Hiểu tác động của hàn laser lên tính chất cơ học của vật liệu hàn

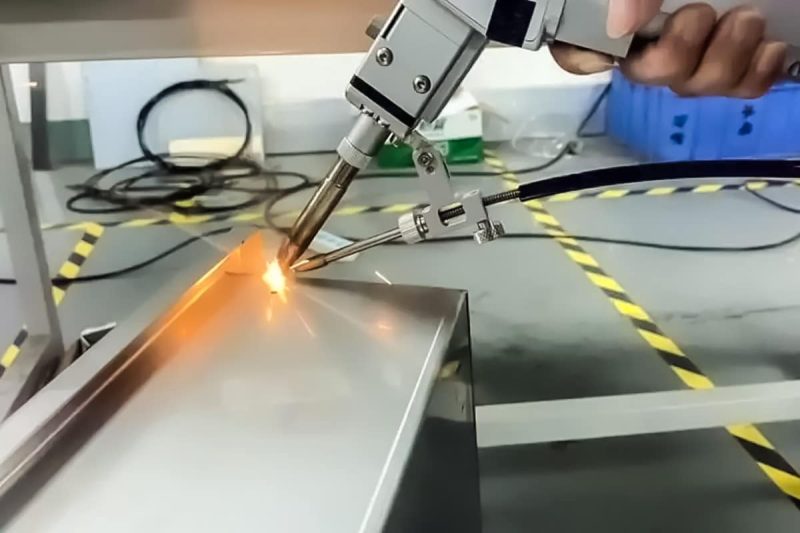

As a high-energy-density, non-contact advanced welding technology, laser welding is widely used in the automotive, aerospace, and electronic manufacturing industries due to its good weld quality, small heat-affected zone, and high degree of automation. In practical applications, laser welding has an important influence on the mechanical properties (strength, ductility, toughness, and fatigue resistance) of materials. This article will conduct an in-depth discussion from four aspects: mechanical property changes, deterioration mechanisms, key influencing factors, and optimization strategies, to help engineers and purchasers better select laser welding equipment and optimize process parameters.

Mục lục

Effect of laser welding on mechanical properties

In modern manufacturing, compared with other traditional welding methods, máy hàn laser can heat and cool rapidly in a very short time, causing significant changes in the organizational structure of the weld zone and the heat-affected zone (HAZ), which has a profound impact on the mechanical properties of the material. The following will be elaborated in detail from four aspects: strength, ductility, toughness, and fatigue resistance.

Strength

Laser welding uses a focused laser beam to form a deep penetration weld on the surface of the material. The weld metal undergoes rapid solidification to form a dense and fine-grain structure, effectively reducing defects such as pores and inclusions, so that tensile strength and yield strength comparable to or even higher than that of the base material can usually be obtained. However, if the heat input is too large or the energy distribution is uneven, it is easy to cause local overburning or undermelting, microcracks, or incomplete penetration, resulting in defects such as reduced weld strength. Therefore, optimizing laser power, welding speed, and focus position is crucial to ensure weld strength.

Ductility

Due to the rapid cooling rate during laser welding, the HAZ area often generates high-hardness martensite or fine pearlite structure, which can increase the apparent hardness but may reduce plastic ductility. By precisely controlling the welding speed and laser energy density to achieve a reasonable heat input level, the formation of equiaxed or recrystallized grains can be promoted, and the strength and ductility can be balanced to ensure that the weld has sufficient plasticity when subjected to impact loads or deformation processing.

Toughness

Toughness is an important indicator of the material’s ability to resist crack propagation. The narrow heat-affected zone of the laser welding machine makes the hardness gradient between the base material and the weld area smaller, which is conducive to improving the overall impact toughness. Especially on materials that are prone to brittle fracture, such as stainless steel and aluminum alloys, laser welding can significantly reduce crack sensitivity. However, in low-temperature or high-impact application scenarios, post-weld heat treatment is required to eliminate residual tensile stress through tempering or aging processes to further improve toughness.

Fatigue Resistance

Weld geometry, surface quality, and residual stress distribution are key factors affecting fatigue life. Laser welding machines can achieve conical or fish-scale micro welds, reduce stress concentration areas, and thus improve fatigue resistance. However, if there are microcracks, spatter, or uncleaned slag on the weld surface, the residual tensile stress is not effectively released, which will become the source of fatigue crack initiation. Given this, surface defects can be eliminated and residual stress can be redistributed through post-weld polishing, vibration aging, or mild tempering processes to extend the fatigue life of welded components.

With its high energy density and precise energy control, laser welding machines achieve fine-grain strengthening and narrow heat-affected zone formation in the weld area, which helps to improve the strength, toughness, and fatigue resistance of welded parts. But at the same time, attention should also be paid to the potential challenges brought by ductility and residual stress. By optimizing laser welding parameters, rationally designing weld geometry, and combining post-weld heat treatment, the comprehensive mechanical properties of welded parts can be maintained or even enhanced while ensuring high efficiency, providing reliable quality assurance for downstream applications.

Mechanism of material deterioration during laser welding

Although laser welding has significant advantages of high energy density and extremely fast cooling rate, the influence of its thermal cycle on metal microstructure cannot be ignored. The deterioration of materials during welding is mainly reflected in the formation of heat-affected zone (HAZ), grain growth and recrystallization process, and the distribution and accumulation of residual stress. These factors directly determine the mechanical properties and service life of the weld and are an important basis for evaluating welding quality. The following will analyze these three core mechanisms one by one.

Formation of the heat-affected zone

The heat-affected zone refers to the area that does not melt during welding, but undergoes metallographic transformation and structural changes due to temperature increase. The heat-affected zone of laser welding is much narrower than that of traditional processes such as arc welding, but its temperature gradient is extremely large, and the temperature in the area can change suddenly from hundreds of degrees to below the melting point. Generally, HAZ can be divided into:

- Coarse Grain Zone: Close to the fusion line, the grains grow significantly, the hardness increases, but the toughness decreases significantly.

- Fine Grain Zone: The temperature is slightly lower than the coarse grain zone, the grains grow moderately, and the strength and toughness are relatively good.

- Partial Recrystallization/Amorphous Zone: Farthest from the weld, the metallographic structure is complex and diverse.

Different regional proportions and distributions will directly affect the strength, ductility and fatigue performance of the welded joint.

Grain growth and recrystallization

Under high temperatures, metal grains have strong thermodynamic drive, and grain growth or recrystallization will occur.

- Grain growth: The grain diameter of the weld metal and HAZ area increases, and the grain boundaries decrease, resulting in increased hardness but decreased toughness, which makes it particularly prone to becoming a crack propagation path.

- Recrystallization: After welding and subsequent cooling, some areas undergo recrystallization, generating a new, uniform, and fine equiaxed crystal structure, which is very beneficial to improving the overall mechanical properties.

Controlling the growth and recrystallization ratio of grains is an important means to ensure the performance of welded joints. For example, by adjusting the welding power and welding speed, rapid heating-cooling can be achieved, grain coarsening can be limited, and recrystallization can be promoted.

Residual stress

The heat input of laser welding is concentrated and localized, so a complex residual stress field is formed around the weld and HAZ. Residual stress is usually divided into:

- Tensile Residual Stress: concentrated on the weld surface and the surface of the heat-affected zone, it will promote crack initiation, reduce fatigue life, and corrosion resistance.

- Compressive Residual Stress: distributed inside the weld and in areas far away from the weld, it has a certain positive effect on inhibiting crack propagation.

If the tensile stress cannot be effectively released, it will become a safety hazard in later service. Therefore, in many important structures, post-weld heat treatment (such as low-temperature tempering and vibration aging) is required to reduce the residual tensile stress and improve the service reliability of welded components.

During laser welding, the micro-deterioration of the material is mainly concentrated in the organizational evolution of the heat-affected zone, the change of grain size, and the generation of residual stress. Although laser welding has the advantages of reducing HAZ and heat input, if the welding parameters and thermal cycle are not properly controlled, coarse grains, residual tensile stress, and other unfavorable factors may still occur. By accurately adjusting the process parameters, optimizing the energy distribution, and implementing appropriate post-weld treatment, the high efficiency of laser welding can be fully utilized while minimizing the negative impact on material properties, thereby achieving a balance between welding quality and service safety.

Key factors affecting mechanical property changes

During laser welding, the mechanical properties of the weld and the surrounding metal are not static, but are affected by a variety of process factors. Different combinations of welding parameters will directly determine the weld penetration, metal structure, residual stress distribution, and defect risk, thereby affecting the strength, toughness, ductility, and fatigue resistance of the finished product. In-depth understanding of these key factors and optimizing them in practice are the core of ensuring welding quality and stability. The following will discuss their mechanism of action and optimization ideas from four aspects: heat input and energy density, welding speed, joint design and geometry, and post-weld heat treatment.

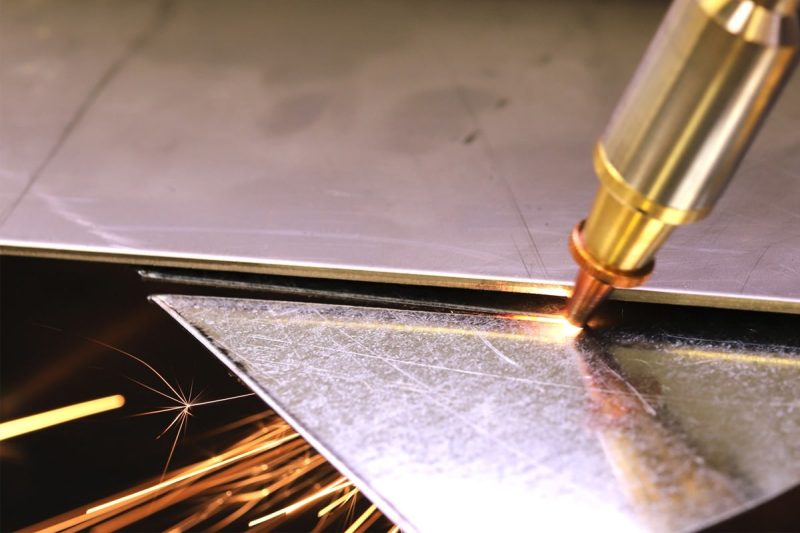

Heat input and energy density

During laser welding, heat input and energy density are the core process variables that determine penetration, weld formation, and microstructure evolution. Heat input refers to the heat energy absorbed by the weld per unit length, which directly determines the volume of the molten pool and the temperature distribution in the welding area. If the heat input is too high, although it helps to achieve deep penetration welding and improve the strength of the joint, it will also lead to significant coarsening of the grains, increase the width of the heat-affected zone, and cause residual tensile stress to accumulate in the weld, thereby reducing ductility and toughness. On the contrary, too low heat input will cause insufficient fusion of weld metal, resulting in defects such as incomplete penetration, pores, and slag inclusions, which will affect the density and fatigue life of the joint.

The energy density is closely related to the power distribution of the laser beam in the weld area. High energy density can quickly melt the metal in a very short time to form a weld feature of “deep penetration and narrow seam formation”, which is particularly critical for improving weld strength and dimensional accuracy. However, if the energy density is unevenly distributed, it is also very easy to cause problems such as local overburning, spattering, or abnormal molten pool morphology, affecting welding consistency and aesthetics. Therefore, in the actual process formulation, it is necessary to combine the material type, plate thickness, and required weld performance to accurately control the laser power, focus position, and travel speed to obtain an ideal energy input level and uniform energy distribution.

Tốc độ hàn

Welding speed is one of the important parameters that affect the intensity of heat input and the cooling rate of the weld. As the welding speed increases, the heat input per unit time decreases, and the cooling rate of the molten pool accelerates, thereby limiting the size of the heat-affected zone and the formation of coarse-grained structure, which helps to refine the grains and improve the strength and hardness of the weld metal. Under high welding speed conditions, laser welding can achieve smaller deformation and excellent dimensional accuracy, which is especially suitable for occasions with high requirements for workpiece precision, such as the manufacture of precision sheet metal and aerospace parts.

However, if the welding speed is set too high, the fluidity of the molten pool will be weakened, and the metal will not be able to fully wet the edge of the joint, which is prone to quality problems such as weld discontinuity, lack of fusion, and slag inclusion. On the contrary, when the welding speed is too low, the heat input of the weld increases significantly, the volume of the molten pool expands, and the cooling process is prolonged, which will aggravate grain coarsening and increase the residual stress level. In order to strike a balance between high strength and high toughness, the selection of welding speed should be verified by multiple rounds of tests based on the thickness of the workpiece, laser power, and joint shape, striving to make the weld uniform and dense, the structure refined, and minimize welding defects.

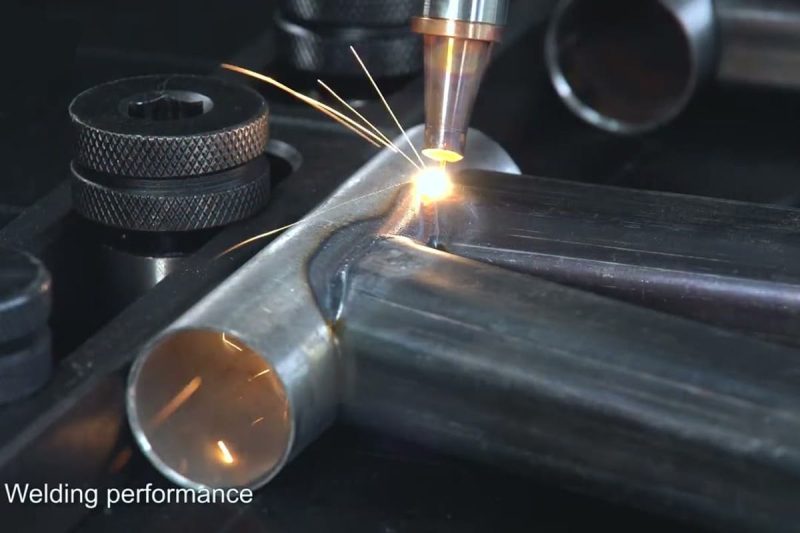

Joint design and geometry

Joint design and geometry have a direct and far-reaching impact on the mechanical properties and reliability of laser-welded joints. Different joint forms not only determine the depth and width of penetration but also affect the stress distribution of the weld and the types of defects that may occur. For thin plate welding, butt joints can provide continuous and uniform welds and reduce assembly difficulties; while for medium and thick plates or high-load workpieces, the use of V-shaped, Y-shaped and other groove designs is more helpful to increase the weld metal volume, improve the fusion quality and fatigue resistance of the weld.

Reasonable joint geometry can also help reduce the welding stress concentration area and avoid microcracks from extending along the edge of the joint. Detailed parameters such as weld size, angle, groove depth, and splicing gap need to be tailored according to different materials and load conditions. For example, V-shaped grooves are suitable for deep penetration welding and reduce the risk of incomplete fusion, while U-shaped or double V-shaped grooves can achieve multi-pass welding in thick plates, improving the overall strength and toughness of the joint. Through standardized joint design and precision assembly, weld defects can be minimized, and product consistency and long-term service reliability can be improved.

Post-weld heat treatment (PWHT)

Post-weld heat treatment (PWHT) is an important part of the laser welding process to ensure the stability of joint performance and improve the reliability of use. Due to the characteristics of local high-temperature heating and extremely fast cooling in laser welding, large tensile stress usually remains in the weld and heat-affected zone, which not only increases the risk of low-temperature brittle fracture but also hurts fatigue life. Through a reasonable PWHT process, the residual stress can be significantly reduced, the metal microstructure can be optimized, and the toughness and mechanical properties of the welded joint can be further improved.

In practical applications, PWHT mainly includes several process methods: tempering is used to reduce the brittleness of the hardened structure and improve the toughness and ductility of the joint; annealing enhances the dimensional stability of the weld by softening the structure and releasing residual stress; aging helps stabilize the microstructure of the weld metal and improves long-term strength and corrosion resistance; in addition, vibration aging can also be used as an auxiliary means to further dissipate some residual stress through mechanical vibration. Each process has its specific application scenario and temperature range. For example, steel parts are usually tempered at 550~650℃, aluminum alloys are suitable for artificial aging at about 160℃, and high-strength titanium alloys need to be annealed in a vacuum environment to avoid oxidation and performance degradation.

Correctly selecting and executing post-weld heat treatment can not only reduce crack initiation and improve low-temperature toughness but also make the grains more uniform and stable, and extend the service life of the weld under complex loads. Especially in fields with extremely high safety requirements, such as aerospace, pressure vessels, and high-end equipment manufacturing, PWHT has become a key process to ensure welding quality and achieve long-term reliability.

In general, during laser welding, heat input and energy density determine the depth of penetration, cooling rate and degree of microstructure refinement; welding speed directly affects weld integrity and heat-affected zone width; joint geometry dominates stress distribution and defect control; post-weld heat treatment further improves the comprehensive mechanical properties of welded parts by adjusting the microstructure and eliminating residual stress. Only through scientific design and system debugging, and the organic integration of the above factors, can the strength, ductility, toughness, and fatigue resistance of the weld be maximized, providing high-reliability welding solutions for various industries.

Strategies to maintain or enhance mechanical properties

To achieve high strength, high toughness, and excellent fatigue resistance in laser welding, it is necessary to manage the welding process system in a refined manner. From welding parameters to material compatibility to quality inspection, each link directly affects the final mechanical performance. The following three strategies are designed to help companies establish a systematic process to ensure stable and continuously optimized product quality.

Optimized welding parameters

The key parameters, such as laser power, welding speed, focus position, and auxiliary gas flow, can be accurately optimized by combining experimental design with numerical simulation. In the welding of Ti6Al4V titanium alloy, the Taguchi method was used to conduct orthogonal experiments on laser power and welding speed, successfully reducing porosity by 30% and increasing tensile strength by 5% (see related research). For stainless steel sheets, response surface analysis can quickly locate the optimal combination of preheating temperature and laser energy density, achieve an ideal match between penetration depth and width, and reduce crack generation. By dynamically monitoring the changes in molten pool temperature and morphology, combined with online feedback adjustment, the high consistency of weld quality can be guaranteed.

Material selection and compatibility

At the material level, metals with high compatibility with laser welding, such as low-carbon steel, stainless steel, and aluminum alloys, should be preferred to obtain the best fusion effect and microstructure. In some complex occasions, alloying wire or powder eutectic technology can also be used to improve the bonding performance of dissimilar metal joints; for example, adding copper-based welding wire to steel-aluminum welding can significantly reduce the formation of brittle phases and improve fatigue life. In addition, surface cleaning before welding, moderate preheating, and the use of inert gas protection such as argon are particularly critical for inhibiting the formation of oxide inclusions and pores.

Quality Assurance and Testing

Establishing a sound quality management system is the last line of defense to ensure the reliability of laser-welded parts. It is recommended to combine non-destructive testing (UT, RT, PT) with online welding process monitoring (such as coherent imaging) to capture internal defects and molten pool anomalies in real time. Before the finished product goes online, the weld should be subjected to tensile, impact, and fatigue tests, combined with microstructure analysis to verify the effectiveness of process parameters and material selection. Through closed-loop feedback, the test results are used to continuously optimize the process, which can significantly reduce the rework rate and improve customer satisfaction.

Through systematic parameter optimization, precise material matching, and strict quality inspection, the mechanical properties of laser-welded joints can be comprehensively improved. The above three strategies complement each other, not only can improve the strength and toughness of the weld, but also can effectively extend the fatigue life, meeting the strict requirements of various industries for high-reliability welded parts.

tóm tắt

Laser welding is continuously expanding its application scenarios with its advantages of high efficiency, precision, and automation. However, factors such as heat-affected zone, grain behavior, and residual stress in the welding process have an important impact on the strength, ductility, toughness and fatigue resistance of the material. By optimizing laser welding machine parameters, rationally designing joints, implementing post-weld heat treatment, and strict quality control, the mechanical properties of welded parts can be effectively maintained or enhanced. For users who pursue high-quality laser welding equipment and perfect technical solutions, AccTekLaser‘s laser welding equipment, with many years of industry experience and a professional R&D team, will provide you with customized laser welding solutions to help you continue to lead in the field of laser welding.

Thông tin liên lạc

- [email protected]

- [email protected]

- +86-19963414011

- Số 3 Khu A, Khu công nghiệp Lunzhen, Thành phố Yucheng, Tỉnh Sơn Đông.

Nhận giải pháp Laser