Hiệu quả làm sạch của công nghệ làm sạch bằng laser là gì?

In modern manufacturing and industrial maintenance, the importance of cleaning processes is increasingly recognized by companies. Whether it’s surface pretreatment of components before production or maintenance of equipment during use, the quality and efficiency of cleaning directly impact product performance and lifespan. Traditional cleaning methods, such as mechanical polishing, chemical solvent cleaning, and sandblasting, can remove contaminants to a certain extent, but these methods are often accompanied by high labor intensity, substrate wear, high consumables consumption, and severe environmental pollution.

With the promotion of green manufacturing and lean production concepts, companies urgently need to find cleaning methods that are both efficient and environmentally friendly. Against this backdrop, máy làm sạch laze has emerged. This non-contact cleaning method uses a high-energy laser beam to target the surface of a material, precisely removing rust, oxide layers, paint, oil stains, and fine particles while leaving the surface intact. With the advancement of laser generator technology, laser cleaning has gradually overcome previous limitations in power, efficiency, and stability, and is now suitable for large-scale industrial applications.

This article will delve into the topic of laser cleaning efficiency, covering principles, factors influencing efficiency, advantages, limitations, challenges, and finally, a comparison with traditional cleaning methods. This article will comprehensively analyze the value and prospects of laser cleaning in practical industrial applications. Furthermore, drawing on AccTek’s practical experience with laser cleaning solutions, this article aims to help more companies recognize the crucial role of this advanced technology in the future of manufacturing.

Mục lục

Làm sạch bằng tia laser là gì?

Định nghĩa và Nguyên tắc cơ bản

Laser cleaning is a cleaning method that uses a high-energy-density laser beam to selectively irradiate a material surface, rapidly removing adhering contaminants through photothermal, photomechanical, or photochemical effects. The key advantages of laser cleaning are its non-contact nature and high selectivity: it only targets the contaminant layer without abrading the underlying material.

This technology relies on a laser generator. Parameters such as the laser wavelength, pulse width, and power provided by the laser generator determine the cleaning efficiency and effectiveness. For example, a pulsed laser generator can release high energy in a very short time, instantly vaporizing or stripping contaminants, while a continuous laser generator is more suitable for removing large areas and thick layers of contaminants.

Các loại máy phát laser

- Pulsed laser generators: These emit extremely short, high-energy pulses with instantaneous high peak power, making them ideal for precision cleaning applications such as decontamination of electronic components and surface treatment in cultural relic preservation.

- Continuous Laser Generators: Output a continuous, stable laser beam, making them ideal for large-area oxide removal and cleaning thick rust layers.

Các ứng dụng

- Laser Rust Removal: Widely used in steel structures, bridges, and ship repair applications.

- Laser Surface Preparation: Removes surface oxide layers or residues before spraying, welding, and bonding.

- Mold Cleaning: Suitable for removing surface dirt from injection molds, tire molds, and other applications.

- Cultural Relics Conservation: Removes surface contaminants from cultural relics without damaging the substrate.

- Energy and Aerospace: Used for fine cleaning of nuclear power equipment and turbine blades.

Overall, laser cleaning is an efficient, environmentally friendly, and precise surface cleaning method, centered around a laser generator. It not only addresses many of the drawbacks of traditional methods but also provides new cleaning and surface treatment solutions for a wide range of industries.

Làm sạch bằng laser hoạt động như thế nào?

Làm sạch bằng tia laser hoạt động như thế nào

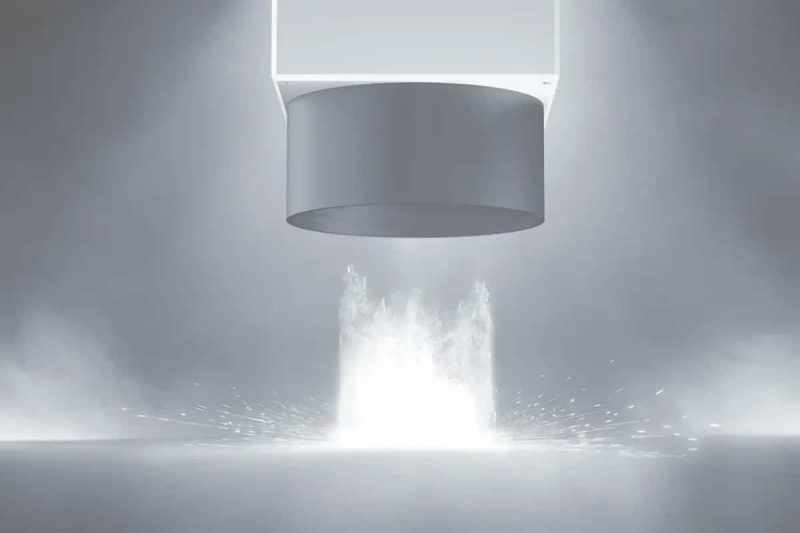

The basic principle of laser cleaning is the interaction between laser light and matter. When a high-energy laser beam strikes a contaminated surface, the contaminated layer rapidly absorbs the energy and undergoes physical or chemical changes, freeing it from the substrate. The main processes involved include:

- Photothermal effect: The contaminant is rapidly heated to a temperature where it vaporizes or decomposes, achieving removal.

- Photomechanical effect: The instantaneous high energy causes a localized, dramatic expansion of the material, generating shock waves that cause the contaminant layer to flake off.

- Photochemical effect: The laser irradiation triggers a chemical reaction, breaking the contaminant down into gases or easily removable substances.

Interaction between Laser and Material

Different materials have different absorption rates for laser energy. If the contaminant layer has a high absorption rate for laser light, while the substrate has a high reflectivity or transmittance for the laser, selective cleaning can be achieved. For example, a rust layer on a steel surface has a high absorption rate for laser light of a specific wavelength, while the metal substrate reflects relatively more energy. This allows for efficient rust removal without damaging the substrate.

Contaminant Removal and Surface Treatment

Laser cleaning not only removes contaminants but also alters the surface microstructure. For example, moderate laser cleaning can increase surface roughness, thereby improving the adhesion of subsequent coatings, welding, or bonding. This makes laser cleaning both a cleaning method and an effective surface preparation method.

The operating principle of laser cleaning determines its precision and controllability. By optimizing laser generator parameters, it is possible to effectively remove contaminants while also improving surface properties to a certain extent.

Factors Affecting Cleaning Efficiency

Laser cleaning efficiency isn’t determined by a single factor; rather, it results from the combined effects of laser generator parameters, material properties, and the characteristics of the contaminant itself. In practical applications, only by properly aligning these factors and dynamically adjusting them through process optimization can we ensure effective cleaning while avoiding damage to the substrate. The following aspects are particularly critical:

Thông số laze

- Wavelength: The wavelength of the laser determines how it interacts with different materials. Generally speaking, metal surfaces absorb infrared lasers more efficiently, making them more effective at removing rust. Certain organic contaminants or coatings are more readily absorbed by ultraviolet or visible lasers. The choice of wavelength directly affects the efficiency of laser energy deposition within the contaminant.

- Pulse Duration: Pulsed lasers are the most commonly used laser cleaning method. Short pulses (nanoseconds or picoseconds) can vaporize or detonate contaminants in a very short time, while minimizing the time it takes for heat to be transferred to the substrate, effectively preventing thermal damage. They are suitable for surface treatment of precision components or high-value-added materials. Long pulses, on the other hand, provide more stable energy deposition and are more suitable for removing large areas and thick layers of contaminants.

- Power and Energy Density: The average laser power and single-pulse energy density determine the efficiency of contamination removal. Higher power results in faster cleaning, but excessive energy density can easily cause substrate melting, ablation, or discoloration. Therefore, in practical applications, laser power, pulse frequency, and scanning speed must be appropriately adjusted based on the contaminant characteristics and substrate tolerance to ensure efficient removal while maintaining surface quality.

Tính chất vật liệu

- Absorptivity: The efficient application of laser energy to the contaminant depends on the absorptivity of the substrate and the contamination layer. Typically, the absorptivity of the contamination layer is higher than that of the substrate, which is the key to the selective removal achieved by laser cleaning. If the substrate also has a high laser absorptivity, pulse parameter optimization and dynamic focusing are necessary to avoid excessive laser energy on the substrate.

- Thermal conductivity: Thermal conductivity varies significantly among materials. Highly thermally conductive materials (such as copper and aluminum) quickly diffuse the laser energy, reducing the instantaneous heating efficiency of the contaminant and making cleaning more difficult. Conversely, materials with lower thermal conductivity (such as steel and stainless steel) more easily concentrate the energy on the contamination layer, achieving efficient removal. For high thermal conductivity materials, it’s often necessary to select a laser generator with higher energy or a more suitable wavelength to improve efficiency.

Đặc tính chất gây ô nhiễm

- Type: Laser response to lasers varies significantly depending on the type of object being cleaned. For example, rust and oxide layers on metal surfaces absorb laser light well and are easily removed. Organic contaminants such as oil and lubricants, on the other hand, may carbonize or form residue, requiring specific wavelengths and scanning strategies.

- Thickness: The thicker the contaminant layer, the greater the cleaning energy required. In practice, complete removal of thick contaminants often requires multiple scans; otherwise, the process can easily result in “incomplete cleaning.” Therefore, thickness is a factor directly impacting laser cleaning efficiency.

- Adhesion: The stronger the bond between the contaminant layer and the substrate, the more difficult it is to remove directly with a laser. For example, severely oxidized metal surfaces often require higher power or repeated scans, while loosely attached dust or thin films can be quickly removed with a low-energy-density laser.

Laser cleaning efficiency depends on a comprehensive match between laser generator parameters, material properties, and contaminant characteristics. Only by fully understanding the properties of the target material and contaminants, and by rationally selecting the laser wavelength, pulse duration, and power density, combined with optimized scanning paths, can we achieve maximum substrate protection while ensuring efficiency. Therefore, process optimization and equipment selection are both indispensable and crucial for achieving optimal results in different laser cleaning applications.

Ưu điểm của việc làm sạch bằng laser

Laser cleaning technology has been gaining increasing attention in the industrial manufacturing and surface treatment industries in recent years. Its advantages lie not only in improved cleaning performance but also in environmental friendliness, safety, and cost-effectiveness. Compared to traditional methods such as chemical cleaning, mechanical grinding, and sandblasting, laser cleaning demonstrates distinct competitive advantages.

Non-contact and non-abrasive

Traditional cleaning methods, such as manual grinding, grinding wheels, or sandblasting, often rely on physical friction to remove surface contamination. This inevitably causes abrasion to the substrate surface, even causing minor deviations in shape or size, impacting component precision and lifespan.

Laser cleaning is a completely different approach. Its operating principle is the interaction between high-energy laser pulses and contaminants, instantly vaporizing or removing contaminants without direct contact with the substrate. This non-contact cleaning method is particularly suitable for high-precision workpieces, sensitive surfaces, or high-value components, such as aircraft engine blades, precision molds, and electronic components. It ensures thorough cleaning while avoiding the surface damage associated with traditional methods.

Environmental friendliness

Environmental friendliness is a major advantage of laser cleaning over traditional methods. While chemical cleaning methods are highly efficient, they require the use of strong acids, bases, or organic solvents, which not only pollute the environment but may also pose health risks to operators. Mechanical cleaning methods, such as sandblasting, generate significant amounts of waste and dust, requiring additional disposal measures.

Laser cleaning eliminates the need for any chemicals; it relies solely on the physical interaction of the laser with the contaminants. Byproducts are primarily small amounts of dust and fumes, which can be safely collected and disposed of using a dedicated fume extraction system. This “green cleaning” approach significantly reduces secondary pollution, complies with increasingly stringent global environmental regulations, and aligns with the corporate trend toward sustainable development.

Precise and Controllable

Laser cleaning offers a high degree of controllability. By adjusting laser generator parameters (such as wavelength, pulse duration, power density, and scanning speed), operators can precisely control the cleaning range, depth, and effectiveness.

This precision, down to the micron level, ensures that only surface contaminants or oxide layers are removed without damaging the substrate. This makes it particularly suitable for demanding applications such as aerospace, electronics manufacturing, and mold processing. For example, in automotive mold maintenance, laser cleaning not only removes adherent residue but also maintains mold surface finish and dimensional accuracy, extending its service life.

Reduced Operating Costs

Although the initial investment in laser cleaning equipment is relatively high, its long-term operating costs are significantly lower than traditional methods. Traditional chemical cleaning requires ongoing purchases of chemicals, while mechanical cleaning relies on sandpaper, abrasives, or blasting media. These consumables incur ongoing expenses. Furthermore, chemical cleaning requires additional waste liquid disposal, while sandblasting requires waste disposal, all of which increase operational burdens.

Laser cleaning, on the other hand, is virtually non-consumable. Beyond electricity consumption and routine maintenance, daily operations require no frequent purchases of additional cleaning materials. In the long term, this method not only reduces operating costs but also reduces additional labor and waste disposal expenses. This cost advantage is particularly significant for large-scale production companies.

Overall, laser cleaning excels in its non-contact, non-wearing nature, environmental friendliness, precise controllability, and long-term economical performance, significantly outperforming traditional cleaning methods. It not only meets the stringent requirements of high-end manufacturing for cleanliness quality and surface integrity, but also helps companies achieve dual benefits in terms of environmental protection and cost control.

With the continuous advancement of laser generator technology, the application scenarios of laser cleaning will further expand. Its advantages will become increasingly prominent in industries such as aerospace, automotive manufacturing, electronics, and precision mold processing, which have extremely high requirements for cleanliness and surface protection.

Những hạn chế và thách thức

Although laser cleaning has attracted widespread attention in the industrial sector due to its advantages of high efficiency, environmental friendliness, and precise control, it still faces certain limitations and challenges in practical application. Understanding these limitations can help companies make more rational and efficient decisions when selecting cleaning solutions.

Risks of Material Damage and Surface Discoloration

Laser cleaning utilizes high-energy laser pulses to irradiate the target surface, instantly removing contamination layers. However, improper cleaning parameters, such as excessive power or slow scanning speeds, can cause overheating of the substrate surface, resulting in melting, ablation, and even discoloration. This situation requires particular care in precision industries with extremely high surface quality requirements, such as aerospace and medical device manufacturing.

Safety Requirements

Laser, as a high-energy beam, poses potential hazards to the human body. During laser cleaning, operators must wear specialized laser goggles to protect their eyes from laser radiation. Furthermore, the cleaning process generates smoke and fine particles. Inadequate ventilation and exhaust systems can adversely affect the operating environment and personnel’s health. Therefore, comprehensive safety precautions and strict operating procedures are essential when using laser cleaning equipment.

Equipment and Operating Costs

Compared to traditional chemical cleaning or mechanical polishing, laser cleaning equipment requires a higher initial investment. The high-quality laser generator, precision optical system, and control system make the overall equipment cost far higher than some traditional cleaning methods. Furthermore, while laser cleaning offers lower long-term operating costs, the initial investment remains a significant barrier for small and medium-sized enterprises with limited budgets.

Limited Effectiveness on Certain Contaminants

Laser cleaning is not a panacea. Its cleaning effectiveness may be limited when dealing with certain transparent materials (such as glass), highly reflective materials (such as some highly polished metals), or extremely complex contaminant structures. For example, laser cleaning alone may not be able to completely remove highly penetrating oil stains or deep oxide layers, requiring the use of other cleaning methods.

While laser cleaning offers many advantages, its application still faces challenges such as high equipment costs, stringent safety requirements, and limited effectiveness on some materials. Only by fully understanding these limitations can companies optimally configure the laser generator and related supporting systems based on their specific needs to achieve optimal cleaning results.

Laser Cleaning vs. Traditional Cleaning Methods

To fully assess the application prospects of laser cleaning, it is necessary to compare it with traditional cleaning methods. Common traditional cleaning methods include chemical cleaning, mechanical cleaning, and ultrasonic cleaning.

Làm sạch bằng tia laser so với làm sạch bằng hóa chất

Chemical cleaning relies on acid-base solutions or organic solvents to remove contaminants. While highly efficient, it often results in the discharge of large amounts of chemical waste, causing serious environmental pollution. Furthermore, prolonged exposure to chemical agents poses health risks to operators. In contrast, laser cleaning is a “dry cleaning” technology that requires no chemical agents, avoids secondary pollution, and better complies with current environmental regulations.

Laser Cleaning vs. Mechanical Cleaning

Mechanical cleaning typically removes contaminant layers using sandpaper, wire brushes, or sandblasting. While simple and direct, these methods often cause abrasion to the substrate surface and may even damage the material’s structural integrity. Laser cleaning, on the other hand, is a non-contact cleaning method. The laser and the surface interact only through energy transfer, without direct friction, thus preserving the substrate’s original shape.

Laser Cleaning vs. Ultrasonic Cleaning

Ultrasonic cleaning is commonly used for cleaning precision parts. It uses high-frequency sound waves to create cavitation in a liquid, removing surface dirt. However, this method requires a cleaning fluid and is limited in effectiveness when cleaning complex structures. Laser cleaning, with its high directionality and focusing capabilities, can precisely clean complex shapes or hard-to-reach areas, extending its application range.

Cost and Efficiency Comparison

In the long term, while laser cleaning equipment requires a higher initial investment, it reduces the need for large quantities of consumables (such as cleaning fluids and sandpaper) and offers lower overall operating costs. Furthermore, laser cleaning boasts a high degree of automation and can be integrated with robotic systems or production lines, significantly improving efficiency and reducing labor costs.

Compared to traditional methods, laser cleaning offers significant advantages in environmental friendliness, non-contact operation, and automation. While it still has disadvantages in terms of initial investment and in some applications, its application prospects are expected to expand with advances in laser generator technology and cost reductions.

Phần kết luận

Laser cleaning, as an emerging industrial surface treatment technology, is gradually replacing traditional cleaning methods due to its high efficiency, environmental friendliness, and precise controllability. By properly configuring the laser generator and optimizing laser parameters, laser cleaning can not only remove rust and coatings from metal surfaces, as well as clean precision components, but also demonstrates significant application potential in a wide range of fields, including aerospace, automotive manufacturing, and electronics.

However, practical challenges in laser cleaning must be addressed, such as high equipment costs, stringent safety requirements, and limited cleaning effectiveness on some materials. However, with the continuous advancement of laser generator technology and the growing global emphasis on green manufacturing and environmental regulations, these issues are gradually being addressed.

For businesses, choosing laser cleaning is not only a technological upgrade but also a development strategy. By adopting laser cleaning, companies can reduce operating costs while maintaining product quality, aligning with the trend of sustainable development. The value of laser cleaning is gaining increasing recognition, particularly in fields such as metal processing, industrial manufacturing, and precision engineering.

Nhận giải pháp Laser

As a professional laser solutions provider, we are committed to providing our customers with advanced laser-based cleaning technologies and equipment support. We not only tailor efficient and reliable laser cleaning solutions, but also offer comprehensive after-sales service and technical support to help customers improve production efficiency and product quality. Laser cleaning will play a vital role in even more industries in the future, and AccTekLaser will remain at the forefront, becoming your trusted partner.

Thông tin liên lạc

- [email protected]

- [email protected]

- +86-19963414011

- Số 3 Khu A, Khu công nghiệp Lunzhen, Thành phố Yucheng, Tỉnh Sơn Đông.

Nhận giải pháp Laser