Why Are Pulsed Lasers More Powerful?

This article mainly discusses the scientific principles, advantages, design considerations, application areas, and challenges of pulsed lasers and deeply explores their high peak power and versatility.

Gantry Fiber Laser Cutting Machine Vs Desktop Fiber Laser Cutting Machine: Comparative Analysis

This article compares and analyzes the structure, performance, and application scenarios of gantry and desktop fiber laser cutting machines to help companies choose the most suitable equipment.

Environmental Considerations and Regulations for Fiber Laser Cutting Processes

This article mainly discusses the environmental impact of fiber laser cutting process, relevant regulatory framework, mitigation strategies, environmental certification and industry cooperation to help enterprises achieve sustainable development and comply with environmental regulations.

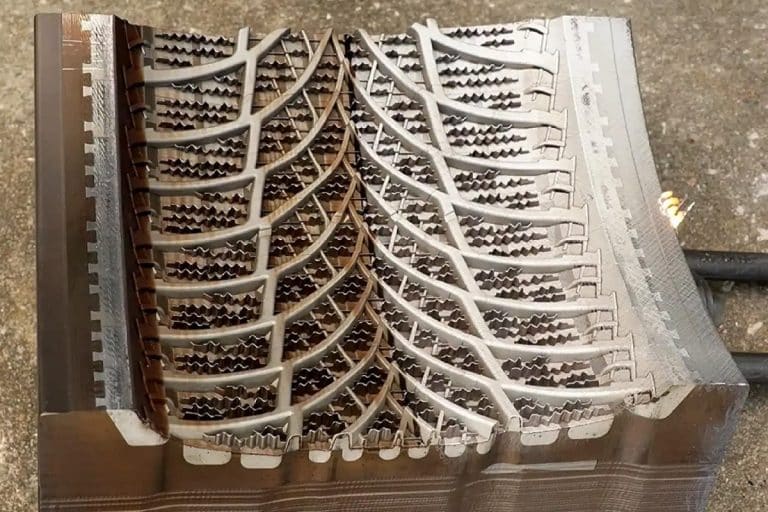

Common Defects in CO2 Laser Cutting and Their Mitigation Methods

This article mainly introduces the principles, common defects, and optimization measures of CO2 laser cutting to improve processing quality and stability.

Will Pulsed Laser Cleaning Damage the Substrate?

This article provides a comprehensive overview of how pulsed laser cleaning works, the mechanisms that may cause substrate damage, influencing factors, and effective strategies to ensure safe and efficient cleaning across various industries.

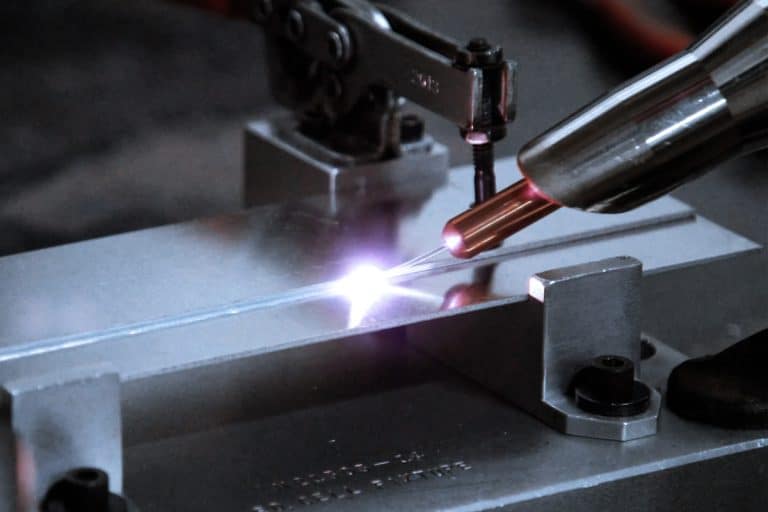

How Does Laser Welding Achieve Deep Melting of Materials?

This article mainly discusses how laser welding can achieve deep melting of materials, including its basic principles, key factors affecting penetration depth, the formation mechanism of deep penetration, and optimization control strategies to improve welding quality and production efficiency.

How Do Pulse Frequency and Repetition Rate Affect Laser Cleaning Efficiency?

This article will explore in depth the effects of pulse frequency and repetition rate on laser cleaning efficiency and provide optimization strategies for different applications.

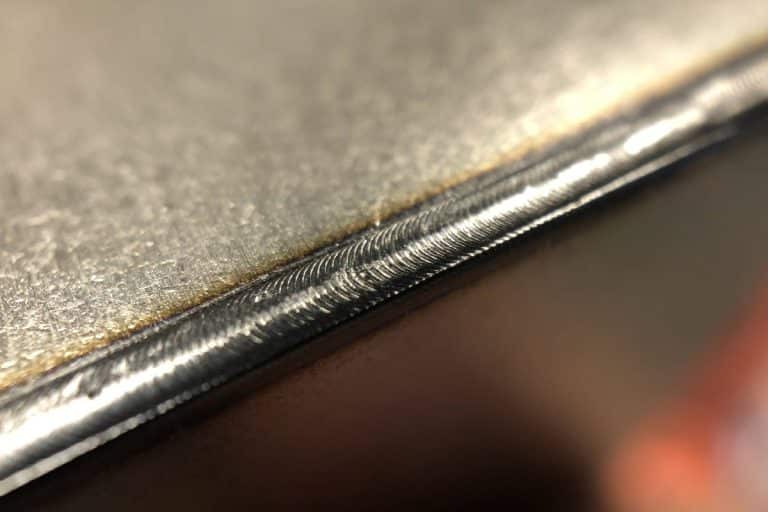

What Are the Challenges of Laser Welding Thin Materials?

This article will explore the challenges and response strategies of thin materials laser welding to help manufacturers master this technology and improve production efficiency and product quality.

How to Achieve the Minimum Incision Width in CO2 Laser Cutting?

This article will analyze the key factors affecting the kerf width of CO2 laser cutting and provide optimization strategies to help manufacturers improve accuracy, and production efficiency, reduce material waste, and improve economic benefits.

The Influence of Autofocus on the Cutting Accuracy of Fiber Laser Cutting Machine

This article discusses the definition and types of autofocus technology and its impact on fiber laser cutting accuracy and analyzes the challenges and optimization solutions it faces to improve production efficiency and processing quality.

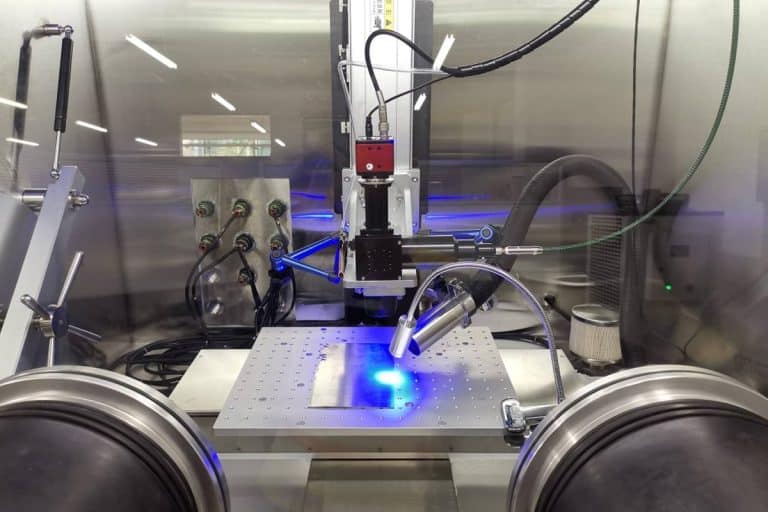

How Does the Focusing Optical System of a Laser Welding Machine Work?

This article analyzes the principles, structure, and optimization methods of fiber laser welding optics and explores their key role in improving welding quality, efficiency, and reliability.

The Influence of Auxiliary Gas Selection on Laser Cutting Process

This article mainly introduces the role and selection strategy of auxiliary gas in the laser cutting process, analyzes the impact of different gases on cutting quality, and proposes an optimization plan so that the laser cutting machine can achieve the best processing effect.

What Are the Factors That Affect the Effect of Laser Cleaning?

This article systematically analyzes the key factors that affect the effect of laser cleaning, from laser parameters, material properties, environmental conditions to system settings, and comprehensively analyzes how to scientifically optimize the cleaning process to achieve efficient, precise and non-destructive surface treatment solutions.

What Are the Factors That Affect the Cutting Quality and Precision of Fiber Laser Cutting?

This article mainly outlines fiber laser cutting solutions, covering equipment stability, process optimization, and support services to improve cutting quality and efficiency.

Understanding the Impact of Laser Welding on the Mechanical Properties of Welded Materials

This paper analyzes the influence mechanism of laser welding on mechanical properties and proposes process optimization, material compatibility, and quality inspection strategies to improve the overall performance of welds.

How Effective Is Laser Cutting?

This article mainly outlines the principles, key influencing factors, and application value of laser cutting technologies such as fiber laser cutting machines, CO2 laser cutting machines, and Nd: YAG laser cutting machines in high-precision automated manufacturing.

How Does the Wavelength of the Laser Beam Affect the Welding Process?

This article mainly outlines the key effects of laser wavelength on welding performance, compares the wavelength characteristics of Nd: YAG, fiber, and CO2 laser generators, and proposes a selection strategy based on materials, processing, and costs.

What Materials Can Be Cleaned with Pulsed Laser Technology?

This article mainly systematically explains the working principle, applicable materials, advantages, and challenges of pulse laser cleaning technology, providing readers with a comprehensive technical overview.

The Difference Between Open-Loop Control System and Closed-Loop Control System of Fiber Laser Cutting Machine

This article mainly makes a comprehensive comparison between the open-loop control system and the closed-loop control system in the fiber laser cutting machine, and analyzes in detail the core differences between the two in terms of feedback mechanism, cutting accuracy, system cost, and application scenarios.

How Does the Beam Delivery System Affect the Efficiency of a Laser Welding Machine?

In modern manufacturing, the efficiency of a laser welding machine not only depends on the type of laser source and power, but also on the beam transmission system, which ensures accuracy, stability, and energy efficiency performance during welding.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.