Do Fiber Laser Generators Lose Power over Time?

This article focuses on the reasons why fiber laser generator power decreases over time and proposes effective strategies to mitigate power loss through high-quality equipment, regular maintenance, and an optimized environment.

What Environmental Considerations Should Be Taken When Using Laser Welding Machines?

This article discusses the environmental issues and corresponding measures to be taken when using laser welding machines.

How Does a CO2 Laser Cutting Machine Achieve High-Precision Cutting?

This article mainly introduces the principles and key technologies behind the high-precision cutting capabilities of CO2 laser cutting machines, and analyzes their core structural components and advantages.

Which Laser Generator Is Best for Welding?

This article mainly compares CO2 laser generators, fiber laser generators, and Nd: YAG laser generators to help users make scientific selections based on their welding needs.

Why Are Pulsed Lasers More Powerful?

This article mainly discusses the scientific principles, advantages, design considerations, application areas, and challenges of pulsed lasers and deeply explores their high peak power and versatility.

Gantry Fiber Laser Cutting Machine Vs Desktop Fiber Laser Cutting Machine: Comparative Analysis

This article compares and analyzes the structure, performance, and application scenarios of gantry and desktop fiber laser cutting machines to help companies choose the most suitable equipment.

Environmental Considerations and Regulations for Fiber Laser Cutting Processes

This article mainly discusses the environmental impact of fiber laser cutting process, relevant regulatory framework, mitigation strategies, environmental certification and industry cooperation to help enterprises achieve sustainable development and comply with environmental regulations.

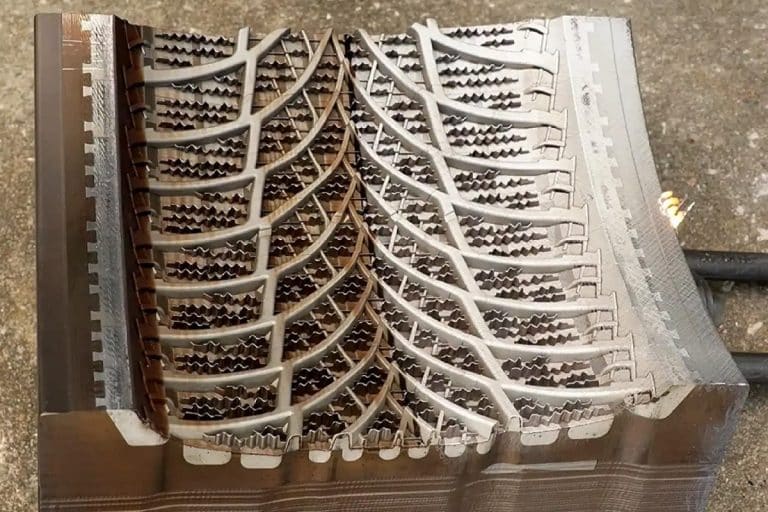

Common Defects in CO2 Laser Cutting and Their Mitigation Methods

This article mainly introduces the principles, common defects, and optimization measures of CO2 laser cutting to improve processing quality and stability.

Will Pulsed Laser Cleaning Damage the Substrate?

This article provides a comprehensive overview of how pulsed laser cleaning works, the mechanisms that may cause substrate damage, influencing factors, and effective strategies to ensure safe and efficient cleaning across various industries.

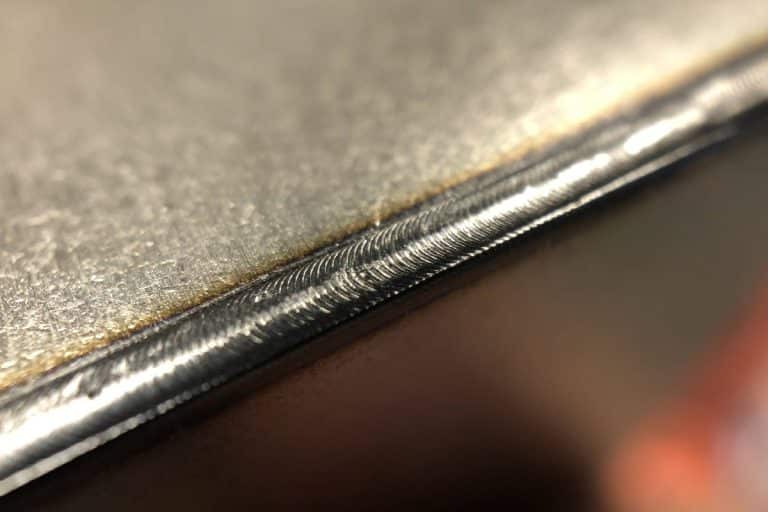

How Does Laser Welding Achieve Deep Melting of Materials?

This article mainly discusses how laser welding can achieve deep melting of materials, including its basic principles, key factors affecting penetration depth, the formation mechanism of deep penetration, and optimization control strategies to improve welding quality and production efficiency.

How to ensure consistent welding quality when using laser welding machines?

This article analyzes the key factors affecting the stability of laser welding quality and proposes practical control methods to help enterprises achieve consistent and reliable welding quality.

Optimize Laser Welding Process Parameters for Various Applications

This article examines laser welding parameters and their optimization across various industries, enabling manufacturers to enhance welding quality and production efficiency.

A Comprehensive Guide to Choosing the Right Laser Cutting Machine

This article provides a comprehensive analysis of how to select the most suitable fiber laser cutting machine based on materials, industry, and configuration to improve cutting efficiency, reduce costs, and enable intelligent production for manufacturing enterprises.

How Laser Cutting Improves Overall Efficiency and Productivity in Manufacturing Processes

This article will systematically analyze how laser cutting comprehensively improves the overall efficiency and productivity of manufacturing processes from multiple dimensions, including technology, processes, automation, and quality control.

What Are the Limitations of Laser Cleaning?

This article will systematically analyze the main limitations of laser cleaning from an engineering and application perspective, and provide mature and practical solutions to help manufacturing companies make informed decisions.

What to Consider Before Buying a Laser Cutting Machine

This guide explains how to choose the right laser cutting machine—comparing fiber and CO2 options, key buying factors, and tips for smarter investment.

What Training Is Required for the Safe Operation of a Laser Cleaning Machine?

This article delves into the safety operation training requirements for laser cleaning machines in industrial applications, covering laser safety, protective equipment, equipment maintenance, risk management, and compliance standards.

Optimize Laser Welding Parameters for Different Applications

This article focuses on optimizing laser welding parameters, covering key factors, practical influences, and strategies to improve welding processes across industries.

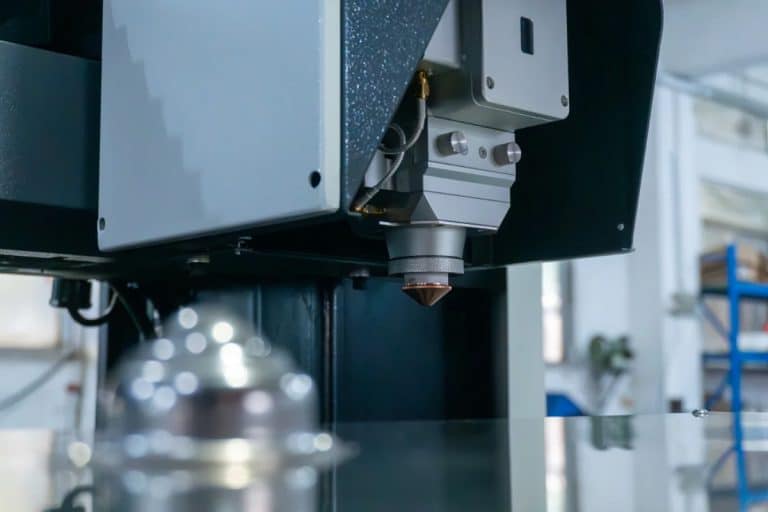

How Does the Focal Length of a Laser Cutting Machine Affect the Cutting Process?

This article primarily discusses the impact of a laser cutting machine’s focal length on cutting quality and efficiency. It analyzes the advantages and disadvantages of different focal lengths, as well as key selection criteria.

Does Laser Welding Require a Welding Mask?

This article mainly introduces the basic concepts of laser welding, potential safety risks, and how to choose and correctly use welding helmets to ensure safe operation.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.