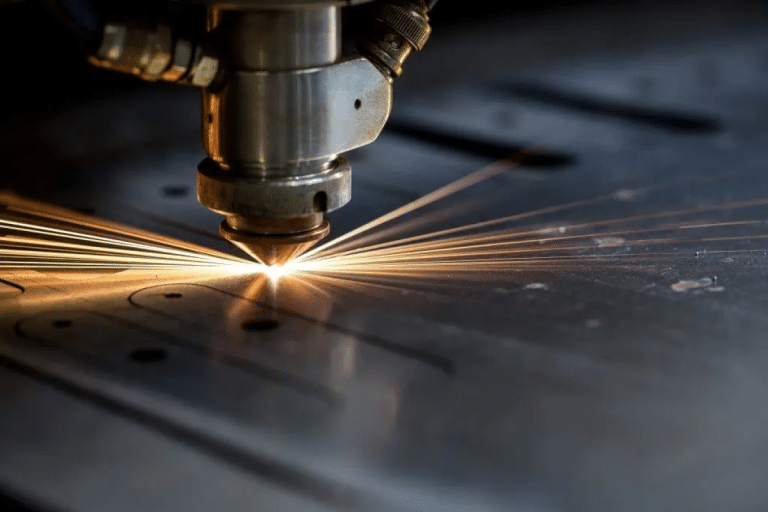

Autogenous Laser Welding VS Filler Laser Welding

This article delves into the fundamental differences between autogenous laser welding and filler laser welding, exploring their principles, applications, advantages, and limitations.

What Factors Affect Laser Welding Efficiency?

This article delves into the key factors influencing laser welding efficiency, providing a comprehensive guide to mastering this complex technology and achieving superior welding results.

How Do Laser Parameters Affect The Cleaning Process?

This article explores how these laser parameters affect the cleaning process, providing insights for achieving the best results for a variety of industrial needs.

Effect of Auxiliary Gas Selection on Laser Cutting

This article explores the impact of assist gas selection on laser cutting, understands how different gases affect laser cutting, and provides guidance on selecting the best gas for a specific application.

Odors Associated with Laser Cutting Machine

This article explores the sources, types, and management of odors associated with laser-cutting machines, providing a comprehensive overview of this important but often overlooked aspect of laser-cutting technology.

What to Consider Before Buying a Laser Cutting Machine

This article explores the essential aspects to evaluate before purchasing a laser cutting machine, guiding you through the complexities of this technology to ensure you make a smart, strategic investment.

Laser Welding VS TIG Welding

This article delves into a comprehensive comparison of laser welding and TIG welding, examining their principles, processes, advantages, disadvantages, and applications to help you choose the right welding method.

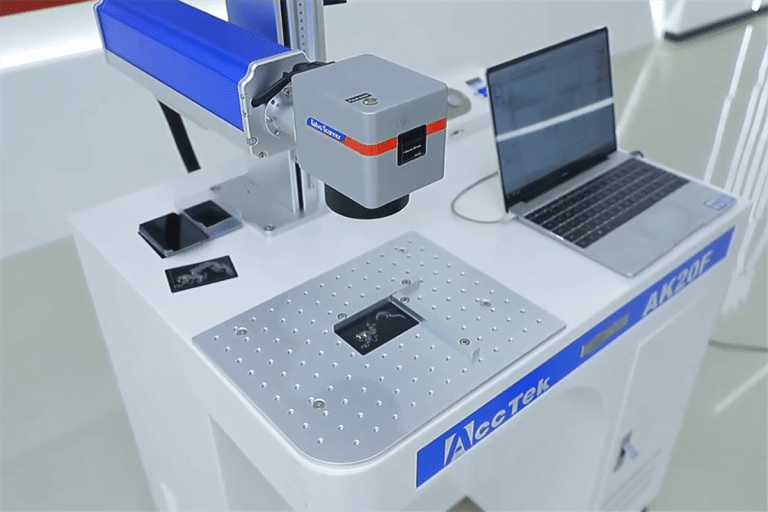

How Does The Choice of Laser Type Affect Marking Capabilities?

This article takes an in-depth look at the principles, advantages, disadvantages, and ideal applications of different types of laser marking machines to help you choose the right laser marking machine for your marking needs.

What Factors Affect The Effect of Laser Cleaning?

This article explores the factors that affect laser cleaning in detail and provides insight into how each factor affects the overall efficiency and effectiveness of laser cleaning.

How To Choose The Power of A Laser Welding Machine?

This article provides detailed guidance on how to select the right laser welding machine power. Understanding these factors will help manufacturers achieve high-quality, reliable welds based on their unique production needs.

What Software Can Control and Operate the Laser Cutting Machine?

Laser-cutting technology has revolutionized modern manufacturing and fabrication processes. In this article, we’ll take a deep dive into the world of laser cutting systems, analyzing the various software solutions available and their respective advantages and disadvantages.

Are Laser Cutting And CNC Machining The Same?

This article will delve into the similarities and differences between these two processing methods to help readers better understand their characteristics and advantages.

Running a Laser Cutting Business: Regulations And Certifications

Laser cutting is a versatile and precise technology. In this comprehensive article, we’ll look closer at the world of laser-cutting businesses and explore the regulatory and certification requirements entrepreneurs must consider.

Does Laser Welding Require The Use of Welding Wire?

In this article, we will examine the fundamentals of laser welding, explore the various laser welding techniques, and determine whether or not the use of welding wire.

Laser Cutting File Formats Comprehensive Guide

Laser cutting has become a cornerstone of modern manufacturing and design. In this comprehensive guide, we’ll take a journey into the world of laser-cutting software and the various file formats that power this cutting-edge technology.

Laser Cleaning VS Other Non-Contact Cleaning Methods

In this article, we’ll explore the principles, applications, benefits, and limitations of each cleaning method to gain an understanding of their capabilities and drawbacks.

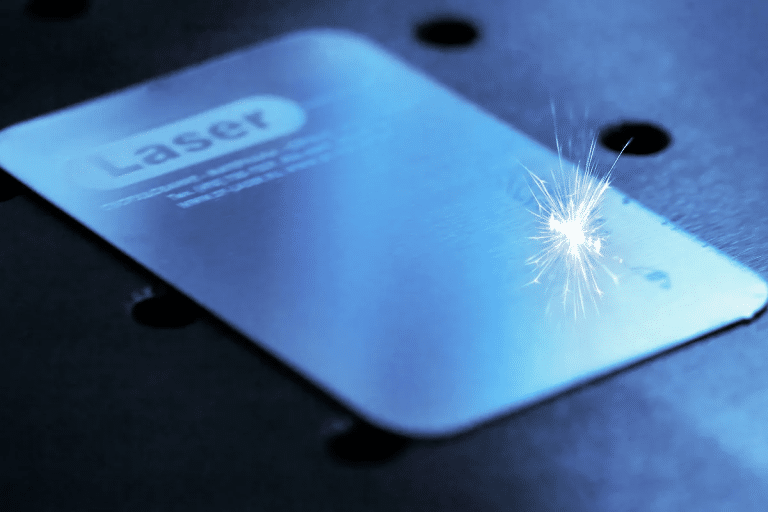

The Difference Between Laser carving, Etching And Marking

This article will explore the differences between laser engraving, etching, and marking to help readers better understand their principles, applicability, and advantages and disadvantages.

Effect of Laser Cutting Power

Laser cutting power can have a profound impact on material interaction, cut thickness, cut quality, cutting speed, material compatibility, and heat-affected zone. Let’s discuss ways to determine the optimal laser-cutting power for various applications.

Complete Guide to Laser Generator Brands

At the heart of a laser cutting machine is the laser generator, we will take a deep dive into the strengths and weaknesses of each brand and provide you with the knowledge you need to choose the right laser generator brand.

Laser Marking: Which is Better About CO2 Laser or Fiber Laser?

This article provides detailed information about CO2 and fiber laser to determine which laser generator is better suited for your specific marking needs.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.