How Does the Beam Delivery System Affect the Efficiency of a Laser Welding Machine?

In modern manufacturing, the efficiency of a laser welding machine not only depends on the type of laser source and power, but also on the beam transmission system, which ensures accuracy, stability, and energy efficiency performance during welding.

How Does Beam Quality Affect the Performance of a Laser Welding Machine?

This article mainly introduces the impact of beam quality on laser welding performance, analyzes the key influencing factors, and proposes practical strategies to optimize beam quality to help improve welding effects and efficiency.

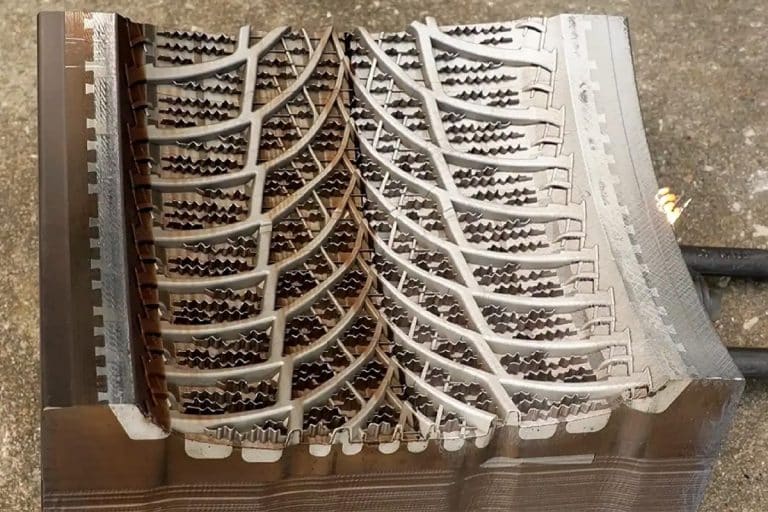

Capabilities and Limitations of Fiber Laser Cutting Machines for Complex Designs

This article systematically introduces the core components, main functions, industry applications in complex designs, and key factors affecting the precision of fiber laser cutting machines, and proposes optimization strategies to help achieve high-quality processing.

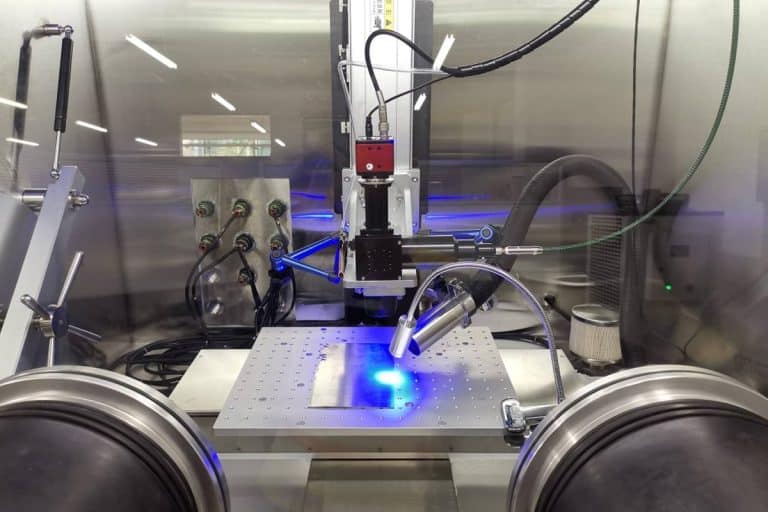

Applications of Pulsed Laser Cleaning

This article mainly introduces the principles, advantages and applications of pulsed laser cleaning in various industries.

Effect of focal length on laser welding results

This article mainly introduces the importance of focal length in laser welding and its influence on welding effect, and provides practical optimization suggestions.

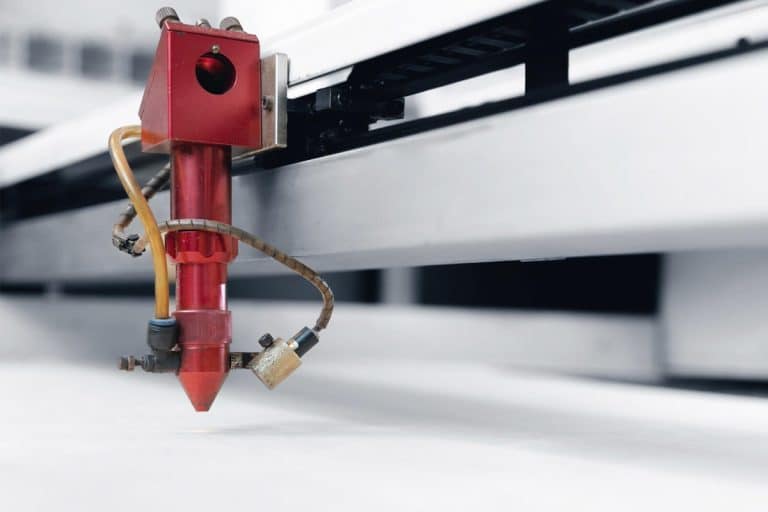

Can a CO2 Laser Cutting Machine Perform Cutting and Engraving Tasks at the Same Time?

Can CO2 laser cutting machines achieve “multi-purpose use” of precise cutting and fine engraving? This article combines the principle with the functional characteristics of AccTek’s CO2 laser cutting machines to provide you with an in-depth analysis.

How to Set up a Pulse Laser Cleaning Machine?

This article mainly introduces the key points of the full process setting of the pulse laser cleaning machine from working condition evaluation, equipment selection, parameter setting to safety specifications and automation integration, aiming to provide users with a set of efficient, stable and sustainable laser surface treatment solutions.

Do Fiber Laser Generators Lose Power over Time?

This article focuses on the reasons why fiber laser generator power decreases over time and proposes effective strategies to mitigate power loss through high-quality equipment, regular maintenance, and an optimized environment.

What Environmental Considerations Should Be Taken When Using Laser Welding Machines?

This article discusses the environmental issues and corresponding measures to be taken when using laser welding machines.

How Does a CO2 Laser Cutting Machine Achieve High-Precision Cutting?

This article mainly introduces the principles and key technologies behind the high-precision cutting capabilities of CO2 laser cutting machines, and analyzes their core structural components and advantages.

What Software Can Control and Operate the Laser Cutting Machine?

Laser-cutting technology has revolutionized modern manufacturing and fabrication processes. In this article, we’ll take a deep dive into the world of laser cutting systems, analyzing the various software solutions available and their respective advantages and disadvantages.

Are Laser Cutting And CNC Machining The Same?

This article will delve into the similarities and differences between these two processing methods to help readers better understand their characteristics and advantages.

Running a Laser Cutting Business: Regulations And Certifications

Laser cutting is a versatile and precise technology. In this comprehensive article, we’ll look closer at the world of laser-cutting businesses and explore the regulatory and certification requirements entrepreneurs must consider.

Does Laser Welding Require The Use of Welding Wire?

In this article, we will examine the fundamentals of laser welding, explore the various laser welding techniques, and determine whether or not the use of welding wire.

Laser Cutting File Formats Comprehensive Guide

Laser cutting has become a cornerstone of modern manufacturing and design. In this comprehensive guide, we’ll take a journey into the world of laser-cutting software and the various file formats that power this cutting-edge technology.

Laser Cleaning VS Other Non-Contact Cleaning Methods

In this article, we’ll explore the principles, applications, benefits, and limitations of each cleaning method to gain an understanding of their capabilities and drawbacks.

The Difference Between Laser carving, Etching And Marking

This article will explore the differences between laser engraving, etching, and marking to help readers better understand their principles, applicability, and advantages and disadvantages.

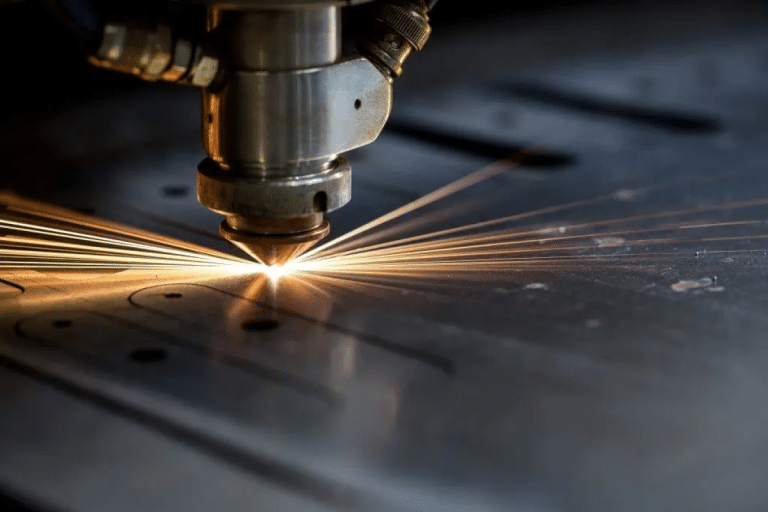

Effect of Laser Cutting Power

Laser cutting power can have a profound impact on material interaction, cut thickness, cut quality, cutting speed, material compatibility, and heat-affected zone. Let’s discuss ways to determine the optimal laser-cutting power for various applications.

Complete Guide to Laser Generator Brands

At the heart of a laser cutting machine is the laser generator, we will take a deep dive into the strengths and weaknesses of each brand and provide you with the knowledge you need to choose the right laser generator brand.

Laser Marking: Which is Better About CO2 Laser or Fiber Laser?

This article provides detailed information about CO2 and fiber laser to determine which laser generator is better suited for your specific marking needs.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.