1000W Laser Welding Machine

Photoelectric Technology

AccTek Laser focus on designing and manufacturing photoelectric-related system. We provide accurate and exquisite processing quality with leading R&D capability.

Integration Ability & Experienced

With an experienced, completed, and elite R&D team, customized such as automated, integrated with the robot, system integration, etc. are all available.

Professional Service

AccTek Laser's laser welding machine is a professional laser welding machine designed and manufactured in China. Our elite engineering team provides related service support.

Equipment Features

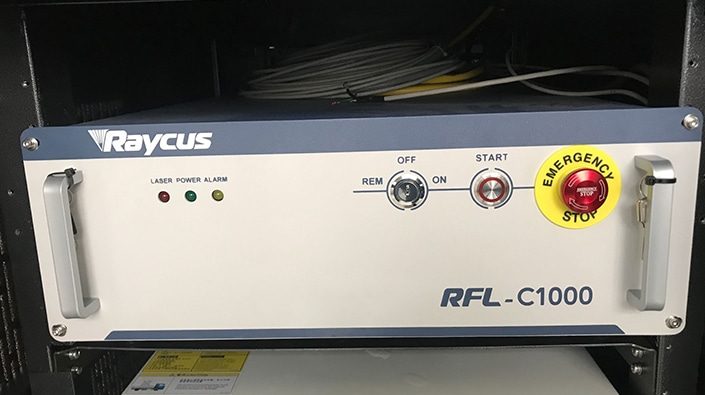

Famous Laser Generator

Using well-known brand laser generators (Raycus / JPT / Reci / Max / IPG), a high photoelectric conversion rate ensures the laser power and makes the welding effect better. AccTek can design different configurations to meet customer needs.

Industrial Water Chiller

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the welding machine to provide consistent welding quality and helping to improve the overall quality of the weld itself. It can also increase welding output by reducing the downtime of fiber laser welding machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser welding machine.

Laser Welding Gun

The laser welding gun is ergonomically designed, light in shape, comfortable to hold, and easy to control and operate. The hand-held welding gun is easy to hold and can be operated at any angle, making welding more convenient and flexible.

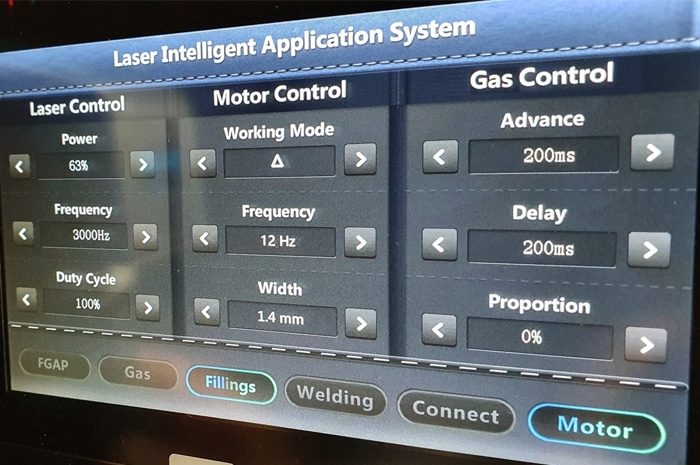

Interactive Touch Screen Control System

AccTek provides high-performance, intuitive, and easy-to-use operating systems. It expands the tolerance range and weld width of machined parts and provides better weld formation results. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

Technical Specifications

| Model | AKH-1000 | AKH-1500 | AKH-2000 | AKH-3000 |

|---|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber laser | |||

| Range of Adjustable Power | 1-100% | |||

| Laser Wavelength | 1064nm | |||

| Way of Workinging | Continuous/Modulation | |||

| Speed Range | 0-120mm/s | |||

| Repeat Precision | ±0.01mm | |||

| Welding Gap Requirements | ≤0.5mm | |||

| Cooling Water | Industrial thermostatic water tank | |||

Laser Welding Capacity

| Material Type | Welding Form | Thickness (mm) | Laser Power (W) | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|---|

| Carbon Steel (Q235B) | Butt Welding | 0.5 | 1000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1000 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1000 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 1000 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Stainless Steel (SUS304) | Butt Welding | 0.5 | 1000 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 1000 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Brass | Butt Welding | 0.5 | 1000 | 55~65 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1000 | 40~55 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1000 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 1000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1000 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1000 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 1000 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 1000 | 45~55 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 1000 | 35~45 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 1000 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

- In the welding data, the core diameter of the 1000W laser output fiber is 50 microns.

- This welding data adopts the Raytools welding head, and the optical ratio is 100/200 (collimator/focus lens focal length).

- Welding shielding gas: Argon (purity 99.99%).

- Due to the differences in equipment configuration and welding process used by different customers, this data is for reference only.

Product Features

- The operation is simple and easy to learn, and the weld seam is not deformed.

- The laser output is stable, ensuring the consistency of the weld.

- High power density after laser focusing.

- The welding seam is smooth and beautiful, the welding workpiece will not be deformed, and the welding is firm without a subsequent grinding process, saving time and cost.

- 360-degree micro-welding without dead angle. After the laser beam is focused, a small spot can be obtained, which can be precisely positioned and used for the welding of small and small workpieces and can realize mass production.

- The welding speed is fast and the operation is simple, which is 2-10 times faster than the traditional welding speed.

- Long service life, providing a safer and more environmentally friendly welding method.

- High energy density, low heat input, small thermal deformation, narrow and deep melting zone, and heat-affected zone.

- The cooling speed is fast, the fine weld structure can be welded, and the joint performance is good.

- Compared with the contact welding method, laser welding saves electrodes, reduces daily maintenance costs, and greatly improves production efficiency.

- The welding seam is thin, the penetration depth is large, the taper is small, the precision is high, and the appearance is smooth and beautiful.

- No consumables, small size, flexible processing, low operation, and maintenance costs.

Product Application

Frequently Asked Questions

- Regular Cleaning: The machine and its components need to be kept clean from dust, debris, and any residue that may have accumulated during the welding process. This includes cleaning laser optics, lenses, and other optical components. Also, follow the manufacturer’s guidelines for cleaning procedures and recommended cleaning agents.

- Cooling System Maintenance: Laser welding machines usually have a cooling system to dissipate the heat generated during operation. Check and maintain your cooling system regularly, including coolant levels, filters, and any necessary maintenance tasks specified by the manufacturer to keep your cooling system functioning properly.

- Optics Cleaning And Alignment: Regularly inspect laser optics to ensure they are clean, undamaged, and properly aligned. Misaligned optics can affect the quality of the laser beam and welding results. It is recommended to follow the cleaning and maintenance guidelines provided by the manufacturer.

- Gas Supply: If your laser welding machine uses an assist gas such as nitrogen, argon, or helium, you need to ensure that the gas supply is properly maintained and regulated. Monitor gas levels, check for leaks, and replace cylinders if necessary.

- Laser Generator Maintenance: The laser generator is a critical component in the machine and it may require periodic inspection, cleaning, and calibration to maintain its performance. Follow the manufacturer’s guidelines for cleaning, inspection, and any necessary maintenance tasks associated with the laser generator.

- Comply With Safety Regulations: Operators need to follow the safety guidelines and procedures provided by the manufacturer to operate and maintain the laser welding machine safely. This includes wearing appropriate personal protective equipment (PPE) and following proper safety procedures, helping to minimize the risk of errors, accidents, and unnecessary wear and tear on machinery.

- Regular Maintenance: Arrange qualified technicians for regular maintenance and inspection to ensure that all parts of the laser welding machine are in good working condition. This helps identify and resolve any potential issues before they escalate.

- Software And Firmware Updates: Stay abreast of software and firmware updates from manufacturers to ensure your machine maintains peak performance and receives the latest features and improvements.

- Voltage: Laser welding machines typically require a specific voltage level to function properly. Common voltage options include 110V, 220V, or 380V, depending on the machine’s design and power requirements. It is important to determine the voltage requirements specified by the manufacturer and ensure that the power supply can provide the necessary voltage.

- Frequency: The frequency of the power supply is also a factor to consider. In some cases, laser welding machines may require a specific frequency, such as 50Hz or 60Hz, depending on the area in which they are used. You will need to check the specifications of the machine and verify frequency compatibility with your power supply.

- Power Capacity: Laser welding machines need to consume a lot of power due to their high wattage. The manufacturer provides information on the power requirements of the machine, including rated power draw or power draw. It must be ensured that the power supply capacity meets or exceeds the power consumption required by the machine.

- Power Supply Stability: Laser welding machines are sensitive to fluctuations in the power supply, so a stable power supply is required for consistent performance. Power fluctuations or voltage surges can affect machine operation and can cause damage. A voltage stabilizer or uninterruptible power supply (UPS) is recommended to minimize fluctuations, voltage spikes, or electrical disturbances that may negatively affect the machine’s performance.

- Steel: Laser welding is commonly used to weld different types of steel such as carbon steel, stainless steel, and tool steel. The exact type and grade of steel may vary, so welding parameters may need to be adjusted accordingly.

- Aluminum: Laser welding can be used to weld aluminum and its alloys, including common alloys such as 6061 and 7075. Due to aluminum’s high reflectivity and thermal conductivity, specific laser parameters and techniques are required.

- Copper And Brass: Laser welding can effectively join copper and brass materials, including pure copper, copper alloys, and various brass materials. These metals are commonly used in electrical and plumbing applications, and laser welding can provide precise and reliable welds.

- Titanium: Laser welding can be used to weld titanium and its alloys because of its ability to provide precise and controlled heat input. Titanium is widely used in aerospace and medical industries due to its high strength, corrosion resistance, and biocompatibility.

- Nickel Alloys: Laser welding can be used to join a variety of nickel-based alloys, including Inconel, Hastelloy, and Monel. These alloys are commonly used in high-temperature and corrosive environments such as gas turbines, chemical processing, and aerospace applications.

- Precious Metals: Laser Haige can also be used to weld precious metals, such as gold, silver, platinum, and their alloys. These materials are often used in jewelry making and other high-value applications.

- Safety: Laser welders emit a powerful laser beam that can cause serious injury to the operator or others if proper safety precautions are not followed. Operators need to be trained in safety protocols such as donning proper personal protective equipment (PPE), understanding laser safety classifications, and knowing how to implement safety interlocks and emergency shutdown procedures.

- Machine Setup And Calibration: Laser welding machines need to be properly set up and calibrated for accurate and consistent welds. The operator needs to know how to aim the laser beam, set the proper power level, adjust the focus, and configure other welding task-specific parameters. This knowledge ensures accurate and efficient welding results.

- Material Considerations: Different materials have different properties and therefore require specific laser settings and techniques to achieve the best welding results. Operators need to understand the properties of various materials, such as their melting point, emissivity, and thermal conductivity, which can help determine appropriate laser settings and welding strategies.

- Troubleshooting: Laser welding machines may encounter problems during operation, such as beam alignment problems, power fluctuations, or cooling system failures. Operators should be trained in troubleshooting techniques to identify and resolve common problems. Additionally, they should know about routine maintenance procedures to keep machines in good working order.

- Machine Operation: Operating a laser welding machine requires knowledge of the machine control panel, software interface, and various settings. Training can help operators learn how to set the correct laser parameters, adjust focus, and control power output for different welding applications.

- Process Optimization: Skilled operators can optimize the laser welding process to increase efficiency, reduce defects and maximize productivity. Training needs to cover topics such as parameter optimization, welding speed, beam delivery considerations, and welding monitoring methods to enable operators to achieve the best results for specific applications.

- Interlocks: Laser welding machines are often equipped with interlocks to ensure safe operation. These interlocks may include a door interlock that prevents the laser from being fired when the enclosure is open. Interlocks help prevent accidental exposure to laser radiation.

- Emergency Stop Button: An emergency stop button is a common safety feature on laser welding machines. It allows the operator to quickly stop the laser beam in an emergency or any dangerous situation.

- Laser Safety Certification: Laser welding machines are usually designed and manufactured in compliance with international laser safety standards, such as the CE (Conformité Européene) mark for European safety standards. Manufacturers can obtain safety certification for their laser systems to ensure they meet specific safety requirements and regulations.