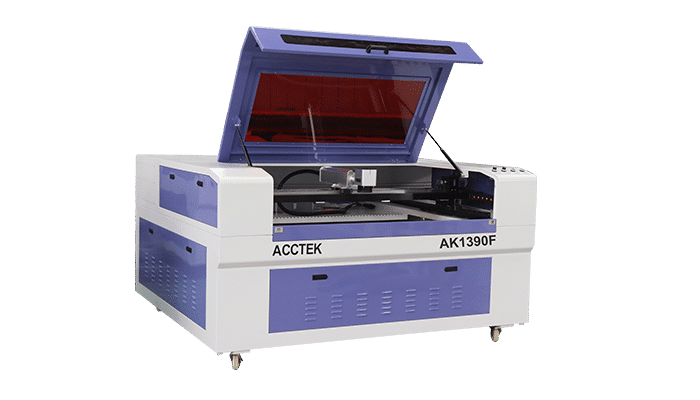

Timber Laser Cutting Machine

Photoelectric Technology

AccTek Laser focus on designing and manufacturing photoelectric-related system. We provide accurate and exquisite processing quality with leading R&D capability.

Integration Ability & Experienced

With an experienced, completed, and elite R&D team, customized such as automated, integrated with the robot, system integration, etc. are all available.

Professional Service

AccTek Laser's laser cutting machine is a professional laser cutting machine designed and manufactured in China. Our elite engineering team provides related service support.

Equipment Features

High Power CO2 Laser Tube

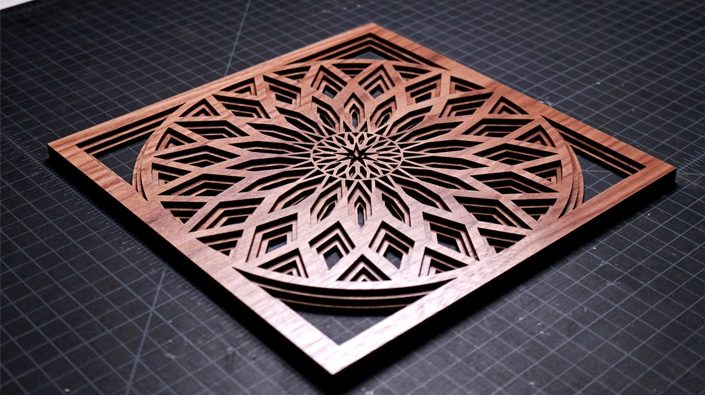

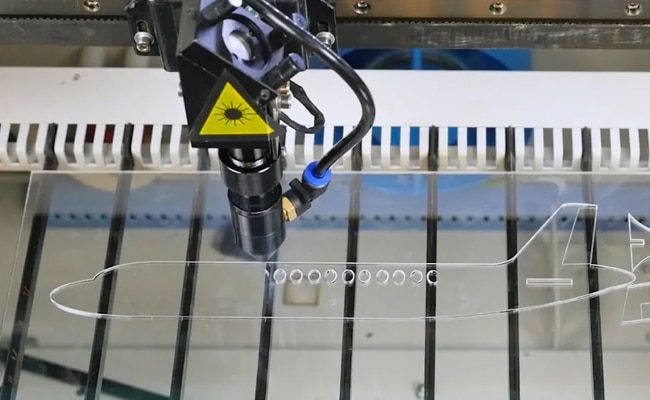

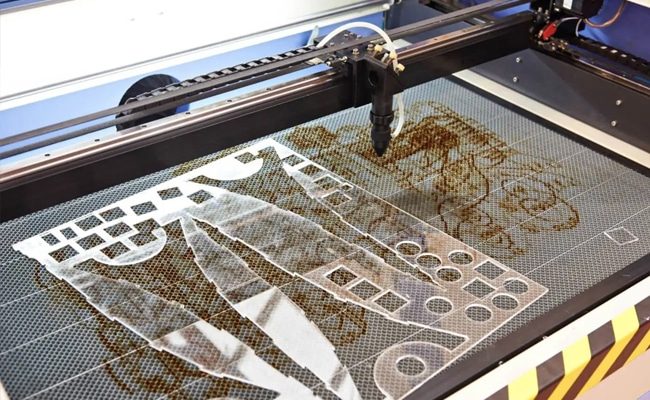

The machine is equipped with a powerful CO2 laser tube, which can provide precise and efficient cutting and engraving performance on various materials, including acrylic, wood, leather, fabric, glass, and so on. A high-powered laser tube ensures clean, precise cuts and smooth edges, while also enabling detailed engraving, making it suitable for intricate designs and industrial applications.

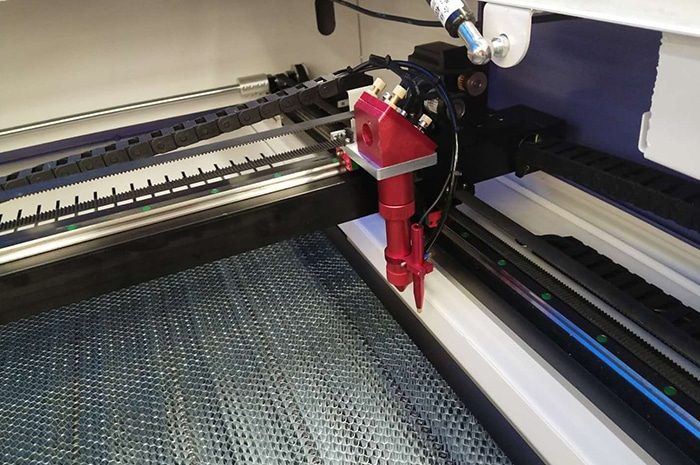

Advanced Motion System

The machine is equipped with an advanced motion system to ensure smooth and accurate movement of the laser head during cutting and engraving. This precise motion control enables clean, sharp cuts while also enabling detailed and intricate engraving on a variety of materials.

High-Quality Optics

The machine is equipped with high-quality optics capable of producing a narrower, more stable laser beam, ensuring precise cutting paths and cleaner edges even on complex designs and delicate materials. In addition, high-quality optics help reduce beam divergence and losses, thereby improving energy efficiency.

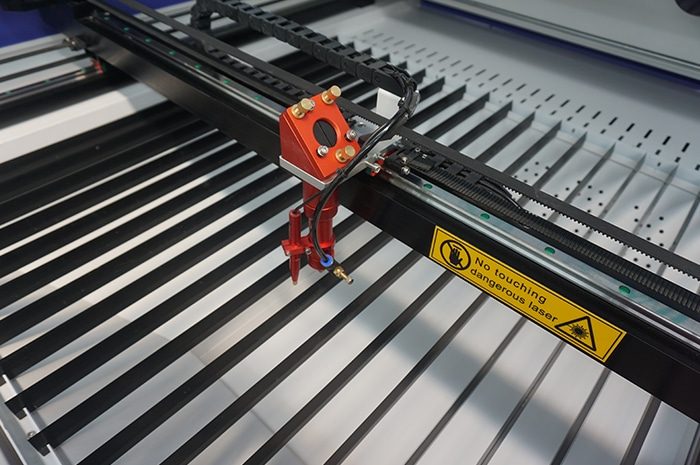

High-Precision CO2 Laser Head

The high-precision CO2 laser head is selected, and it has a red dot positioning function to ensure that the laser beam is precisely aligned with the focusing optics and the nozzle. An accurate laser beam contributes to consistent and uniform cutting results. Additionally, the CO2 laser head is equipped with height control, which ensures consistent focus and compensates for any variations in material thickness or uneven surfaces.

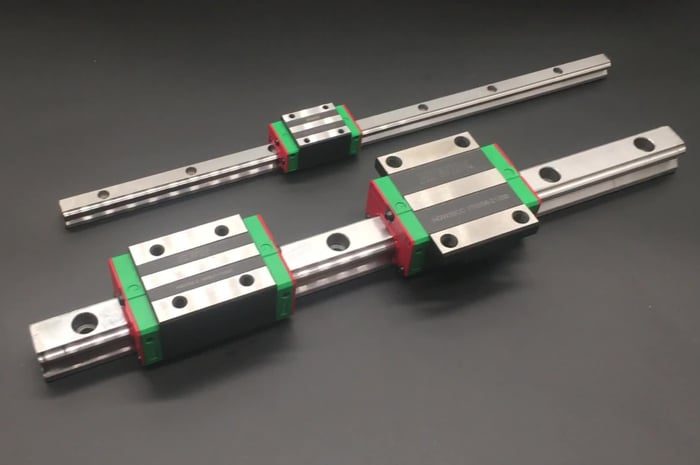

High-Precision HIWIN Rail

The machine is equipped with a Taiwan HIWIN guide rail with excellent precision. HIWIN is manufactured to tight tolerances, ensuring smooth and stable linear motion. This level of precision contributes to accurate and consistent laser cutting, especially when working with intricate designs and fine details. In addition, HIWIN rails are designed to minimize friction, resulting in smooth and quiet movement.

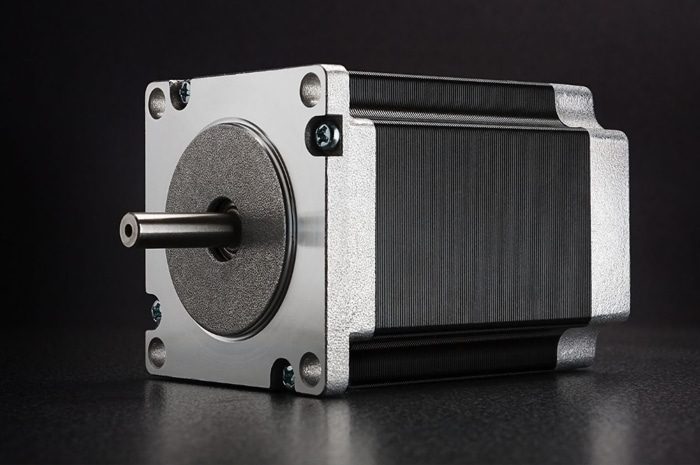

Reliable Stepper Motor

The machine adopts a stepper motor with strong power and reliable performance to ensure the normal operation of the machine. Not only are stepper motors cost-effective, but they also provide precise control of moving parts, ensuring high-quality laser cutting and stable positioning of optical components for reliable, efficient operation.

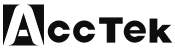

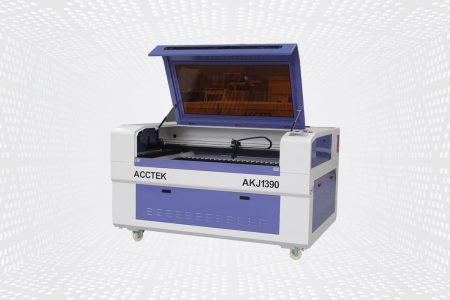

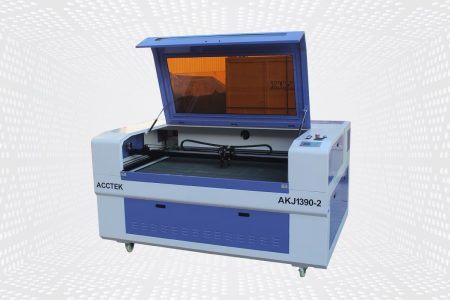

Technical Specifications

| Model | AKJ-6040 | AKJ-6090 | AKJ-1390 | AKJ-1610 | AKJ-1810 | AKJ-1325 | AKJ-1530 |

|---|---|---|---|---|---|---|---|

| Working Area | 600*400mm | 600*900mm | 1300*900mm | 1600*1000mm | 1800*1000mm | 1300*2500mm | 1500*3000mm |

| Laser Medium | CO2 laser | ||||||

| Laser Power | 80-300W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Cutting Speed | 0-20000 mm/min | ||||||

| Engraving Speed | 0 - 40000mm/min | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cooling System | Water-cooling | ||||||

Laser Welding Capacity

| Laser Power | Cutting Speed | 3mm | 5mm | 10mm | 15mm |

|---|---|---|---|---|---|

| 25W | Max Cutting Speed | 4mm/s | / | / | / |

| Optimal Cutting Speed | / | / | / | / | |

| 40W | Max Cutting Speed | 10mm/s | 5mm/s | / | / |

| Optimal Cutting Speed | 8mm/s | / | / | / | |

| 60W | Max Cutting Speed | 15mm/s | 10mm/s | 4mm/s | / |

| Optimal Cutting Speed | 12mm/s | 8mm/s | / | / | |

| 80W | Max Cutting Speed | 20mm/s | 15mm/s | 8mm/s | / |

| Optimal Cutting Speed | 18mm/s | 10mm/s | 6mm/s | / | |

| 100W | Max Cutting Speed | 25mm/s | 20mm/s | 12mm/s | 8mm/s |

| Optimal Cutting Speed | 22mm/s | 18mm/s | 10mm/s | 5mm/s | |

| 130W | Max Cutting Speed | 30mm/s | 25mm/s | 15mm/s | 11mm/s |

| Optimal Cutting Speed | 28mm/s | 22mm/s | 13mm/s | 8mm/s | |

| 150W | Max Cutting Speed | 35mm/s | 30mm/s | 20mm/s | 15mm/s |

| Optimal Cutting Speed | 33mm/s | 30mm/s | 20mm/s | 15mm/s | |

| 180W | Max Cutting Speed | 40mm/s | 35mm/s | 25mm/s | 18mm/s |

| Optimal Cutting Speed | 37mm/s | 32mm/s | 20mm/s | 15mm/s | |

| 200W | Max Cutting Speed | 50mm/s | 45mm/s | 35mm/s | 25mm/s |

| Optimal Cutting Speed | 48mm/s | 42mm/s | 30mm/s | 22mm/s |

Comparison of Different Cutting Methods

| Features | Laser Cutting | Router Cutting | Band Saw Cutting | Chain Saw Cutting |

|---|---|---|---|---|

| Precision | High | High | Moderate to High | Moderate to Low |

| Cutting Speed | High | Moderate to High | Moderate to High | Low to Moderate |

| Cutting Thickness | Thin to Thick | Thin to Thick | Thick | Very Thick |

| Cleanliness of Cut | Very Clean | Clean | Clean | Rough |

| Kerf Width | Very Narrow | Narrow | Moderate | Wide |

| Intricate Cuts | Yes (Detailed) | Yes | Limited | No |

| Material Wastage | Minimal | Moderate | Moderate | Significant |

| Safety | Safer (No Contact) | Safe | Moderate | Potentially Hazardous |

| Noise Level | Low | Moderate | Moderate | High |

| Suitable for Logs | No | No | No | Yes |

| Maintenance | Low | Moderate | Moderate | Moderate to High |

| Tool Mobility | Fixed (Machine) | Fixed (Machine) | Stationary | Portable |

| Cost | High | Moderate | Moderate | Moderate |

Product Features

- The machine with a high-quality CO2 laser generator, this machine is ideal for cutting and engraving various types and thicknesses of wood.

- The machine has different laser power options, with higher laser power cutting thicker materials faster and cleaner.

- The machine has high precision and accuracy to achieve complex designs and fine details.

- The machine comes with a user-friendly touchscreen interface that allows users to design, import, and control the cutting or engraving process, making machine setup and operation easier.

- The machine has material compatibility and can handle a variety of wood materials, including different types of hardwood, plywood, MDF, and veneer.

- The machine is equipped with a red dot pointer that helps operators visually see the laser path before cutting or engraving, assisting with precise positioning and alignment.

- The machine is compatible with a variety of design software, allowing users to create or import patterns and designs for cutting and engraving.

- The machine is equipped with a stable and reliable cooling system that can maintain the laser tube at the optimal working temperature and extend its service life.

- The machine features adjustable cutting and engraving speeds to optimize productivity while maintaining quality.

- The machine is equipped with an autofocus system feature that ensures the laser maintains an optimal distance from the material surface for consistent cutting and engraving results.

Product Application

Equipment Selection

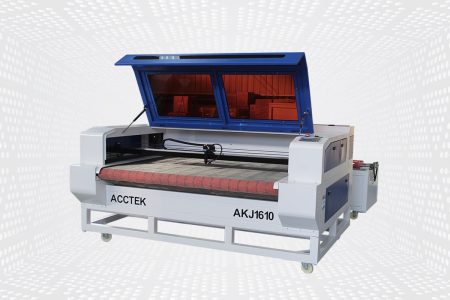

High Configuration CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With CCD Camera

CO2 Laser Cutting Machine With Electric Lift Table

Fully Enclosed CO2 Laser Cutting Machine

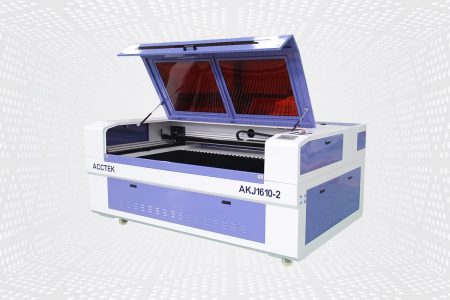

Double Head CO2 Laser Cutting Machine

CO2 Laser Cutting Machine With Automatic Feeding Device

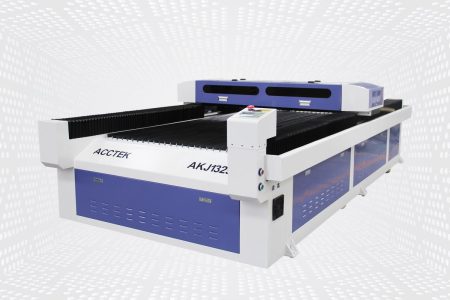

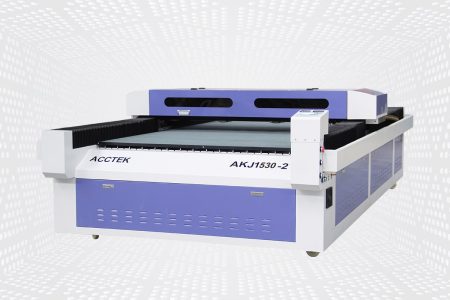

Large-Size CO2 Laser Cutting Machine

Double Head Large Size CO2 Laser Cutting Machine

Why Choose AccTek?

Impeccable Precision

Unrivaled Quality

Customized Solutions

Excellent Customer Support

Frequently Asked Questions

- Burn marks: Laser cutting generates heat, which may cause burn marks to appear on the edges of the cut. This may be more noticeable on light-colored timber, and additional finishing work may be required to remove or hide the marks.

- Material scorch: The heat generated by the laser during laser cutting can cause the surface of the timber to scorch, especially when cutting slowly or using high-power settings. This may require additional finishing steps to eliminate or minimize the charring effect.

- Material selection: Not all timber types are suitable for laser cutting. Some timbers may produce toxic fumes or odors when heated by lasers, making them unsuitable for indoor or confined space operations.

- Material thickness: Laser cutting has limitations when cutting thicker wood materials. Cut depth depends on laser power and timber type, so extremely thick timber may require multiple cuts or other cutting methods.

- Material warping: The intense heat generated during laser cutting can cause thinner timber materials to warp or bend. This distortion can affect the accuracy and quality of the cut, especially on delicate or complex designs.

- Cost: Purchasing and maintaining a laser cutter can be expensive, especially for high-power models. For small-scale or hobby woodworkers, this cost can be a barrier.

- Noise and smoke: Laser cutters can make noise and produce smoke, especially when cutting certain materials, which may require adequate ventilation and noise control measures.

- Safety precautions: Laser-cutting machines involve high-power laser beams that may pose safety risks to operators. Proper training and safety measures can help minimize these risks.

- Personal protective equipment: The operator and anyone in the vicinity of the laser cutting machine should wear appropriate protective equipment, including safety glasses, gloves, and protective clothing that protects against laser radiation. Laser protective glasses should be selected based on the wavelength of the laser.

- Ventilation: Laser cutting may produce fumes and potentially toxic gases that may be hazardous to health if inhaled. Adequate ventilation and exhaust systems should be in place to remove these by-products from the workspace and maintain air quality.

- Training: Make sure those operating the laser cutting machine are adequately trained and understand its safe operation. Training should cover machine controls, emergency procedures, and safety protocols.

- Maintenance: Regularly inspect and maintain your laser cutting machine according to the manufacturer’s guidelines, which include cleaning optics, replacing worn parts, and ensuring proper alignment.

- Fire hazard: Timber is a flammable material and laser cutting produces intense heat. If the timber is not fixed correctly or flammable materials are nearby, there is a risk of fire, and fire extinguishers, refractory materials, and other fire prevention measures should be provided.

- Safety procedures: Develop safety procedures and guidelines for laser cutting operations (including procedures for handling fire, injury, and machine failure) and ensure that all operators are familiar with and follow these procedures.

- Machine quality: The quality of the laser cutting machine itself plays a vital role in its service life. High-quality machines built with durable components tend to last longer than cheaper, lower-quality alternatives.

- Maintenance: Regular maintenance and proper care can extend the life of your timber laser-cutting machine. Laser cutting machine maintenance includes cleaning the machine, lubricating moving parts, replacing worn parts, and ensuring that the laser source is well maintained.

- Usage: The frequency and intensity of use of the machine will affect its service life. Machines used for heavy production work or running for long periods of time each day may wear out faster than machines used intermittently for lighter tasks.

- Environmental factors: The operating environment also affects the service life of the machine. Dust, humidity, temperature fluctuations, and other environmental factors can cause wear and tear. Proper climate control and cleaning around the machine can help alleviate these problems.

- Manufacturer reputation: A machine manufacturer’s reputation is a good indicator of its potential service life. Established manufacturers typically produce long-lasting machines and have a good track record of providing good support and spare parts availability.

- Operator skills: The skill and expertise of a machine operator affect its longevity. Experienced operators are more likely to use the machine correctly and avoid mistakes that can lead to damage.