Safety Features And Certifications For Laser Welding Machines

As an important piece of equipment in the modern manufacturing industry, the laser welding machine’s efficient and precise welding technology brings huge development opportunities to various industries. However, as the application range of laser technology continues to expand, people are increasingly paying attention to the safety and compliance issues of laser welding machines. When using a laser welding machine, one of the common concerns is whether the laser welding machine has the necessary safety functions and whether it has passed the corresponding certification. This article will delve into the safety features and certifications of laser welding machines to help readers better understand and deal with related safety challenges.

Table of Contents

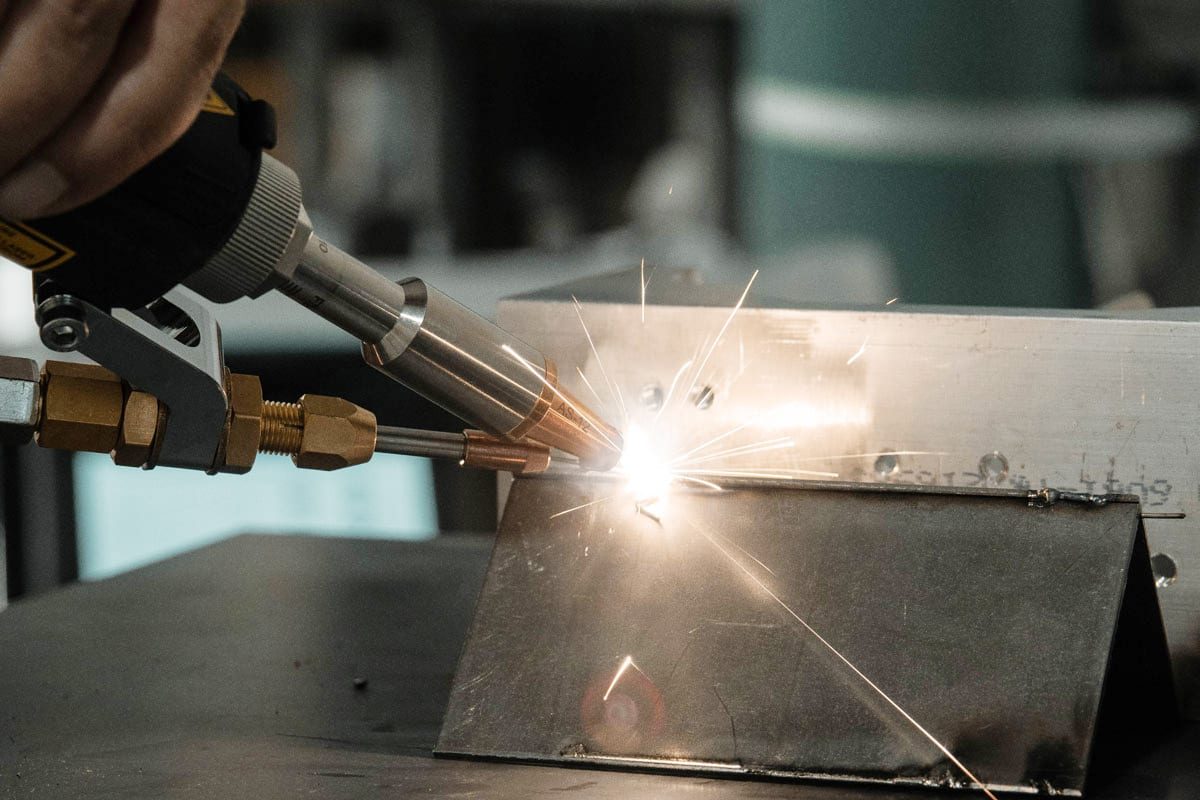

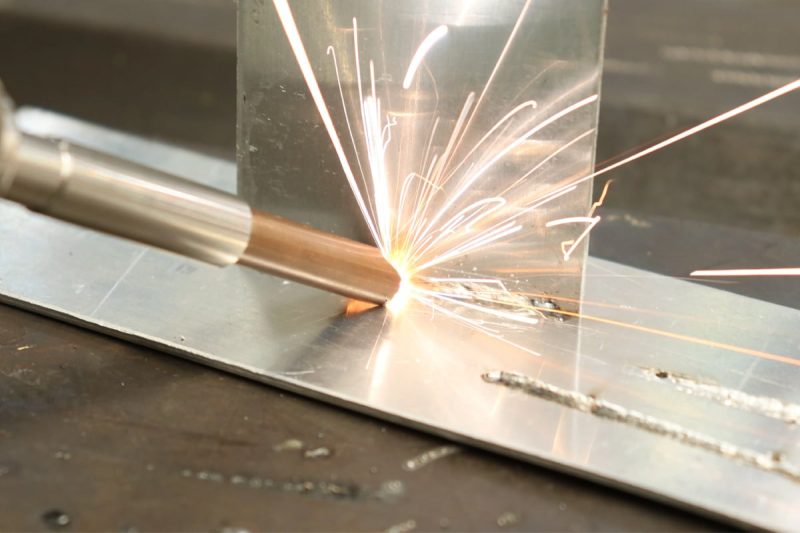

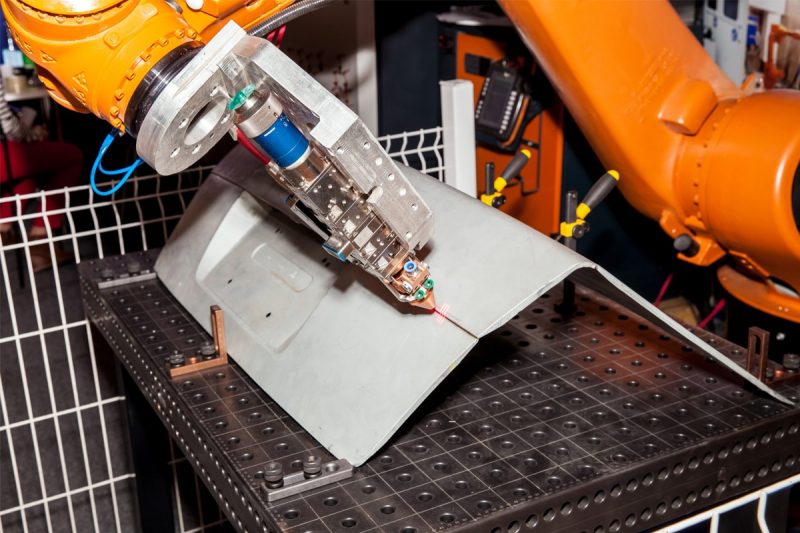

Basic Working Principle Of Laser Welding Machine

The laser welding machine is an advanced equipment that uses high-energy laser beams for welding. Its basic working principle is as follows:

- Laser generator generates laser beam: The core of the laser welding machine is the laser generator, which generates a high-energy laser beam by exciting the laser medium (such as gas, solid, or semiconductor).

- Laser beam focusing: The generated laser beam is focused into a high-density spot through the lens system, greatly increasing the energy density at the focus.

- Material heating and melting: The focused laser beam irradiates the welded joint and heats it to a molten or semi-molten state. In this way, local heating of the welded joint can be achieved in a very short time without causing excessive heat conduction to the surrounding area.

- Welded joint connection: Once the material of the welded joint reaches a molten or semi-molten state, the laser beam stops working, and the welded joint forms a solid connection after solidification.

- Weld filler (optional): In some applications, laser welding machines can also be equipped with filler material, which is used to add additional material to the welded joint to fill the gap.

The working principle of the laser welding machine is simple and efficient. It can achieve high-speed and high-precision welding and is suitable for the welding needs of various materials and complex structures.

The Importance Of Laser Welding Machine Safety

The importance of laser welding machine safety cannot be underestimated, which is mainly reflected in the following aspects:

- Protect operator safety: The laser welding machine will produce high-energy laser beams during operation. If not effectively controlled and protected, operators may be harmed by laser radiation, causing injuries to the eyes, skin, and other parts. Therefore, ensuring the safety of operators is the top priority for laser welding machine safety.

- Prevent equipment failure and damage: If the laser welding machine malfunctions or is used improperly, it will not only affect production efficiency but may also lead to equipment damage or accidents. By strengthening safety measures and equipment maintenance, the risk of equipment failure and damage can be reduced and the reliability and stability of the equipment can be improved.

- Reduce environmental pollution and release of hazardous substances: Harmful gases and particulate matter may be produced during the laser welding process. If not effectively controlled and processed, they may cause pollution to the environment and even endanger personnel health. Therefore, ensuring the safety of laser welding machines can effectively reduce the risk of environmental pollution and the release of hazardous substances.

- Maintain production safety and stability: Laser welding machines are usually used on manufacturing production lines. If an accident or failure occurs in a laser welding machine, it may cause production interruption or delay, affecting production safety and stability. Therefore, ensuring the safety of laser welding machines is one of the keys to maintaining production safety and stability.

Therefore, only by strengthening safety management and control can we ensure the safe and reliable operation of laser welding machines during the production process and provide stable and reliable technical support for the development of enterprises.

Safety Features Of Laser Welding Machines

The safety features of laser welding machines are key measures to ensure the safety of operators, equipment, and the environment. The following are common laser welding machine safety features:

- Protective covers and safety doors: Laser welding machines are usually equipped with protective covers and safety doors to limit the leakage of laser radiation and prevent operators from coming into contact with the laser beam. These devices can effectively protect the safety of operators and prevent accidental injuries.

- Emergency stop button: The laser welding machine is equipped with an emergency stop button to immediately stop the operation of the equipment in an emergency. Once an accident or operation error occurs, the operator can immediately press the emergency stop button to cut off the power supply of the equipment to prevent further development of the accident.

- Laser radiation monitoring and alarm system: Some advanced laser welding machines are equipped with laser radiation monitoring and alarm systems to monitor the intensity and location of laser radiation. When the laser radiation exceeds the safe range, the system will sound an alarm and automatically stop the operation of the equipment to protect the safety of operators.

- Protective glasses and protective clothing: Operators need to wear appropriate protective glasses and protective clothing to prevent damage to eyes and skin caused by laser radiation. These protective equipment can effectively reduce the risk of operator injury and improve work safety.

- Safety signs and warning signs: Laser welding machines are usually marked with relevant safety signs and warning signs to remind operators to pay attention to safety matters and operating procedures. These signs and symbols can help operators better understand the potential dangers of laser welding machines, thereby reducing the occurrence of accidents.

In short, these safety functions of the above laser welding machine can effectively protect the safety of operators, ensure the safe operation of equipment, and reduce the risk of accidents.

Certification And Standards For Laser Welding Machines

Certification and standards for laser welding machines are important safeguards to ensure their safety, reliability, and compliance. The following is an introduction to certifications and standards related to laser welding machines:

CE Certification

CE certification is a mandatory certification mark of the European Common Market and applies to various types of industrial equipment such as laser welding machines. Obtaining CE certification means that the laser welding machine complies with relevant European safety and environmental protection requirements, ensuring that it can be sold and used in the European market.

FDA Certification

In the United States, the Food and Drug Administration (FDA) regulates the safety and compliance of laser devices. If a laser welding machine is to be sold in the US market, it usually needs to obtain FDA certification. FDA certification ensures that the laser welding machine complies with relevant U.S. regulations and standards, ensuring the safety and legality of the equipment in the U.S. market.

ISO Certification

ISO (International Organization for Standardization) has developed a series of international standards related to quality management, environmental management, and safety management. Laser welding machine manufacturers can prove that their products meet the requirements of international standards and improve the market competitiveness of their products by obtaining ISO certification. For example, the ISO 9001 standard involves quality management systems, the ISO 14001 standard involves environmental management systems, the ISO 45001 standard involves safety management systems, etc.

IEC Standard

The International Electrotechnical Commission (IEC) has developed a series of international standards related to the safety of electrical equipment. For laser welding machines, the IEC 60825 standard is an important reference standard, involving the safety and radiation safety requirements of laser products. This standard specifies the classification, labeling, safety requirements, and testing methods of laser products to ensure the safe use of laser products.

National Standard

In addition to international certifications and standards, different countries may develop their own safety standards and certification systems for laser welding machines. For example, in China, the General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) and the Standardization Administration of China (SAC) promulgated the Safety Technical Specifications for Laser Products (GB 7247.1-2012), which stipulates the safety requirements and testing methods for laser products.

Industry Standard

In addition to general certifications and standards, some industry organizations and associations may develop specific laser welding machine safety standards and guidelines. For example, the Laser Research Association of America (LIA) has developed a series of standards and training courses related to laser safety to help professionals in the industry better understand laser safety knowledge and technology.

To sum up, the certification and standards of laser welding machines involve many aspects such as CE certification, FDA certification, ISO certification, IEC standards, national standards, and industry standards. By complying with relevant certifications and standards, the safety, reliability, and compliance of laser welding machines can be ensured, and the competitiveness of the equipment in the market can be improved.

Laser Welding Machine Safety Assessment And Maintenance

Laser welding machine safety assessment and maintenance are critical to ensuring the safety of operators and equipment. The following are several key aspects regarding the safety assessment and maintenance of laser welding machines:

Regular Security Assessment

Regular safety assessment of laser welding machines is an important step to ensure the safety of the equipment. Safety assessment can include checking whether the protective cover and safety door of the equipment are intact, whether the laser radiation monitoring system is operating normally, and whether the emergency stop button is sensitive and reliable. Through regular security assessments, potential safety hazards in the equipment can be discovered in time and measures can be taken to solve them.

Operator Training

Comprehensive safety training for operators is one of the key measures to ensure the safety of laser welding machines. Operators should understand the hazards of laser radiation, the correct use of emergency stop buttons, the importance of wearing protective equipment, and other safety knowledge. Regular safety training can help operators improve their safety awareness and reduce the risk of operational errors and accidents.

Equipment Maintenance And Upkeep

Regular equipment maintenance and upkeep is an important means to ensure the safety of laser welding machines. This includes cleaning the optical components of the laser generator, checking the cooling system of the laser generator, calibrating the laser radiation monitoring system of the laser welding machine, etc. Regular maintenance and upkeep can ensure the normal operation of equipment and reduce the occurrence of failures and accidents.

Safe Operating Procedures

Developing and strictly implementing safe operating procedures is crucial to ensuring the safety of laser welding machines. Safety operating procedures should include the correct use of equipment, emergency handling procedures, wearing requirements for safety protective equipment, etc. Operators must strictly abide by safety operating procedures when using laser welding machines to ensure a safe and reliable operation process.

Emergency Plans And Drills

Developing a complete emergency plan and conducting regular drills is one of the important measures to ensure the safety of laser welding machines. The emergency plan should include how to use the emergency stop button, rescue procedures, accident handling procedures, etc. Regular emergency drills can improve operators’ ability to respond to emergencies and minimize losses caused by accidents.

Through regular safety assessments, operator training, equipment maintenance, and upkeep, the formulation and execution of safe operating procedures, as well as emergency plans and drills, the safety of laser welding machines can be effectively ensured and the safety of operators and equipment can be ensured.

Summarize

In general, laser welding machines have multiple safety functions and certification standards to ensure safety. From protective covers and safety doors to emergency stop buttons to laser radiation monitoring and alarm systems, these safety features keep operators, equipment, and the environment safe. In addition, laser welding machines certified by CE, FDA, and ISO can ensure compliance with European, American, and international standards, further strengthening their safety and compliance. However, in daily use, it is still necessary to strengthen regular maintenance and inspection, operator training and management, and emergency plans and response to ensure the safe operation of laser welding machines. In summary, the safety functions and certification of laser welding machines are important measures to ensure their safety and compliance and are also the basis for the sustainable development of the manufacturing industry.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions