How Can Laser Cleaning Help Reduce Waste and Improve Sustainability?

This article will take a deep look at how laser cleaning technology can reduce waste, protect resources, and promote new possibilities for sustainable development!

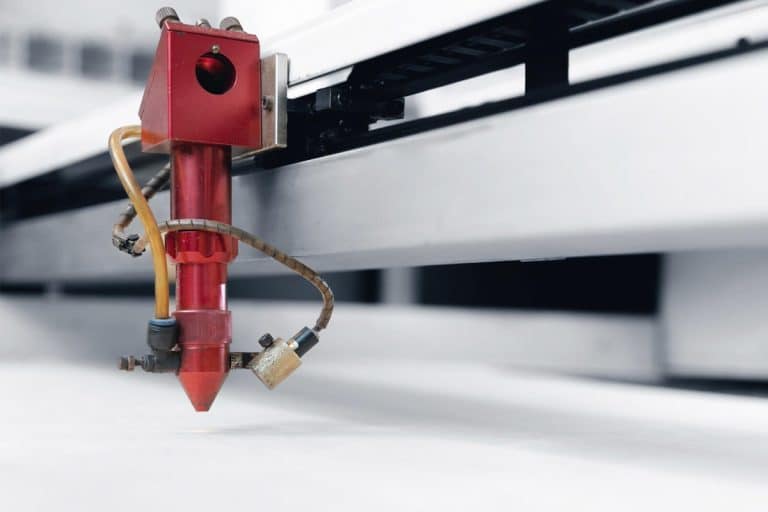

How CO2 Laser Cutting Minimizes Material Waste?

This article introduces how to minimize material waste in the CO2 laser-cutting process by precisely controlling laser-cutting parameters, optimizing material arrangement, and selecting appropriate equipment and materials.

Advantages of Automatic Nozzle Changer in Fiber Laser Cutting Machine

This article mainly introduces how the automatic nozzle changer of the fiber laser cutting machine can achieve fast and efficient replacement through program control, thereby improving the accuracy and intelligence level of the equipment.

How to Improve the Strength of Laser Welded Joints

This article mainly discusses the factors affecting the strength of laser welded joints, improvement techniques, the importance of post-weld treatment, and solutions to common challenges, providing comprehensive guidance for optimizing welding quality.

The Influence of Control System on Fiber Laser Cutting Machine

The control system of the fiber laser cutting machine plays a vital role in ensuring cutting accuracy, improving production efficiency and operating convenience, and is one of the indispensable core technologies in modern manufacturing.

Advantages and Limitations of Pulse Laser Cleaning Machines

This article mainly discusses the principles and advantages of pulsed laser cleaning technology, focusing on its high efficiency, non-contact, and environmentally friendly characteristics, and provides guidance for selecting laser cleaning solutions.

Understanding the Cooling System of Fiber Laser Cutting Machine

This article mainly introduces the functions, types, and maintenance points of the cooling system of the fiber laser cutting machine, highlighting its importance to equipment stability and cutting quality.

Laser Welding of Dissimilar Materials Guide

This article discusses the challenges, advantages, and key considerations of laser welding dissimilar materials, and provides technical guidance for achieving high-quality welds.

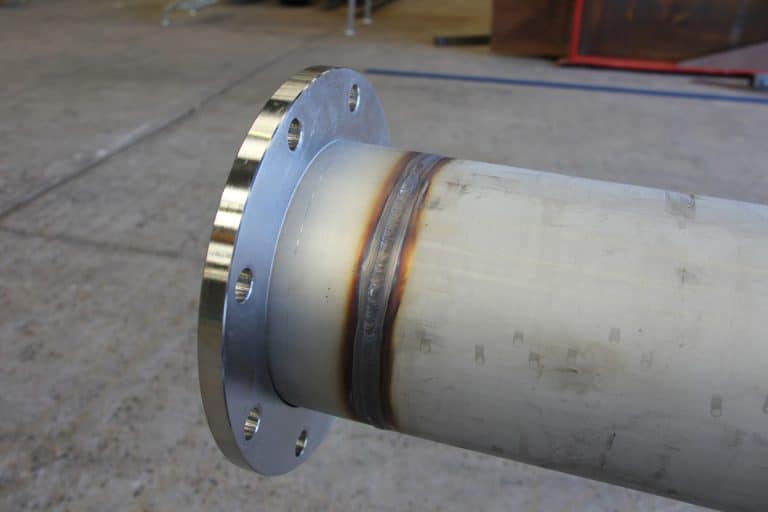

How Does Laser Welding Produce High-Quality Weld Seams?

This article primarily explores how laser welding can achieve high-quality weld joints through precise control of process parameters such as laser power, beam quality, and welding speed.

What Are the Advantages and Limitations of Laser Marking?

This article systematically analyzes the characteristics, advantages and disadvantages, and application scenarios of three marking technologies: fiber laser, CO2 laser, and UV laser, and provides some guidance for selecting a suitable laser marking system.

How Does Beam Quality Affect the Performance of a Laser Welding Machine?

This article mainly introduces the impact of beam quality on laser welding performance, analyzes the key influencing factors, and proposes practical strategies to optimize beam quality to help improve welding effects and efficiency.

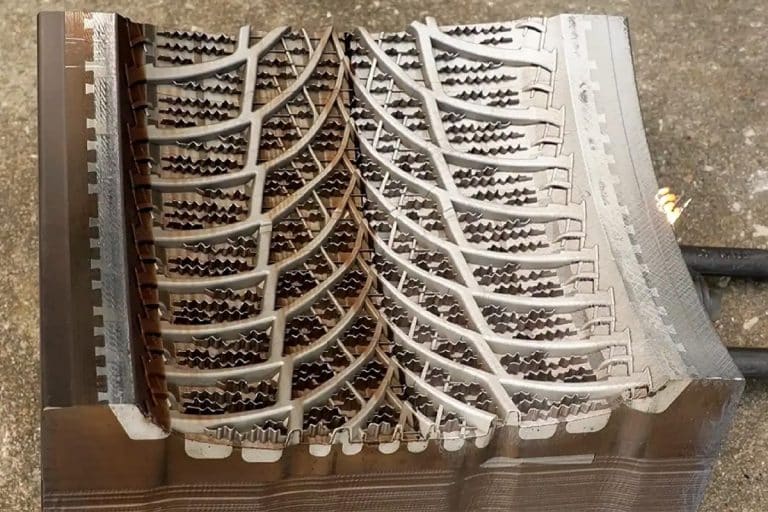

Capabilities and Limitations of Fiber Laser Cutting Machines for Complex Designs

This article systematically introduces the core components, main functions, industry applications in complex designs, and key factors affecting the precision of fiber laser cutting machines, and proposes optimization strategies to help achieve high-quality processing.

Applications of Pulsed Laser Cleaning

This article mainly introduces the principles, advantages and applications of pulsed laser cleaning in various industries.

Effect of focal length on laser welding results

This article mainly introduces the importance of focal length in laser welding and its influence on welding effect, and provides practical optimization suggestions.

Can a CO2 Laser Cutting Machine Perform Cutting and Engraving Tasks at the Same Time?

Can CO2 laser cutting machines achieve “multi-purpose use” of precise cutting and fine engraving? This article combines the principle with the functional characteristics of AccTek’s CO2 laser cutting machines to provide you with an in-depth analysis.

How to Set up a Pulse Laser Cleaning Machine?

This article mainly introduces the key points of the full process setting of the pulse laser cleaning machine from working condition evaluation, equipment selection, parameter setting to safety specifications and automation integration, aiming to provide users with a set of efficient, stable and sustainable laser surface treatment solutions.

Do Fiber Laser Generators Lose Power over Time?

This article focuses on the reasons why fiber laser generator power decreases over time and proposes effective strategies to mitigate power loss through high-quality equipment, regular maintenance, and an optimized environment.

What Environmental Considerations Should Be Taken When Using Laser Welding Machines?

This article discusses the environmental issues and corresponding measures to be taken when using laser welding machines.

How Does a CO2 Laser Cutting Machine Achieve High-Precision Cutting?

This article mainly introduces the principles and key technologies behind the high-precision cutting capabilities of CO2 laser cutting machines, and analyzes their core structural components and advantages.

Which Laser Generator Is Best for Welding?

This article mainly compares CO2 laser generators, fiber laser generators, and Nd: YAG laser generators to help users make scientific selections based on their welding needs.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.