Lazer Kesim Makinesi Satın Almadan Önce Dikkat Edilmesi Gerekenler

Modern imalatta, lazer kesim makineleri have become indispensable tools across industries such as metal fabrication, signage production, home decoration, electronics, and precision component processing. Compared with traditional cutting methods, laser cutting technology offers non-contact operation, smooth cutting edges, minimal heat-affected zones, and reduced material waste—significantly improving both production efficiency and product quality. As automation and smart manufacturing continue to advance, more companies are investing in laser cutting equipment to handle complex tasks while reducing labor costs and ensuring consistent quality.

Whether it’s a fiber lazer kesim makinesi designed for high-precision metal sheet cutting or a CO2 lazer kesim makinesi suitable for non-metal and thin material processing, selecting the right equipment directly affects production cost, accuracy, and long-term maintenance. Each model and power configuration differs in performance, material compatibility, and application range. This article serves as a comprehensive laser cutting machine buying guide, providing insights into the key factors you should consider before making a purchase—helping you make a more informed and strategic investment decision for your manufacturing needs.

İçindekiler

Understanding Laser Cutting Machines

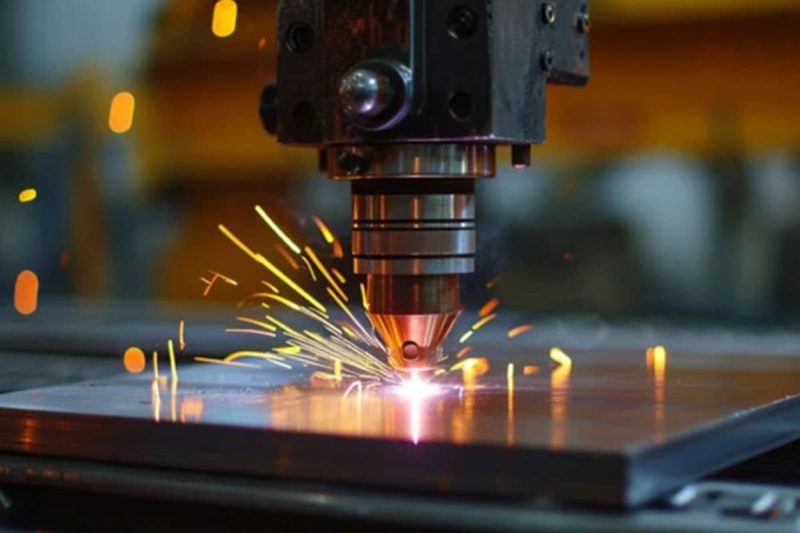

A laser cutting machine is an advanced processing device that uses a high-energy-density laser beam to irradiate a workpiece, causing the material to melt, evaporate, or burn rapidly, thus achieving high-precision separation. Compared with traditional mechanical or plasma cutting, laser cutting technology has advantages such as high cutting precision, high speed, high automation, fine kerf, and minimal thermal deformation. Depending on the type of laser generator and the application field, the mainstream laser cutting machines on the market are mainly divided into two categories: fiber laser cutting machines and CO2 laser cutting machines.

Fiber Lazer Kesim Makinesi

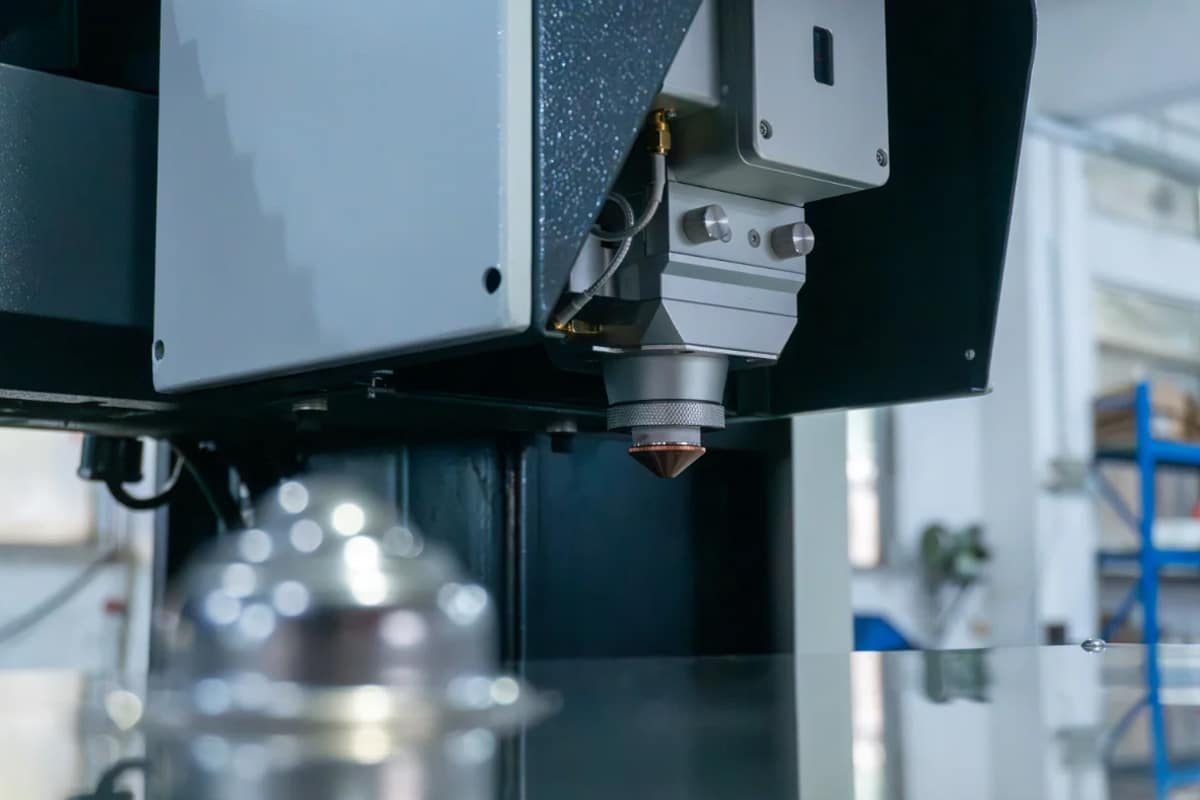

Technical Principle

Fiber laser cutting machines use a fiber laser generator as the light source. A high-density laser beam is transmitted through an optical fiber and focused onto the workpiece surface by a focusing lens, causing the material to melt or vaporize instantly. Subsequently, an auxiliary gas (such as oxygen, nitrogen, or air) blows away the molten slag, achieving high-speed, high-precision cutting.

Main Advantages

- High Cutting Efficiency: Fiber laser generators have extremely high photoelectric conversion efficiency, achieving cutting speeds 2-3 times faster than CO2 lasers.

- Low Operating Costs: No laser gas is required, there is no reflector structure, maintenance is simple, and energy consumption is low.

- Superior Cutting Quality: Smooth kerf, requiring no post-processing grinding, making it particularly suitable for precision parts manufacturing.

- High Stability: Fiber laser generators have a compact structure, good shock resistance, and high long-term operational stability.

- Wide Applicability: Especially suitable for metallic materials, including paslanmaz çelik, karbon çeliği, bakır, alüminyum, Ve galvanizli

Potential Disadvantages

Fiber laser cutting machines have limited processing effects on non-metallic materials (such as wood, acrylic, and plastics); additionally, the initial purchase cost is relatively high, posing a significant investment barrier for small processing enterprises.

Typical Application Scenarios

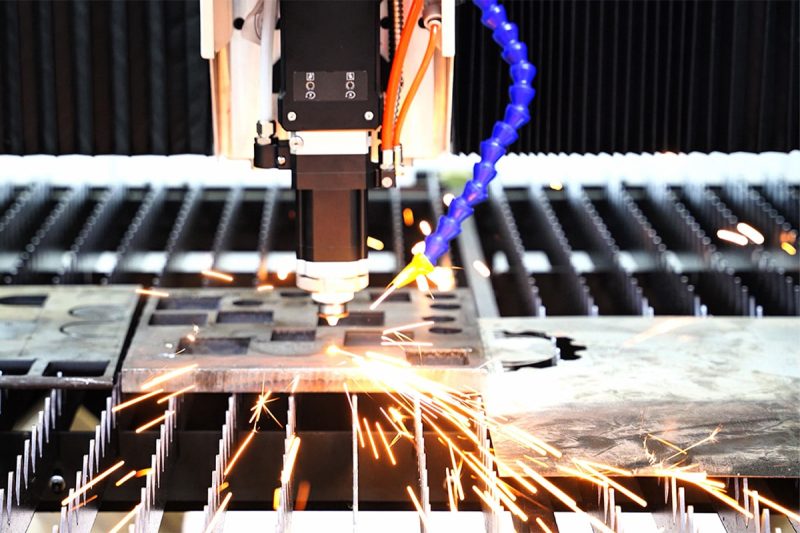

Fiber laser cutting machines are widely used in metal product processing, sheet metal manufacturing, automotive parts, kitchen equipment, machinery manufacturing, and aerospace fields, and are the mainstay equipment for metal cutting in modern industry.

CO2 Lazer Kesim Makinesi

CO2 Laser Cutting Machine Technical Principle

CO2 laser cutting machines use carbon dioxide gas as the working medium, generating a continuous laser beam through electrical excitation. The laser is guided to the cutting head by a reflector and then focused onto the material surface by a focusing lens to complete the cutting. Unlike fiber lasers, CO2 laser cutting is a gas laser cutting method with a softer beam quality, suitable for processing non-metallic materials.

Key Advantages

- High Material Adaptability: Can cut odun, akrilik, plexiglass, kumaş, leather, paper, and some thin metals.

- Smooth Cutting Edges: Uniform laser heat distribution results in a smooth, burr-free cut surface.

- Flexible Shaping: Capable of cutting complex shapes and curves, suitable for industries such as decoration, advertising, and art production.

- Easy Operation: With an automatic control system, batch processing of non-metallic materials can be easily completed.

Potential Disadvantages

CO2 laser cutting machines have low photoelectric conversion efficiency (approximately 10%) and high power consumption; they also require frequent maintenance and have a complex optical path system, necessitating regular replacement of reflectors and laser tubes. Cutting efficiency is low for thick metal sheets, making them unsuitable for heavy industrial metal processing.

Typical Applications

CO2 laser cutting machines are widely used in advertising signage, architectural decoration, arts and crafts, furniture manufacturing, and packaging industries, making them the preferred equipment for non-metallic material processing.

When selecting laser cutting equipment, companies need to comprehensively consider their processing materials, cutting thickness, budget, and production scale: if the main processing is of metal sheets, a fiber laser cutting machine is recommended; if non-metallic or composite material processing is involved, a CO2 laser cutting machine offers better value for money. Furthermore, the brand of the equipment, after-sales service, system compatibility, and long-term operating costs should also be considered to ensure stable and efficient operation.

Key Factors to Consider Before Buying a Laser Cutting Machine

Purchasing a laser cutting machine is a significant investment decision, impacting not only the equipment’s cost but also a company’s production efficiency, processing quality, and long-term operating expenses. Whether you’re considering a fiber laser cutting machine or a CO2 laser cutting machine, the following key factors deserve careful consideration before placing an order.

Bütçe Hususları

Laser cutting machine prices vary considerably, ranging from small models costing a few thousand dollars to high-powered industrial equipment costing hundreds of thousands of dollars. When planning your budget, companies should consider not only the initial purchase cost but also long-term operating costs, including:

- Consumables: Fiber laser generators have virtually no consumables, while CO2 lasers require regular replacement of the laser tube and reflector.

- Power Consumption: Fiber laser generators have high photoelectric conversion efficiency (over 30%) and lower energy consumption.

- Maintenance Costs: High-end models typically feature automatic diagnostics and remote maintenance capabilities, reducing maintenance frequency.

A reasonable budgeting strategy should strike a balance between performance and cost, while reserving funds for training, spare parts, and future upgrades.

Malzeme Uyumluluğu

Different types of laser cutting machines have their own advantages for different materials:

- Fiber laser cutting machines: Suitable for cutting metallic materials such as carbon steel, stainless steel, copper, aluminum, and galvanized sheet.

- CO2 laser cutting machines: More suitable for non-metallic materials such as wood, acrylic, plexiglass, leather, and fabric.

When selecting a model, it is essential to clearly define the main types and thicknesses of the materials to be processed. If the company’s production needs involve processing multiple materials, a multi-functional laser cutting system or a hybrid model with different laser sources can be considered to improve flexibility and production efficiency.

Cutting Thickness and Power Selection

Laser power directly determines the maximum thickness and cutting speed that the machine can cut. Generally speaking:

- 1–3kW fiber laser cutting machines are suitable for thin sheet processing (0.5–8mm);

- 4–6kW are suitable for medium-thickness sheets (10–20mm);

- 8–12kW and above high-power models can efficiently cut thick sheets (25mm and above).

The laser power should be matched according to the thickness of the main products. If a company primarily processes thin sheets and purchases a high-power laser cutter, it may result in over-investment and energy waste. Therefore, a power configuration assessment based on actual production needs should be conducted before purchasing a machine.

Cutting Speed and Production Efficiency

The cutting speed of a laser cutting machine affects overall production capacity and order delivery cycle. Fiber laser cutting machines typically offer faster cutting speeds, especially in the processing of medium and thin sheet metal.

- The following factors should be considered during the evaluation

- Maximum acceleration and traverse speed

- Motion control system quality

- Laser power and material matching

A machine that combines excellent speed and control performance can significantly improve production efficiency while ensuring cutting quality, resulting in a higher return on investment (ROI).

Precision and Stability

In high-end manufacturing, precision is a core indicator of laser cutting machine performance. High-precision models typically employ servo motors, high-rigidity body structures, and imported guide rail systems to ensure stable positioning during long-term operation.

Ideal cutting precision includes:

- Positioning accuracy: within ±0.03mm;

- Repeatability: within ±0.02mm.

Furthermore, machine stability is particularly important for batch processing. A stable optical path design and high-quality components ensure consistent cutting results each time, avoiding finished product deviations.

Power Requirements and Energy Consumption

Before purchasing, it is essential to understand the specific power requirements of the equipment (e.g., 380V three-phase or 220V single-phase) and assess whether the factory’s power system can support long-term high-power operation.

Fiber laser generators, due to their high photoelectric conversion efficiency (up to 35%), consume significantly less energy than CO2 lasers under the same power conditions. Choosing high-efficiency equipment not only saves on electricity costs but also aligns with current energy-saving and environmental protection trends.

Kullanım Kolaylığı ve Yazılım Uyumluluğu

Modern laser cutting machines are mostly equipped with intelligent control systems and user-friendly interfaces. High-quality equipment should be compatible with mainstream CAD/CAM design software (such as AutoCAD, CorelDRAW, SolidWorks, etc.) and support multi-language interfaces. Furthermore, automation features (such as automatic layout, intelligent path optimization, and remote monitoring) can significantly improve ease of operation and production efficiency. For companies using laser equipment for the first time, choosing a model with simple operation and an intuitive interface is particularly important.

Bakım ve Servis Gereksinimleri

Any laser cutting equipment requires regular maintenance to ensure long-term stable operation. Evaluation should focus on:

- Whether the manufacturer provides systematic maintenance training;

- Whether vulnerable parts (such as nozzles, lenses, and protective lenses) are easy to replace;

- The responsiveness of the after-sales team.

Fiber laser cutting machines have a relatively low maintenance frequency, while CO2 laser equipment requires regular optical path adjustment and laser tube replacement. Excellent after-sales service not only reduces downtime but also helps companies quickly respond to unexpected problems and maintain production continuity.

Safety and Compliance

Laser equipment is a high-energy optical processing device, making safety protection paramount.

- High-quality models should be equipped with the following safety features:

- Fully enclosed protective cover and laser protective glass;

- Emergency stop button;

- Beam leakage prevention structure.

At the same time, it should be ensured that the equipment complies with international standards (such as CE, ISO, and FDA certifications) to meet the regulatory requirements of export markets. This not only enhances equipment safety but also helps businesses expand into overseas markets.

Additional Features and Expandability

In a highly competitive manufacturing environment, the expandability and upgrade potential of equipment are becoming increasingly important. Today, many laser cutting machines offer optional features such as:

- Automatic focusing systems;

- Dual-platform exchange tables;

- Automatic loading and unloading systems;

- Dust and fume purification systems.

These features further improve operational efficiency and processing quality, preparing for future capacity expansion and automation upgrades.

Before purchasing a laser cutting machine, businesses should conduct a comprehensive evaluation from multiple dimensions, including budget planning, material compatibility, cutting speed, processing accuracy, and ease of maintenance. This not only determines whether the equipment can meet current production needs but also affects long-term operational stability and return on investment.

Different types of laser cutting machines—such as fiber laser cutting machines and CO2 laser cutting machines—each have their advantages in performance, cost, and application areas. Only by fully understanding process requirements and processing characteristics can the most suitable model be selected to achieve higher production efficiency and superior cutting quality. By making scientific purchases and configuring equipment reasonably, manufacturing enterprises can achieve the dual goals of cost control and capacity improvement in the face of fierce market competition.

Researching and Comparing Options

Researching and comparing different brands and models is a crucial step before deciding to purchase a laser cutting machine. The market offers a wide variety of laser equipment, from fiber laser cutters to CO2 laser cutters, each with different performance, price, and maintenance requirements. By systematically gathering information, analyzing data, referring to user feedback, and conducting actual test demonstrations, buyers can more scientifically determine which machine best meets their company’s production needs and budget goals.

Gathering Information

First, be sure to obtain firsthand information from official websites, industry reports, and professional technical documents. These documents typically detail the machine’s cutting power, light source type, processing range, compatible materials, and technical parameters.

Additionally, visiting the manufacturer’s online showcase or product videos can help you gain a more intuitive understanding of the structure and working principles of laser cutting machines. By comparing the configurations and performance differences of different brands, you can initially filter out models that better meet your needs.

Reading Reviews and User Recommendations

Online reviews and company use cases are important indicators of a laser cutting machine’s stability. Viewing the experiences of other manufacturers, metal processing plants, or process companies can help you understand the equipment’s long-term performance.

Focus on the machine’s stability under high-intensity production, cutting accuracy, maintenance costs, and after-sales response. It’s also crucial to distinguish between genuine user feedback and advertising recommendations to obtain a more objective basis for judgment.

Sektör Uzmanlarına veya Meslektaşlarına Danışın

In addition to online information, consulting industry experts, technical advisors, or experienced peers is essential. Professionals can typically provide in-depth evaluations from technical perspectives, such as laser source brand, control system, and software compatibility. For companies purchasing laser equipment for the first time, such advice can effectively prevent erroneous investments due to information asymmetry.

Request Quotes and Demonstrations

Before making a final decision, be sure to request detailed quotes and on-site demonstrations from multiple suppliers. Quotes should clearly include: the main unit, control system, light source brand, accessories, and shipping and installation costs. On-site demonstrations are the most direct way to verify the performance of a laser cutting machine.

By observing cutting speed, kerf quality, energy consumption, and the control interface, you can truly experience the machine’s processing performance. Comparing test results from different brands helps you make the optimal balance between price and performance.

Researching and comparing different models of laser cutting machines is a crucial step in ensuring a scientific and rational purchasing decision. By systematically collecting information, analyzing real user feedback, seeking professional advice, and conducting on-site demonstrations, buyers can gain a comprehensive understanding of the machine’s performance and cost-effectiveness. The final choice should be based on data support and experience, rather than solely on price. Only in this way can higher production efficiency, more stable processing quality, and a longer-term return on investment be achieved in the field of laser cutting.

Tedarikçileri ve Markaları Değerlendirmek

When purchasing a laser cutting machine, choosing a reliable supplier or manufacturer is often more crucial than selecting a particular model. Even the most advanced equipment can lead to problems later on if it lacks comprehensive after-sales support, sufficient spare parts supply, and continuous technical upgrades.

Therefore, before formally signing a purchase contract, companies should conduct comprehensive evaluations to assess the supplier’s professionalism and reputation, ensuring that the selected fiber laser cutting machine or CO2 laser cutting machine can operate stably in the long term and truly bring continuous benefits.

Üretici İtibarı ve Deneyimi

Choosing a laser cutting machine manufacturer with extensive industry experience is the first step in ensuring equipment performance and quality. Experienced manufacturers typically possess more refined production processes, a more stable technical support team, and have accumulated numerous application cases within the industry. When evaluating a supplier, consider the following aspects:

- Establishment date and production scale

- Domestic and international market reputation and export experience

- Product line completeness (e.g., laser cutting machines, welding machines, cleaning machines, etc.)

More experienced manufacturers typically prioritize long-term cooperation and customer reputation, and are better equipped to customize designs to meet the needs of different industries.

Garanti ve Satış Sonrası Destek

Even the best equipment requires reliable after-sales support. Before signing a contract, carefully understand the supplier’s warranty period, technical support coverage, and repair response speed. An ideal after-sales system should include:

- Remote fault diagnosis and technical guidance

- On-site repair and replacement services

- Warranty coverage for key components

Comprehensive after-sales service not only reduces equipment downtime risks but also ensures continuous support for the company during production.

Customer Service Response Capability

Technical problems are inevitable during equipment operation, making the supplier’s response speed and service efficiency crucial. An excellent laser cutting machine brand often possesses a comprehensive customer service system and a professional engineering team, capable of providing remote support or on-site troubleshooting services quickly. This not only significantly reduces the risk of production downtime but also demonstrates the manufacturer’s emphasis on customer operational efficiency.

Spare Parts and Consumables Availability

Laser cutting machines are high-precision equipment, and their components, such as light sources, lenses, nozzles, and cooling systems, require periodic replacement after prolonged use. Therefore, choosing a manufacturer with ample spare parts supply and a well-established logistics system can effectively avoid downtime due to parts shortages. Attention should also be paid to consumable prices, transportation time, and whether local distributors are supported.

Upgradeability and Future-Oriented Expansion Options

With rapid technological advancements, a laser cutting machine with scalability and upgrade capabilities will be more competitive in the future. Companies should focus on whether the equipment supports:

- Laser power upgrades (e.g., from 1.5kW to 3kW or 6kW)

- Expansion of automatic loading and unloading systems

- Upgrades to software control systems or intelligent monitoring modules

These designs not only extend the equipment’s lifespan but also help companies quickly adapt to market changes when new materials and processes emerge.

Evaluating laser cutting machine suppliers and brands involves more than just price comparisons; it’s a comprehensive assessment of equipment quality, technical support, and service guarantees. Choosing a reputable, experienced, and well-serviced manufacturer means greater stability and lower operational risk in future production.

Only by giving equal importance to equipment performance and brand service can a company ensure a lasting competitive advantage and economic return in the laser cutting field.

Making a Decision

After a comprehensive review of equipment parameters, brand reputation, and after-sales service, companies need to move on to the most crucial step—making a purchase decision. This step not only concerns the one-time equipment investment but also impacts the company’s production efficiency, cost structure, and competitiveness for years to come.

Therefore, the decision-making process should be based on rational analysis and data evaluation, comprehensively considering long-term factors such as price, performance, maintenance, and energy consumption to ensure that the chosen laser cutting machine can continue to create value for the company in the future.

Weighing the Pros and Cons

Among various models and brands of laser cutting machines, buyers need to conduct a horizontal comparison of price, cutting performance, energy consumption, maintenance costs, and production efficiency. For example, fiber laser cutting machines are highly efficient and energy-efficient in metal processing but have higher costs; while CO2 laser cutting machines perform excellently on non-metallic materials but require more frequent maintenance. By comparing these differences, companies can more clearly identify which equipment best meets their business needs.

Considering Long-Term Costs

The purchase of a laser cutting machine is not just an initial investment; but it should also focus on its total lifecycle cost. Long-term costs include:

- Power consumption: Energy consumption varies significantly depending on the power of the fiber laser.

- Consumables and wear parts: The frequency of replacing nozzles, lenses, coolant, etc., affects operating costs.

- Labor and maintenance: The availability of automated feeding and intelligent control functions directly impacts labor input.

A comprehensive assessment of these factors helps companies more accurately calculate the return on investment (ROI) of their equipment, avoiding budget overruns or maintenance difficulties later on.

Narrowing down the choices

Blindly pursuing high configurations or low prices among numerous brands and models is often counterproductive. Companies should select a few machines that best meet their current production needs and future expansion potential based on their production scale, the types of materials processed, and target output.

For example, small factories can prioritize medium-power fiber laser machines to control budgets, while mass-production metal manufacturing companies can choose high-power laser cutting centers to improve efficiency.

Making the final purchase decision

The final purchase decision should be made based on thorough research and comparison. The ideal choice is a laser cutting machine that balances current process requirements with future development potential. Before signing a procurement agreement, companies are advised to reconfirm:

- Whether the equipment performance meets the cutting requirements of the target production line.

- Whether there is room for technological upgrades or expansion;

- Whether the supplier’s after-sales support and training are comprehensive.

Purchasing a laser cutting machine is a decision that requires a comprehensive balance of technology, budget, and strategy. By scientifically weighing the pros and cons, calculating long-term costs, selecting core needs, and combining them with future development directions, companies can maximize their returns on laser equipment investment.

A reliable, easily maintained, and continuously upgradable laser cutting machine is not only a production tool but also a long-term asset that propels companies towards intelligent manufacturing.

özetle

Purchasing a laser cutting machine is a far-reaching investment decision, affecting not only equipment performance and processing precision but also directly impacting a company’s production efficiency and cost control. Whether choosing a fiber laser cutting machine or a CO2 laser cutting machine, a comprehensive evaluation should be conducted based on the actual materials to be processed, cutting thickness, production capacity planning, and long-term operational needs.

During the selection process, rationally comparing the performance parameters of different brands and models, and thoroughly researching the supplier’s reputation and after-sales support, are crucial to ensuring stable equipment operation and a return on investment. Through systematic market research, technology comparison, and service evaluation, companies can achieve higher production efficiency and lower maintenance risks while maintaining a controllable budget.

Essentially, scientific selection is not a one-time purchase but a crucial step towards automation and intelligent manufacturing. Only by making decisions based on a full understanding of laser cutting technology and market trends can this investment truly translate into a long-term competitive advantage.

Looking for a Laser Solution

If you’re looking for a laser cutting machine that offers stable performance, high cutting precision, and low maintenance costs, choosing the right manufacturer is crucial. Different industries, materials, and production scales have varying needs for laser cutting equipment. In such cases, an experienced partner who can provide professional technical support will significantly reduce procurement risks.

AccTek Lazer focuses on the research and development, and production of laser cutting technology, offering a variety of fiber laser cutting machine models ranging from low-to-medium power to high power, widely used in metal processing, machinery manufacturing, and decorative building materials industries. With stable performance, excellent cutting results, and comprehensive after-sales support, AccTek has become a trusted choice for many manufacturing companies.

If you’re looking for a more targeted laser cutting solution, please contact us to let our expertise bring greater efficiency and better cost performance to your production line.

İletişim bilgileri

- [email protected]

- [email protected]

- +86-19963414011

- 3 Bölge A, Lunzhen Sanayi Bölgesi, Yucheng Şehri, Shandong Eyaleti.

Lazer Çözümleri Alın