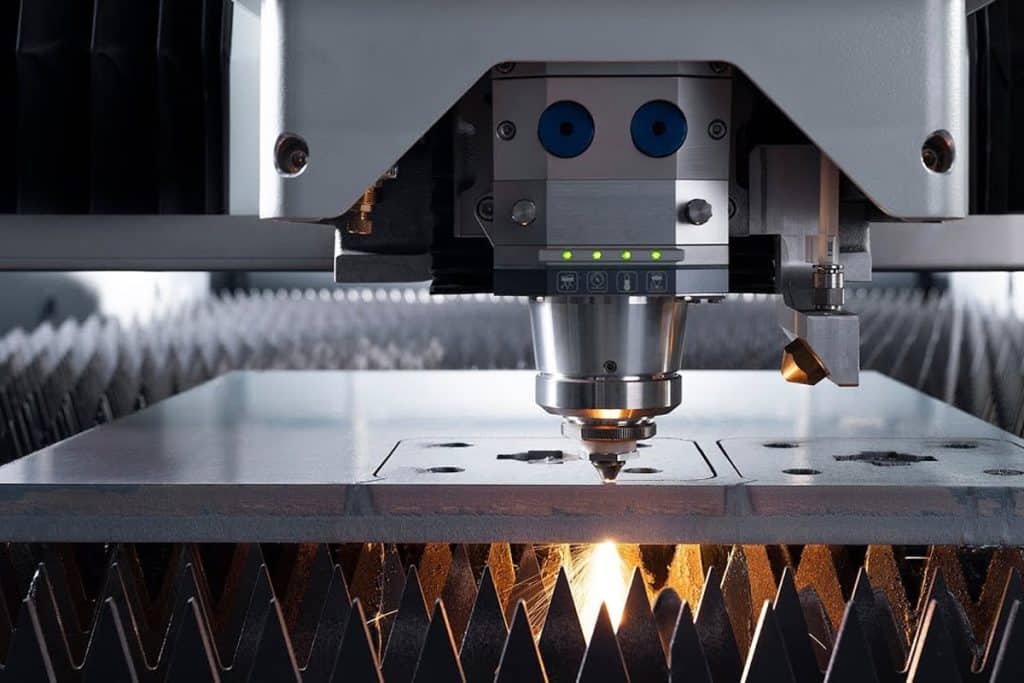

How Laser Cutting Improves Overall Efficiency and Productivity in Manufacturing Processes

This article will systematically analyze how laser cutting comprehensively improves the overall efficiency and productivity of manufacturing processes from multiple dimensions, including technology, processes, automation, and quality control.

What to Consider Before Buying a Laser Cutting Machine

This guide explains how to choose the right laser cutting machine—comparing fiber and CO2 options, key buying factors, and tips for smarter investment.

How Does the Focal Length of a Laser Cutting Machine Affect the Cutting Process?

This article primarily discusses the impact of a laser cutting machine’s focal length on cutting quality and efficiency. It analyzes the advantages and disadvantages of different focal lengths, as well as key selection criteria.

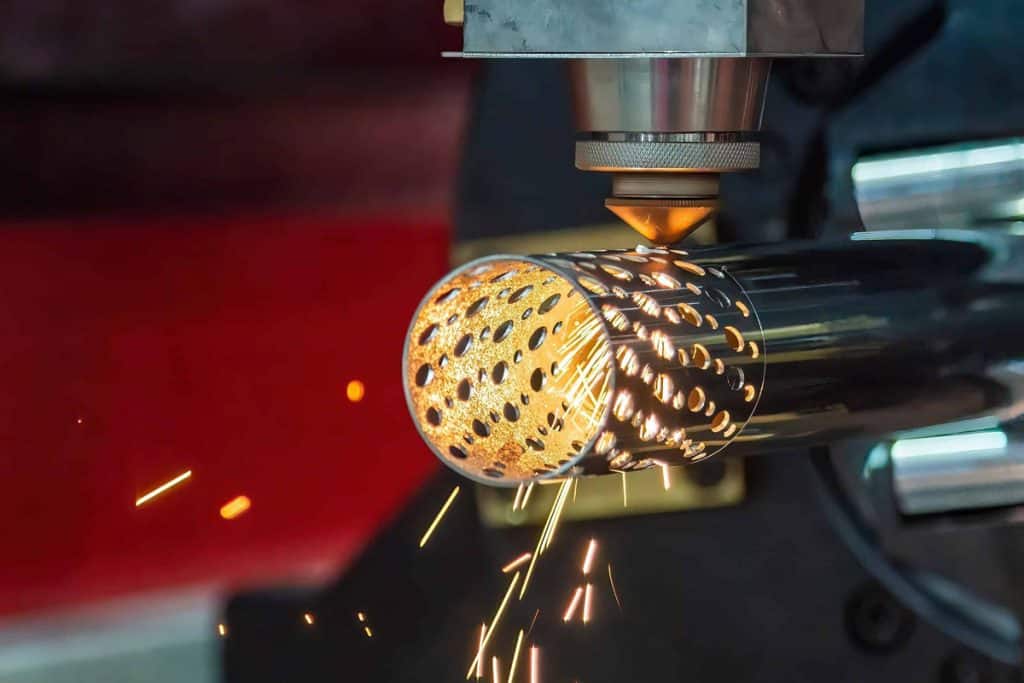

Motion System in Fiber Laser Cutting Machine

This article mainly introduces four common types of motors in the motion system of fiber laser cutting machines and analyzes their comprehensive impact on cutting accuracy, speed and equipment performance.

Understanding the Smells Associated with Laser Cutters

This article mainly discusses the causes, common types, and impacts of odors produced by laser cutting machines during processing, and proposes effective methods to reduce odors and improve the working environment.

A Comprehensive Guide to Determining Laser Power for Laser Cutting Machines

This article mainly introduces how to determine and optimize the laser power of the laser generator to improve the accuracy, efficiency, and stability of laser cutting and welding.

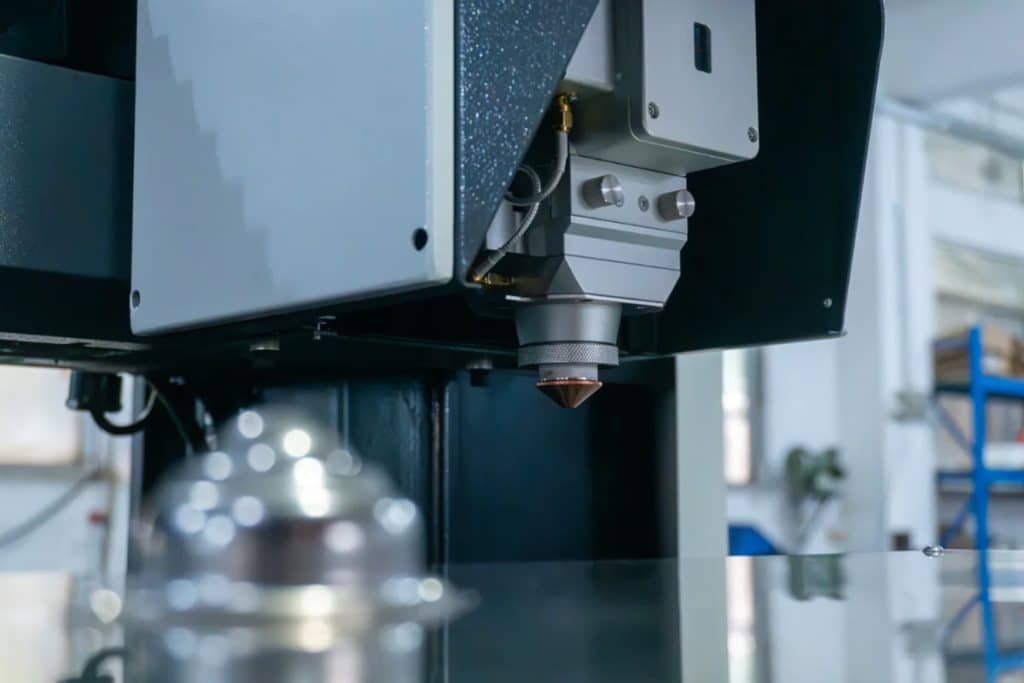

Laser Cutting Machine Nozzle Guide

This article mainly introduces nozzle types, sizes, materials, and factors affecting performance, helping you choose the right nozzle and improve cutting accuracy and efficiency.

The Influence of Auxiliary Gas Selection on Laser Cutting Process

This article mainly introduces the role and selection strategy of auxiliary gas in the laser cutting process, analyzes the impact of different gases on cutting quality, and proposes an optimization plan so that the laser cutting machine can achieve the best processing effect.

What Are the Factors That Affect the Cutting Quality and Precision of Fiber Laser Cutting?

This article mainly outlines fiber laser cutting solutions, covering equipment stability, process optimization, and support services to improve cutting quality and efficiency.

How Effective Is Laser Cutting?

This article mainly outlines the principles, key influencing factors, and application value of laser cutting technologies such as fiber laser cutting machines, CO2 laser cutting machines, and Nd: YAG laser cutting machines in high-precision automated manufacturing.