Guide des buses de la machine de découpe laser

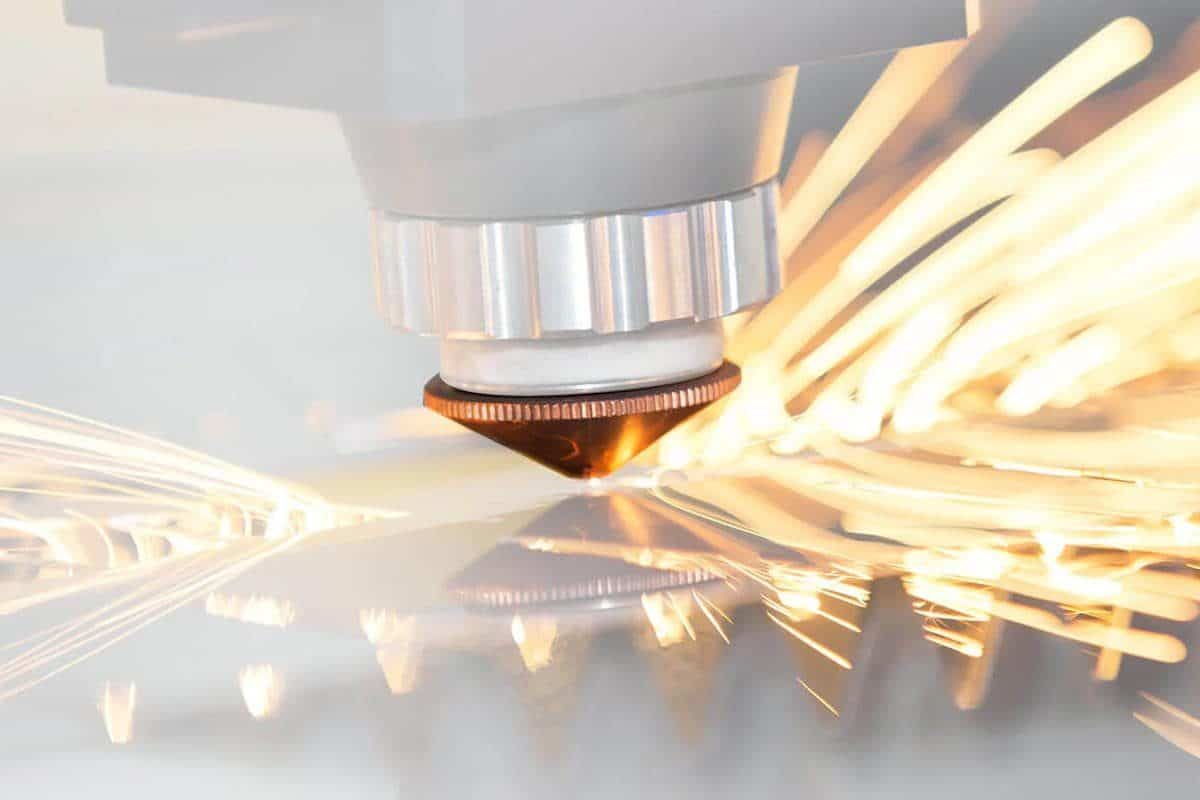

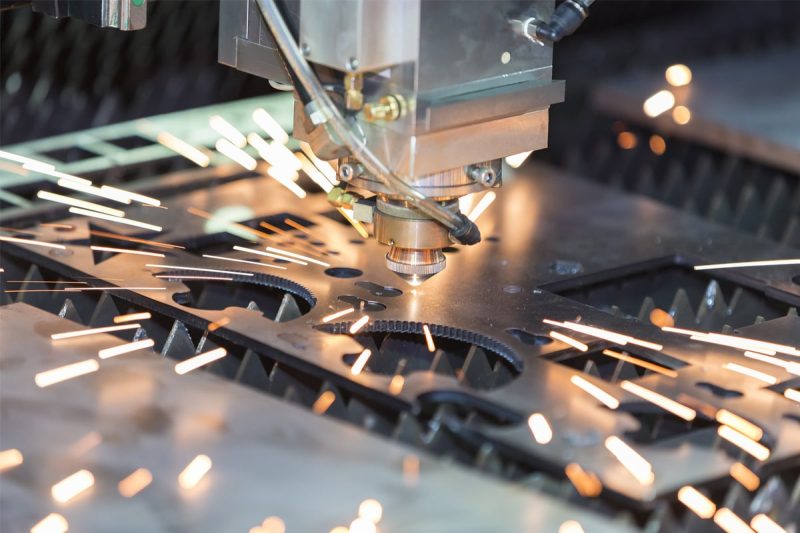

Le machine à découper au laser nozzle is a critical component at the end of the laser cutting head. It not only guides the laser beam, but also controls the flow of assist gas and protects the focusing lens from spatter contamination. The choice and condition of the nozzle directly impact cutting quality, efficiency, and the lifespan of the equipment. Proper nozzle selection and maintenance are crucial to achieving smooth cuts, reducing burrs, and maximizing machine uptime.

Table des matières

Understanding Laser Cutting Machine Nozzles

This section will start with the definition and systematically explain what a laser cutting nozzle is, its core role in the cutting process, and why the selection and maintenance of the nozzle will directly affect the cutting quality and equipment reliability.

Definition: A laser cutting machine nozzle is a precision component mounted at the end of the cutting head, typically machined from metals such as brass or copper. The nozzle’s shape, opening diameter, and internal geometry are specifically designed to physically guide the laser beam and assist the gas to precisely and stably impact the workpiece surface. The nozzle serves as both the interface between the optical system and the workpiece and the first line of defense for assist gas flow formation and optical protection.

The main function of the nozzle

- Focusing the laser beam and stabilizing energy density: The nozzle opening and concentricity directly affect the laser beam’s spot shape and energy distribution upon reaching the workpiece. A coaxial, non-deflective nozzle maintains a stable energy density, thereby reducing kerf distortion and improving cutting consistency.

- Delivering and regulating the assist gas flow field: The nozzle directs a controlled flow of high-pressure oxygen, nitrogen, or air to accelerate the evacuation of molten metal from the kerf. The nozzle diameter and internal cavity structure determine the gas velocity and distribution, which in turn influences cutting depth, edge oxidation (or the avoidance of oxidation), and burr formation.

- Protecting the focusing lens and internal optics: During the cutting process, slag, spatter, or air flow disturbances can cause particles to rebound into the cutting head cavity. The nozzle acts as a physical barrier, reducing particle entry into the optical path, minimizing the risk of lens contamination and reflective damage, thereby extending optical component life and reducing maintenance frequency.

- Assisting thermal management and kerf quality control: The nozzle, combined with the appropriate gas type and pressure, helps control the cooling rate within the kerf, minimizing the heat-affected zone (HAZ), and improving the cut edge finish. Especially when cutting at high power and thick plates, the cooling of the nozzle and the stability of the airflow have a significant impact on the yield.

Although the nozzle is a small component in the cutting head, it has a decisive impact on the cutting accuracy, edge quality, processing speed, and equipment reliability of the laser cutting machine. Correct nozzle selection, precise installation, and regular maintenance are the basis for ensuring efficient and stable cutting.

Nozzle type

This section introduces two common structures of laser cutting machine nozzles: single-layer nozzles and double-layer nozzles. It also explains their working principles, advantages and disadvantages, typical application scenarios, and suggestions on actual cutting parameter selection to help you make the most appropriate nozzle selection for different materials and processing requirements.

Single-layer nozzle

- Definition and Structure: Single-layer nozzles have a simple structure, with a single gas path within the nozzle body. Assist gas enters the kerf directly through a single opening or directional aperture.

- Airflow Characteristics: The concentrated airflow and stable spray direction create a narrow, strong air column, which facilitates rapid and precise slag removal from thin sheets.

- Applicable Materials and Thicknesses: Commonly used for thin sheet cutting (e.g., acier au carbone, acier inoxydable, or aluminium ≤3–6 mm, depending on power). They excel in fine cutting applications requiring a smooth edge finish and a narrow heat-affected zone (HAZ).

avantage:

- Simple structure and low cost;

- Narrow kerf and smoother surface for thin plate and fine contour cutting;

- Easier to maintain and replace.

shortcoming:

- Limited gas throughput hinders deep cutting or rapid slag removal on thick plates.

- Dross buildup and poor penetration are common during high-power, high-thickness cutting.

Parameter recommendations:

- Thin sheets with smaller diameters (e.g., ~0.8–1.5 mm) achieve better edge quality.

- When using nitrogen (stainless steel/aluminum) or oxygen (carbon steel), adjust the pressure and cutting speed based on the material thickness to optimize cleanliness and efficiency.

Double-layer / dual-layer nozzle

- Definition and Structure: A double-layer nozzle features two coaxial air paths (or two openings) within the nozzle body, creating airflows with different parameters in the inner and outer layers. This enables more complex pneumatic control and enhanced kerf purge capabilities.

- Airflow Characteristics: The double-layer design allows the inner and outer airflows to work synergistically—the inner layer stabilizes the beam and locally removes slag, while the outer layer provides diffuse cooling and protection. The result is a stronger, more stable overall airflow and improved cooling.

- Applicable Materials and Thicknesses: Particularly suitable for high-power fiber laser cutting and thick plate processing (such as medium to thick carbon steel, stainless steel, and thick aluminum alloys), as well as applications requiring oxidation-free kerfs or high surface quality (colorless cutting is possible when used with high-pressure nitrogen).

avantage:

- More flexible gas flow and control enable more efficient slag removal in deep grooves.

- Improved cooling efficiency extends nozzle and optical component life.

- Maintains consistent cutting quality and minimizes flashback even on thick plates or at high power.

shortcoming:

- Complex structure and high cost;

- Requires a higher gas source and parameter adjustment (needs proper pressure/flow matching and more precise calibration);

- Relatively difficult to maintain and replace.

Parameter recommendations:

- When cutting thick plates, use a larger diameter and higher gas pressure (especially the outer gas flow), and pay attention to adjusting the internal and external gas flows in layers.

- When colorless cutting is required for stainless steel or aluminum, use high-purity nitrogen and preferably choose a double-layer nozzle to reduce oxidation and discoloration.

Single-layer and double-layer nozzles each have their strengths. Single-layer nozzles are primarily characterized by their simple structure, economy, and suitability for fine-cutting thin plates. Double-layer nozzles, on the other hand, offer stronger airflow, improved cooling, and are more suitable for thicker plates and high-power applications. Correctly assessing the material being processed, thickness, and production capacity requirements, along with the appropriate gas type and parameters, is crucial for selecting the right nozzle and achieving high-quality laser cutting. For further fine-tuning tailored to specific application conditions, please refer to the equipment data sheet or contact our after-sales engineers for optimization recommendations.

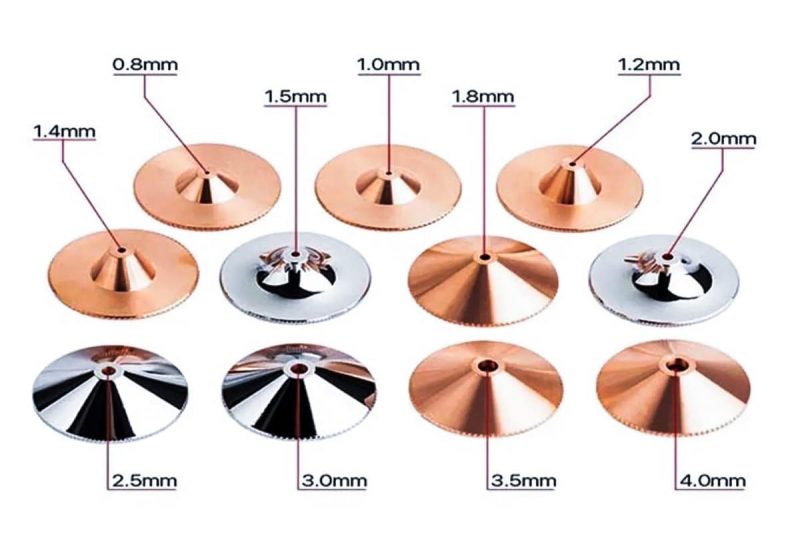

Nozzle size

Nozzle orifice diameter is a key parameter affecting cutting quality and efficiency. While the nozzle itself does not directly change the physical diameter of the laser beam, the orifice determines the flow rate, velocity, and spray pattern of the assist gas, which in turn influences slag removal efficiency, kerf width, heat-affected zone, and cutting stability.

The influence of different calibers on cutting

- Airflow Concentration and Speed: Smaller apertures produce more concentrated airflow and higher speed (at the same source pressure), making them suitable for precisely targeting the slag impact point. Larger apertures allow for greater airflow, making them more effective for removing slag from deep grooves.

- Kerf Width and Heat-Affected Zone (HAZ): Smaller apertures tend to produce narrower kerfs and smaller HAZs. Larger apertures typically produce wider kerfs and larger HAZs, but can improve yields for thicker plates.

- Gas Consumption and Cost: Larger apertures consume more auxiliary gas (especially high-pressure nitrogen) per unit time, resulting in higher operating costs. Smaller apertures also increase instantaneous consumption under high-pressure conditions, but are generally more economical.

- Impact on Lens and Nozzle Life: Larger apertures, due to their larger exposed surface area, are more susceptible to backsplash. Improper airflow control or positioning can accelerate wear on the nozzle and protective lens. Smaller apertures, however, can also overheat and damage under high power conditions if insufficient cooling is applied.

Caliber segmentation and typical adaptation

- Small diameter: 0.8–1.5 mm

- Applications: Precision cutting of thin sheets, complex contours, and small parts.

- Features: Narrow kerf, smooth surface, and small HAZ.

It is recommended to use high-precision parameters, high or stable gas pressure (to ensure that the slag is effectively discharged), and usually nitrogen or low-pressure oxygen (depending on the material).

- Medium diameter: 1.5–2.5 mm

- Applications: Medium thickness (common shop orders and prototypes), general mass production.

- Features: Balances precision and slag removal capabilities, offering strong adaptability.

It is recommended to use medium air pressure and moderate cutting speed for medium-thickness work on carbon steel, stainless steel and aluminum.

- Large diameter: ≥2.5 mm (3.0 mm is common).

- Applications: Thick plates, heavy-load production, and applications requiring high-speed slag removal.

- Features: High gas throughput and high slag removal efficiency, but with a wide kerf and relatively reduced accuracy.

It is recommended to use higher air pressure, greater power and slower cutting speed to ensure cutting penetration and reduce bottom dross; it is preferred to use a double-layer nozzle to enhance airflow stability and cooling effect.

Example of matching with workpiece material/thickness

- Thin plates (e.g., ≤3 mm) → 1.0–1.5 mm (small diameter), preferably using high-purity nitrogen (stainless steel/aluminum) or a moderate amount of oxygen (carbon steel).

- Medium-thick plates (approximately 3–12 mm) → 1.5–2.0 mm (medium diameter), choosing between nitrogen and oxygen, and adjusting the cutting speed based on the material.

- Thick plates (>12 mm) → 2.5–3.0 mm (large diameter) or larger, preferably using a double-layer nozzle and a higher gas flow (or oxygen-assisted cutting to increase cutting speed if oxidation discoloration is acceptable).

Linked with air pressure, focus and cutting speed

After selecting the caliber, the following parameters must be optimized:

- Gas Pressure: Small diameters generally require a more stable or higher local pressure to maintain effective jetting; large diameters require a higher overall flow rate and appropriate jet velocity.

- Nozzle Height (Stand-Off) and Concentricity: The smaller the diameter, the more sensitive the cutting effect of nozzle position errors. Ensure concentricity and set the correct height according to machine tool parameters.

- Cutting Speed and Power: When using a small diameter to improve accuracy, speed and power should be adjusted appropriately to avoid drossing and overburning. Large diameters are generally used with higher power and slower traverse speeds when cutting thick plates.

Maintenance points

Smaller diameters are more susceptible to partial clogging with slag and require more frequent inspection and cleaning. A shorter cleaning cycle (e.g., daily or per-shift inspection) is recommended. For large diameters, pay attention to wear and deformation of the nozzle edge during intensive use. Any enlargement or irregularity of the nozzle should be promptly replaced to prevent compromised kerf quality. Regardless of the nozzle diameter, if burnout, cracks, or significant decentering are observed, the nozzle should be replaced immediately and the optical path and focus recalibrated.

If extreme precision and narrow kerfs are the goal, consider a small nozzle diameter of 0.8–1.5 mm. For a balance between productivity and quality, choose a medium nozzle diameter of 1.5–2.0 mm. For thick plates or high-volume production, choose a large nozzle diameter of 2.5 mm or larger (preferably a double-layer nozzle), combined with higher airflow and appropriate cutting parameters.

The correct nozzle size is not an isolated parameter; it interacts with gas type/pressure, focusing method, laser power, and cutting speed. Before production begins, it is recommended to conduct trial cuts on a small batch to document the optimal nozzle diameter and parameter combination. This will create a reliable process chart to improve consistency and productivity.

Nozzle material

Nozzle material directly impacts thermal management, wear resistance, service life, and cutting stability. Common nozzle materials are brass and copper. This section will explain their physical properties, advantages and disadvantages, applicable scenarios, maintenance tips, and selection recommendations to help you choose the most cost-effective nozzle for fiber laser cutting.

Basic influence of materials on cutting performance

- Thermal Conductivity: Materials with good thermal conductivity dissipate heat more quickly, reducing the risk of localized nozzle overheating, deformation, or ablation, thereby maintaining stable airflow and kerf quality.

- Wear and Corrosion Resistance: Materials with high wear and corrosion resistance are less susceptible to damage at high production volumes or in oxygen-rich environments, reducing replacement frequency.

- Processing and Cost: The material itself and processing accuracy determine cost, which in turn influences replacement strategies and overall operating costs.

Brass nozzle

- Physical Properties and Performance: Brass is an alloy of copper and zinc, offering both workability and strength. Its thermal conductivity is good, but slightly inferior to pure copper. Manufacturing costs and unit prices are generally lower than pure copper.

- Advantages: Low cost and high cost-effectiveness; easy processing, capable of creating complex internal cavities; stable and durable performance in most common machining operations (short runs, thin plate cutting).

- Disadvantages: Its thermal conductivity is inferior to pure copper, making it more susceptible to heating during prolonged high-power or continuous dwell cutting. Under extremely high power or heavy plate loads, its lifespan and stability may be lower than those of copper nozzles.

- Useful Applications: Daily light-duty or intermittent thin/medium-thick plate cutting; cost-sensitive production lines where extreme durability is not a priority.

- Maintenance Recommendations: Small-diameter brass nozzles require more frequent cleaning to prevent clogging. Significant burnout, diameter expansion, or edge burrs should be promptly replaced to maintain cutting quality.

Copper nozzle

- Physical Properties and Performance: Pure copper or high-thermal-conductivity copper alloys offer improved heat conduction and heat dissipation, effectively controlling nozzle temperature rise and deformation during high-power, continuous operation.

- Advantages: Excellent thermal conductivity and rapid heat dissipation allow for higher power and long-term continuous operation; more stable during high-intensity cutting or thick plate processing, reducing cutting deviations caused by deformation; generally longer lifespan, making them particularly economical (in terms of lifespan) in high-volume production environments.

- Disadvantages: Higher unit cost than brass; higher processing and manufacturing costs, resulting in increased inventory investment.

- Applicable Applications: High-power fiber laser cutting machines, workshops with frequent continuous operations or thick plate processing; applications with high requirements for edge quality, repeatable positioning accuracy, and nozzle lifespan.

- Maintenance Recommendations: Even copper nozzles require regular inspection for concentricity and bore integrity. Even under prolonged heavy loads, it is recommended to inspect nozzles on a shift-by-shift basis and maintain a nozzle replacement log to optimize costs.

Brass and copper each have their advantages. Brass is suitable for cost-sensitive, routine machining with regular loads, offering a good price-performance ratio. Copper is ideal for high-power, continuous production scenarios with high precision and lifespan requirements. When selecting a nozzle material, we recommend a comprehensive evaluation of laser power, machining load, material type, and production cycle time, along with a maintenance and replacement plan tailored to the operating conditions to achieve optimal cutting stability and cost-effectiveness. If you require more detailed selection advice (for a specific machine model or power range), I can provide more tailored parameter and maintenance interval recommendations based on your machine model and common operating conditions.

Factors affecting nozzle performance

Even if the nozzle model and material are selected correctly, the actual cutting effect is still affected by several operational and environmental factors. This section briefly explains the common factors to facilitate the quick identification and troubleshooting of problems in daily production.

- Cleanliness (Nozzle Cleanliness): Slag, dust, or spatter inside or outside the nozzle can alter the airflow pattern and partially block the nozzle, resulting in reduced purge efficiency, rough cuts, or partial incomplete cuts. Small-diameter nozzles are particularly susceptible to clogging, so a regular cleaning and inspection system should be established.

- Concentricity and Focus (Centering and Focusing): The nozzle must be coaxial with the laser beam and maintain the correct nozzle-to-workpiece distance (stand-off). Eccentricity or focal offset can result in overburning on one side, incomplete cuts on the other, or offset cuts. Pay attention to positioning accuracy during installation and perform optical path alignment or autofocus checks as necessary.

- Assist Gas and Gas Pressure: The assist gas type (oxygen/nitrogen/compressed air) and pressure directly affect slag removal, cutting speed, and cut edge color. Insufficient pressure can cause dross buildup, while excessive pressure or turbulent airflow can create turbulence and impair the cut edge finish. Refer to machine tool parameters and make fine adjustments based on the material and diameter. Maintaining a stable and clean gas source is also crucial.

- Cutting Speed and Laser Power: These cutting speeds and laser power must be coordinated with the nozzle diameter and gas parameters. Excessively fast speeds can delay slag removal, resulting in burrs. Excessively slow speeds or excessively high power can increase slag accumulation and thermal effects. It’s recommended to create a process chart through trial cuts, recording the optimal parameters for different combinations.

- Environment and Maintenance: Details such as workshop temperature and humidity, air quality (including moisture, oil, and particulate content), and nozzle assembly torque can also affect nozzle performance. Using a clean, stable air source and standardized installation procedures can significantly reduce the risk of failure.

Is there visible slag or blockage in the nozzle? Are the nozzle and laser beam concentric and at the correct focal length? Does the type and pressure of the assist gas used match the material and diameter recommendations? Do the cutting speed and power match the nozzle diameter? Is the gas source clean and the pressure stable? By quickly troubleshooting in this order, most cutting problems caused by nozzles can be quickly located and resolved.

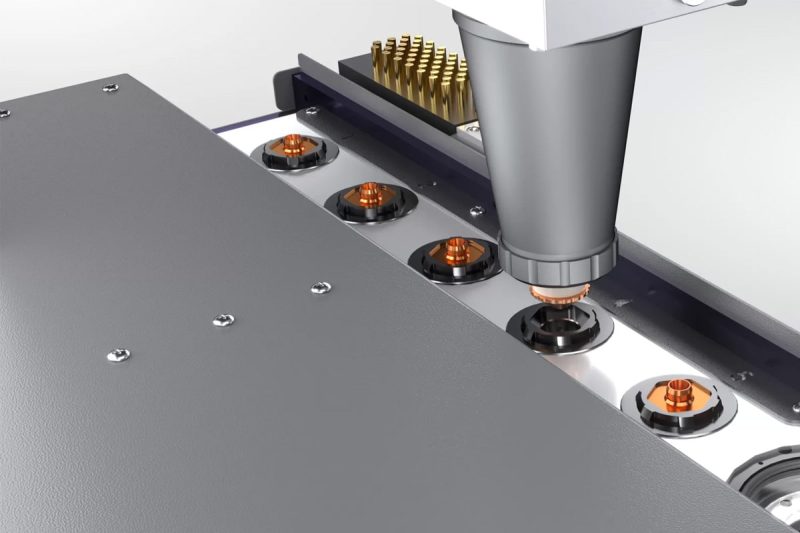

How to choose the right nozzle

Nozzle selection isn’t determined by a single parameter; it’s a complex combination of material type, plate thickness, cutting objectives (speed, surface quality, colorless cutting), machine power, and gas conditions. Below are more systematic decision-making points, common scenario recommendations, and operational tips to facilitate rapid nozzle selection and optimization in actual production.

Decision Points

- What material will be cut? (Carbon steel/Stainless steel/Aluminum/Other)

- What is the thickness range of the plate? (Thin plate/Medium plate/Thick plate)

- Is speed the most important goal, or is edge quality/colorless cutting a priority?

- What are the laser power and gas source capabilities of the machine? (Higher power machines can support larger diameters and higher pressures.)

- Is oxidation discoloration acceptable? (O2 can accelerate carbon steel, but it will cause oxidation discoloration.)

After determining the above questions, quickly select the model according to the following classification suggestions. Recommendations by material and thickness (common industry reference):

Mild / Carbon Steel

- Combustion-supporting gas: Oxygen is often used to increase cutting speed and utilize oxidation to aid cutting.

- Nozzle Type: Single or double-layered is acceptable, with double-layered nozzles preferred for thicker plates to enhance slag removal and cooling.

- Size Recommendations: Thin plates (≤3 mm) can use 1.0–1.5 mm; medium-thick plates (3–12 mm) use 1.5–2.5 mm; thick plates (>12 mm) are recommended to use ≥2.5 mm.

If speed is the priority and color is not important, a larger diameter and oxygen-assisted cutting can be selected; if a smooth surface is required, the speed can be reduced or post-processed appropriately.

Acier inoxydable

- Combustion-supporting gas: High-purity nitrogen for non-oxidizing, colorless cutting.

- Nozzle type: A double-layer nozzle is preferred to ensure stable high-pressure nitrogen flow and kerf cooling.

- Suggested size: 1.0–2.0 mm is generally used for thin to medium-thick materials; for thicker materials, increase the size to 2.0–2.5 mm and increase the gas pressure.

Nitrogen has high requirements for cleanliness and pressure, and the quality of the gas source directly affects the color and smoothness of the cut edges.

Aluminum and aluminum alloys

- Combustion-supporting gas: High-pressure nitrogen is preferred (compressed air is a cost-effective option, but may cause slight discoloration).

- Nozzle type: Double-layer nozzles offer advantages for high-thermal-conductivity materials (improving cooling and slag removal).

- Size recommendation: 1.5–2.5 mm is commonly used. For thicker plates, adjust upwards and use higher power and pressure.

Aluminum dissipates heat quickly and has a low melting point, so it requires appropriate power and higher gas pressure to prevent slag from adhering.

Other practical selection rules

- Thin plates (≤3 mm) → Small diameter (0.8–1.5 mm), single-layer preferred (for narrow gaps and high precision).

- Medium-thick plates (3–12 mm) → Medium diameter (1.5–2.0 mm), select the gas and single/double-layer cutting based on the material.

- Thick plates (>12 mm) → Large diameter (≥2.5 mm), double-layer cutting with higher gas pressure or oxygen-assisted cutting (for carbon steel) preferred.

- High-power machine tools/continuous production lines → Copper nozzles and double-layer construction preferred for extended life and stability.

- Colorless cutting required (e.g., stainless steel for food, medical, or decorative applications) → High-purity nitrogen + double-layer cutting with small diameter for optimized surface finish.

Debugging and Verification Techniques

- Test cuts before mass production: For new materials or thicknesses, perform 1-3 test cuts, record the optimal nozzle diameter, air pressure, power, and speed, and create a process chart.

- Observe the kerf and bottom dross: If there is excessive bottom dross, increase the air pressure or use a larger nozzle diameter. If the kerf is black or severely oxidized, switch to nitrogen or reduce the oxygen flow rate.

- Pay attention to the life of the lens and nozzle: Do not hesitate to replace the nozzle; enlarging the nozzle diameter or edge burnout will quickly affect product consistency.

Gas source quality: Nitrogen must be clean and oil-free, and compressed gas must be filtered and dried; otherwise, it will promote nozzle clogging and lens contamination.

Quick Checklist (Final Confirmation Before Selection)

- Are the material type and thickness clearly defined?

- Is speed or surface quality the primary objective?

- Is the machine’s power and gas capabilities (pressure/flow/purity) compatible with the selected nozzle?

- Are test cuts planned to confirm the parameters?

When selecting a nozzle, consider the material, thickness, cutting target, and machine capabilities. Small diameters are recommended for thin plates, while large diameters are recommended for thick plates. For colorless/high-gloss finishes, high-pressure nitrogen and double-layer nozzles are recommended. For high power and continuous production, copper and double-layer structures are preferred. The most reliable approach is to establish a process card through trial cutting and then optimize the process based on actual operational data.

Common problems and troubleshooting

Nozzle problems are a common source of quality and stability issues in laser cutting. Common symptoms include rough cuts or bottom dross, asymmetrical cuts (overburning on one side while undercutting on the other), unstable penetration, and nozzle overheating, deformation, or cracking. The root causes are often attributed to: nozzle blockage with slag or dust inside or outside, misalignment between the nozzle and the laser beam or skewed installation, insufficient auxiliary gas pressure or contaminated gas source, mismatch between cutting parameters (speed/power) and nozzle diameter, or nozzle material incompatibility with the workload (for example, brass is prone to heat loss under high power and prolonged operation).

When encountering problems, it is recommended to quickly troubleshoot and resolve them in the following order: First, perform a visual inspection—check the nozzle diameter for slag blockage, burn marks, or cracks; also, check the surrounding protective cover and protective mirror for contamination. Next, check the gas supply system—confirm that the gas pressure meets the recommended value in the process chart, that the gas is clean (free of oil, water, or particles), and that the gas line and filter are clear of blockages or leaks. Next, confirm the nozzle installation and optical path alignment—ensure the nozzle is coaxial with the laser beam, that the assembly is tight, and that the nozzle-to-workpiece standoff distance is correct. If the machine has automatic alignment or self-test functions, run the calibration procedure. After completing these basic checks, perform a test cut to observe the kerf shape, edge finish, and changes in bottom dross to determine whether cleaning/parameter adjustment can resolve the problem or whether the nozzle or lens must be replaced. If the nozzle diameter is significantly enlarged, or if burrs or cracks appear on the edge, replace it immediately. If the protective lens is severely contaminated, clean or replace it immediately to avoid further risk of light reflection.

Quick solutions for common faults: Nozzle buildup: Stop the machine, remove, and clean with a dedicated cleaning needle or soft brush. If severe, perform ultrasonic cleaning or simply replace the nozzle. Asymmetrical or skewed cuts: Reinstall and tighten to the specified torque, calibrating concentricity and focus. Excessive bottom dross: First check the air pressure and purity, increase the pressure appropriately, or replace with a larger nozzle, then optimize speed/power. Nozzle overheating or damage: Check the nozzle height and focus, avoid working too close, and consider switching to a copper nozzle with better thermal conductivity or reducing the continuous load.

To reduce the failure rate, it is recommended to establish and implement the following preventative measures: Maintain a clean air source (install and regularly replace a filter/dryer); schedule nozzle inspection and cleaning intervals based on shifts or production volume (smaller diameters require more frequent inspections under higher loads); record the usage time and replacement reason for each nozzle to create a lifespan database; strictly install nozzles according to machine parameters and record torque and height settings; and perform test cuts and create process cards before introducing new materials or thicknesses. By combining a quick troubleshooting process with regular maintenance and data logging, most nozzle-related issues can be minimized, maintaining consistent cutting quality and high equipment availability.

Résumer

Although small, the laser cutting machine nozzle plays a crucial role in the cutting process. Selecting the appropriate nozzle type, size, and material, and maintaining cleanliness and proper installation can significantly improve cutting quality and efficiency.

En tant que fabricant professionnel d'équipements laser, Laser AccTek has accumulated extensive experience in nozzle application and maintenance through years of industry experience. If you are looking to further optimize your cutting process or are seeking high-performance laser cutting solutions, we are your trusted partner.

Coordonnées

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, zone industrielle de Lunzhen, ville de Yucheng, province du Shandong.

Obtenez des solutions laser