Environmental Advantage: The Sustainability Benefits Of Laser Cutting

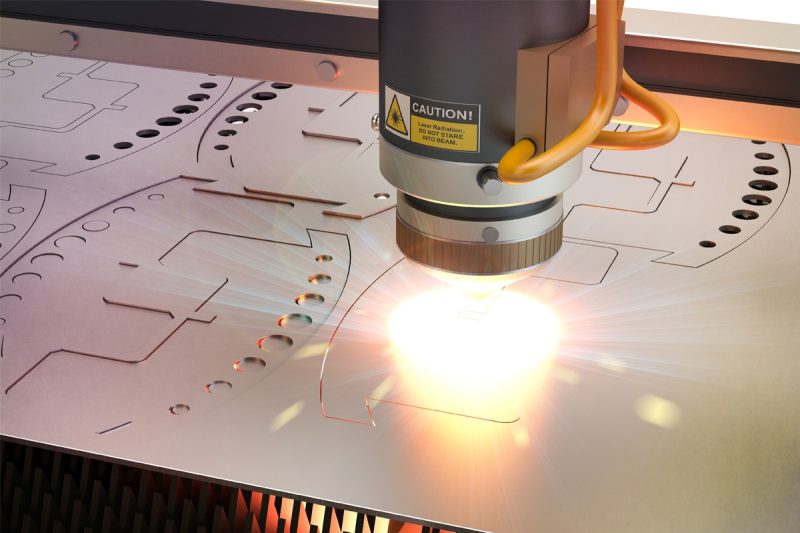

Nowadays, environmental protection has become an important issue worldwide. With the advancement of industrialization and technological progress, people are paying more and more attention to resource utilization and environmental impact in the production process. As an efficient and precise processing method, laser cutting technology’s sustainable benefits are of great significance in the field of environmental protection. Laser-cutting technology makes a positive contribution to environmental protection by reducing material waste, improving energy efficiency, and reducing chemical use and emissions.

This article will introduce the basic principles of laser cutting technology, discuss the importance of laser cutting in environmental protection, analyze the advantages of laser cutting and environmental protection, and look forward to the future development trend of laser cutting.

Table of Contents

Basic Principles Of Laser Cutting Technology

Laser cutting technology is a process that uses laser beams to process materials with high precision. Its basic principle is to use the high energy of the laser beam to locally heat the material to instantaneous melting or vaporization, and then use airflow or mechanical force to melt or vaporize the material. The chemical material is blown away to achieve the cutting of the material. The following are the basic principles of laser cutting technology:

- Laser generation: In the laser cutting system, the laser generator generates a high-energy, highly focused laser beam. Commonly used laser generators include carbon dioxide laser generators (CO2 laser generators) and solid-state laser generators.

- Laser focusing: Focusing the laser beam to a very small focus through optical components such as lenses or mirrors. The energy density at this focal point is very high, enough to locally heat the material to extremely high temperatures.

- Material processing: When the laser beam is focused on the surface of the material, the temperature of the surface of the material rises rapidly, reaching the temperature of melting or vaporization. For metallic materials, the energy of the laser beam can directly melt them; for non-metallic materials, the energy of the laser beam can cause instantaneous evaporation of the surface to form a gaseous state.

- Airflow or mechanical force removal: While the material is being processed, air flow or mechanical force is used to blow away the melted or vaporized material to keep the cutting process clean.

Laser-cutting technology has the advantages of fast cutting speed, high precision, and low energy consumption. It is widely used in metal processing, electronic component manufacturing, the automotive industry, aerospace, and other fields.

The Importance Of Maintaining Sustainable Benefits In Laser Cutting

As an efficient and precise processing technology, laser cutting’s sustainable benefits are of great significance to environmental protection and sustainable utilization of resources. The following are important to maintain the sustainable benefits of laser cutting:

- Reduce material waste: Laser cutting technology can accurately cut materials according to design requirements, reducing material waste. Compared with traditional mechanical cutting, laser cutting can utilize raw materials more effectively and reduce resource consumption.

- Energy saving: During the laser cutting process, energy is mainly used for the work of the laser generator and the operation of auxiliary equipment. Compared with traditional cutting methods, laser cutting consumes less energy. By improving energy efficiency, the energy demand can be reduced and the environmental load can be reduced.

- Reduced chemical use and emissions: There are no chemical solvents or coolants involved in the laser cutting process, reducing the use of chemicals. In addition, laser cutting emits less harmful gases and causes less pollution to the environment.

- Improve production efficiency: Laser cutting has the characteristics of high speed and high precision, which can complete processing tasks quickly and accurately. Improving production efficiency can not only reduce production costs but also reduce resource consumption and achieve sustainable development.

- Promote circular economy: Laser cutting technology can achieve precise processing of materials, allowing the processed materials to be better recycled. By recycling waste materials, the extraction of fresh resources can be reduced and damage to the environment reduced.

- Promote industrial upgrading: The continuous innovation and promotion of technology will promote the further development and maturity of laser cutting technology. The continuous improvement and application promotion of laser cutting technology will promote the upgrading and transformation of related industries and provide new impetus and support for sustainable economic development.

Therefore, maintaining the sustainable benefits of laser cutting is of great significance for achieving environmental protection, and promoting economic development and social sustainability.

Advantages Of Laser Cutting Related To Environmental Protection

Laser cutting has many advantages in terms of environmental protection. The advantages of laser cutting and environmental protection will be introduced in detail below:

Reduce Material Waste

Laser-cutting technology can accurately cut materials according to design requirements, reducing material waste. By controlling parameters such as the focal length, power, and scanning speed of the laser beam, high-precision processing of materials can be achieved and waste generation can be minimized. Compared with traditional mechanical cutting, laser cutting can utilize raw materials more effectively and reduce resource consumption and waste, which is of great significance to protecting the environment and saving resources.

Improve Energy Efficiency

During the laser cutting process, energy is mainly used for the work of the laser generator and the operation of auxiliary equipment. Laser cutting consumes less energy than traditional cutting methods. Laser cutting technology has the characteristics of efficient energy conversion and can accurately convert energy into laser beams, thereby achieving efficient processing of materials. By improving energy efficiency, the energy demand can be reduced and the environmental load can be reduced. It helps reduce production costs and improve the competitiveness of enterprises.

Reduce Chemical Use And Emissions

There are no chemical solvents or coolants involved in the laser cutting process, reducing the use of chemicals. Traditional cutting methods often require the use of chemical solvents or coolants to lower the temperature of the material, and these chemicals can cause environmental pollution. In the laser cutting process, only the laser beam is used to process the material, and no harmful chemicals are produced, which helps to improve air quality and reduce the risk of environmental pollution.

Improve Production Efficiency

Laser cutting has the characteristics of high speed and high precision, which can complete processing tasks quickly and accurately. An efficient production process can not only reduce production costs but also reduce the consumption of resources and achieve sustainable development. By improving production efficiency, energy consumption and emissions during the production process can be reduced, reducing the impact on the environment.

Promote Circular Economy

Laser cutting technology can achieve precise processing of materials, allowing the processed materials to be better recycled. By recycling waste materials, the extraction of fresh resources can be reduced and damage to the environment can be reduced. The application of laser cutting technology promotes the development of a circular economy, promotes the sustainable utilization of resources, provides new paths and models for sustainable development, helps improve environmental quality, and improves people’s quality of life.

Promote Industrial Upgrading

With the continuous innovation, promotion, and application of laser cutting technology, related industries are also constantly upgrading and transforming. The continuous improvement and application promotion of laser cutting technology will promote the development of related industries and promote the optimization and upgrading of the industrial structure. This will not only help improve the competitiveness and profitability of the industry but also make greater contributions to environmental protection and sustainable use of resources.

In short, laser-cutting technology has many advantages that are closely related to environmental protection. Through continuous innovation and technology promotion, laser cutting can further play a positive role in environmental protection and achieve sustainable economic development and social sustainability.

The Future Development Trend Of Laser Cutting

The future development trend of laser cutting technology will present the following characteristics:

Automation And Intelligence

With the continuous development of artificial intelligence and automation technology, laser-cutting equipment will become more intelligent and automated. Future laser cutting systems will more intelligently monitor, control, and optimize the processing process, thereby improving production efficiency and processing quality.

Greater Accuracy And Speed

Future laser-cutting technology will achieve higher processing accuracy and speed. With the continuous improvement of laser generator technology, optical technology, and control systems, laser cutting equipment will be able to achieve higher precision and faster processing to meet the increasing demand for processing quality and efficiency.

Multifunctionality And Flexibility

Future laser-cutting equipment will have more functions and greater flexibility. In addition to traditional cutting, drilling, engraving, and other functions, future laser cutting equipment will also have more processing capabilities, such as surface treatment, material modification, etc., to meet the needs of different industries and application fields.

Application Of New Materials And New Processes

With the continuous advancement of material science and process technology, future laser cutting technology will be able to be applied to more types and more complex new materials and processes. For example, laser cutting technology will be more widely used in 3D printing, flexible electronics, biomedicine, and other fields.

Environmental Protection And Energy Saving

Future laser-cutting technology will pay more attention to environmental protection and energy saving. By optimizing the processing process, improving energy efficiency, reducing waste generation, and other measures, laser-cutting technology will further reduce the impact on the environment and achieve more sustainable development.

Cross-Industry Integration And Application

In the future, laser cutting technology will be more deeply integrated and applied with technologies and applications in other industries. For example, the combination of laser cutting technology with artificial intelligence, big data, the Internet of Things, and other technologies will promote the development of emerging industries such as intelligent manufacturing and industrial Internet.

In short, the laser wavelength has a direct impact on the marking ability, and the influencing factors involve material selection, absorption capacity, and marking effect. Selecting the appropriate wavelength can maximize marking efficiency and quality. Therefore, in practical applications, the optimal laser wavelength needs to be selected based on specific material properties and marking requirements.

Summarize

With the continuous advancement of technology, the advantages of laser cutting in environmental protection will be better utilized and applied. In the future, we can look forward to further improvements in laser cutting technology in terms of material selection, cutting speed, and precision control to meet the needs of environmental protection and sustainable development. At the same time, the intelligence and automation of laser-cutting equipment will continue to improve, further reducing labor costs and improving production efficiency.

To sum up, the sustainable benefits of laser cutting are crucial to environmental protection. It can not only reduce resource waste and energy consumption but also reduce environmental pollution, making an important contribution to achieving sustainable development goals. We have reason to believe that in the context of increasing global environmental awareness,laser-cutting technology will play a more important role in the future and make greater contributions to building a cleaner and greener society.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions