¿Cómo afecta el sistema de suministro del haz a la eficiencia de una máquina de soldadura láser?

In modern manufacturing, the efficiency of laser welding machines is not only dependent on the type of laser source (such as fiber, CO2, or ultrafast lasers) and power, but is also closely related to beam delivery systems. The system includes core components such as optical fibers, reflectors, focusing lenses, and welding heads, and its transmission efficiency directly affects the quality of the laser beam, focusing accuracy, and energy stability. High-quality beam transmission components reduce energy loss and spot offset, resulting in more consistent high-precision weld quality and weld speed in welding and cutting, while reducing heat-affected zones (HAZs) and defect rates.

A properly designed beam transmission system also needs to consider the safety and stability of the industrial environment, including efficient collision through high reflectivity mirror or fiber mode transmission, and adopt a closed optical path or automatic focus mechanism, such as automatic light coupling, remote monitoring or AI focus optimization, to cope with interference such as vibration and temperature changes in welding and ensure continuous operation reliability. Therefore, for every market-oriented high‑precision laser wearing machine, the beam transmission system is the hero behind the scenes and is the key guarantee for efficient, stable, and low-maintenance-cost operations.

Tabla de contenido

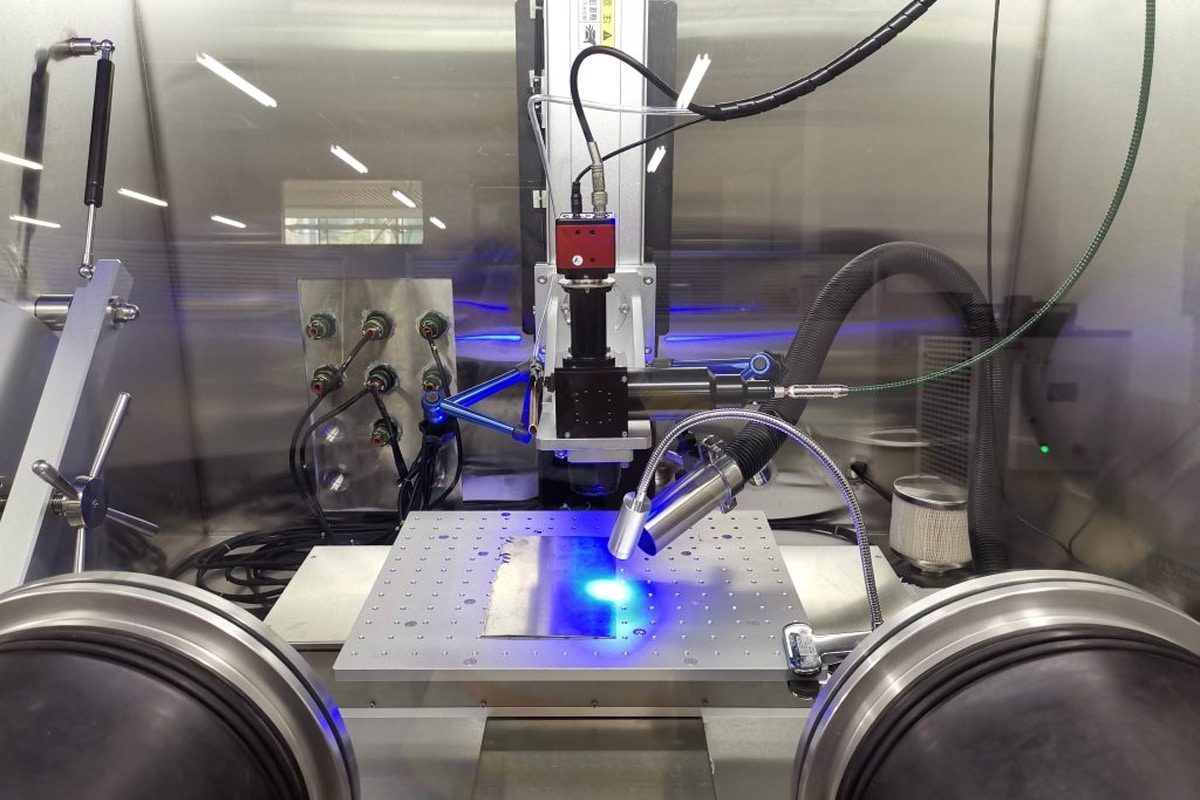

Understanding Beam Delivery Systems

In modern manufacturing, beam delivery systems are the key core of efficiently and accurately transporting laser light from the production source to the welding point. It is usually composed of optical fibers or reflectors, focusing lenses, protective windows, and welding heads etc. It needs to ensure low energy loss and beam quality to achieve stable and high-precision welding. High-quality fiber transmission or high reflectivity mirrors combined with precision alignment can minimize spot offset and losses, ensuring that the high-precision laser welding machine can maintain consistent welding depth and weld quality on different materials (such as stainless steel, carbon steel, and aluminum alloy).

In addition, a properly designed beam transmission system must also consider the reliability and maintenance ease of industrial applications. Therefore, for customers who pursue cost-effectiveness, the beam transmission system is the driving force behind the performance of the laser welding machine; excellent design and maintenance directly determine the weld accuracy, production efficiency, and equipment reliability. If you want to obtain a more stable and efficient welding experience, you should focus on the selection, alignment method, and daily maintenance specifications of beam transmission components.

Key components of the beam transmission system

In a high-precision laser welding machine, every component of the beam transmission system is crucial and directly determines the welding quality, efficiency, and stability. The following is an analysis of the four core components:

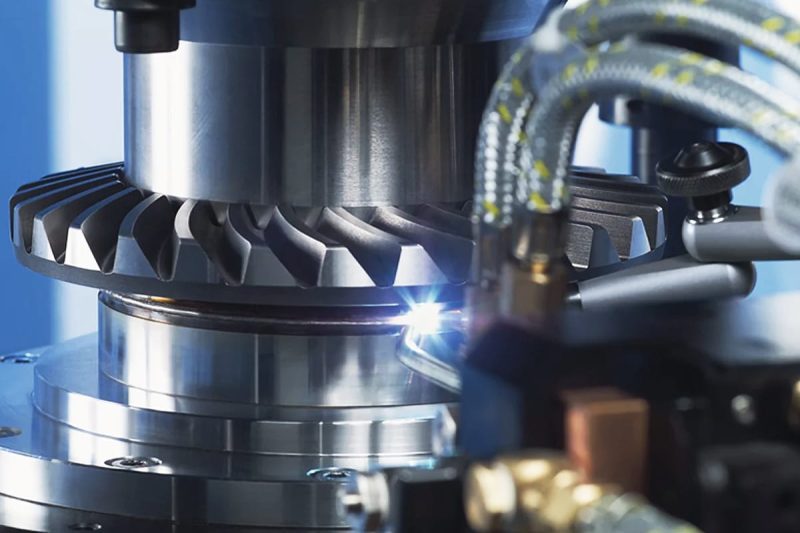

Fiber optic:Fiber is responsible for transmitting the laser from the laser source to the welding head and determines the maximum transmission power. High-quality optical fiber (such as self-cooling, low modal scattering, standard QBH connector) can significantly reduce attenuation and improve overall efficiency and stability. Especially in high-power multi-kilowatt fiber laser welding systems, the performance of the optical fiber directly affects the system life and maintenance frequency.

Beam expander:Beam expanders are used to control the beam diameter and divergence angle, and can be refractive or reflective (such as Galilean, Cassegrain). They can reduce spot diffusion, improve focusing accuracy, and enhance welding accuracy. Reflective beam expanders can also avoid chromatic aberration and spherical aberration, and are suitable for UV/IR/ultrafast laser systems.

Mirrors & Reflectors:These optical devices carry out beam path steering and must have high reflectivity coatings (such as metal or silver film) to reduce reflection losses and maintain beam quality consistency. High-power systems also use reflective focusing lenses (parabolic or off-axis) to avoid lens damage and achieve a high-stability welding head design.

Nozzle & Focusing Head:The focusing head collects the beam and controls the welding focus, which is an important component that determines the weld penetration depth and weld quality. Efficient focusing heads often have autofocus functions and provide shielding gas with the nozzle, which can effectively prevent oxidation and spatter and improve welding stability.

The core components in the beam delivery system work together to form a stable & high-precision beam delivery system. High-quality optical fiber, precision beam expanders, high-power resistant reflectors, and high-performance focusing heads jointly ensure welding accuracy, penetration depth, and system stability. Careful design and selection can not only significantly improve the operating efficiency of the máquina de soldadura láser de fibra but also help manufacturers reduce maintenance costs and achieve cost-effective output.

Key factors affecting beam delivery efficiency

In a high-performance laser welding machine, beam delivery efficiency is the core indicator that determines welding quality and production stability. This is not only related to system design, but also to daily operation and maintenance. The following four factors comprehensively affect beam delivery performance and welding outcome:

Beam Quality (M2)

The smaller the M2 value, the closer the beam is to the ideal Gaussian mode, with higher energy density and focusing ability. Studies have shown that reducing M2 (from 11.6 to 1.25) can increase the welding speed by about 5.5 times, increase the weld stability (CPK) by 2.3 times, and improve the overall welding efficiency. This directly optimizes the weld penetration and throughput of laser beam welding on materials such as aluminum alloy and carbon steel.

Power Loss

Small losses in the transmission path can be accumulated and amplified into a decrease in output power. The main sources include:

- Fiber bending and mode mismatch

- Mirror/reflector surface contamination or coating aging

- Closed optical path failure

Even if only 1–2% of the energy is lost, it will affect weld consistency and production capacity. Therefore, achieving a low-loss optical path and regular maintenance are the basis for ensuring stable output.

Estabilidad del sistema

Focus shift caused by optical path eccentricity or mechanical vibration will cause deviations in weld position and depth, increase machine downtime and scrap rate, and cause a decrease in OEE (Overall Equipment Effectiveness). Intelligent optical path alignment and mechanical platform design can significantly improve system stability.

Requisitos de mantenimiento

Maintenance frequency and strategy directly affect transmission efficiency, including but not limited to:

- Clean the fiber optic interface or focusing lens.

- Replace the protective window coating mirror.

- Dust prevention and regular calibration

Good maintenance keeps beam efficiency at a high level, reducing unscheduled maintenance and energy losses.

In the beam transmission system, four major factors jointly determine the efficiency of beam transmission and the overall performance improvement of the laser welding machine: First, excellent beam quality (Beam Quality, M2 and BPP) enables the laser to focus more accurately, thereby achieving higher welding speed and weld accuracy; second, low-loss optical path design and mirror coating can minimize power loss and ensure stable energy output; third, reliable system stability can avoid downtimes and welding errors caused by focus offset or mechanical vibration; finally, standardized maintenance management (such as regular cleaning of fiber interfaces, mirrors, and protective windows) can ensure long-term stable operation and reduce failure rates. Overall optimization of these links can not only significantly improve welding precision and productivity, but also bring you lower maintenance costs and higher operating returns on your laser welding machine investment.

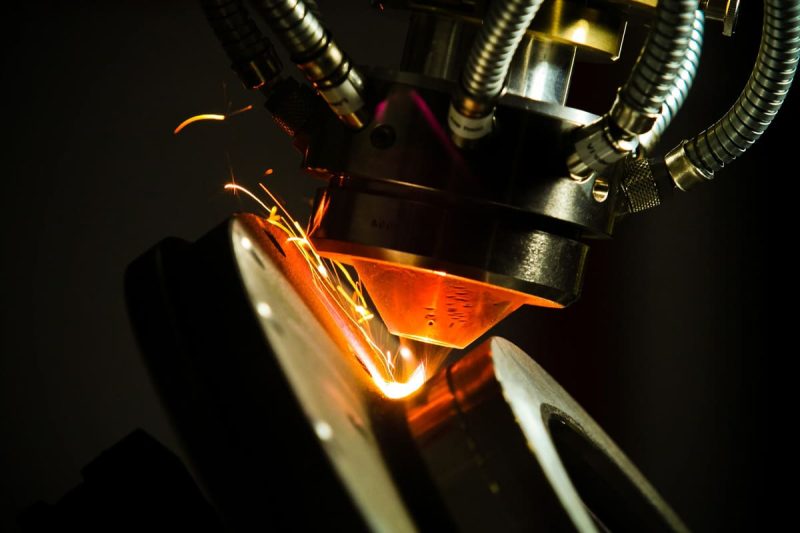

The specific impact of the beam delivery system on welding efficiency

In a high-performance laser welding machine, the beam delivery system is not only for transmitting lasers, but also the core link that determines welding efficiency and product quality. The following is a detailed analysis of the four key dimensions:

Welding speed: A high-quality beam delivery system can maintain efficient energy transfer, allowing the laser to complete welding tasks in a shorter time. For example, by improving beam delivery performance, the seam travel rate is accelerated, the cycle time is significantly shortened, and production efficiency is significantly improved.

Accuracy and precision: Excellent beam quality (low M2, high BPP) can support micro-welding and precision component processing. In practical applications, the spot size can be controlled to less than 0.2mm, which is widely used in industries such as aerospace and medical that have extremely high requirements for weld geometry and surface.

Material utilization: Precise focusing and stable energy output mean a smaller heat-affected zone (HAZ), thereby reducing material deformation and heat loss. This not only reduces scrap rate but also saves material costs and improves manufacturing sustainability.

Overall equipment efficiency: Efficient beam delivery not only reduces system downtime and welding error rate, but also increases the equipment’s hourly throughput. Therefore, optimizing the beam delivery system is a key measure to achieve high OEE and production continuity.

By optimizing the transmission efficiency, beam quality, stability, and maintenance specifications in the beam transmission system, faster welding speed, higher precision, less material loss, and stronger equipment reliability can be achieved. For buyers, this means that they can obtain more competitive cost-effectiveness and higher operating returns in the purchase of laser welding machines.

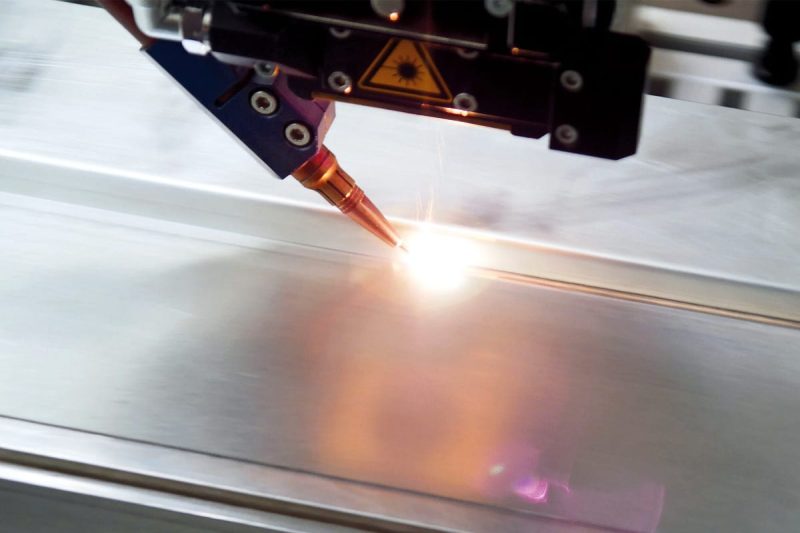

Suggestions for optimizing the beam transmission system to improve efficiency

In a high-performance laser welding machine, the beam transmission system directly determines the welding quality and production efficiency. Optimizing this system can not only improve welding speed, accuracy, and consistency also reduce energy consumption and maintenance costs, which can bring higher returns on investment to investors. Therefore, this section will discuss specific optimization measures in depth from three aspects: “Alignment and calibration”, “quality control”, and “advanced function upgrade”.

Alignment & Calibration

Optical path alignment is the first step to ensure efficient transmission. Regularly using a red light calibrator (or a low-power visible light laser pointer) to align core components such as fiber output, collimating lens, and focusing head can avoid spot offset and focus drift, thereby improving welding consistency and repeatability.

- Calibration process and frequency: It is recommended to perform optical path alignment checks after the first installation of the equipment, after major repairs, and monthly, or before each batch of production. Use a beam analyzer to monitor the spot shape to confirm that parameters such as M2 and BPP remain within the design range; use a power meter to measure the power difference before and after transmission to verify whether the loss is within an acceptable range.

- Tools and methods: Automatic or semi-automatic alignment using a high-precision self-collimating CCD goniometer or laser alignment table helps to quickly detect small deviations and make immediate corrections, especially in environments with vibration or temperature changes, which can significantly improve system stability.

- Safety and records: Be sure to follow safety regulations during calibration and avoid direct visual contact with the laser. Record each calibration data and establish a historical archive of optical path stability to facilitate subsequent trend analysis and preventive maintenance.

Medidas de control de calidad

Strict quality control is the key to maintaining beam transmission efficiency.

- Real-time monitoring of transmission loss: Arrange laser power meters at key nodes of the optical path to monitor laser power changes in real time. When abnormal loss is detected (for example, >1–2%), promptly check for fiber bending, mirror contamination, or coating aging to avoid hidden energy loss accumulation affecting welding results.

- Cleaning and replacement cycle: Develop a cleaning and replacement plan for mirrors, protective windows, and focusing heads based on the degree of dust and splash in the use environment. For example, in dusty or splashing scenes, protective lenses should be checked daily or every shift to avoid scattering and absorption caused by contamination; under normal conditions, high-precision optical coating components should be cleaned weekly and replaced every other month to maintain a low-loss optical path.

- Environment and protection: Provide corresponding protection measures for optical components, such as sealed optical path cabins, gas purges or gas protection devices to reduce the entry of airborne particles and welding slag into the optical path; perform vibration isolation treatment on fiber interfaces and optical tables to reduce the impact of mechanical vibration on the stability of the light spot.

Advanced Features

In addition to mature optimization measures, advanced technologies can achieve smarter and more stable beam transmission:

- Actively cooled focusing head: For high-power and long-term operation, active water-cooled or air-cooled focusing heads can be optionally equipped to reduce the temperature drift of optical components, extend life, and ensure that the focusing accuracy remains unchanged during long-term production.

- Automatic or semi-automatic alignment systems (Opto-mechanical alignment systems): Apply online alignment systems based on CCD or sensors to monitor optical path deviations in real time and drive micro-reflectors or adjustment mechanisms to automatically compensate, reduce manual intervention, and improve production continuity and consistency.

- Remote monitoring and intelligent diagnosis: integrated sensors and an IoT remote monitoring platform can collect indicators such as beam power, focus position, temperature, etc., in real time; combined with AIalgorithm to analyze abnormal trends, early warning of potential faults, support remote maintenance decisions, and reduce downtime risks.

- Modular optical interface: design of quickly replaceable fiber interfaces and focusing head modules, so that the equipment can flexibly adapt to different process requirements (such as switching from welding to marking or engraving), improve equipment utilization, and provide multi-scenario application value.

Through precise Alignment & Calibration, strict Quality Control Measures, and the introduction of Advanced Features such as Active Cooling, automatic alignment, and intelligent monitoring, the efficiency and stability of the beam transmission system can be significantly optimized, thereby improving welding precision, speeding up production rhythm, and reducing energy consumption and maintenance costs. For investors who pursue high cost performance and reliability, paying attention to and investing in the optimization of the beam transmission system can lead to significant returns in the purchase and operation of laser welding machines, ensuring long-term stable production capacity and excellent welding quality.

Resumir

In a high-performance laser welding machine, the beam delivery system is the core of the overall machine efficiency. By optimizing the optical path, ensuring high-quality beam quality (such as low M2 and high energy density), and reducing power loss during transmission, the welding speed and weld accuracy can be greatly improved. For example, high-quality optical components and precise alignment can enable the laser to concentrate energy to quickly form a stable weld, reduce the heat-affected zone and defect rate, thereby improving production consistency and yield. In addition, reliable system stability and strict maintenance management (such as regular cleaning of optical fibers, mirrors, and protective windows) can reduce unexpected downtime and welding errors, which is crucial to improving OEE (Overall Equipment Effectiveness). Only by achieving efficient and stable transmission in the beam transmission link can the laser welding machine maintain high productivity and high-quality output in various materials (such as acero inoxidable, aleación de aluminio, y acero carbono) and complex working conditions.

From the perspective of return on investment (ROI), optimizing the beam delivery system can significantly reduce operating costs and accelerate the payback period. According to industry cases, laser welding systems can achieve investment recovery within 18-24 months by improving production efficiency and reducing defective products and rework, and the optimization of beam transmission is an important driving force. For example, reducing energy consumption losses and maintenance downtime not only directly saves energy and labor costs but also improves equipment utilization and overall production line output. For investors, cost-effective laser welding machines should take into account efficient beam transmission and perfect maintenance solutions, so as to gain a stronger market advantage in international competition and bring higher long-term benefits and operational value to welding projects.

Obtenga soluciones láser

If you are looking for a cost-effective máquina de soldadura láser de fibra o máquina de soldadura láser portátil, or need a customized laser welding solution for stainless steel, carbon steel, aluminum alloy and other materials, Láser AccTek provides everything from beam transmission system calibration (ensuring optimal laser focus and energy transfer) to regular maintenance and fault diagnosis (referring to industry best practices to maintain long-term stable operation of the system), to advanced focus head upgrades and AI parameter optimization (supporting a variety of processes such as deep penetration welding, high-speed welding or micro welding), software and remote monitoring technology (realizing online diagnosis and early warning), as well as on-site operation training and process testing services to help you quickly achieve high-precision welding, high-capacity output and low maintenance costs; no matter which market you are in around the world, we can provide professional consulting, sample testing and ROI evaluation to ensure that your laser welding machine investment gets the maximum return and help improve production efficiency. If you need to learn more about the detailed plan or get a quote, please feel free to Contáctenos!

Información del contacto

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zona A, Zona Industrial de Lunzhen, Ciudad de Yucheng, Provincia de Shandong.

Obtenga soluciones láser