Environmental Considerations and Regulations for Fiber Laser Cutting Processes

Fiber laser cutting, as an efficient processing technology in modern manufacturing, is widely used in metalworking, automotive manufacturing, aerospace, and electronics industries. Its high precision and efficiency make it an important alternative to traditional cutting methods. However, while benefiting from the productivity improvements brought by fiber laser cutting, companies also need to pay attention to its environmental impact and comply with national environmental regulations to achieve sustainable development. This article will delve into the environmental considerations of fiber laser cutting technology, regulatory frameworks, mitigation strategies, certifications and accreditations, and industry cooperation trends, providing enterprises with best practices that align with environmental compliance requirements.

Table of Contents

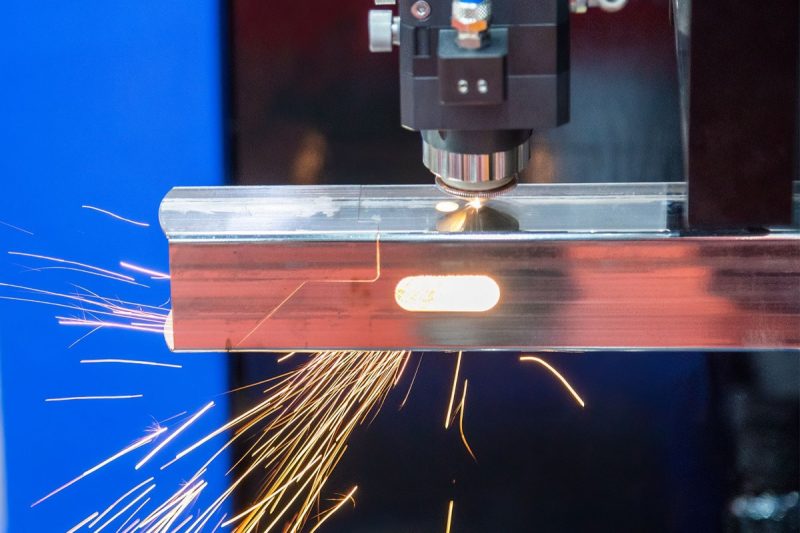

Environmental Impact of Fiber Laser Cutting

As the manufacturing industry continues to develop, fiber laser cutting has been widely used in various sectors due to its efficiency and precision. Although it significantly improves production efficiency and reduces operational costs, the environmental impact during its operation also requires attention. The environmental impacts of fiber laser cutting technology can be analyzed in several aspects, including energy consumption and efficiency, air pollutant emissions, hazardous waste generation, and noise pollution.

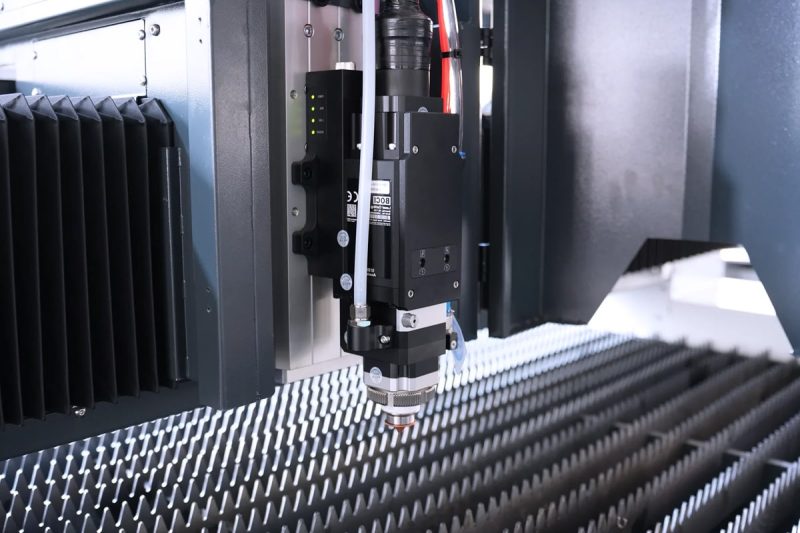

Energy Consumption and Efficiency

Fiber laser cutting machines use high-energy laser beams to melt, vaporize, or ablate materials, and compared to traditional CO2 laser cutting machines, fiber laser cutting machines are more energy-efficient. Typically, fiber laser cutting machines can reduce energy consumption by 30%-50%, meaning they can complete the same amount of work with lower energy usage. However, despite the higher efficiency, high-power laser cutting machines still require substantial electricity, especially in high-intensity industrial production environments, where energy consumption remains high.

Furthermore, the power demands of such equipment place higher requirements on energy management and cost control. In modern production, businesses should focus more on energy management, not only selecting high-efficiency laser cutting equipment but also optimizing energy usage during the production process. Using intelligent control systems to monitor and adjust energy use in real-time can further reduce energy waste.

Air Pollutant Emissions

During fiber laser cutting, metal vapor, particulate matter, and oxides are produced when metals are melted or vaporized under high temperatures. Materials like aluminum, iron, and nickel, when cut, may release harmful gases. If these gases and particles are discharged into the air without treatment, they can affect air quality and potentially harm workers’ health.

To reduce air pollution, businesses should invest in efficient air filtration and exhaust gas treatment systems, such as HEPA (High-Efficiency Particulate Air) filters, electrostatic precipitators, and gas adsorption systems, which can effectively filter and remove harmful gases and particulates. This will not only ensure worker health but also help mitigate environmental pollution. Regular maintenance of these exhaust treatment systems is also essential to ensure optimal operation, even under heavy use.

Generation of Hazardous Waste

In addition to metal vapor and exhaust gases, fiber laser cutting generates metal debris, slag, and cooling liquid waste, some of which contain heavy metals or other harmful substances. If these wastes are not properly managed, they can pollute soil and water sources, leading to environmental damage.

To prevent this, businesses need to implement comprehensive waste management systems and strictly adhere to environmental regulations for waste classification and disposal. For example, metal waste can be recycled and reused, while hazardous waste should be treated by professional channels to ensure it does not cause long-term environmental harm. Moreover, businesses should promote environmental awareness among employees and regularly inspect and maintain equipment to avoid waste leakage due to equipment malfunction or improper operation.

Noise Pollution

High-power fiber laser cutting machines also laser generator noise, primarily from the laser’s operation, high-speed airflow, and auxiliary equipment such as air compressors and cooling systems. Although the noise level is generally lower than that of traditional plasma or flame cutting, in long-duration and high-intensity production environments, the noise can still adversely affect workers’ health, particularly leading to hearing damage or other occupational health issues.

To address this, businesses can implement noise control measures such as using soundproof walls and sound-absorbing materials in workshops, and designing equipment with noise-reduction features. Additionally, providing workers with necessary hearing protection devices, such as earmuffs or earplugs, is essential to ensure their health and safety in noisy environments. These measures will not only improve the work environment but also enhance worker productivity by reducing health-related issues caused by noise.

While fiber laser cutting offers significant technical advantages and improved production efficiency, its environmental impact cannot be overlooked. Businesses must balance the pursuit of efficiency and precision with the consideration of energy consumption, air pollution, waste management, and noise control. By optimizing production processes, introducing green technologies and equipment, and strengthening waste recycling and noise management, businesses can reduce their environmental footprint and achieve sustainable development, all while adhering to environmental regulations.

Environmental Compliance and Regulatory Framework

Governments and international organizations worldwide have established strict regulatory requirements to address the environmental impacts of industrial manufacturing. Especially for fiber laser cutting technology, which is an energy-intensive process, adherence to relevant regulations is mandatory. Companies need to ensure that their production processes comply with environmental standards to promote sustainable development. Below are some key environmental compliance regulations:

China's Air Pollution Prevention and Control Law & Solid Waste Pollution Prevention and Control Law

In China, companies must comply with the Air Pollution Prevention and Control Law and the Solid Waste Pollution Prevention and Control Law. These two laws require strict management of air pollutant emissions and solid waste. Fiber laser cutting equipment, during operation, may generate exhaust gases and metal waste. Companies should adopt effective measures such as installing exhaust treatment systems and recycling waste to ensure that these byproducts do not pollute the air, water, or soil.

EU CE Certification & RoHS Directive

In the EU market, fiber laser cutting equipment must obtain CE certification to ensure compliance with safety, health, and environmental requirements. Additionally, the RoHS directive restricts the use of harmful substances in electronic equipment, requiring manufacturers to reduce or eliminate substances like lead, mercury, and cadmium. These measures aim to ensure that the equipment does not harm the environment or human health during use.

US EPA (Environmental Protection Agency) Regulations

The US Environmental Protection Agency (EPA) has established strict regulations for industrial emissions, wastewater treatment, and solid waste management. Fiber laser cutting equipment must comply with these regulations to ensure that harmful gases, particularly toxic gases and particles produced during metal cutting, are not released beyond permissible limits. Additionally, wastewater and waste disposal must meet EPA standards to avoid environmental pollution. Companies must implement effective air purification and wastewater treatment systems to comply with EPA requirements.

ISO 14001 Environmental Management System

ISO 14001 is a globally recognized environmental management system standard that provides a framework for systematically managing environmental impacts. By certifying ISO 14001, companies can identify and reduce negative environmental effects in their production processes, ensure efficient energy use, and minimize waste generation. For fiber laser cutting companies, following this standard not only helps reduce energy consumption but also lowers costs through resource recycling and waste management, thereby increasing production efficiency.

Environmental Compliance and Corporate Responsibility

Complying with environmental regulations is not only a legal obligation but also a key way for companies to enhance their social responsibility and establish a green brand image. Environmental compliance can improve a company’s competitiveness in the market, as an increasing number of consumers and clients are concerned about corporate environmental performance. Furthermore, companies that meet environmental standards may benefit from tax incentives and green policies provided by governments. On the other hand, companies that fail to comply with environmental regulations may face fines and shutdowns.

Compliance management is not just about avoiding legal risks; it is a core strategy for optimizing production, reducing costs, and enhancing sustainable development. By establishing effective environmental management systems and adopting green technologies and equipment, companies can maximize both environmental performance and economic benefits.

Environmental Mitigation Strategies

Fiber laser cutting technology, while being an efficient manufacturing process, still has potential negative impacts on the environment during actual production. To minimize the environmental impacts of fiber laser cutting, companies must adopt a series of mitigation measures. By optimizing resource utilization, improving energy efficiency, reducing waste emissions, and controlling noise pollution, companies can not only ensure compliance with environmental regulations but also enhance overall production efficiency and social responsibility.

Here are several effective environmental mitigation strategies:

Improve Energy Efficiency

Improving energy efficiency is one of the core strategies to mitigate the environmental impact of fiber laser cutting. While fiber laser cutting already demonstrates significant progress in energy consumption compared to traditional cutting technologies, companies can further optimize energy usage by:

- Choosing High-Efficiency Laser Generators: High-efficiency laser generators not only provide greater cutting capacity but also reduce unnecessary energy consumption. Using advanced laser generator and smart control systems helps minimize energy waste.

- Optimizing Cutting Paths: Through automated cutting path planning, unnecessary pauses and adjustments can be reduced, making energy usage more efficient.

- Using Energy-Saving Equipment: For example, adopting more efficient cooling systems or optimizing auxiliary equipment can further reduce energy consumption.

By implementing these methods, companies can not only lower operating costs but also significantly reduce carbon emissions.

Equip High-Efficiency Exhaust Treatment Systems

During fiber laser cutting, particularly in metal cutting, harmful gases and metal particles may be produced, which pose potential risks to air quality and worker health. Therefore, companies need to equip high-efficiency exhaust treatment systems to ensure that these pollutants are properly treated:

- HEPA Filters: HEPA filters can effectively remove small particles from the air, reducing the pollution of harmful gases and particles in the environment.

- Activated Carbon Adsorption Technology: Activated carbon can absorb harmful gases, such as volatile organic compounds (VOCS) and other pollutants, preventing them from being released into the air.

- Intelligent Emission Monitoring Systems: By installing emission monitoring devices, companies can continuously track pollutant concentrations to ensure compliance with environmental standards.

These exhaust treatment systems effectively reduce pollutant emissions, safeguard worker health, and minimize environmental damage.

Recycle and Reuse Metal Waste

During fiber laser cutting, large amounts of metal scrap and waste are generated, which often contain recyclable resources. If companies can efficiently recycle this waste, it will significantly reduce resource waste:

- Classify Metal Waste: By classifying metal waste according to material types, companies can ensure that metal scrap is efficiently recycled and reused, reducing the need for new resources and lowering waste disposal costs.

- Waste Reuse: For example, metal scraps can be used to manufacture other products or melted down and reprocessed, reducing the consumption of new resources.

Recycling and reusing metal waste is one of the key measures to reduce the environmental impact of fiber laser cutting, helping to conserve resources and promote the development of a circular economy.

Noise Control

Although the noise level of fiber laser cutting equipment is lower than traditional plasma or flame cutting, it can still have an adverse effect on worker health during extended periods of operation. Therefore, noise control is essential:

- Optimize Equipment Operating Environment: By adjusting the equipment layout and avoiding placing machines in noise-sensitive areas, noise transmission can be minimized.

- Use Soundproof Covers: Equipping laser cutting machines and related auxiliary equipment with soundproof covers helps reduce noise generation.

- Apply Acoustic Materials: Using sound-absorbing materials on workshop walls, floors, and around equipment further reduces noise pollution by minimizing noise reflection.

Noise control measures not only improve the work environment but also enhance employee comfort and reduce the occurrence of occupational diseases.

By adopting the environmental mitigation strategies outlined above, fiber laser cutting companies can effectively reduce energy consumption, harmful gas emissions, metal waste, and noise pollution during production. These measures not only help ensure that companies comply with environmental regulations but also improve their market competitiveness and brand image. By further improving energy efficiency, optimizing exhaust treatment, strengthening waste recycling, and controlling noise pollution, companies can achieve both environmental and economic benefits, driving sustainable development.

Environmental Certification and Accreditation

Obtaining environmental certifications and accreditations not only ensures that a company complies with environmental regulations but also significantly enhances its competitiveness in the international market. Environmental certification demonstrates a commitment to sustainable practices, boosting both brand reputation and customer trust. By obtaining recognized certifications, companies can show stakeholders, customers, and regulatory bodies their dedication to environmental protection and responsible business operations. Below are some key environmental certifications that companies can pursue:

ISO 14001: Environmental Management System Certification

ISO 14001 is a globally recognized standard for environmental management systems (EMS). It provides a framework for businesses to effectively manage their environmental responsibilities, reduce their carbon footprint, and improve resource efficiency. By implementing ISO 14001, companies can systematically identify, assess, and control their environmental impacts, including waste management, energy consumption, and emissions.

- Benefits: ISO 14001 helps companies align their environmental practices with international standards, ensuring compliance with local and global regulations. It also promotes operational efficiency, reduces waste, and enhances environmental performance, making the company more attractive to eco-conscious customers and investors.

LEED Green Building Certification (for Green Factories)

The LEED (Leadership in Energy and Environmental Design) certification is an internationally recognized system for certifying buildings based on their environmental performance. Although it is typically associated with the construction and design of energy-efficient buildings, LEED can also be applied to industrial and manufacturing facilities, including factories that use fiber laser cutting technology.

- Benefits: Achieving LEED certification for a factory demonstrates a company’s commitment to environmental sustainability in terms of energy efficiency, water conservation, and sustainable construction practices. LEED-certified buildings provide a healthier and more productive working environment for employees while reducing operational costs associated with energy use and water consumption. Additionally, LEED certification enhances the company’s green image, appealing to environmentally conscious clients and partners.

Energy Star Certification (for Energy-Efficient Equipment)

The Energy Star certification is awarded to energy-efficient products and equipment that meet strict energy performance criteria. For companies involved in manufacturing fiber laser cutting machines or using them in their operations, obtaining Energy Star certification for equipment ensures that the devices meet or exceed energy efficiency standards.

- Benefits: Energy Star-certified equipment typically consumes less power, reduces greenhouse gas emissions, and leads to long-term cost savings for the company. These certifications are particularly attractive to businesses seeking to minimize their energy costs and environmental impact. Furthermore, promoting Energy Star-certified products enhances customer trust and demonstrates the company’s commitment to sustainable practices.

EPEAT Green Electronics Certification

The Electronic Product Environmental Assessment Tool (EPEAT) certification is a global rating system that recognizes environmentally friendly electronic products. For manufacturers in the laser cutting industry, EPEAT certification can be awarded to laser cutting machines and other electronics that meet criteria for reduced environmental impact throughout their lifecycle, including energy use, materials sourcing, and end-of-life disposal.

- Benefits: EPEAT certification helps manufacturers gain recognition for producing sustainable electronics, enhancing product appeal in markets where sustainability is a high priority. It also provides consumers and businesses with clear guidelines on choosing eco-friendly products, encouraging the adoption of environmentally conscious technologies.

Environmental certifications and accreditations play a critical role in demonstrating a company’s commitment to sustainability and responsible business practices. Certifications like ISO 14001, LEED, Energy Star, and EPEAT not only ensure compliance with environmental regulations but also enhance a company’s competitive advantage in the global market. These certifications foster consumer trust, improve operational efficiency, and help businesses build a strong green brand image, which can ultimately lead to increased market share and long-term business success. By pursuing and maintaining these certifications, companies can show their dedication to reducing their environmental footprint and achieving sustainable growth.

Collaboration and Industry Initiatives

As global attention to sustainable manufacturing grows, governments, industry organizations, and enterprises are taking measures to promote environmentally friendly practices in fiber laser cutting. Through the implementation of green supply chain programs, the establishment of industry environmental standards, and government incentives, companies can effectively reduce their carbon footprint, improve production efficiency, and enhance their competitiveness in international markets.

Green Supply Chain Programs by Multinational Enterprises

Many leading global manufacturers are establishing green supply chain management systems, requiring suppliers to adopt environmentally friendly technologies and sustainable materials to minimize the environmental impact of production. For instance, major automotive, aerospace, and electronics manufacturers are reducing carbon emissions across their supply chains by mandating the use of energy-efficient laser cutting equipment and minimizing waste generation. These initiatives not only help reduce environmental pollution but also enhance corporate social responsibility (CSR) and build stronger trust among customers and investors.

Industry Alliances Setting Environmental Standards

Industry associations and standardization organizations play a vital role in promoting environmentally responsible production. For example, the Laser Institute of America (LIA) has developed the Green Laser Processing Guidelines, offering best practices for sustainable manufacturing. These include reducing energy consumption during laser cutting, optimizing cutting paths to minimize material waste, and implementing high-efficiency exhaust treatment systems. Additionally, the European Photonics Industry Consortium (EPIC) and the International Organization for Standardization (ISO) are actively advancing environmental standards for the laser manufacturing sector, ensuring compliance with global sustainability goals.

Government Subsidies and Policy Incentives

Governments worldwide are introducing subsidies and tax incentives to encourage enterprises to invest in green production technologies. Examples include:

- Chinahas outlined its commitment to promoting smart and green manufacturing in its “14th Five-Year Plan,” allocating special funds to support companies that meet environmental standards.

- The European Union has launched the “Green Industrial Plan,”offering financial support to manufacturers using energy-efficient equipment and low-emission technologies.

- The United States provides tax reductions and low-interest loans under the “Clean Energy Incentive Program”for companies purchasing energy-efficient laser cutting machines.

- Japan has established a Green Manufacturing Fund to encourage research and adoption of eco-friendly laser processing technologies, aiming to lower carbon emissions.

These government incentives not only reduce the financial burden of adopting green technologies but also drive the entire laser manufacturing industry toward sustainability.

Collaboration among enterprises, industry organizations, and governments is essential for achieving sustainable manufacturing. By sharing technology, establishing industry standards, and providing policy support, stakeholders can work together to promote eco-friendly practices in fiber laser cutting. Companies should actively participate in industry alliances, stay updated on the latest environmental standards, and take full advantage of government subsidies and incentive programs to minimize their environmental impact while strengthening their market position. In the future, only businesses with strong green manufacturing capabilities will maintain a competitive edge in the global market.

Economic Impact

While implementing environmental measures may increase short-term operational costs, the long-term economic benefits of green manufacturing far outweigh the initial investment. By optimizing energy usage, reducing waste, enhancing brand value, and meeting international market requirements, businesses can lower costs, improve market competitiveness, and ensure sustainable development.

Reducing Energy Consumption

Using high-efficiency fiber laser cutting machines can significantly reduce power consumption. For example, next-generation laser generators offer improved energy efficiency, minimizing unnecessary energy waste. Additionally, optimizing cutting paths further decreases energy use. Lower electricity costs lead to higher profit margins, and many countries provide tax incentives or subsidies for energy-efficient equipment, further reducing operational expenses.

Minimizing Waste

Governments worldwide are tightening environmental regulations, imposing heavy fines or production shutdowns on companies that fail to comply with emission standards. By investing in efficient waste gas treatment systems, recycling metal scraps, and adopting environmentally friendly manufacturing processes, businesses can lower emission risks and reduce waste disposal costs. For instance, recycling cutting waste into reusable materials not only minimizes waste but also generates additional revenue.

Enhancing Brand Image

As global consumers become more environmentally aware, businesses that adopt green manufacturing gain a competitive edge. Sustainable production practices help improve brand reputation, making companies more attractive to environmentally conscious clients. This is particularly crucial in high-end manufacturing, automotive, and precision processing industries, where environmental compliance is a key factor in supplier selection. Green certifications, carbon neutrality commitments, and sustainable supply chain management can help businesses attract long-term partnerships and expand their customer base.

Meeting International Standards

Many international markets have strict environmental compliance requirements, such as the EU’s CE certification and RoHS directive, and the US EPA environmental regulations. Companies aiming to enter these markets must adhere to these standards. By proactively implementing green production measures, businesses can ensure compliance with international regulations, avoiding export restrictions due to non-compliance. Furthermore, obtaining environmental certifications increases the likelihood of securing partnerships with multinational corporations, expanding global market opportunities.

Although the initial investment in green manufacturing may seem significant, the long-term benefits—from reducing energy costs and regulatory fines to enhancing brand value and expanding global reach—are undeniable. Green manufacturing not only helps businesses lower operational costs but also strengthens their sustainability, positioning them for long-term success in a competitive global market.

Conclusion

Fiber laser cutting technology enhances manufacturing efficiency while also requiring businesses to take environmental responsibility. By optimizing energy consumption, reducing pollutant emissions, improving waste recycling rates, and obtaining environmental certifications, companies can achieve sustainable development without compromising production efficiency. Furthermore, aligning with the industry’s green manufacturing trends not only strengthens market competitiveness but also contributes to global environmental protection efforts.

AccTek Laser is committed to providing high-efficiency, eco-friendly fiber laser cutting solutions while strictly adhering to international environmental standards. If your company is looking for high-performance, low-emission laser cutting equipment, feel free to contact us to explore more possibilities for green manufacturing!

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions