Understanding the Radiation of Laser Cutting Machines

This article introduces the radiation types, health risks, relevant regulations and safety protection measures of laser cutting machines to help companies improve efficiency while protecting the health of operators.

Regulations and Standards for the Use of Laser Cleaning Machines

This article explores the regulations and standards that govern the use of laser cleaning machines, emphasizing the importance of ensuring operator safety, maintaining equipment integrity, protecting environmental quality, and upholding product quality.

How to Achieve High Contrast in Laser Marking

This article mainly discusses how to achieve high-contrast marking effects and improve product readability and brand visual quality by optimizing laser marking technology, and adjusting material preparation and environmental conditions.

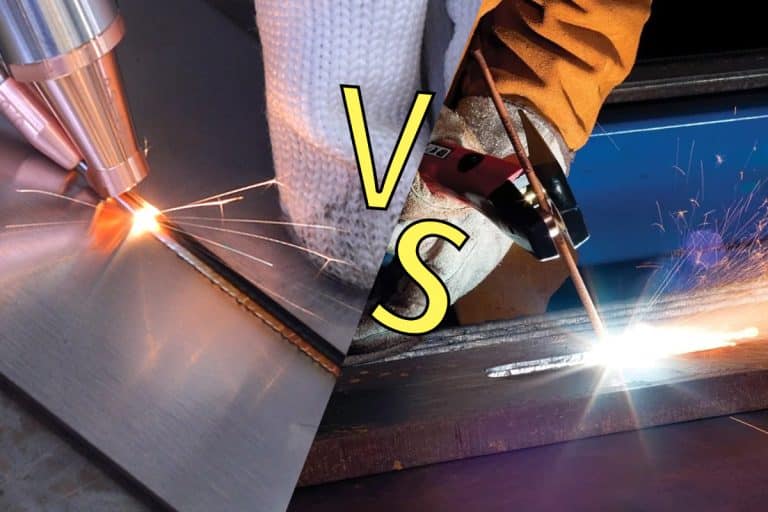

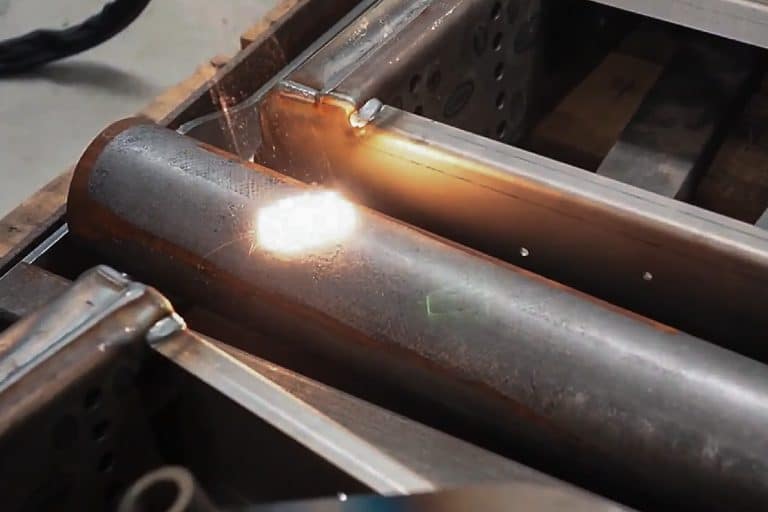

Laser Welding Vs Arc Welding

This article briefly compares the working principles, advantages, disadvantages and applications of laser welding and arc welding to help readers choose the appropriate welding method.

How to Start a Laser Cutting Business?

This article details the key steps and precautions for starting a laser cutting business, helping novices to smoothly enter the industry and ensure the successful operation of the business.

Sustainability of Laser Cutting Technology

This article mainly discusses the sustainable advantages of laser cutting technology, analyzes its positive impact on the environment, compares it with traditional cutting methods, environmental protection practices, and the challenges and solutions it faces.

Can a Laser Cutting Catch Fire?

This article introduces in detail the various dangerous factors that may cause fires during the laser cutting process and provides practical safety measures to help users comprehensively prevent and reduce the occurrence of fire accidents.

Can Laser Cleaning Be Used on Sensitive Materials Without Causing Damage?

This article explores the potential for laser cleaning in processing sensitive materials such as cultural relics, electronic components, and aerospace parts, and analyzes whether the technology will cause material damage in these areas.

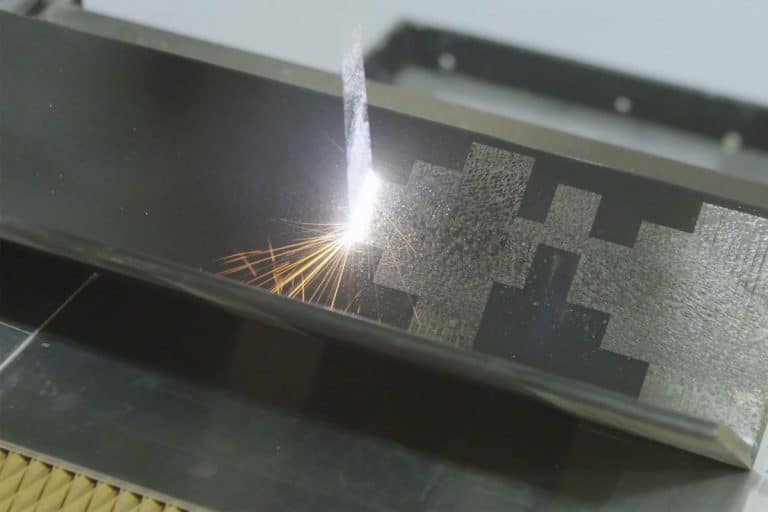

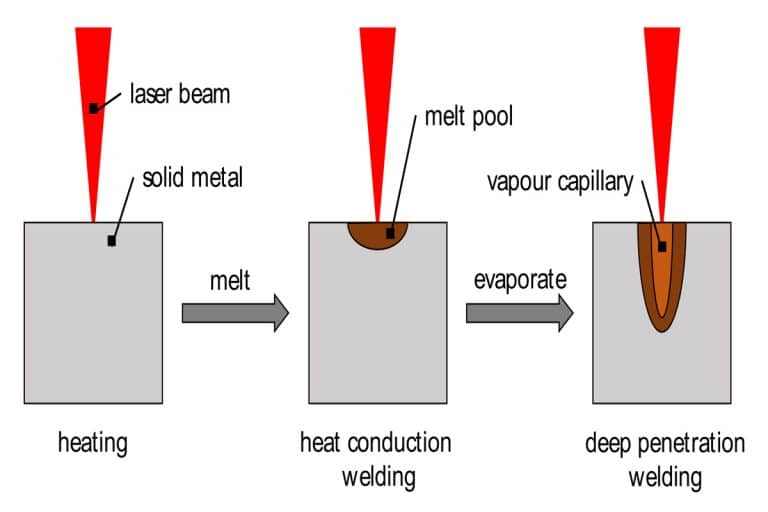

How Does the Focal Point of the Laser Beam Affect the Quality of the Weld?

This article discusses how laser beam focusing affects welding quality, including its impact on penetration depth, weld width, etc., and how to optimize laser beam focusing to achieve high-quality welding.

What Factors Affect the Quality of Laser Marking?

This article mainly introduces the key factors that affect the quality of laser marking, including laser type, material properties, laser parameter settings, environmental conditions and operator skills, to help readers optimize the marking effect.

Understand How Laser Parameters Affect the Cleaning Process

This article mainly introduces the influence of key parameters in the laser cleaning process on the cleaning effect of different materials, and proposes an optimization scheme to achieve efficient and safe pulsed laser cleaning and surface treatment.

What Are the Common Problems of Laser Welding Machines?

This article mainly analyzes the common technical problems and causes of laser welding machines in practical applications, and provides targeted solutions and preventive measures to help companies improve welding quality, stabilize equipment performance, and optimize production efficiency.

Laser Cleaning Machine Cooling System Maintenance Guide

This article systematically introduces the components of a laser cleaning machine’s cooling system, common problems, and key maintenance points, helping you ensure continued efficient and safe operation of your equipment.

Understanding the Smells Associated with Laser Cutters

This article mainly discusses the causes, common types, and impacts of odors produced by laser cutting machines during processing, and proposes effective methods to reduce odors and improve the working environment.

What is the Cleaning Efficiency of Laser Cleaning?

This article mainly explains the definition, working principle, efficiency influencing factors, and advantages of laser cleaning, compares it with traditional methods, and summarizes its application value and prospects in industrial manufacturing.

A Complete Guide to Safety Precautions for Laser Welding Machines

This article mainly introduces the application, potential safety risks, and protective measures of fiber laser welding machines, and looks forward to their development trends in intelligence and greenness.

A Comprehensive Guide to Determining Laser Power for Laser Cutting Machines

This article mainly introduces how to determine and optimize the laser power of the laser generator to improve the accuracy, efficiency, and stability of laser cutting and welding.

Laser Cutting Machine Nozzle Guide

This article mainly introduces nozzle types, sizes, materials, and factors affecting performance, helping you choose the right nozzle and improve cutting accuracy and efficiency.

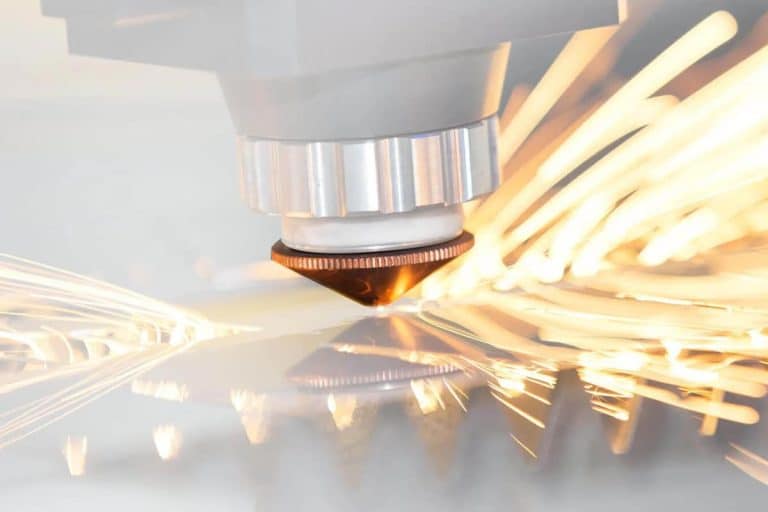

What Are the Considerations for Laser Welding in Terms of Weld Penetration and Depth-to-Width Ratio?

This article systematically analyzes the key influencing factors and optimization methods of laser welding machines in terms of weld penetration and depth-to-width ratio, helping manufacturing companies achieve welding quality that combines high strength, high precision, and aesthetics.

Comprehensive Guide to Selecting the Right Laser Cleaning Parameters

This article will systematically introduce the types of laser cleaning parameters, selection points, optimization methods, and typical application scenarios to help you find the optimal solution for different tasks.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.