How Laser Cutting Improves Overall Efficiency and Productivity in Manufacturing Processes

In the context of increasingly fierce global manufacturing competition, companies are facing unprecedented cost pressures, delivery pressures, and technological upgrade challenges. The market demand for high-efficiency, high-precision, and low-cost production methods continues to rise, and the limitations of traditional processing techniques in terms of speed, accuracy, and flexibility are becoming increasingly apparent. Especially in industries with extremely high demands on processing quality, such as metal processing, machinery manufacturing, automotive parts, and aerospace, manufacturing companies urgently need an advanced cutting solution that can both increase capacity and ensure processing consistency.

It is against this industry backdrop that laser cutting technology has rapidly emerged and gradually replaced some traditional cutting methods, becoming one of the core processes in modern manufacturing systems. With its non-contact processing, high-precision cutting, high degree of automation, and excellent material adaptability, laser cutting not only significantly improves production efficiency and processing quality but also provides a technological foundation for flexible production and rapid response to market demands. More and more manufacturing companies are beginning to regard laser cutting as a key tool for improving overall productivity, optimizing manufacturing processes, and enhancing global competitiveness.

İçindekiler

Lazer Kesim Teknolojisini Anlamak

In modern manufacturing systems, laser cutting is no longer just a single processing technique, but a core manufacturing technology that integrates high precision, high efficiency, and high flexibility. With the continuous development of laser technology, CNC systems, and automation levels, laser cutting is profoundly changing the production model of metal processing and mechanical manufacturing. Understanding the technical advantages of laser cutting in terms of precision, functionality, efficiency, and cost helps manufacturing companies more comprehensively evaluate its practical value in improving productivity and competitiveness.

Precision and Accuracy of Laser Cutting

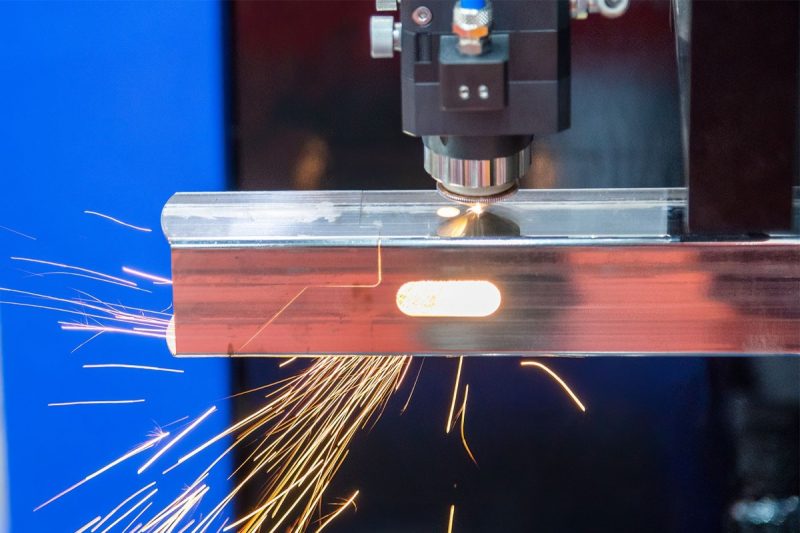

Laser cutting technology, with its superior processing precision and dimensional accuracy, has become the preferred solution for high-precision cutting in modern manufacturing. Through the precise focusing of a high-energy-density laser beam, laser cutting can complete the processing of complex contours and fine structures within a very small cutting area, resulting in narrow kerfs, smooth edges, and high repeatability. The entire cutting process is controlled by a CNC system, effectively avoiding human error and ensuring high consistency in size, tolerance, and shape for each workpiece. This stable and reliable precision is particularly important for metal processing, mechanical manufacturing, automotive parts, and aerospace industries with strict quality requirements.

Versatility of Laser Cutting

Laser cutting possesses excellent process flexibility and material adaptability, and can be widely applied to the processing needs of various metal materials and different thicknesses. By adjusting laser power, cutting speed, and auxiliary gas parameters, the same Lazer kesme makinesi can complete the cutting tasks of various materials such as karbon çeliği, paslanmaz çelik, Ve alüminyum alloys, without frequent tool or mold changes. In addition, laser cutting supports the rapid processing of complex geometric shapes, irregular structures, and personalized designs, giving it a significant advantage in multi-variety, small-batch, and customized production, providing manufacturing companies with greater production flexibility.

Speed and Efficiency of Laser Cutting

In terms of processing efficiency, laser cutting technology demonstrates significant advantages. With the maturity of fiber laser technology, high-power laser cutting machines can achieve high-speed operation while ensuring cutting quality, significantly shortening the processing time per piece. Laser cutting is a non-contact processing method, requiring no tool changes or complex adjustments, reducing equipment downtime and helping to improve overall equipment utilization. This high-speed, high-stability processing characteristic makes laser cutting particularly suitable for continuous production and batch order processing, effectively improving the overall production rhythm of manufacturing companies.

Cost-Effectiveness of Laser Cutting

From a long-term operational perspective, laser cutting offers excellent overall cost-effectiveness. Although the initial investment in laser cutting equipment is relatively high, its advantages in material utilization, labor costs, and maintenance costs are significant. High-precision cutting reduces material waste and rework rates, while a high degree of automation reduces reliance on manual labor. Furthermore, modern laser cutting machines are highly energy-efficient, operate stably, and have long maintenance cycles, resulting in continuously decreasing unit processing costs over the equipment’s lifespan. For manufacturing companies aiming for large-scale, standardized production, laser cutting is a manufacturing technology with long-term investment value.

Overall, laser cutting technology offers a highly synergistic set of advantages in terms of precision, flexibility, processing efficiency, and cost control. It not only meets the current manufacturing industry’s demand for high-quality, high-efficiency production but also lays a solid foundation for automation and intelligent manufacturing. For this reason, more and more manufacturing companies are adopting laser cutting as a core processing method, driving continuous upgrades in their overall production processes and manufacturing capabilities.

Improving Manufacturing Efficiency Through Laser Cutting

In the modern manufacturing environment, efficiency is not only reflected in the processing speed of a single process but also in the degree of coordination and responsiveness of the overall production process. Laser cutting technology, with its high degree of automation, digital control, and process flexibility, is becoming an important tool for manufacturing companies to optimize production processes, shorten delivery cycles, and improve operational efficiency. By introducing laser cutting in several key stages, companies can build a more efficient, stable, and resilient manufacturing system.

Laser Cutting Simplifies Production Processes

Laser cutting can highly integrate multiple independent steps in traditional processing, significantly simplifying the production process. Due to its high cutting accuracy and excellent edge quality, many parts can directly enter subsequent assembly or welding processes after cutting, reducing the need for secondary processing such as grinding and finishing. At the same time, laser cutting eliminates the need for frequent tool or mold changes, reducing equipment debugging and line changeover time, making the production process smoother and more efficient, and helping to shorten the overall manufacturing cycle.

Laser Cutting Supports Rapid Prototyping and Iterative Design

In the product development and engineering design stages, laser cutting provides great convenience for rapid prototyping. By directly reading CAD/CAM design files, laser cutting machines can complete sample processing in a very short time, allowing design teams to quickly verify structure, dimensions, and assembly effects. When design adjustments are needed, the next round of cutting can be performed immediately by simply modifying the program, without additional mold investment. This efficient iterative capability significantly shortens the product development cycle and improves the company’s responsiveness to market changes.

Laser Cutting Facilitates Just-in-Time Production

The high stability and predictability of laser cutting make it ideal for just-in-time production models. Through precise production planning and stable cutting quality, companies can flexibly arrange production according to order requirements, reducing inventory accumulation and capital tie-up. The rapid start-up and high repeatability of laser cutting equipment also make the handling of temporary or urgent orders more efficient, thereby improving the overall production plan execution capability.

Laser Cutting Enables Customized and Personalized Production

With the increasing market demand for customized products, the value of laser cutting in flexible manufacturing is becoming increasingly prominent. Laser cutting does not rely on fixed molds and can easily handle the processing requirements of different sizes, shapes, and designs. This allows manufacturing companies to achieve small-batch, multi-variety, and even single-piece customized production without significantly increasing costs, providing customers with more differentiated and value-added products.

Laser Cutting Reduces Waste and Environmental Impact

Laser cutting, while improving efficiency, also contributes to more environmentally friendly manufacturing practices. Through intelligent layout and high-precision cutting, material utilization is significantly improved, reducing scrap and waste. At the same time, the laser cutting process is characterized by low noise, minimal dust, and controllable energy consumption, meeting the requirements of modern manufacturing for green production and sustainable development. This not only reduces production costs but also helps companies improve environmental compliance and brand image.

Overall, laser cutting systematically improves manufacturing efficiency on multiple levels through process simplification, accelerated R&D, optimized production planning, flexible manufacturing support, and enhanced environmental benefits. It not only improves the processing efficiency of individual processes but also optimizes the operation of the entire manufacturing process. For manufacturing companies that want to achieve efficient operations and rapid response in a highly competitive market, laser cutting has become an indispensable key technology for improving overall manufacturing efficiency.

Enhancing Production Capacity

As manufacturing companies continuously expand production capacity, respond to order fluctuations, and shorten delivery cycles, production capacity has become a crucial indicator of a company’s competitiveness. Laser cutting technology not only excels in single-piece processing efficiency but also demonstrates significant advantages in continuous operation, mass production, and automated collaboration. By rationally configuring laser cutting equipment and integrating it with automation systems, manufacturing companies can achieve continuous improvement in production capacity while ensuring stable quality.

High-Speed Cutting Capability of Laser Cutting

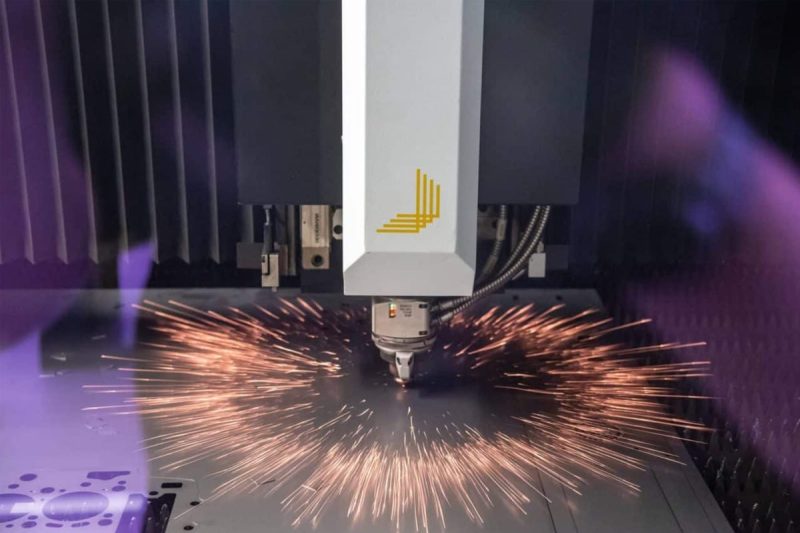

High-speed cutting is one of the core factors in improving production capacity with laser cutting. With the continuous advancement of fiber laser technology and motion control systems, modern laser cutting machines can achieve higher cutting speeds and shorter acceleration and deceleration times while maintaining high cutting quality. Especially in the field of thin metal sheet processing, high-speed laser cutting can significantly shorten the processing time per piece, improve the output efficiency per unit time of the equipment, and thus effectively increase overall production capacity.

Stable Performance of Laser Cutting in Batch Processing

In mass production scenarios, production capacity depends not only on speed but also on the stability and consistency of the processing process. Laser cutting precisely controls the cutting path and parameters through a CNC system, ensuring high consistency in size and quality for each workpiece, reducing rework and downtime caused by quality fluctuations. Furthermore, laser cutting equipment can operate continuously for extended periods, suitable for the stable processing needs of medium to large batch orders, providing reliable capacity assurance for manufacturing companies.

Deep Integration of Laser Cutting with Automation Systems

Another key advantage of laser cutting in improving production capacity is its high compatibility with automation systems. By integrating with automatic loading and unloading systems, robots, intelligent warehousing, and production management systems (such as MES), laser cutting machines can achieve a higher level of automated production. This automated integration not only reduces manual intervention and material waiting time but also significantly improves the overall operating efficiency of the production line, enabling manufacturing companies to achieve higher output with limited human resources.

In summary, laser cutting enhances the production capacity of manufacturing companies on multiple levels through high-speed cutting, stable batch processing capabilities, and deep integration with automation systems. It not only improves the processing efficiency of a single piece of equipment but also provides a technological foundation for building an efficient, continuous, and scalable production system. For manufacturing companies pursuing large-scale production and long-term capacity growth, laser cutting is undoubtedly an important support for achieving improved production capacity.

Improved Quality and Consistency

In modern manufacturing, product quality and processing consistency have become critical factors influencing customer satisfaction and brand reputation. Whether for mass production or customized processing, manufacturing companies need to ensure the stability and reliability of every product in terms of dimensions, appearance, and performance. Laser cutting technology, with its high-precision control and non-contact processing characteristics, provides a solid technical guarantee for improving cutting quality and maintaining processing consistency.

Clean, Burr-Free Cutting Results

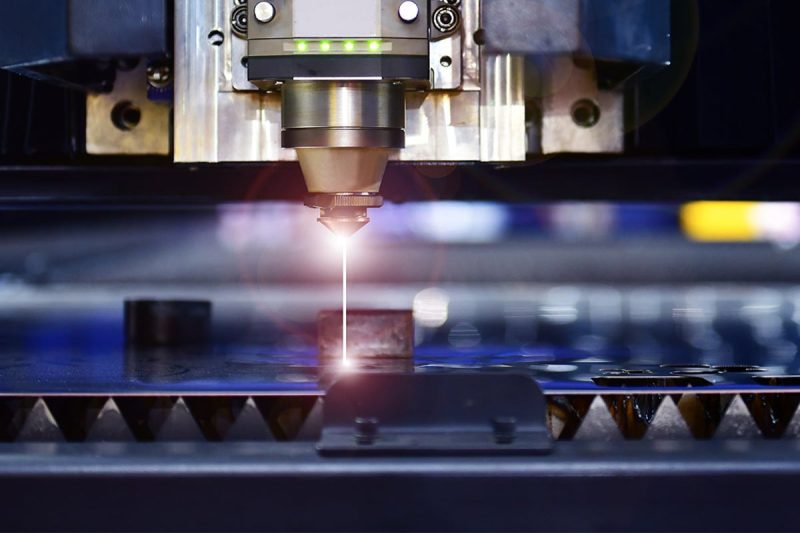

Laser cutting processes materials using a highly focused laser beam, resulting in a concentrated and controllable cutting process that produces smoother and more even cutting edges. Compared to traditional cutting methods, laser cutting significantly reduces the generation of burrs, slag, and irregular edges, allowing many workpieces to proceed directly to subsequent assembly or welding processes after cutting. This not only improves the aesthetic quality of the product but also reduces secondary processing steps such as grinding and deburring, thereby further improving overall manufacturing efficiency.

Reduced Risk of Material Deformation

Material deformation is a common problem affecting cutting quality and assembly accuracy. Laser cutting is a non-contact processing method with concentrated heat and short processing time, resulting in a relatively small heat-affected zone. This effectively reduces warping and stress deformation caused by uneven heating. This advantage of laser cutting is particularly evident in the processing of thin sheet metal and high-precision components, helping to ensure the dimensional stability of the workpiece during subsequent processing and use.

Kalite güvencesi

Laser cutting machines are precisely controlled by CNC systems, making processing parameters repeatable and traceable, thus making the production process more standardized and controllable. In mass production, laser cutting ensures that each workpiece is processed according to the same process parameters, reducing quality fluctuations caused by human error. This highly consistent processing result provides a reliable foundation for companies to implement quality management systems and meet international quality standards, and also helps to enhance customer trust in product stability.

Overall, laser cutting brings significant improvements in quality and consistency to manufacturing companies through clean, burr-free cutting results, minimized material deformation, and a stable and controllable processing process. It not only helps companies reduce rework rates and quality risks but also provides technical assurance for high-standard manufacturing and long-term stable delivery. For manufacturing companies pursuing high quality and high reliability, laser cutting has become one of the indispensable core processing technologies.

Maximizing Productivity Through Laser Cutting Automation

As manufacturing accelerates towards digitalization and intelligence, automation has become a crucial means of increasing productivity and maintaining a competitive edge. Laser cutting technology, inherently highly digital and integrable, has become one of the core pieces of equipment in automated manufacturing systems. By combining laser cutting with advanced control systems, automated equipment, and intelligent algorithms, manufacturing companies can reduce reliance on manual labor while achieving more stable, efficient, and sustainable production.

CNC Control and Programming

Modern laser cutting machines are typically equipped with advanced CNC control systems that precisely manage cutting paths, speed, power, and auxiliary gas parameters. Through standardized programming and parameter recall, the cutting process of complex parts can be quickly reproduced, reducing manual intervention and debugging time. Furthermore, CNC systems support seamless integration with CAD/CAM software, allowing design data to be directly converted into cutting programs, further improving production preparation efficiency and processing consistency.

Robot Integration and Material Handling

Integrating laser cutting machines with industrial robots and automatic loading and unloading systems is a key way to achieve efficient automated production. Robots can handle repetitive tasks such as sheet metal loading, finished product unloading, and workpiece transfer, reducing manual labor intensity and human error. This integration not only shortens equipment waiting times but also enables laser cutting to operate continuously for extended periods, significantly increasing the overall production line output.

Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning technologies are gradually being applied to the field of laser cutting to optimize cutting parameters and improve processing stability. By analyzing large amounts of production data, intelligent systems can automatically adjust cutting parameters to adapt to different materials and working conditions, thus maintaining stable cutting quality. At the same time, AI algorithms can be used to predict potential anomalies, helping companies take action before problems occur, further improving production efficiency and equipment reliability.

Remote Monitoring and Maintenance

Remote monitoring and predictive maintenance are important components of laser cutting automation. Through networked systems, manufacturing companies can monitor equipment operating status, energy consumption, and processing progress in real time, promptly identifying anomalies and making adjustments. Simultaneously, data-driven maintenance strategies help reduce unexpected failures and unplanned downtime, improving equipment utilization. This intelligent maintenance model not only reduces maintenance costs but also enhances the controllability of the production process.

In summary, through CNC control, robot integration, artificial intelligence optimization, and remote monitoring and maintenance, laser cutting automation drives continuous productivity improvements on multiple levels. It not only improves the processing efficiency of individual machines but also provides technical support for building an intelligent and scalable manufacturing system. For companies that want to maintain a leading position in future manufacturing competition, laser cutting automation has become a crucial path to achieving efficient production and intelligent upgrading.

Özet

In summary, laser cutting technology is no longer merely a substitute for traditional cutting methods, but rather a crucial strategic technology driving manufacturing companies towards improved efficiency, expanded capacity, stable quality, and intelligent upgrades. From high-precision processing to high-speed cutting, from flexible production to automated integration, laser cutting continuously delivers value at every critical stage of the manufacturing process, helping companies maintain a competitive edge in a complex and ever-changing market environment.

By introducing laser cutting technology, manufacturing companies can not only significantly simplify production processes and shorten delivery cycles, but also maintain stable processing quality and consistency even with the coexistence of mass production and customized demands. Simultaneously, with the continuous integration of CNC control, automation systems, and artificial intelligence technologies, laser cutting is becoming a core piece of equipment in intelligent manufacturing systems, laying a solid foundation for companies’ future digital upgrades.

As a manufacturer long focused on the research and development of laser cutting equipment and global market services, AccTek Lazer is committed to providing high-performance, high-reliability laser cutting solutions to customers in various industries. Whether it’s improving the efficiency of existing production lines or planning automated and intelligent production layouts, our laser cutting machines can meet stringent manufacturing requirements in terms of precision, efficiency, and stability, helping companies achieve sustainable growth.

In the context of the ongoing upgrading trend in the manufacturing industry, choosing the right laser cutting solution has become a crucial step for companies to improve productivity and long-term competitiveness. AccTek Laser will continue to support global customers in moving towards a more efficient and intelligent manufacturing future with mature technology and professional services.

İletişim bilgileri

- [email protected]

- [email protected]

- +86-19963414011

- 3 Bölge A, Lunzhen Sanayi Bölgesi, Yucheng Şehri, Shandong Eyaleti.

Lazer Çözümleri Alın