The Principle Of CO2 Laser Marking Technology

CO2 laser marking technology is a processing method that uses a carbon dioxide laser generator to mark, cut, or engrave. Its principle is as follows:

- Laser generator generates laser beam: CO2 laser generator generates laser beam by exciting carbon dioxide gas. Usually, this kind of laser generator uses the transition of electron energy levels to excite gas molecules and cause them to emit laser light.

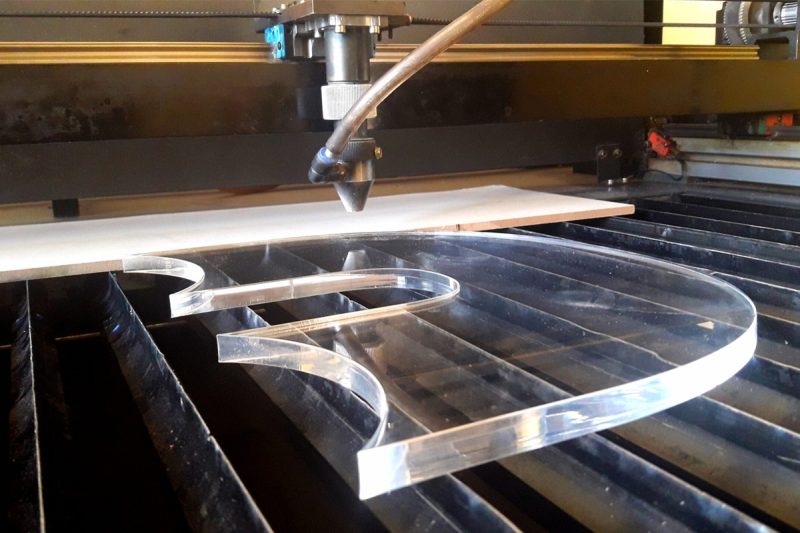

- Laser beam focusing: The generated laser beam is focused through the optical lens system to increase the energy density of the laser beam to a level that can handle materials.

- Interaction with plastic: The focused laser beam interacts with the plastic surface. When the laser beam interacts with the plastic, the energy is converted into heat, causing localized heating.

- Plastic processing: After the plastic is locally heated, it can undergo various changes, including melting, vaporization, chemical reactions, etc. The specific changes depend on the type of plastic and the setting of laser parameters.

- Mark, cut, or engrave: By controlling the path and intensity of the laser beam, you can mark, cut out specific shapes, or engrave on plastic surfaces. The accuracy of these machining processes depends on the focus size and position of the laser beam, as well as the adjustment of laser parameters.

Advantages Of CO2 Laser Marking In Plastic Processing

CO2 laser marking has multiple advantages in plastic processing, including but not limited to:

- Non-contact processing: CO2 laser marking is a non-contact processing technology. The laser beam acts directly on the plastic surface without contact, avoiding physical damage or deformation caused by contact and maintaining the integrity of the material.

- High precision: CO2 laser marking has extremely high precision, which can realize the processing of small sizes, complex patterns, and details, and meet the accuracy requirements of different application fields, such as electronic products, medical equipment, etc.

- High efficiency: CO2 laser marking is fast and efficient, which can greatly improve production efficiency. Compared with traditional cutting or engraving methods, laser marking can complete a large number of processing tasks in a short time.

- Wide applicability: CO2 laser marking technology is suitable for various types of plastic materials, including polypropylene (PP), polyethylene (PE), polycarbonate (PC), polystyrene (PS), etc., with strong Versatility.

- No pollution, no waste: CO2 laser marking is a pollution-free processing method that does not require additional chemicals or solvents and does not produce waste, complying with environmental protection requirements.

- Strong flexibility: The CO2 laser marking system can be flexibly configured according to processing needs, enabling the integration of automated production lines and improving the flexibility and automation of the production line.

Types Of Plastics That CO2 Laser Can Mark

Thermoplastic

A thermoplastic is a plastic that softens or melts within a certain temperature range and then solidifies when cooled. CO2 laser marking has excellent performance in processing thermoplastics, mainly including:

- Polypropylene (PP): Polypropylene is a common thermoplastic with good chemical stability and corrosion resistance. CO2 laser marking can mark its surface with high precision and is used in product identification, packaging, and other fields.

- Polyethylene (PE): Polyethylene has good processability and impact resistance, and is often used in packaging, pipes, and other fields. CO2 laser marking can mark it and improve product identification.

- Polyvinyl chloride (PVC): Polyvinyl chloride is a commonly used plastic material with good mechanical properties and chemical stability. CO2 laser marking can carry out high-definition markings on its surface and can be used in product identification, decoration, and other fields.

Thermoset Plastic

Thermoset plastics solidify into an infusible state after processing and have high heat resistance and mechanical strength. CO2 laser marking also has certain applications in the processing of thermosetting plastics:

- Epoxy resin: Epoxy resin has excellent mechanical properties and chemical stability and is commonly used in composite materials, adhesives, and other fields. CO2 laser marking can make clear marks on its surface for product identification and decoration.

- Phenolic resin: Phenolic resin has the characteristics of high-temperature resistance and corrosion resistance and is often used to manufacture parts with high wear resistance and insulation performance requirements. CO2 laser marking can mark it finely and improve product identification.

Engineering Plastics

Engineering plastics have excellent mechanical properties, heat resistance, and chemical corrosion resistance, and are often used in automotive parts, electronic product casings, and other fields. CO2 laser marking is also suitable for processing engineering plastics:

- Polyamide: Polyamide has good strength and stiffness and is often used to make mechanical parts, gears, etc. CO2 laser marking can mark it finely and be used for product identification and decoration.

- Polycarbonate: Polycarbonate has excellent transparency and impact resistance and is often used in the manufacture of glasses, safety helmets, and other products. CO2 laser marking can mark the surface to improve product identification.

Other Plastic Materials

Application Of CO2 Laser Marking In Different Plastic Processing

Electronic Product Manufacturing

In the field of electronic product manufacturing, plastic parts are often used in components such as casings and panels. CO2 laser marking can be used for:

- Product identification: CO2 laser marking technology is used on the surface of the plastic shell to identify the product model, serial number, production date, and other information to improve product recognition and anti-counterfeiting.

- Fine engraving: Fine engraving on plastic panels or shells, such as patterns, text, etc., to enhance the beauty and uniqueness of the product.

Medical Device Manufacturing

Medical devices are often made of plastic materials, such as syringes, surgical instruments, etc. CO2 laser marking can be used for:

- Product identification: Mark the medical device name, batch number, production date, and other information on the surface of the medical device to ensure product traceability and quality control.

- Surface treatment: Texturing, marking, and other processing on the surface of medical devices to improve the feel or add anti-counterfeiting functions.

Auto Parts Manufacturing

Plastic materials are widely used in automobile parts, such as car light housings, instrument panels, etc. CO2 laser marking can be used for:

- Parts marking: Mark vehicle model information, part numbers, etc. on the surface of plastic parts to facilitate production management and maintenance.

- Fine processing: Fine processing of patterns, text, etc. on the plastic surface to enhance the aesthetics and quality of the product.

Packaging Industry

In the packaging industry, plastic is often used in packaging bags, bottles, etc. CO2 laser marking can be used for:

- Product identification: Mark product name, production date, instructions for use, and other information on the surface of packaging bags or bottles to ensure product quality and safety.

- Anti-counterfeiting function: CO2 laser marking technology is used to process anti-counterfeiting marks on the packaging surface, such as barcodes, QR codes, etc., to improve the anti-counterfeiting properties of the product.

Manufacturing

In the manufacturing industry, plastic materials are widely used in the manufacture of various products, such as home appliances, tools, etc. CO2 laser marking can be used for:

- Product identification and decoration: Mark the company logo, product model, production date, and other information on the surface of plastic products, and perform decorative processing at the same time to enhance the quality and added value of the product.

- CO2 laser marking technology plays an important role in plastic processing in many fields such as electronic product manufacturing, medical device manufacturing, auto parts manufacturing, packaging industry, and manufacturing industry, providing efficient and effective solutions for product identification, decoration, and anti-counterfeiting. Precise solutions.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.