How to ensure consistent welding quality when using laser welding machines?

This article analyzes the key factors affecting the stability of laser welding quality and proposes practical control methods to help enterprises achieve consistent and reliable welding quality.

Optimize Laser Welding Process Parameters for Various Applications

This article examines laser welding parameters and their optimization across various industries, enabling manufacturers to enhance welding quality and production efficiency.

Optimize Laser Welding Parameters for Different Applications

This article focuses on optimizing laser welding parameters, covering key factors, practical influences, and strategies to improve welding processes across industries.

Does Laser Welding Require a Welding Mask?

This article mainly introduces the basic concepts of laser welding, potential safety risks, and how to choose and correctly use welding helmets to ensure safe operation.

How to Control the Quality of Laser Welding

This article systematically analyzes the main challenges of laser welding in terms of thermal management, material reflectivity, and process stability, and provides targeted process and equipment optimization solutions to ensure stable welding quality and improved efficiency.

How Does Laser Welding Affect the Heat-Affected Zone (HAZ)?

This article mainly introduces the basic knowledge, significant characteristics and mitigation strategies of the heat-affected zone (HAZ) in laser welding, providing a reference for improving the quality and reliability of welded joints.

What Are the Common Problems of Laser Welding Machines?

This article mainly analyzes the common technical problems and causes of laser welding machines in practical applications, and provides targeted solutions and preventive measures to help companies improve welding quality, stabilize equipment performance, and optimize production efficiency.

A Complete Guide to Safety Precautions for Laser Welding Machines

This article mainly introduces the application, potential safety risks, and protective measures of fiber laser welding machines, and looks forward to their development trends in intelligence and greenness.

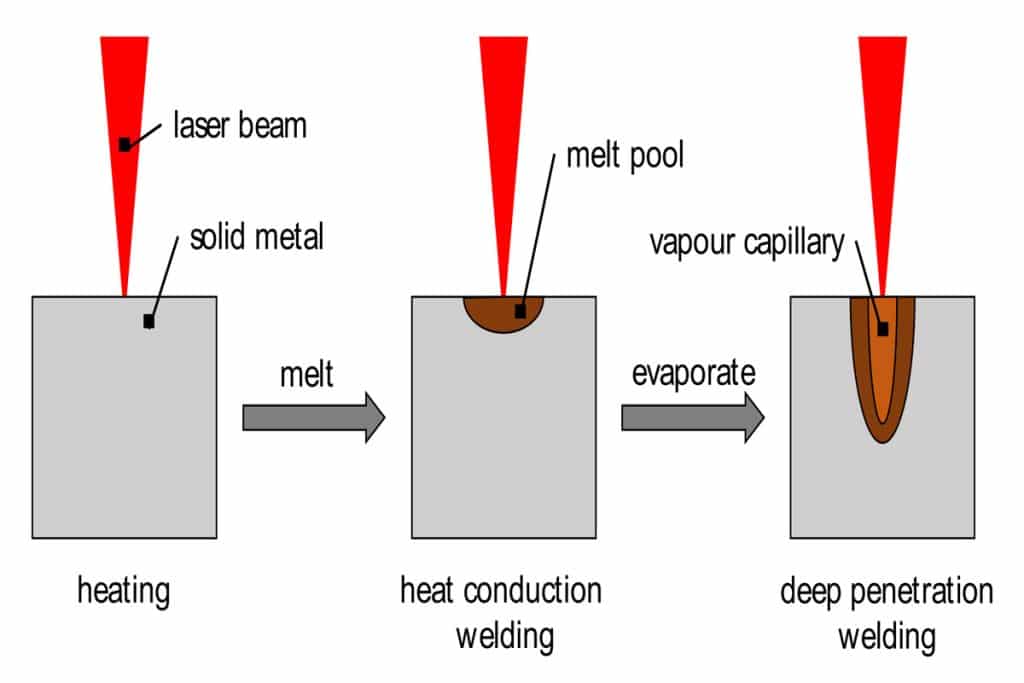

What Are the Considerations for Laser Welding in Terms of Weld Penetration and Depth-to-Width Ratio?

This article systematically analyzes the key influencing factors and optimization methods of laser welding machines in terms of weld penetration and depth-to-width ratio, helping manufacturing companies achieve welding quality that combines high strength, high precision, and aesthetics.

How Does the Focusing Optical System of a Laser Welding Machine Work?

This article analyzes the principles, structure, and optimization methods of fiber laser welding optics and explores their key role in improving welding quality, efficiency, and reliability.