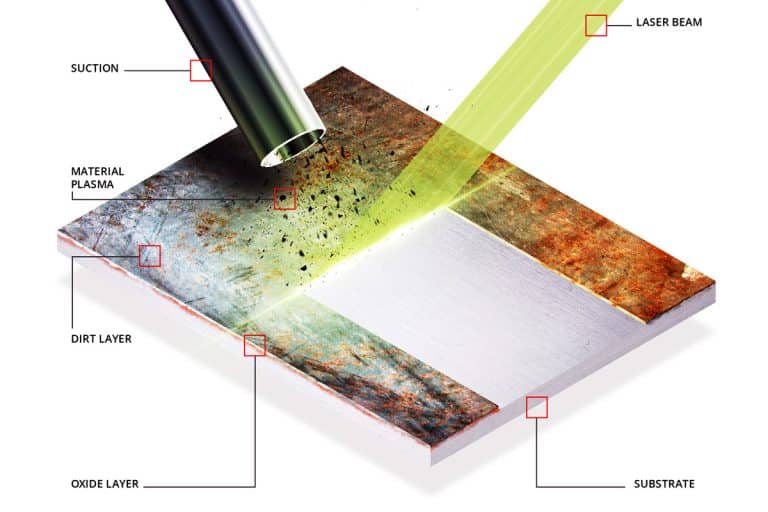

How Do Pulse Frequency and Repetition Rate Affect Laser Cleaning Efficiency?

This article will explore in depth the effects of pulse frequency and repetition rate on laser cleaning efficiency and provide optimization strategies for different applications.

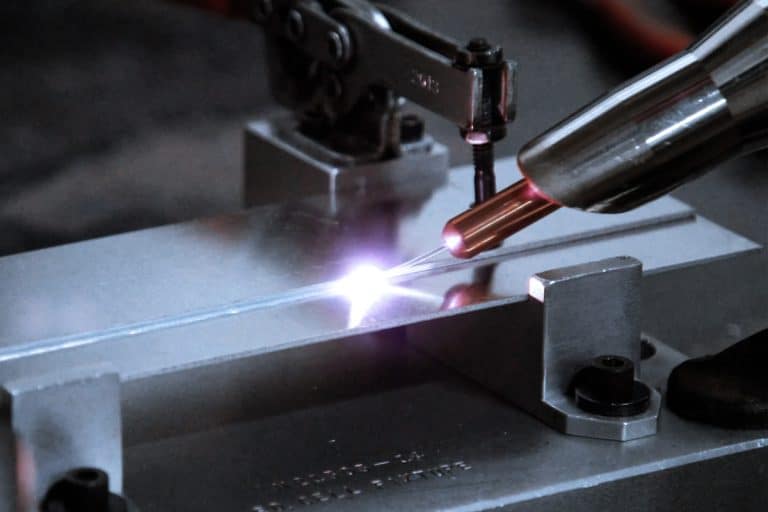

What Are the Challenges of Laser Welding Thin Materials?

This article will explore the challenges and response strategies of thin materials laser welding to help manufacturers master this technology and improve production efficiency and product quality.

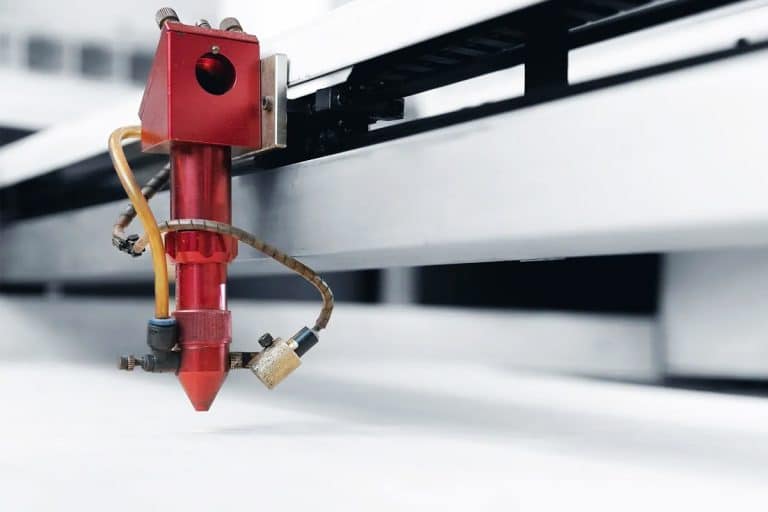

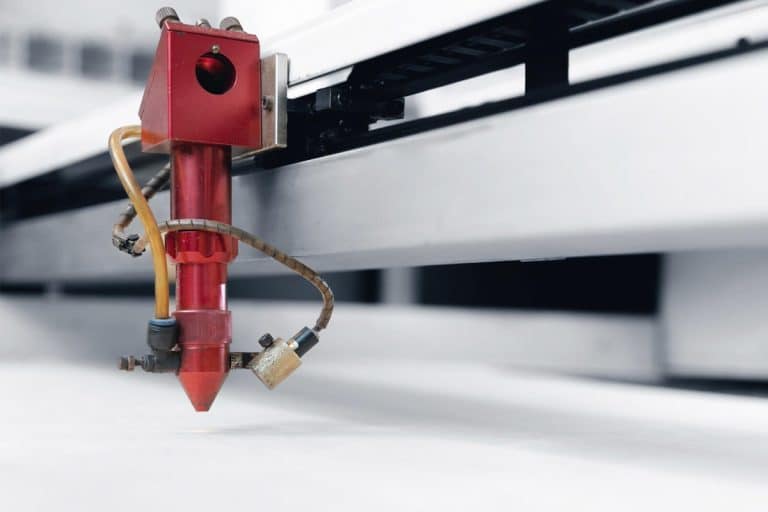

How to Achieve the Minimum Incision Width in CO2 Laser Cutting?

This article will analyze the key factors affecting the kerf width of CO2 laser cutting and provide optimization strategies to help manufacturers improve accuracy, and production efficiency, reduce material waste, and improve economic benefits.

The Influence of Autofocus on the Cutting Accuracy of Fiber Laser Cutting Machine

This article discusses the definition and types of autofocus technology and its impact on fiber laser cutting accuracy and analyzes the challenges and optimization solutions it faces to improve production efficiency and processing quality.

A Comprehensive Guide to Evaluating Surfaces After Laser Cleaning

This article will explore in depth the cleanliness assessment methods after laser cleaning to help companies ensure that the cleaning effect meets industry standards while optimizing production efficiency and costs.

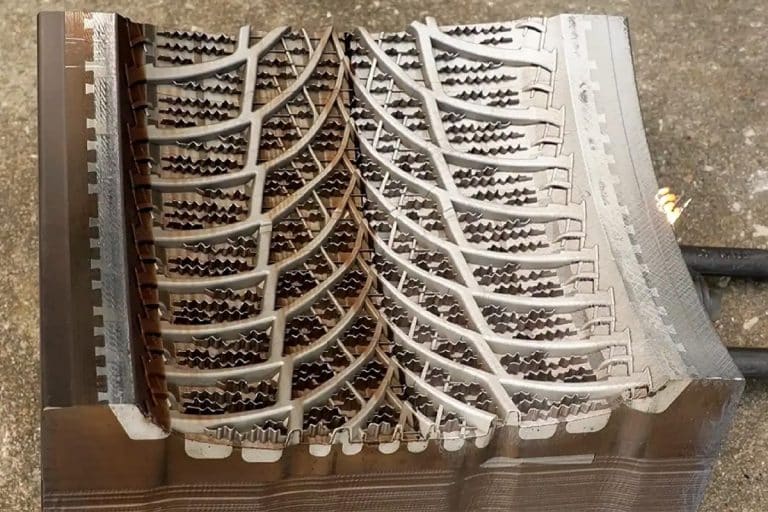

Laser Welding Joint Design

This paper mainly discusses the basic principles, influencing factors, and optimization strategies of laser welding joint design to improve welding quality, optimize production efficiency, and ensure the integrity and strength of the weld.

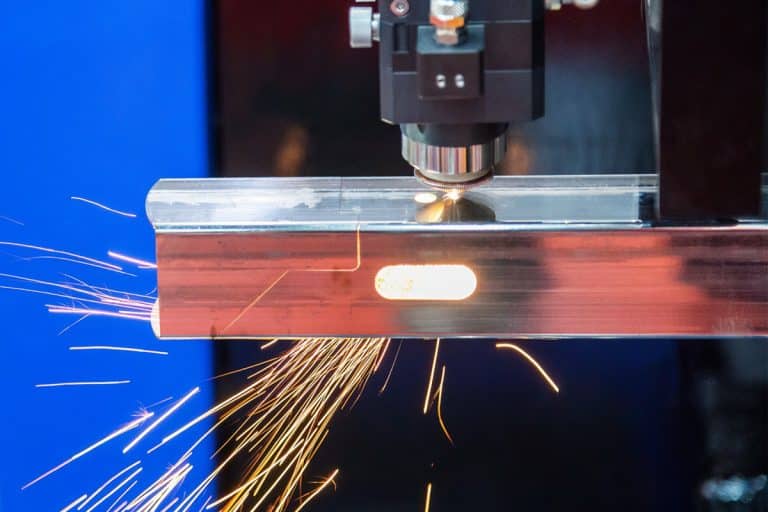

The Influence of Fiber Laser Beam Quality on Cutting Accuracy and Quality

The quality of fiber laser beam has an important influence on the accuracy, efficiency and surface quality of laser cutting. Optimizing the beam quality can significantly improve the cutting effect and production efficiency.

Understanding Operating Costs: Factors Affecting Fiber Laser Cutting Machine Costs

This article deeply analyzes the key factors that affect the operating costs of fiber laser cutting machines and provides optimization strategies to help companies reduce costs, and improve efficiency and market competitiveness.

How to Choose a Suitable CO2 Laser Cutting Machine?

This guide deeply analyzes the working principle of CO2 laser cutting machines, key factors for purchase, market brand comparison, and future technology trends, helping companies choose the most suitable laser cutting equipment to improve processing efficiency and competitiveness.

How Fast Is Laser Cleaning?

This article mainly discusses the principles of laser cleaning technology, factors affecting speed, and methods to improve cleaning efficiency, to help companies optimize laser cleaning processes and improve overall production efficiency.

How Does the Wavelength of the Laser Beam Affect the Welding Process?

This article mainly outlines the key effects of laser wavelength on welding performance, compares the wavelength characteristics of Nd: YAG, fiber, and CO2 laser generators, and proposes a selection strategy based on materials, processing, and costs.

What Materials Can Be Cleaned with Pulsed Laser Technology?

This article mainly systematically explains the working principle, applicable materials, advantages, and challenges of pulse laser cleaning technology, providing readers with a comprehensive technical overview.

The Difference Between Open-Loop Control System and Closed-Loop Control System of Fiber Laser Cutting Machine

This article mainly makes a comprehensive comparison between the open-loop control system and the closed-loop control system in the fiber laser cutting machine, and analyzes in detail the core differences between the two in terms of feedback mechanism, cutting accuracy, system cost, and application scenarios.

How Does the Beam Delivery System Affect the Efficiency of a Laser Welding Machine?

In modern manufacturing, the efficiency of a laser welding machine not only depends on the type of laser source and power, but also on the beam transmission system, which ensures accuracy, stability, and energy efficiency performance during welding.

How Does Beam Quality Affect the Performance of a Laser Welding Machine?

This article mainly introduces the impact of beam quality on laser welding performance, analyzes the key influencing factors, and proposes practical strategies to optimize beam quality to help improve welding effects and efficiency.

Capabilities and Limitations of Fiber Laser Cutting Machines for Complex Designs

This article systematically introduces the core components, main functions, industry applications in complex designs, and key factors affecting the precision of fiber laser cutting machines, and proposes optimization strategies to help achieve high-quality processing.

Applications of Pulsed Laser Cleaning

This article mainly introduces the principles, advantages and applications of pulsed laser cleaning in various industries.

Effect of focal length on laser welding results

This article mainly introduces the importance of focal length in laser welding and its influence on welding effect, and provides practical optimization suggestions.

Can a CO2 Laser Cutting Machine Perform Cutting and Engraving Tasks at the Same Time?

Can CO2 laser cutting machines achieve “multi-purpose use” of precise cutting and fine engraving? This article combines the principle with the functional characteristics of AccTek’s CO2 laser cutting machines to provide you with an in-depth analysis.

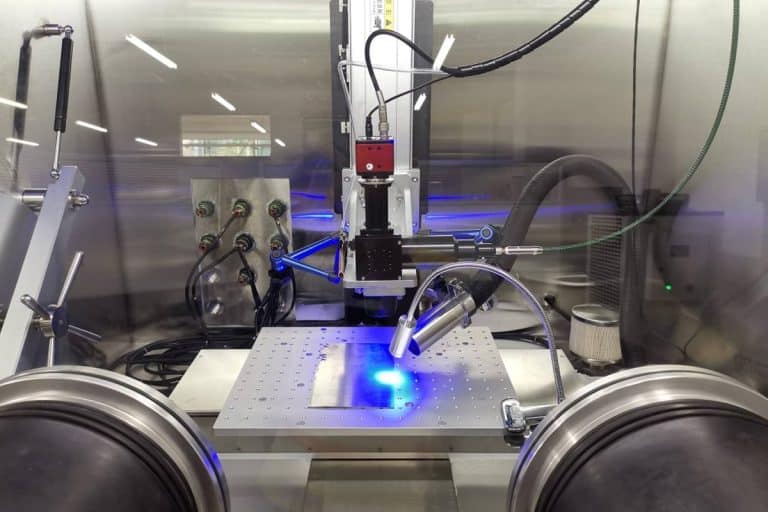

How to Set up a Pulse Laser Cleaning Machine?

This article mainly introduces the key points of the full process setting of the pulse laser cleaning machine from working condition evaluation, equipment selection, parameter setting to safety specifications and automation integration, aiming to provide users with a set of efficient, stable and sustainable laser surface treatment solutions.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.