What Types of Materials Can Laser Cutting Cut?

Discover the diverse range of materials that laser cutting technology can handle, including metals, non-metals, and specialty materials, enhancing precision and versatility in various industries.

How Does The CO2 Laser Cutting Machine Work?

Discover how CO2 laser cutting machines work, including laser beam generation, beam delivery, material interaction, cutting control, and their advantages for precise material processing.

What Are The Factors That Affect The Thickness of Laser Welding

Explore the key factors influencing the thickness of laser welding, including laser power, welding speed, material properties, beam focus, and more, to achieve optimal welding results.

How to Maintain The Laser Cleaning Machine?

Learn essential maintenance practices for laser cleaning machines, including daily, weekly, monthly, and annual tasks, troubleshooting tips, and best practices to ensure long-lasting performance.

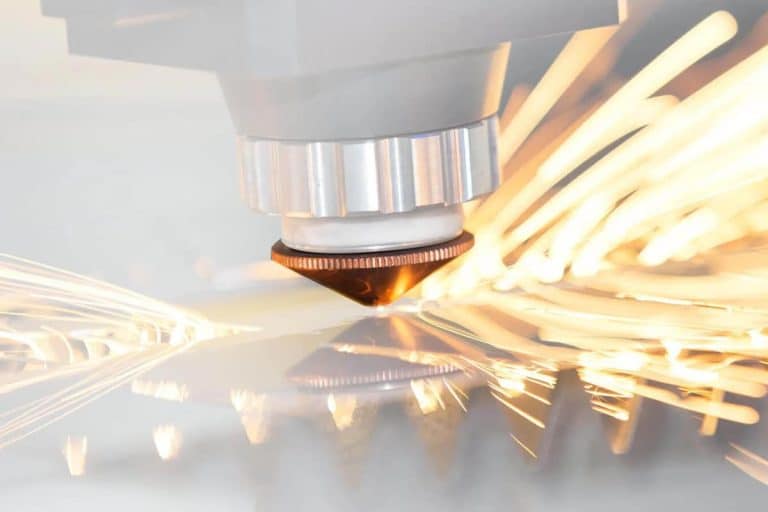

What Are The Three Main Types of Laser Cutting?

Discover the three main types of laser cutting—Fusion Cutting, Flame Cutting, and Sublimation Cutting—and learn their unique processes, advantages, and applications in manufacturing.

What Are The Advantages And Disadvantages of Fiber Laser Marking Machines?

Discover the key advantages and limitations of fiber laser marking machines, including precision, speed, durability, material versatility, costs, and industry applications. Make informed choices for your marking needs.

What Factors Determine The Speed And Accuracy of CO2 Laser Cutting?

Explore the key factors that determine the speed and accuracy of CO2 laser cutting, including laser power, material properties, assist gases, beam focus, and more.

What Welding Defects Can Occur in Laser Welding? How To Solve It?

Learn about common welding defects in laser welding, their causes, and practical solutions to enhance weld quality and reliability, ensuring optimal performance in your applications.

What Are The Factors That Affect The Cost of a Laser Cleaning Machine?

Discover the key factors influencing the cost of laser cleaning machines, including power output, technology, customization, market dynamics, and support services, for informed purchasing decisions.

The Range of Materials That Fiber Laser Cutting Can Cut

Explore the versatility of fiber laser cutting technology and discover the wide range of metals it can precisely cut, from carbon steel to titanium, across diverse industries.

How Does Laser Welding Affect the Heat-Affected Zone (HAZ)?

This article mainly introduces the basic knowledge, significant characteristics and mitigation strategies of the heat-affected zone (HAZ) in laser welding, providing a reference for improving the quality and reliability of welded joints.

Understand How Laser Parameters Affect the Cleaning Process

This article mainly introduces the influence of key parameters in the laser cleaning process on the cleaning effect of different materials, and proposes an optimization scheme to achieve efficient and safe pulsed laser cleaning and surface treatment.

What Are the Common Problems of Laser Welding Machines?

This article mainly analyzes the common technical problems and causes of laser welding machines in practical applications, and provides targeted solutions and preventive measures to help companies improve welding quality, stabilize equipment performance, and optimize production efficiency.

Laser Cleaning Machine Cooling System Maintenance Guide

This article systematically introduces the components of a laser cleaning machine’s cooling system, common problems, and key maintenance points, helping you ensure continued efficient and safe operation of your equipment.

Understanding the Smells Associated with Laser Cutters

This article mainly discusses the causes, common types, and impacts of odors produced by laser cutting machines during processing, and proposes effective methods to reduce odors and improve the working environment.

What is the Cleaning Efficiency of Laser Cleaning?

This article mainly explains the definition, working principle, efficiency influencing factors, and advantages of laser cleaning, compares it with traditional methods, and summarizes its application value and prospects in industrial manufacturing.

A Complete Guide to Safety Precautions for Laser Welding Machines

This article mainly introduces the application, potential safety risks, and protective measures of fiber laser welding machines, and looks forward to their development trends in intelligence and greenness.

A Comprehensive Guide to Determining Laser Power for Laser Cutting Machines

This article mainly introduces how to determine and optimize the laser power of the laser generator to improve the accuracy, efficiency, and stability of laser cutting and welding.

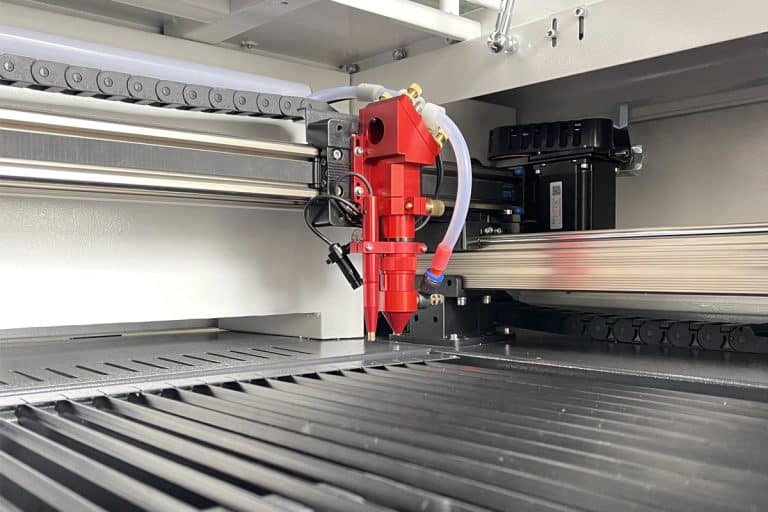

Laser Cutting Machine Nozzle Guide

This article mainly introduces nozzle types, sizes, materials, and factors affecting performance, helping you choose the right nozzle and improve cutting accuracy and efficiency.

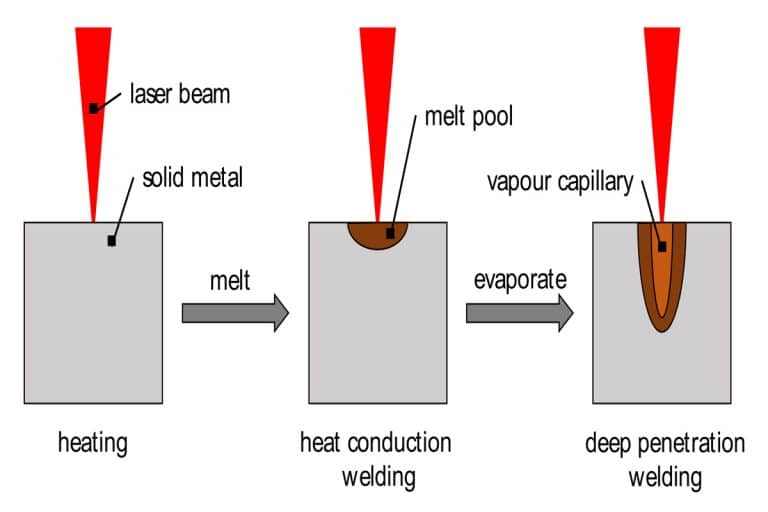

What Are the Considerations for Laser Welding in Terms of Weld Penetration and Depth-to-Width Ratio?

This article systematically analyzes the key influencing factors and optimization methods of laser welding machines in terms of weld penetration and depth-to-width ratio, helping manufacturing companies achieve welding quality that combines high strength, high precision, and aesthetics.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.