, thicknesses, and welding scenarios. Leveraging advanced optical systems and intelligent control technology, AccTek Laser equipment achieves high-precision welding while maintaining both mechanical strength and aesthetic quality.

In actual production, customers require not only stable hardware support but also process guidance and application services tailored to their specific needs. AccTek Laser provides comprehensive services, from initial process evaluation to subsequent production optimization, ensuring every customer receives the optimal welding solution. Whether welding high-strength structural components or precision manufacturing with stringent aesthetic requirements, We offers reliable solutions. If you encounter challenges in your welding process or would like to further improve production efficiency and weld quality, please feel free to Contate-nos. We will provide professional support and opportunities for collaboration.

Informações de contato

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zona A, Zona Industrial de Lunzhen, Cidade de Yucheng, Província de Shandong.

Obtenha soluções a laser