Ein umfassender Leitfaden zur Bestimmung der Laserleistung für Laserschneidmaschinen

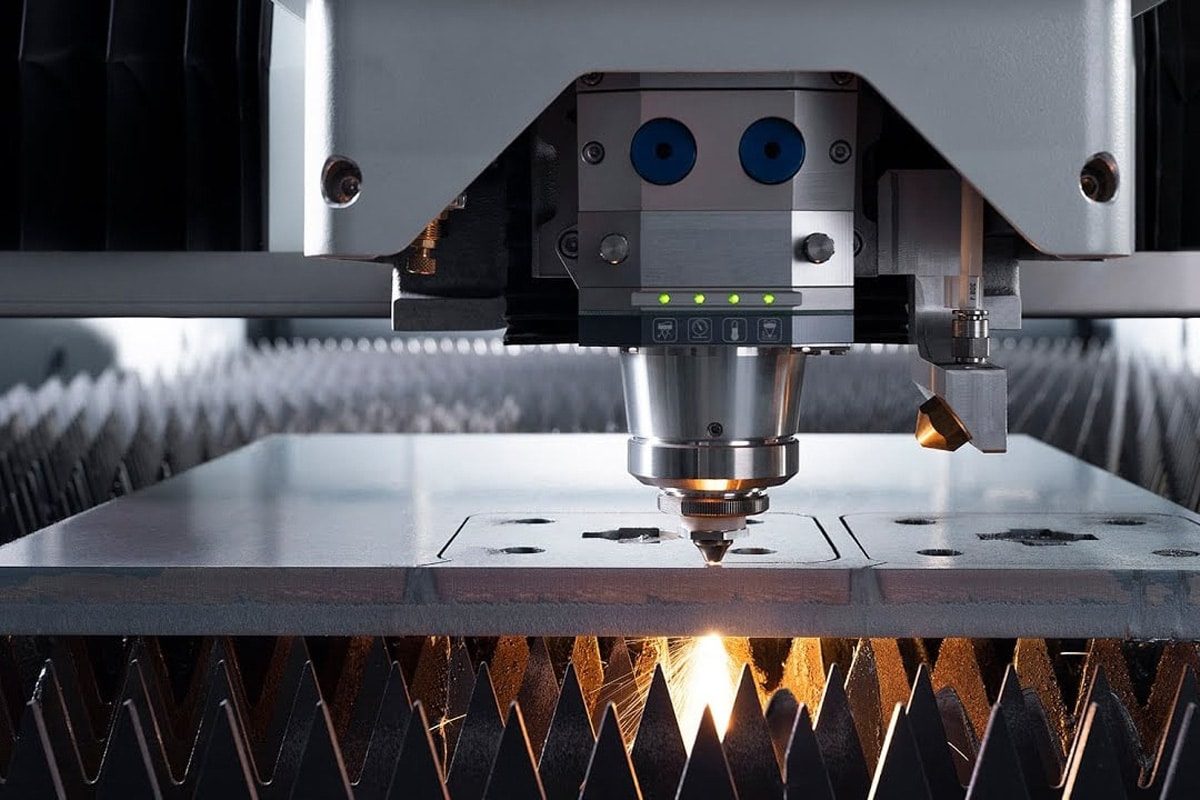

In der modernen Fertigung Laserschneidmaschinen have become a core piece of equipment for metal processing and industrial production. Compared to traditional mechanical cutting methods, laser cutting, with its high precision, high efficiency, and flexibility, has rapidly become the preferred solution for sheet metal processing, automotive manufacturing, aerospace, and precision electronics. Whether cutting thin sheet metal or fabricating thick plate structures, proper laser power settings directly impact cutting efficiency, cut surface finish, and overall production costs.

For an advanced Faserlaser-Schneidemaschine, one of its core components is the laser generator. It is the “energy heart” of the entire system, determining the power output and stability of the beam. Insufficient power may prevent complete penetration of the material, while excessive power can result in excessive melting or rough cutting edges. Therefore, correctly understanding laser power and finding the optimal parameter balance for different application scenarios is a key skill that every manufacturer and equipment user must master.

Furthermore, laser power is not only related to the equipment itself but also closely linked to the material type and thickness. For example, the optimal power for cutting carbon steel and stainless steel differs significantly, while highly reflective materials such as aluminum alloy and copper require higher power and more stable laser generators. At the same time, a growing number of customers are seeking high-power laser cutting solutions to meet the needs of industrial automation, CNC intelligent machining, and mass production. Against this backdrop, mastering laser power adjustment and optimization has become crucial for companies to enhance their competitiveness, reduce operating costs, and improve customer satisfaction.

Inhaltsverzeichnis

Laserleistung verstehen

Was ist Laserleistung?

In laser cutting machines, laser power refers to the energy output by the laser generator. Simply put, it determines how much energy the laser beam can deliver to the material surface per unit time. Power, typically measured in watts (W) or kilowatts (kW), is a key parameter for measuring laser cutting performance.

In industrial applications, machines with different power ranges, from 1000W fiber laser cutting machines to 20,000W ultra-high-power laser cutting machines (20kW high-power laser cutting machines), vary significantly in their processing range and cutting capabilities. For example, low- and medium-power laser cutting machines are well-suited for thin sheet metal processing, while high-power laser cutting machines can easily cut steel plates over 40mm thick.

Unlike other processing methods, laser cutting relies on the high energy density of the beam, enabling even complex precision laser cutting and micromachining operations to maintain extremely high accuracy and smooth finishes. Therefore, understanding the concept of laser power is not only fundamental for operators but also a crucial factor in companies’ decision-making when selecting and applying equipment.

Wie sich die Laserleistung auf den Schneidprozess auswirkt

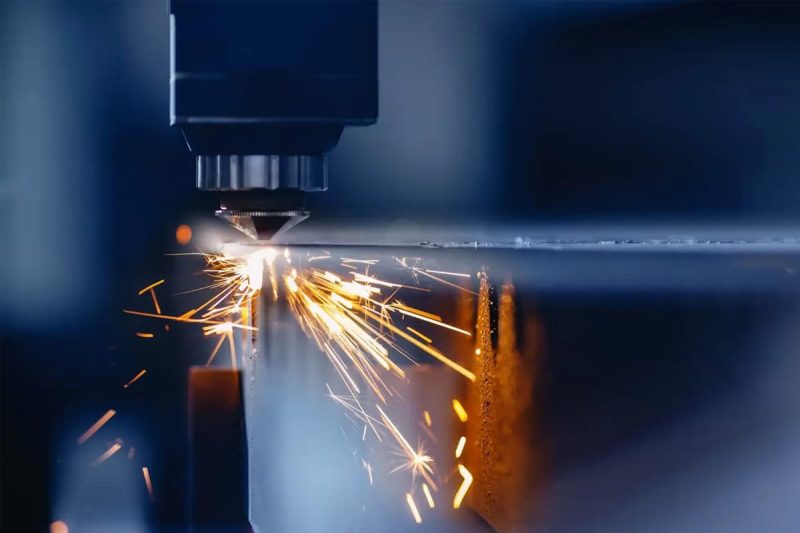

Laser power has a direct and significant impact on cutting performance. When the power is too low, the beam lacks energy and cannot penetrate the workpiece. Common problems include incomplete cutting, burrs on edges, and slow cutting speeds. When power is too high, excessive heat input can lead to excessive kerf width, melted edges, or surface burning.

For example, in Edelstahl laser cutting, insufficient power can result in wire drawing or drossing along the cut edges. In Aluminium laser cutting, excessive power can easily cause uneven edge melting, even impacting subsequent welding processes. For companies, finding the right laser power setting not only ensures cutting quality but also significantly reduces material waste and equipment energy consumption.

Laser power also affects cutting speed. Generally speaking, under the same material and thickness conditions, increasing power appropriately can increase cutting speed and thus productivity. However, it’s important to note that increasing power must be coordinated with factors such as the cutting gas, focal position, and beam quality; otherwise, it can be counterproductive.

Relationship between Laser Power, Material Type, and Thickness

In practical applications, laser power is closely related to the type and thickness of the material.

- Thin Sheet Cutting: For stainless steel or Kohlenstoffstahl plates 1-3mm thick, a 1000W-2000W fiber laser cutting machine is sufficient for high-quality cutting.

- Medium-Thick Plate Cutting: When the thickness increases to 8-20mm, a high-power laser generator of 4000W-6000W is required to ensure cutting efficiency and a smooth cut.

- Ultra-thick plate cutting: In shipbuilding, bridge construction, and heavy machinery manufacturing, cutting steel plates thicker than 30mm is often necessary. This requires laser power exceeding 10kW, and even a 20kW fiber laser cutting system is required to ensure fast and stable cutting.

Different materials have varying laser power requirements. For example:

- Carbon steel is sensitive to oxygen and can be cut quickly at appropriate power levels.

- Stainless steel requires a non-oxidizing edge, so higher power levels with nitrogen assist are often required.

- Aluminum alloy and Kupfer are highly reflective materials, requiring higher laser power and stable beam quality to avoid damage from reflected light.

In summary, laser power is not a fixed parameter but a critical variable that must be flexibly adjusted based on material properties, plate thickness, and processing requirements. Only by fully understanding the relationship between power and materials can the maximum value of laser cutting machines be realized in different industrial applications.

Faktoren, die die Laserleistung beeinflussen

In actual industrial applications, laser power doesn’t act in isolation; it’s affected by a variety of factors. When setting laser cutting machine parameters, operators must comprehensively consider these factors to achieve efficient, stable, and high-quality cutting results. The following key factors directly impact laser power settings.

Materialtyp

Different materials have vastly different laser absorption rates, which directly determine the required laser power.

- Carbon steel cutting: Due to its high laser absorption rate, carbon steel requires relatively low laser power. Oxygen is often used as an assist gas for rapid cutting.

- Stainless steel cutting: Stainless steel requires higher laser power, often combined with nitrogen to prevent oxidation and ensure smooth cut edges.

- Aluminum and copper cutting: These materials are highly reflective, requiring higher laser generator stability and output power. Otherwise, reflected light can easily damage the lens.

Materialstärke

Thickness is one of the most intuitive factors affecting laser power.

- Thin sheet metal cutting: For sheet metal 1–3 mm thick, a 1000W–2000W fiber laser cutting machine is generally sufficient.

- Medium-thick plate fabrication: For steel sheets 8–20 mm thick, a high-power laser generator of 4000W–6000W is required.

- Ultra-thick plate cutting: For materials over 30 mm thick, a power of 10kW or even 20kW is generally required.

Too low a power may result in an incomplete cut, while too high a power may cause excessive melting. Therefore, selecting the appropriate power range is crucial.

Schneidgeschwindigkeit

Cutting speed is closely related to laser power.

- Excessive speed: Even with sufficient power, incomplete cuts may occur.

- Too slow a speed can easily lead to heat accumulation, causing the cut to be too wide or the edges to melt.

Therefore, in CNC laser cutting technology, power and speed must be optimized in a coordinated manner, and the optimal match is usually determined through testing.

Lens Focal Length

The choice of focal length directly determines the energy density of the laser beam at the material surface.

- Short focal length: Suitable for thin plates and high-precision cutting, it concentrates the energy but has limited penetration.

- Long focal length: Suitable for thick plate cutting. Although the energy density is slightly lower, the depth of focus is greater, making it beneficial for processing thick materials.

If the focal length is set incorrectly, even with sufficient power, poor cutting may occur. Therefore, in industrial production, focal length and laser power often need to be adjusted together.

Laserstrahlqualität

Beam quality (M2 value) determines whether the laser can be sufficiently focused into a small spot. A high-quality beam can achieve cutting at relatively low power, while a laser generator with poor beam quality requires higher power to achieve the same effect.

Therefore, businesses must select a high-performance fiber laser generator, which can significantly improve cutting accuracy and production efficiency.

Erforderliche Schnittqualität

Not all machining tasks require the highest possible cut quality.

In some rough machining applications (such as cutting steel structures for construction), moderately reducing quality requirements can reduce power consumption and increase cutting speed.

In contrast, high-end manufacturing (such as aerospace parts and stainless steel kitchenware production) requires burr-free and oxidation-free cut edges, necessitating more precise power regulation.

Maschinenspezifikationen

Laser cutting machines vary in power range between models and brands. Some entry-level machines may only support 1–3 kW of laser power, while high-end industrial models can be equipped with 20 kW laser generators, meeting the needs of heavy industrial processing. Furthermore, the cooling system, control system, and cutting head design can indirectly affect power efficiency.

Methoden zur Bestimmung der Laserleistung

When using a laser cutting machine for production, determining the appropriate laser power is crucial for ensuring cutting quality and efficiency. Power requirements vary significantly depending on the material, thickness, and cutting requirements. Without a scientific method to guide this, problems such as incomplete cutting, excessive melting, and low cutting efficiency can occur. The following methods are commonly used in industrial production to help users determine the most appropriate laser generator power setting.

Materialverträglichkeitstabellen

Many laser equipment manufacturers and industry associations provide laser cutting power charts that list recommended laser power ranges for different material types and thicknesses.

- For example, a 1500W–2000W fiber laser generator is generally recommended for 2mm stainless steel;

- A 10mm carbon steel plate may require a 4000W–6000W laser power;

- For plate thicknesses greater than 20mm, a high-power laser cutting machine with a power of 10kW or higher is required.

These charts not only help new users quickly find reference values but also serve as a foundation for manufacturers to build a CNC laser cutting process database.

Materialprüfung

While parameter tables provide a guide, in actual production, different batches of material may vary in chemical composition, surface coatings, or oxide layers, all of which can affect the optimal laser power setting. Therefore, before mass production begins, companies often conduct sample testing to determine the optimal parameters. This testing process typically includes:

- Step-by-step laser power adjustment;

- Observing the smoothness of the cut edge and the presence of dross;

- Checking whether the cutting speed meets production efficiency requirements.

This approach allows you to achieve the closest-to-ideal cutting results on the actual workpiece, avoiding material waste or production downtime caused by improper power settings.

Empfehlungen des Herstellers

Reputable fiber laser cutting machine manufacturers typically provide detailed power recommendation manuals based on their equipment configuration and market experience. These recommendations often incorporate:

- Fiber laser generator model;

- Cutting head configuration;

- Assist gas type (oxygen, nitrogen, compressed air);

- Optimal power ranges for different material thicknesses.

Following the manufacturer’s recommendations can effectively shorten commissioning time and help new users quickly transition to production. Manufacturer parameter guidance is particularly important when cutting highly reflective materials (such as aluminum and copper), as these materials are highly sensitive to laser power fluctuations.

Online Resources and Databases

With the advancement of industrial digitalization, an increasing number of online platforms and software databases are providing functions for querying and managing laser cutting parameters. For example:

- Some industrial forums share tips on power settings for different materials.

- Some CNC management software (CNC laser cutting software) can create cloud-based databases, helping companies quickly access historically optimized parameters between orders.

- Online cutting parameter recommendation tools within the industry can automatically generate recommended power ranges based on user input of material type, thickness, and cutting speed requirements.

By combining online resources with a company’s own test data, companies can gradually build a unique laser cutting knowledge base, which is crucial for improving long-term production efficiency and reducing operating costs.

Practical Tips for Setting Laser Power

Start with the Manufacturer's Recommendations

When performing laser welding or laser cutting, laser power is the most critical parameter that directly impacts weld quality and cut edge precision. Different fiber laser or CO2 laser generators have specific power adjustment ranges and recommended settings, so following the manufacturer’s instructions is the safest and most scientific starting point. Manufacturers typically specify optimal power parameters for different materials (such as stainless steel, aluminum alloy, and copper) based on the laser generator’s laser beam quality, cooling system, and focusing lens diameter. This not only helps operators avoid excessive heat input and an excessively wide heat-affected zone (HAZ) caused by excessive power, but also ensures equipment stability and longevity. In particular, in the automotive, aviation component, and precision electronics welding industries, strictly adhering to the recommended power range can significantly reduce rework and improve overall production efficiency.

Keep Detailed Records

In actual production, even if the manufacturer’s recommended parameters are followed, varying workpiece thickness, welding speed, and cutting speed can result in significant variations. Therefore, establishing a factory-specific laser power parameter database is crucial. For each experiment, test, or large-scale production run, record the power, pulse duration, focal position, and auxiliary gas (such as nitrogen, oxygen, or compressed air) used for quick recall and reuse. This process not only helps manufacturers improve process consistency but also reduces commissioning time. This is especially true for large-scale stainless steel laser cutting or aluminum laser welding projects. Having a digital parameter database is like a “safeguard” for stable production. Furthermore, by retaining this data, companies can more intuitively compare weld penetration depth and cut edge smoothness at different power levels during ongoing optimization, providing a basis for subsequent quality improvements.

Experimentation and Optimization

While manufacturer recommendations and documented databases provide valuable references, each factory’s production environment, equipment conditions, and customer needs may vary. Therefore, experimentation and optimization are essential. Through systematic parameter testing, changes in weld formation, molten pool stability, and cutting surface roughness can be observed at varying power levels. For example, in automotive body welding, too low power can result in a lack of penetration, while too high power can cause spatter and cracking. In thick plate fiber laser cutting, optimal power matching combined with assist gas flow rates is crucial for achieving high-efficiency, high-quality cutting results. Through continuous experimentation, manufacturers can identify the optimal power-speed matching curve, further enhance heat input control, minimize the heat-affected zone, and ultimately improve both quality and efficiency.

Fehlerbehebung bei Problemen mit der Laserleistung

Laser Cutting Not Deep Enough

When the laser cutting depth is insufficient, it’s often due to insufficient laser generator output power or suboptimal laser beam quality. Low laser power can result in poor cuts or noticeable dross at the edges, especially when cutting thick materials (such as carbon steel, stainless steel, and thick aluminum alloy plates).

Common causes include:

- Aging or decreased laser generator output power;

- Contamination of the focusing lens and reduced transmittance, resulting in poor beam focus;

- Excessive cutting speed, resulting in insufficient energy density;

- Insufficient assist gas flow, preventing effective melt removal.

Optimization can be achieved by increasing laser power, reducing cutting speed, adjusting the focus position, and checking the cleanliness of the optical lens. It’s also crucial to ensure the appropriate assist gas is used. For example, when cutting thick plates, high-purity oxygen can improve penetration, while nitrogen is more suitable for high-quality stainless steel cutting.

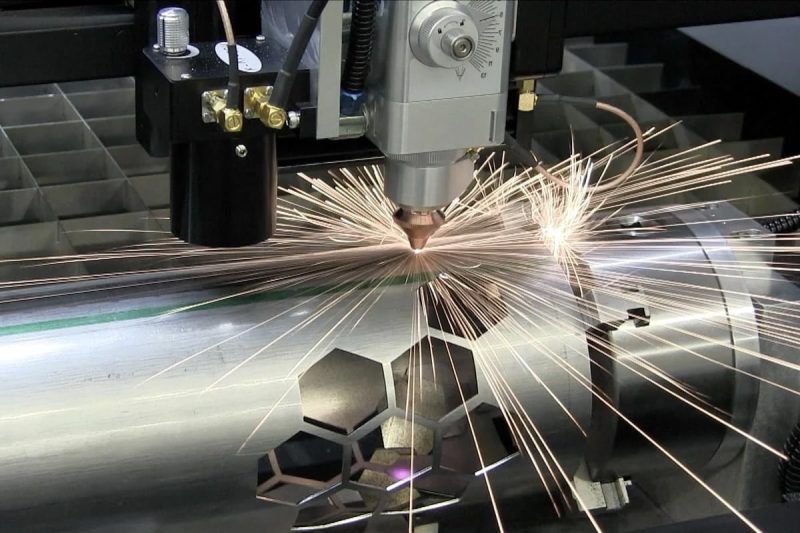

Excessive Burning or Melting in Laser Cutting

During the laser cutting process, if excessive melting, burn marks, or noticeable burrs occur on the edge, it indicates excessive laser power or improper heat input control. Especially when cutting thin materials (such as stainless steel sheets, aluminum plates, and copper), excessive laser power often causes overheating of the material surface, resulting in edge discoloration and excessive melt diffusion.

Common causes include:

- The laser power setting is too high, resulting in an energy density exceeding the material’s tolerance.

- The cutting speed is too slow, resulting in the molten pool heating for too long.

- Insufficient assist gas pressure, resulting in slag residue in the cut kerf;

- The spot diameter is too small, resulting in excessive energy concentration.

Solutions include:

- Appropriately reducing the laser power and adjusting to a more optimal power-speed match;

- Increasing the cutting speed reduces heat accumulation at a single point.

- Using appropriate nitrogen or compressed air to achieve a clean cut edge;

- If necessary, replace or recalibrate the optical lens to improve laser beam focus.

Avoiding excessive melting is particularly important in fields such as precision parts machining, electronic enclosure manufacturing, and automotive interior cutting, as it directly impacts part assembly accuracy and surface aesthetics.

Inconsistent Laser Cutting Results

If inconsistent laser cutting results occur during mass production, such as smooth edges on some workpieces and burrs or incomplete cuts on others, this often indicates fluctuations in equipment status or parameter settings.

Possible causes include:

- Instability in laser generator output power;

- Improper matching of cutting speed and power;

- Lens contamination or optical path deviation, resulting in degraded laser spot quality;

- Fluctuations in assist gas pressure, resulting in uneven slag removal;

- Variations in material composition or thickness between batches.

Solutions include:

- Check the laser generator’s stability to ensure it can continuously output the set power.

- Perform regular maintenance of the optical system, including cleaning and replacing the focusing lens and reflector;

- Optimize process parameters to ensure the optimal balance between cutting speed and laser power.

- Control the gas system to ensure stable gas pressure and flow.

- Inspect raw materials to avoid quality fluctuations due to batch differences.

Through rigorous parameter monitoring and preventive maintenance, companies can not only reduce inconsistencies but also significantly improve production yield and machine uptime, which are particularly critical in the metal fabrication and precision manufacturing industries.

Zusammenfassung

In summary, proper laser power setting is a key factor in determining laser cutting and welding quality. Whether cutting stainless steel, aluminum alloy, or copper, or welding automotive parts, electronic components, or precision machinery, laser power is closely linked to material type, thickness, cutting speed, optical system, and assist gas. By thoroughly understanding the factors influencing power, adhering to manufacturer recommendations, establishing a database of process parameter records, and combining experimental optimization, companies can effectively reduce the heat-affected zone (HAZ), minimize rework and waste, and achieve a balance between high efficiency and high precision.

In actual production, if problems such as insufficient cutting depth, excessive burning or melting, or inconsistent cutting results are encountered, proper troubleshooting and parameter adjustment can often quickly restore ideal cutting quality. This not only ensures the appearance and precision of the final product but also significantly improves the stability and competitiveness of the production line.

As a professional laser cutting equipment manufacturer, AccTek-Laser is committed to providing high-performance laser generator solutions and customized services to customers worldwide. Our equipment excels in power stability, beam quality, and cutting efficiency, making it suitable for processing needs across multiple industries and materials. If you are looking for a reliable partner, please kontaktiere uns to get the laser cutting and welding solutions that best suit your production needs.

Different materials have varying laser power requirements. For example:

Kontaktinformationen

- [email protected]

- [email protected]

- +86-19963414011

- Nr. 3 Zone A, Industriegebiet Lunzhen, Stadt Yucheng, Provinz Shandong.

Holen Sie sich Laserlösungen