What Software Can Control and Operate the Laser Cutting Machine?

Laser-cutting technology has revolutionized modern manufacturing and fabrication processes. In this article, we’ll take a deep dive into the world of laser cutting systems, analyzing the various software solutions available and their respective advantages and disadvantages.

Are Laser Cutting And CNC Machining The Same?

This article will delve into the similarities and differences between these two processing methods to help readers better understand their characteristics and advantages.

Running a Laser Cutting Business: Regulations And Certifications

Laser cutting is a versatile and precise technology. In this comprehensive article, we’ll look closer at the world of laser-cutting businesses and explore the regulatory and certification requirements entrepreneurs must consider.

Does Laser Welding Require The Use of Welding Wire?

In this article, we will examine the fundamentals of laser welding, explore the various laser welding techniques, and determine whether or not the use of welding wire.

Laser Cutting File Formats Comprehensive Guide

Laser cutting has become a cornerstone of modern manufacturing and design. In this comprehensive guide, we’ll take a journey into the world of laser-cutting software and the various file formats that power this cutting-edge technology.

Laser Cleaning VS Other Non-Contact Cleaning Methods

In this article, we’ll explore the principles, applications, benefits, and limitations of each cleaning method to gain an understanding of their capabilities and drawbacks.

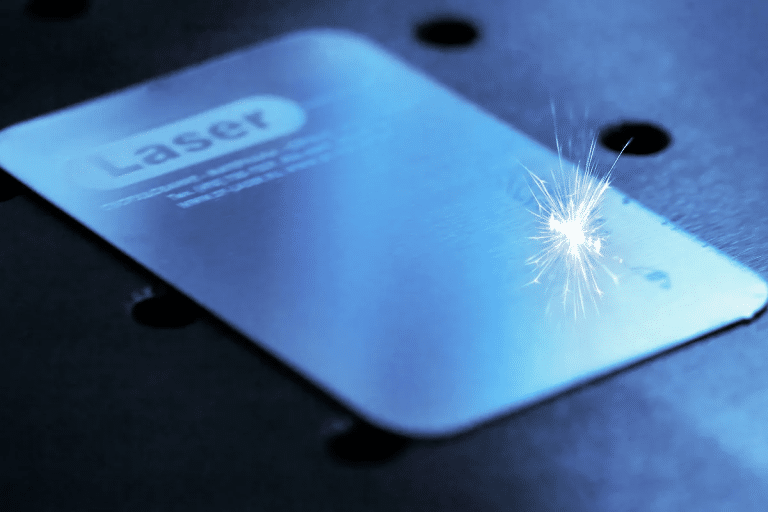

The Difference Between Laser carving, Etching And Marking

This article will explore the differences between laser engraving, etching, and marking to help readers better understand their principles, applicability, and advantages and disadvantages.

Effect of Laser Cutting Power

Laser cutting power can have a profound impact on material interaction, cut thickness, cut quality, cutting speed, material compatibility, and heat-affected zone. Let’s discuss ways to determine the optimal laser-cutting power for various applications.

Complete Guide to Laser Generator Brands

At the heart of a laser cutting machine is the laser generator, we will take a deep dive into the strengths and weaknesses of each brand and provide you with the knowledge you need to choose the right laser generator brand.

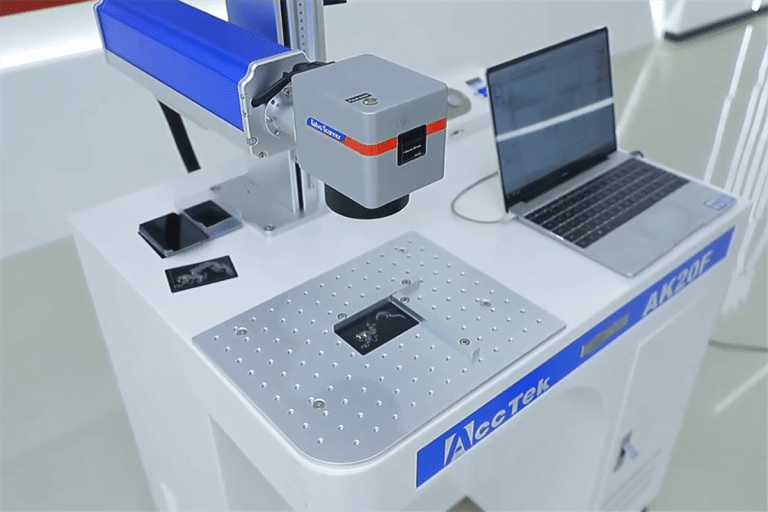

Laser Marking: Which is Better About CO2 Laser or Fiber Laser?

This article provides detailed information about CO2 and fiber laser to determine which laser generator is better suited for your specific marking needs.

How Does Laser Cleaning Affect Surface Roughness and Cleanliness?

This article mainly discusses the impact of laser cleaning on the roughness and cleanliness of the material surface, and how to maximize the laser cleaning effect by optimizing laser cleaning parameters.

What Is the Difference Between CW and Pulsed Fiber Laser Generators?

This article discusses the application requirements, speed, accuracy, material properties, and budget of the two laser generators to help you comprehensively consider which laser generator you should choose.

Power Consumption of Laser Cutting Machines

This article delves into the intricate details of laser-cutting machine power consumption, explores the factors that affect energy use, and provides practical strategies for reducing power consumption.

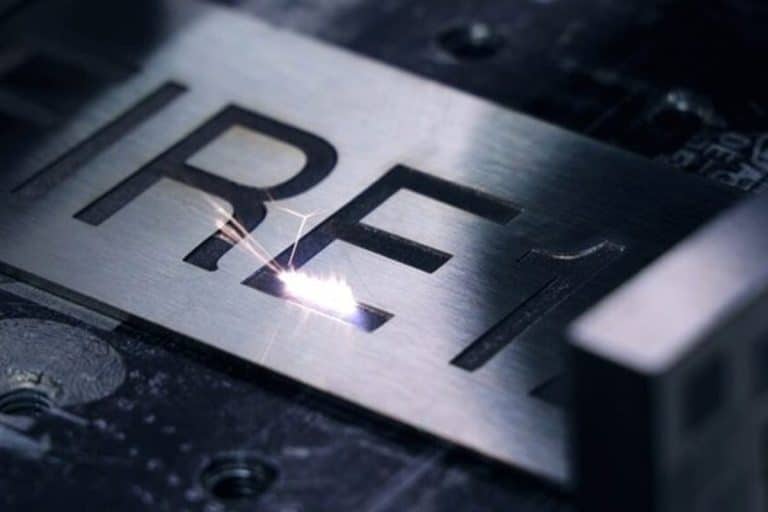

How Does Laser Marking Affect the Surfaces of Different Materials?

This article mainly discusses the problems and solutions of laser marking on the surfaces of different materials, helping you to better choose a marking machine suitable for your business.

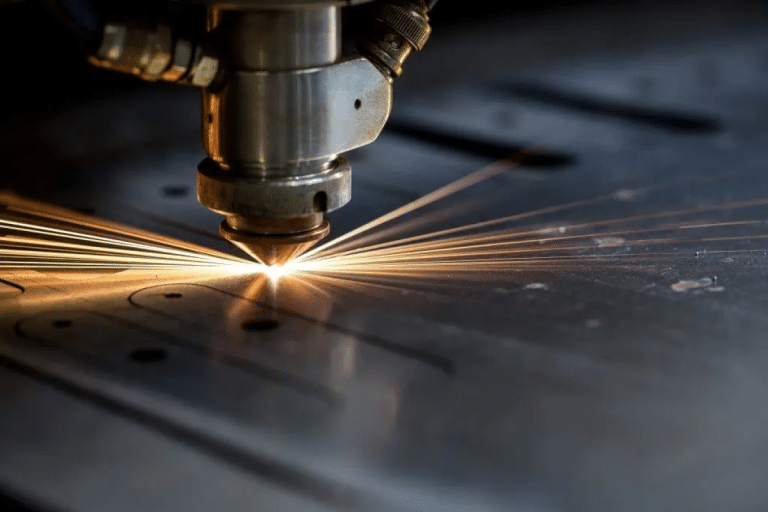

Laser Cutting Nozzle Guide

This guide delves into every aspect of Laser-cutting nozzles, from their types and materials to the factors that influence their performance and selection criteria.

Motor Guide for Laser Cutting Machines

This article provides a comprehensive introduction to the different types of motors used in laser cutting machines, exploring their advantages, disadvantages, and applications to help manufacturers and operators select and optimize motor systems.

How To Determine Laser Cutting Power?

This article provides detailed guidance on how to accurately determine the laser cutting power required for various cutting tasks, thereby improving overall productivity and quality.

Understanding The Operating Costs of Laser Cutting Machines

In this article, we explore the various factors that affect the operating costs of a laser cutting machine, gaining insight into the cost drivers as well as optimization strategies.

Choosing The Right Fiber Laser Cutting Machine: Comprehensive Guide

This comprehensive guide helps companies select the right fiber laser cutting machine by exploring key technical specifications, industry applications, and strategic decision-making criteria.

What Training Is Required To Safely Operate A Laser Cleaning Machine?

This article delves into the comprehensive training required to safely operate a laser cleaning machine, highlighting the importance of education in laser cleaning skill development.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.