What Software Can Control and Operate the Laser Cutting Machine?

Laser-cutting technology has revolutionized modern manufacturing and fabrication processes. In this article, we’ll take a deep dive into the world of laser cutting systems, analyzing the various software solutions available and their respective advantages and disadvantages.

Are Laser Cutting And CNC Machining The Same?

This article will delve into the similarities and differences between these two processing methods to help readers better understand their characteristics and advantages.

Running a Laser Cutting Business: Regulations And Certifications

Laser cutting is a versatile and precise technology. In this comprehensive article, we’ll look closer at the world of laser-cutting businesses and explore the regulatory and certification requirements entrepreneurs must consider.

Does Laser Welding Require The Use of Welding Wire?

In this article, we will examine the fundamentals of laser welding, explore the various laser welding techniques, and determine whether or not the use of welding wire.

Laser Cutting File Formats Comprehensive Guide

Laser cutting has become a cornerstone of modern manufacturing and design. In this comprehensive guide, we’ll take a journey into the world of laser-cutting software and the various file formats that power this cutting-edge technology.

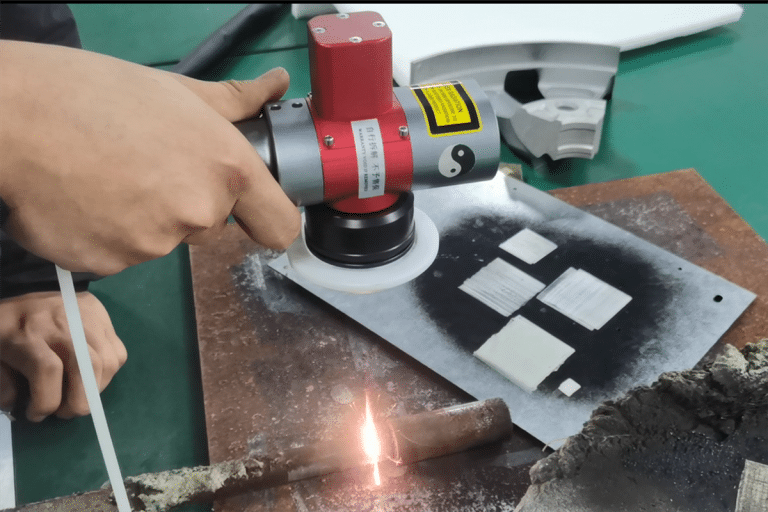

Laser Cleaning VS Other Non-Contact Cleaning Methods

In this article, we’ll explore the principles, applications, benefits, and limitations of each cleaning method to gain an understanding of their capabilities and drawbacks.

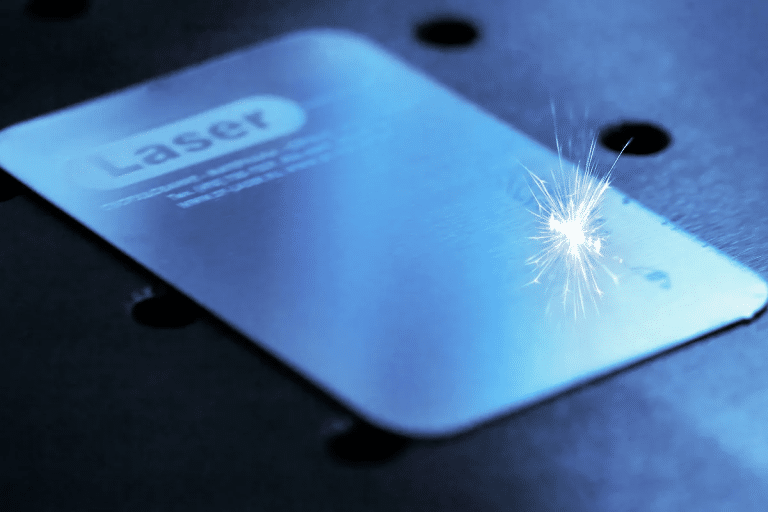

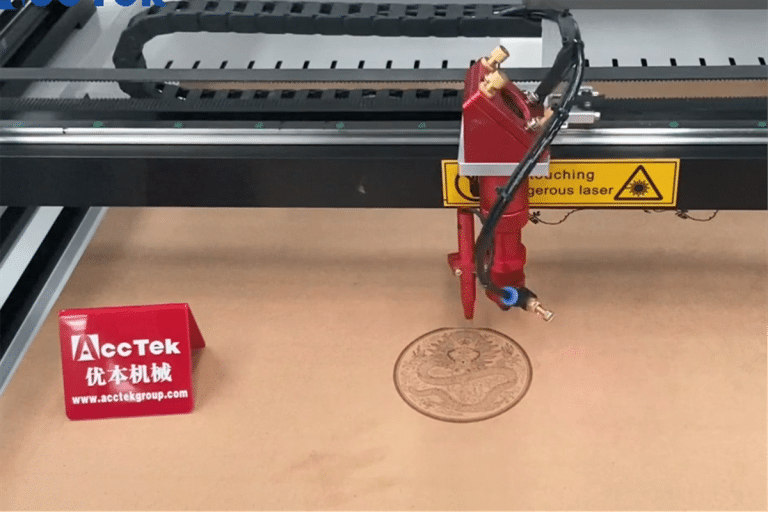

The Difference Between Laser carving, Etching And Marking

This article will explore the differences between laser engraving, etching, and marking to help readers better understand their principles, applicability, and advantages and disadvantages.

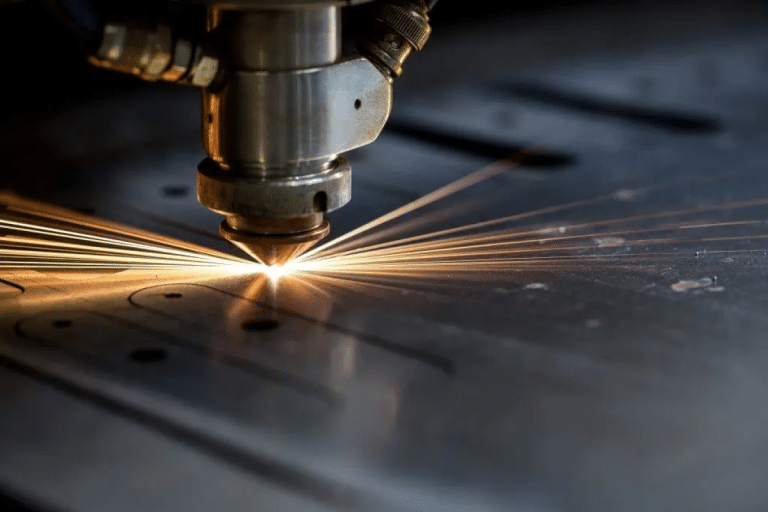

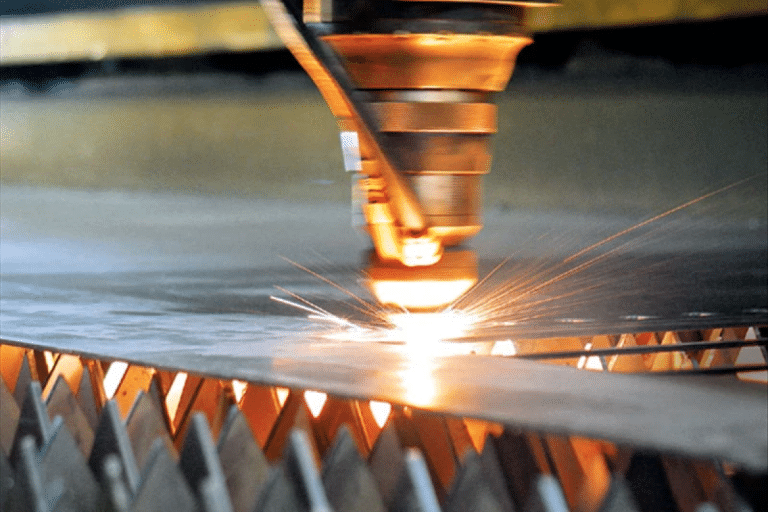

Effect of Laser Cutting Power

Laser cutting power can have a profound impact on material interaction, cut thickness, cut quality, cutting speed, material compatibility, and heat-affected zone. Let’s discuss ways to determine the optimal laser-cutting power for various applications.

Complete Guide to Laser Generator Brands

At the heart of a laser cutting machine is the laser generator, we will take a deep dive into the strengths and weaknesses of each brand and provide you with the knowledge you need to choose the right laser generator brand.

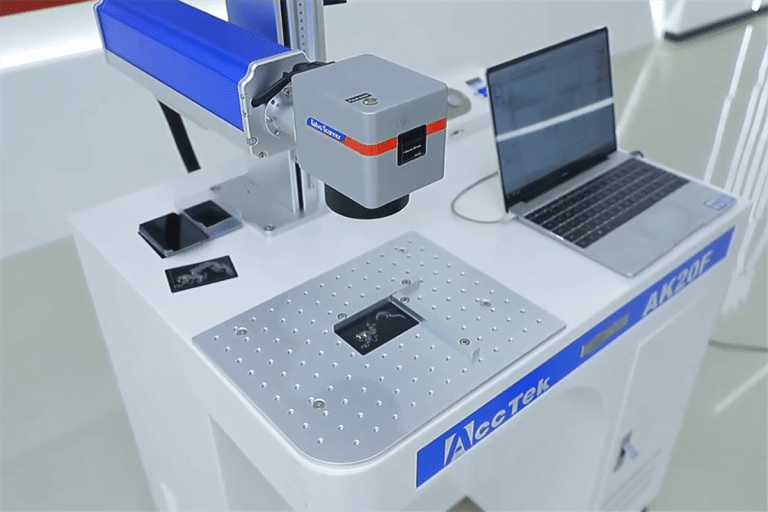

Laser Marking: Which is Better About CO2 Laser or Fiber Laser?

This article provides detailed information about CO2 and fiber laser to determine which laser generator is better suited for your specific marking needs.

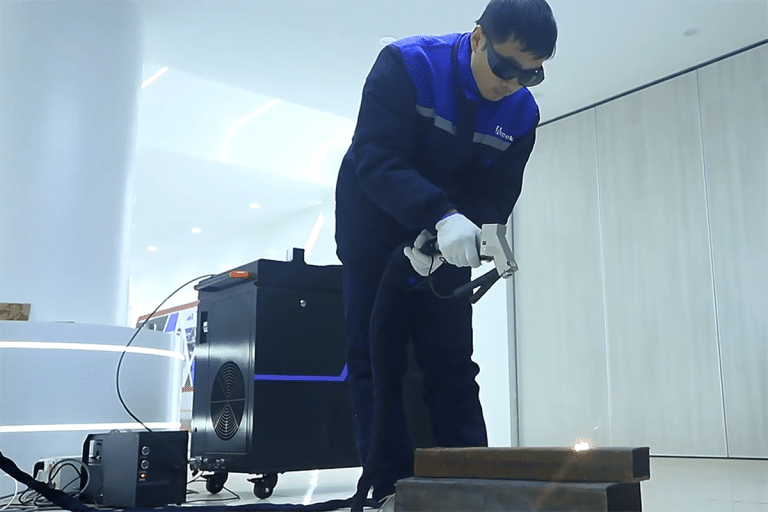

What Precautions Should Be Taken When Using Laser Welding Machine?

Although the laser welding machine is simple to operate and easy to use, there are still some precautions that need to be paid attention to when operating the machine.

How Can The Life Expectancy of a Laser Cleaning Machine Be Improved

The service life of laser cleaning machines has always been a focus of interest for users. This article takes an in-depth look at steps you can take to extend the life expectancy of your laser cleaning machine.

What Materials Cannot Be Cut by Laser Cutting Machines?

Some materials are not suitable for laser cutting. This article will explore some materials that laser-cutting machines cannot cut and analyze the reasons why.

What is The Difference Between Pad Printing And Laser Marking?

This article will compare pad printing and laser marking from the aspects of principle, process flow, advantages and disadvantages, to help you better understand the difference between them.

What Are The Environmental Requirements For The Operation of Laser Cleaning Machines?

Here introduces the factors that need to be paid attention to in the operating environment of the laser cleaning machine from various aspects. This will help you use the machine better.

How Does The Cooling System Affect The CO2 Laser Cutting Machine’s Performance And Life?

Effective cooling plays a vital role in the performance and lifespan of a CO2 laser cutting machine. This article will explore and analyze these effects in depth.

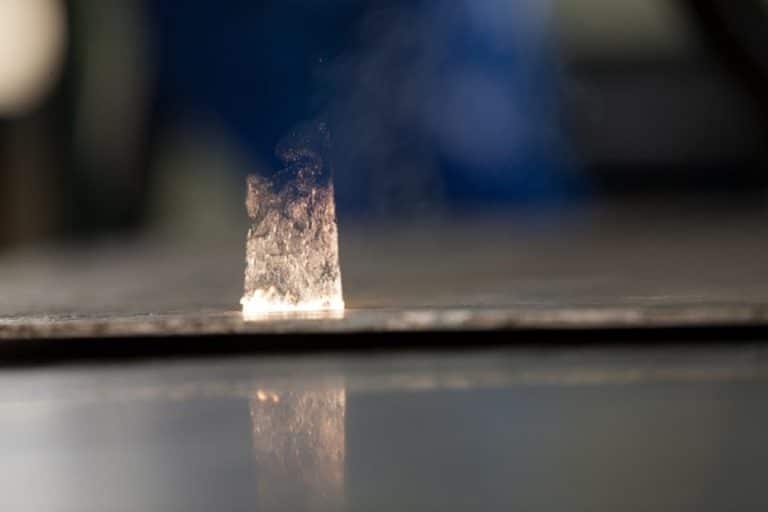

What Causes Laser Welding Spatter?

If you regularly use laser welding in your job, you need to understand why your laser welding machine produces spatter during the welding process and find out the best way to control the effects of spatter.

CW Laser Cleaning Machine VS Pulse Laser Cleaning Machine

This article compares the difference between CW laser cleaning machine and pulse laser cleaning machine for you in many aspects. Understanding these will help you choose the correct laser cleaning equipment.

What Are The Factors That Affect The Cleaning Effect of Laser Cleaning Machines?

The effect of laser cleaning is affected by many factors. This article will introduce the influence of these factors on the cleaning effect and discuss the methods to optimize the cleaning effect.

What Are The Application Industries of CO2 Laser Cutting Machine?

This article introduces some industries where CO2 laser cutting machine is most commonly used. If you are in this field and want to improve production efficiency, choosing CO2 laser cutting is a good solution.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.