Which Laser Generator Is Best for Welding?

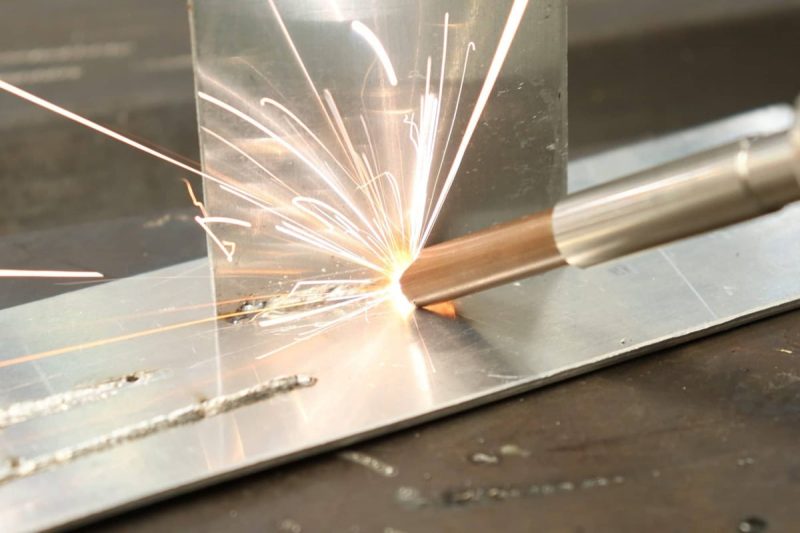

As the manufacturing industry continues to pursue higher product quality and production efficiency, laser welding technology is gradually replacing traditional welding methods due to its advantages of non-contact processing, high precision, low heat-affected zones, and a high degree of automation. It has become a core welding solution in various industries such as aerospace, automotive manufacturing, electronic communications, and medical equipment. Laser welding not only significantly improves joint quality and structural strength, but also reduces material deformation and post-processing costs while maintaining welding efficiency. It is one of the key technologies enabling intelligent manufacturing and precision processing.

In a complete laser welding system, the laser generator, as the source of energy, plays a crucial role in determining heat input control, beam stability, penetration depth, and the final welding quality. Therefore, selecting the right type of laser generator is essential for ensuring welding quality, improving production efficiency, and managing operating costs. This article provides a systematic comparison of the three most commonly used laser generators in current applications: CO2 laser generators, fiber laser generators, and Nd:YAG laser generators, helping you scientifically choose the most suitable solution based on different welding processes and material requirements.

Inhaltsverzeichnis

Type of Laser Generator

In a laser welding system, the laser generator determines the form of energy output, wavelength, beam quality, and material compatibility. Different types of laser generators offer distinct advantages when it comes to welding metals or non-metals, precision control, and energy efficiency. The following is a detailed comparison of the three most commonly used types of laser generators in the industrial sector today:

Faserlaser-Generator

Key Features:

Fiber laser generators belong to the category of solid-state lasers and use ytterbium-doped fiber as the laser gain medium. The laser energy is transmitted and output through the optical fiber, with a wavelength of approximately 1.06 microns. This wavelength is highly absorbable by metals, making fiber lasers exceptionally effective for welding Edelstahl, Kohlenstoffstahl, Aluminium, Kupfer, and other metallic materials.

Scope of application:

It is suitable for efficient welding of most metal materials and is widely used in metal manufacturing, the automotive industry, battery production, aerospace, rail transit, 3C electronics, and medical devices, especially in applications that require high-strength joints and high-precision processes.

Vorteil:

- High beam quality enables an extremely small spot size, resulting in finer weld seams and a smaller heat-affected zone.

- High efficiency, with an electro-optical conversion rate significantly higher than that ofCO2 and Nd:YAG laser generators, making it energy-saving and environmentally friendly.

- Compact design with a small footprint and flexible installation.

- High reliability and stability with minimal maintenance requirements.

- Easily integrable into automated production lines, making it ideal for mass production and continuous processing.

Einschränkung:

- The initial equipment investment is relatively high; (now that the technology is mature, the price is not a big problem)

- The welding effect on transparent materials (such as glass) or most non-metallic materials is poor;

- A professional cooling system is required.

CO2-Lasergenerator

Key Features:

The CO2 laser generator is a type of gas laser, in which laser energy is produced by ionizing a gas mixture—typically composed of carbon dioxide, nitrogen, and helium. It emits a laser beam with a wavelength of 10.6 micrometers, which is strongly absorbed by most non-metallic materials. This makes it particularly effective for welding, cutting, and engraving non-metallic materials.

Scope of application:

It is primarily used for welding and processing non-metallic materials such as plastic, acrylic, wood, paper, leather, fabric, and ceramics. It is widely applied in industries such as packaging, textiles, architectural decoration, advertising displays, and automotive interiors.

Vorteil:

- The laser system is relatively mature, and the equipment cost is low;

- It has an excellent processing effect on non-metallic materials and smooth edges;

- It has good performance in large-format cutting and engraving.

Einschränkung:

- The absorption rate of metal materials is low, especially for highly reflective metals such as aluminum and copper, and the welding efficiency and stability are poor;

- The equipment is large and requires a lot of space for use;

- The beam quality is average and is not suitable for high-precision metal welding;

- The maintenance cost is high during operation, and gas replacement is frequent.

Nd:YAG Laser Generator

Key Features:

The Nd:YAG laser generator is a type of solid-state laser that uses a Neodymium-doped Yttrium Aluminum Garnet crystal as the gain medium. This type of laser can operate in both continuous wave and pulsed modes, making it well-suited for small-scale welding tasks where precise thermal control is required.

Scope of application:

This type of laser generator is widely used in micro-welding applications such as electronic components, jewelry, eyeglass frames, medical devices, and precision instruments. It is particularly suitable for spot welding and seam welding of thin materials and small parts. Notably, with the advancement of fiber laser technology, fiber laser generators are now also being adopted in the field of micro-welding. Our company has launched a specialized fiber laser welding machine tailored for jewelry and other precision applications, offering users higher efficiency and superior welding quality.

Vorteil:

- The laser has strong focusing ability and is suitable for complex welds and high-precision applications;

- The pulsed laser output can effectively control heat input and avoid workpiece deformation;

- It can be transmitted via optical fiber and is suitable for long-distance welding of delicate parts.

Einschränkung:

- The photoelectric conversion efficiency is lower than that of the fiber laser generator, and the energy consumption is higher;

- When using lamp pumps or semiconductor pumps, the lamp tubes or pump sources need to be replaced regularly, and maintenance is frequent;

- The life span is relatively short, and the system stability is limited by its cooling and control system.

A comparative analysis reveals that each type of laser generator has its own unique advantages and suitable application fields. Among them, fiber laser generators have emerged as the most mainstream and popular solution in today’s laser welding applications due to their high beam quality, excellent energy efficiency, superior performance in metal welding, and compact design well-suited for automated integration.

In contrast, CO2 laser generators are more appropriate for non-metal processing, while Nd:YAG laser generators are ideal for small-scale, precision welding tasks. When selecting a laser generator, it is recommended to consider specific application scenarios, material types, precision requirements, and budget constraints. A scientific and tailored selection will ensure optimal welding results and long-term cost-effectiveness.

Factors to Consider When Selecting a Laser Generator

In the construction of a laser welding system, the selection of the laser generator is a critical factor determining the success of the process. The correct choice not only affects the quality and consistency of welding but also impacts long-term operational costs, equipment integration efficiency, and the company’s environmental compliance capabilities. The following key dimensions will assist users in making an informed decision among the various laser sources.

Welding Application Requirements

- Material Type and Thickness: Laser welding shows significant differences in adaptability to different materials. The fiber laser generator has excellent absorption efficiency and processing stability for metal materials (especially high-reflection materials like aluminum and copper), enabling deep penetration and high-strength welding. For non-metal materials such as plastics, fabrics, and wood, the CO2 laser generator is more suitable, as its wavelength is more strongly absorbed by non-metals.

- Welding Speed and Precision Requirements: If the welding task requires both high efficiency and high precision, such as in industries like automotive manufacturing, precision electronics, and medical devices, the fiber laser generator, with its high beam quality and focusing capability, can achieve high-speed welding with minimal heat-affected zones, ensuring the consistency and appearance quality of the weld seams.

- Joint Design and Geometry: Welding positions with complex or non-standard geometries, such as curved surfaces or joints with small gaps, require the laser to have better focusing control and reachability. In such applications, fiber laser generators and Nd:YAG laser generators offer more operational flexibility and are suitable for fine processing.

Power Supply and Power Requirements

- Power Output Requirements: Welding depth is proportional to laser power. For deep penetration welding, thick plate connections, or welding of structural components that require extremely high strength, it is recommended to choose a fiber laser generator with an output power of over 1000W, which can achieve high stability and deep penetration welding under continuous output.

- Balance Between Power and Precision: Some scenarios require both welding strength and weld seam precision, such as electronic enclosures and precision component packaging. In these cases, the laser source needs to maintain high power output while ensuring good control. The fiber laser generator offers better overall performance in this regard.

Strahlqualität

- Focusing performance: beam quality directly affects the diameter and energy density of the weld spot. High-quality laser beams can achieve smaller focus, more delicate welds, and lower thermal deformation, significantly improving the aesthetics and structural strength of welding.

- Laser stability: Especially in mass production or automated production lines, the stability and repeatability of laser power will directly determine the consistency of welding quality, reducing defective rates and rework costs.

Betriebskosten

- Energy Consumption: Fiber laser generators have an extremely high electro-optical conversion efficiency (up to over 35%), which results in lower energy consumption for the same power output, effectively controlling daily operational costs for businesses.

- Maintenance and Service Life: CO2 and Nd:YAG laser generators typically require more frequent replacement of pump sources, gases, or lamps, while fiber laser generators have a more compact and stable structure, with a service life of over 100,000 hours, low maintenance costs, and are suitable for long-term continuous operation.

- Equipment Reliability: In manufacturing environments, any equipment failure can impact the efficiency of the entire production line. Therefore, it is especially important to choose a mature, reliable, and stable laser generator brand and model.

Integration and Automation Capabilities

In the context of the rapid development of Industry 4.0, the automation and intelligence of equipment have become key competitive advantages. Fiber laser generators can be easily integrated into robot systems, CNC machining centers or automatic production lines due to their small size and flexible output methods, greatly improving production efficiency and flexible manufacturing capabilities.

Integration and Automation Capabilities

As environmental regulations become increasingly stringent, choosing laser equipment with low energy consumption and low emissions has become a basic requirement for manufacturing companies. Especially in developed markets such as Europe and the United States, it is necessary to pay attention to whether the equipment meets relevant energy efficiency certifications (such as CE, RoHS, ERP, etc.) and evaluate its overall impact on the environment.

In laser welding projects, the selection of laser generators should not be limited to the performance parameters of the equipment itself but should be systematically considered in combination with the company’s process requirements, product structure, production model, and long-term cost control. At present, fiber laser generators have become the most mainstream choice in the metal processing industry due to their excellent welding performance and operational advantages. However, in specific materials or small precision applications, CO2 and Nd: YAG laser generators still have an irreplaceable position. A scientific selection strategy can help companies build efficient, stable, and environmentally friendly welding systems and improve product quality and market competitiveness.

Zusammenfassen

Different types of laser generators have their advantages in the field of welding. CO2 laser generators are suitable for non-metallic materials, Nd: YAG laser generators are suitable for fine work, and the fiber laser generator has the strongest comprehensive performance and the widest range of adaptability. It performs well in welding speed, precision, energy efficiency, and automation capabilities and is especially suitable for industrial-grade mass production needs.

Bei AccTek-Laser, we specialize in providing high-performance fiber laser welding machines equipped with the world’s leading laser generator technology. Whether you need to weld stainless steel, aluminum alloy, or reflective metal, we can tailor efficient, stable, and environmentally friendly laser welding solutions for you. Feel free to kontaktiere uns to learn about the ideal laser generator configuration for your welding project and open a new chapter of intelligent welding!

Kontaktinformationen

- [email protected]

- [email protected]

- +86-19963414011

- Nr. 3 Zone A, Industriegebiet Lunzhen, Stadt Yucheng, Provinz Shandong.

Holen Sie sich Laserlösungen