Que precauções devem ser tomadas durante a limpeza a laser?

Laser cleaning technology, with its high efficiency, non-contact nature, and high precision, offers significant advantages in removing rust, oil, and coatings from metals. As an advanced laser surface treatment method, máquinas de limpeza a laser have been widely used in industry and manufacturing. However, the laser cleaning process carries potential safety hazards that warrant careful attention. This article will briefly introduce the advantages of laser cleaning technology and emphasize the importance of taking effective measures to mitigate potential risks during use.

Índice

Understanding Laser Cleaning and Its Risks

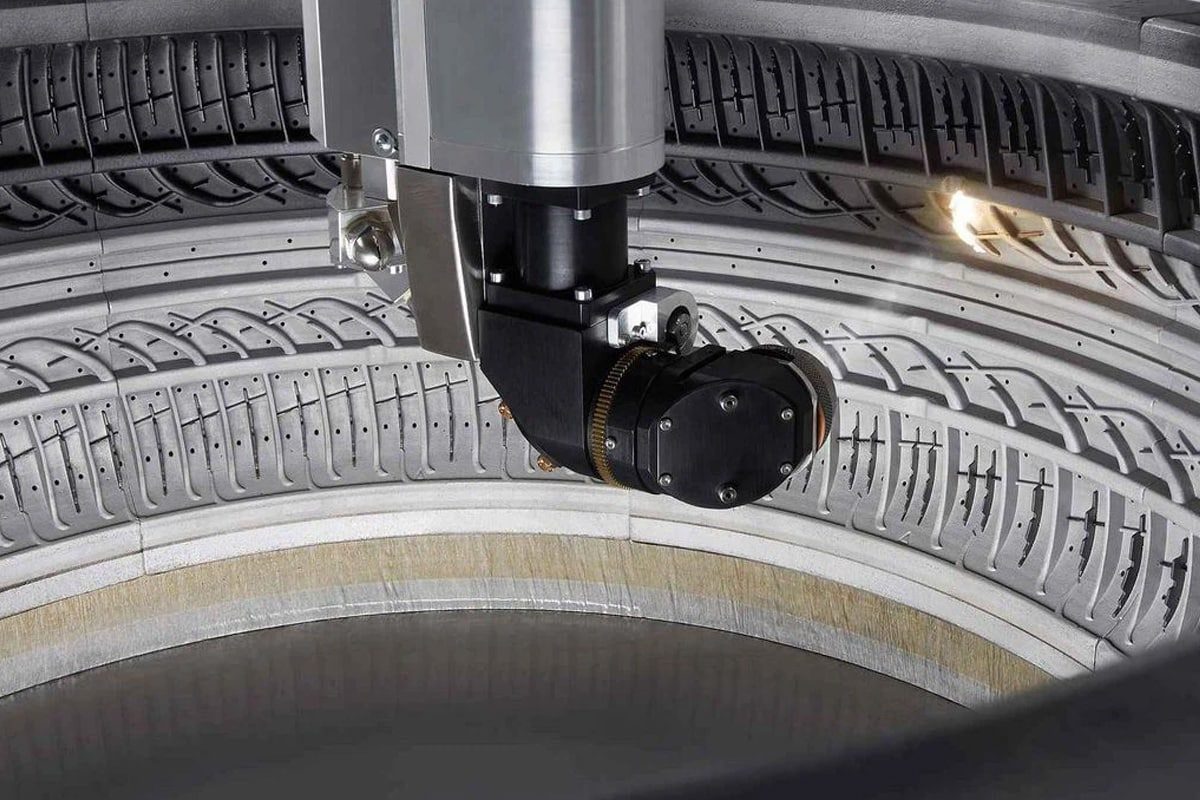

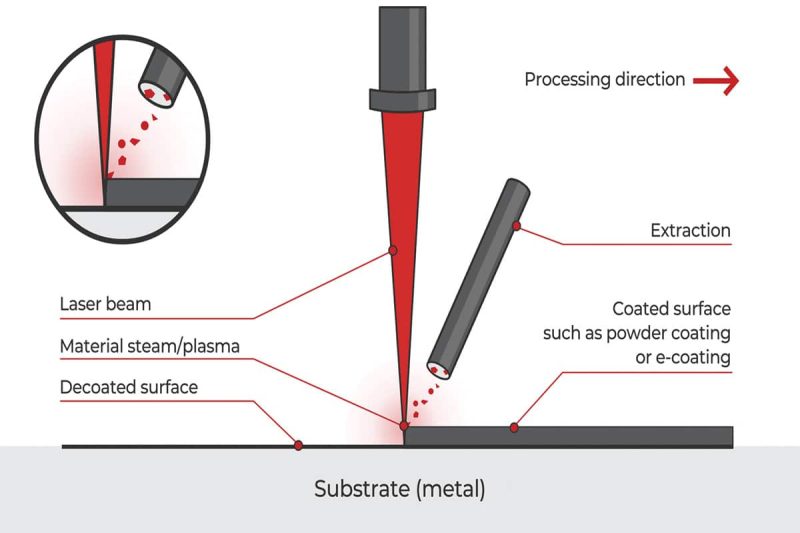

Laser cleaning uses a high-energy laser beam to remove surface contaminants. The laser beam interacts with the surface material, removing rust, paint, and other materials through vaporization or ablation. Compared to traditional chemical cleaning or mechanical sandblasting, laser cleaning offers advantages such as non-contact, non-damaging, and zero chemical contamination. It is widely used in applications such as laser rust removal and surface preparation. Typical applications include metal rust removal, pre-weld cleaning, preservation of historic buildings, and precision mold cleaning.

Although laser cleaning provides efficient cleaning results, improper operation or insufficient protection may lead to several hazards:

- Eye and Skin Damage: Laser beams have extremely high energy density. Direct exposure to the eye may penetrate the cornea and lens, causing permanent damage to the retina. Exposure to the skin may cause burns. It is important to note that even the reflected laser beam can cause damage to the human body. Therefore, laser-protective goggles and protective clothing appropriate for the wavelength must be worn during operation.

- Fume and Particle Hazards: During the cleaning process, the removed coatings, rust, or oil stains generate large amounts of smoke and fine particles. These fumes may contain hazardous substances (such as metal vapor and oxides) and are harmful to the respiratory system if inhaled. Furthermore, concentrated dust poses a flammability risk and must be controlled.

- Fire and Explosion Risk: High-power laser beams can ignite flammable materials (such as oil, paint, and paper), causing fires. Laser exposure in the presence of flammable vapors or dust can cause explosions. Therefore, the cleaning site should be kept away from flammable and explosive materials and equipped with necessary firefighting equipment.

- Electrical Safety Hazards: Laser cleaning machines typically require high-voltage power supplies and contain complex electronic components. During maintenance or troubleshooting, failure to disconnect the power supply or improper operation can easily cause electrical accidents such as electric shock. All equipment must be reliably grounded and have overload protection.

- Other mechanical hazards: Cleaning equipment may contain high-speed rotating parts or moving machinery. Be aware of the risk of mechanical injury during maintenance.

Laser cleaning, as a highly effective rust removal and surface treatment technology, offers irreplaceable advantages in industrial production. However, due to the unique properties of lasers, potential safety hazards during use cannot be ignored. Understanding these potential risks is a prerequisite for taking effective protective measures.

Precauções de segurança

To ensure the safety of the laser cleaning process, a comprehensive set of safety precautions must be implemented. This not only protects the health of the operator but also ensures stable operation of the equipment and a safe environment. The following describes the main categories of safety measures.

Equipamento de Proteção Individual (EPI)

- Laser protective glasses: Choose appropriate protective glasses based on the laser wavelength and power level to protect your eyes from direct or scattered laser light.

- Protective clothing and gloves: Wear flame-retardant work clothing and insulated, heat-resistant gloves to reduce the risk of skin contact with laser light, hot powder, or fumes.

- Dust mask: When working in fume-intensive environments, use an effective dust mask or filter to reduce the inhalation of harmful particulate matter.

Laser protection mechanism

- Safety access control and interlocking: Install a laser-protective door or safety fence in the workspace, equipped with an interlocking system, to automatically shut off laser output if the door is opened or an abnormal situation occurs, preventing laser leakage.

- Warning signs and indicators: Post clear hazard warning signs in the laser cleaning area, and install laser operating indicators to keep non-operating personnel informed of the work status and prevent accidental entry.

- Emergency stop device: The equipment should be equipped with an easily accessible emergency stop button to quickly shut off laser output and power in the event of an abnormality.

Ventilation and smoke exhaust systems

- Efficient fume exhaust equipment: Install local exhaust hoods and ducts equipped with filters or purification equipment to effectively remove fumes and harmful particles generated during the cleaning process, maintaining a clean work environment.

- Air purification equipment: Use an air purification system or oil mist filter when necessary to reduce the impact of metal fumes on workshop air quality.

Firefighting facilities

- Firefighting Equipment: Deploy appropriate fire extinguishers, such as dry powder and carbon dioxide, based on the potential fire types on site, and regularly check their effectiveness.

- Do not use water to extinguish fires: Since laser cleaning often involves metal and electrical components, avoid using water directly to extinguish fires. Instead, cover the fire source with dry powder or dry sand to block oxygen.

- Isolate the cleaning area: Keep access to and from the cleaning area clear. Avoid storing flammable materials and isolate the fire source from combustible materials.

Electrical safety

- Professional Installation and Grounding: The laser cleaning machine must be installed by a professional. Ensure all electrical components are properly grounded and that wiring complies with safety regulations.

- Regular Inspection: Regularly inspect cables, connectors, and control panels, and replace any damaged or deteriorated components.

- Power-off Lockout Procedure: Perform a power-off lockout procedure before maintenance or repair to prevent accidental electric shock and inadvertent startup.

By wearing appropriate personal protective equipment, using adequate safety precautions and firefighting equipment, and taking strict electrical safety measures, you can minimize the risks involved in laser cleaning operations. These precautions together form a safety protection system that is key to ensuring safe operations.

Operational precautions

In addition to hardware and equipment safety, operational risk control is equally important. Standardized operating procedures and training can further reduce the probability of accidents and improve the efficiency and safety of laser cleaning work.

- Operator Training and Certification: All users of laser cleaning equipment must undergo professional training and obtain the appropriate qualifications. They must be familiar with the equipment’s operating principles, safety regulations, and emergency response procedures. Operators must understand the laser system’s user manual and safety manual, and master correct operating procedures and personal protective equipment requirements.

- Equipment Setup and Calibration: Before each use, the laser power, spot parameters, and scanning speed should be appropriately set based on the material type and cleaning requirements. A no-load test should be performed to calibrate the optical path and align the workpiece to ensure that the laser beam accurately illuminates the target surface. Avoid blindly increasing the power under unknown conditions.

- Process Monitoring: The equipment status and operating environment should be continuously monitored during the laser cleaning process. Cleaning results can be observed through cameras or on-site supervision to promptly detect abnormal smoke concentrations or sparks. Ensure that the emergency stop device is always operational to immediately terminate laser output in the event of a hazard.

- Emergency Procedures: Develop and practice emergency response plans for fire, excessive smoke, equipment failure, and personal injury. Regular drills should be conducted to ensure that every operator is familiar with emergency procedures, such as firefighting, first aid, and incident reporting.

Strictly adhering to operating procedures, regular training and assessment, and good on-site monitoring and emergency preparedness are important measures to reduce human errors and accidents. Operational prevention and equipment prevention complement each other to ensure the safe operation of laser cleaning machines.

Maintenance precautions

Maintenance is the basis for ensuring the long-term safe and stable operation of laser cleaning equipment. Regular inspection and maintenance can detect potential faults in advance and prevent them from escalating into safety accidents.

- Daily Inspection: Before each day’s operation, inspect the laser cleaning machine’s condition, including the optical path components, cooling system, and fasteners. Clean dust and dirt from the optical surfaces to maintain a clean beam path.

- Maintenance of Key Components: Regularly maintain key components such as the laser, cooling pump, fan, and circuit board according to manufacturer recommendations, replacing consumable parts such as seals and filters. Ensure the laser source and optical components are in proper working order.

- Software Updates and Backups: Timely updates to the device’s control software and firmware to patch known vulnerabilities and improve system performance. Regularly back up key configurations and parameters to prevent software failures from causing operational anomalies.

- Maintenance Records: Develop detailed maintenance and repair records, documenting every inspection, replacement, and troubleshooting. This not only helps track the device’s condition but also provides reference data for future safety improvements.

Through strict maintenance and record management, the possibility of mechanical failure and safety accidents can be significantly reduced. Maintenance preventive measures ensure that the equipment is always in good condition, providing long-term and stable safety guarantees for the laser cleaning process.

Considerações ambientais

Laser cleaning operations have a certain impact on the surrounding environment. Reasonable consideration of environmental factors not only helps protect the health of operators but also complies with relevant laws and regulations and enhances the corporate social responsibility image.

- Fume and Pollutant Management: Treating and filtering fumes and hazardous substances generated during the cleaning process is crucial. Use high-efficiency filtration and adsorption devices to separate metal vapor and fine particles from exhaust gas to prevent air pollution. Waste residue and chemicals generated should be safely disposed of by environmental regulations.

- Energy Saving and Efficiency: Laser cleaning equipment consumes a lot of energy. Using energy-saving lasers and intelligent control systems to optimize cleaning process parameters can reduce energy waste. Scheduling equipment startup and shutdown to avoid extended periods of idle operation is also part of the energy-saving measures.

- Regulatory Compliance: Different regions have strict regulations regarding industrial emissions, noise, and laser equipment. Companies should be aware of and comply with local environmental, fire, and electrical safety standards to ensure their laser cleaning systems meet all regulatory requirements and pass relevant certification testing.

Incorporating environmental protection, energy conservation, and compliance requirements into laser cleaning operation management can further enhance corporate image and avoid legal risks. Comprehensive environmental management measures provide strong support for the sustainable use of laser cleaning machines.

Resumir

Laser cleaning technology, as an efficient, environmentally friendly, and precise surface treatment and rust removal solution, is becoming a vital tool in industrial production. To maximize the benefits of laser cleaning machines, it’s crucial to thoroughly understand and carefully mitigate their potential risks. A comprehensive safety and prevention system—including multi-faceted processes such as operating procedures, precise training, meticulous maintenance, and strict environmental regulations—can ensure efficient, safe, and stable operation of laser cleaning machines in a variety of industrial scenarios, thereby creating greater production value and economic benefits for businesses.

- High-precision, pollution-free cleaning: Chemical-free and abrasive-free, it’s suitable for surface treatment of a variety of materials, including metals, plastics, and ceramics.

- High performance and energy efficiency: A variety of power options accommodate light to heavy-duty cleaning tasks while reducing energy consumption and maintenance costs.

- Superior quality and long-term value: Utilizing high-quality components and rigorous assembly processes, we ensure stable performance, long life, and easy maintenance.

Contact us for equipment selection. We offer free consultations, sample testing, customized solutions, and user training, ensuring our equipment perfectly matches your workflow and industry needs.

Whatever your cleaning challenge—from automotive, aerospace, manufacturing, to cultural relic restoration—Laser AccTek can provide you with reliable, safe, and efficient laser cleaning solutions. Contate-nos today to begin your laser cleaning upgrade journey and work together towards an efficient, green, and intelligent future.

Informações de contato

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zona A, Zona Industrial de Lunzhen, Cidade de Yucheng, Província de Shandong.

Obtenha soluções a laser