Laser Cleaning Machine Cooling System Maintenance Guide

In modern industrial cleaning, laser cleaning machines, with their high efficiency, environmental friendliness, and lack of consumables, have gradually replaced traditional chemical cleaning and mechanical polishing methods. They are widely used in a variety of industries, including metal rust removal, paint removal, weld pretreatment, and mold cleaning.

However, the cooling system is crucial for maintaining stable and efficient long-term operation of laser cleaning equipment. Acting as the “temperature steward” of the laser generator and optical module, the cooling system is responsible for promptly removing the heat generated by the equipment during high-power operation, thereby ensuring stable laser output power, precise beam quality, and effectively extending the service life of the laser generator and core components.

Improper cooling system maintenance, such as coolant contamination, pump blockage, and poor heat dissipation, can lead to unstable laser output and even equipment downtime, directly impacting production efficiency and processing quality. Therefore, mastering proper cooling system maintenance methods can not only reduce equipment failure rates but also save companies significant repair costs.

Table of Contents

Why Cooling System Maintenance Matters

The cooling system plays a crucial yet often overlooked role in the overall operation of a laser cleaning machine, as it is one of the key components for ensuring long-term, sta ble operation. Whether it’s a fiber laser cleaning machine or a portable laser rust removal system, the health of the cooling system directly impacts the output performance and lifespan of the laser generator. Here are three key reasons why cooling system maintenance is so crucial.

Controlling Temperature Fluctuations and Maintaining Stable Output

During operation, the laser generator of a laser cleaning machine continuously generates significant heat. If the cooling system fails to dissipate this heat promptly, temperature fluctuations will lead to unstable beam energy, which in turn affects cleaning efficiency and processing accuracy. Regular cooling system maintenance, ensuring smooth water circulation and pure coolant, effectively prevents power degradation caused by overheating and ensures stable performance even under prolonged, high-load operation.

Extending Laser Generator Life and Reducing Optical Loss

The cooling system not only cools the laser generator but also protects the internal optical lenses and fiber modules. Substandard coolant quality or poor circulation can cause optical components to be exposed to high temperatures for extended periods, accelerating aging and even causing corrosion. Regularly replacing the coolant, cleaning the filter, and checking the pump flow rate can significantly reduce optical loss, extend the life of the laser generator, and maintain high-efficiency output.

Reducing maintenance costs and minimizing downtime risks

According to industry statistics, over 30% of laser cleaning equipment failures are related to cooling system issues. Minor issues such as scaling, blockage, or pump damage, if not addressed promptly, can often escalate into serious system failures, resulting in costly repairs and downtime. By establishing a standardized cooling system maintenance plan, companies can proactively prevent potential problems, ensure continuous production line operation, and improve overall operational efficiency.

The stability of the cooling system determines the operational quality and economic benefits of a laser cleaning machine. A clean, efficient, and well-maintained cooling system not only maintains stable laser generator output power but also extends the overall equipment life and reduces operating costs. For users seeking high performance and long-term reliability, cooling system maintenance is not an optional extra but a fundamental component to ensure continuous and efficient equipment operation.

Key Components of a Laser Cleaner's Cooling System

Within the overall structure of a laser cleaning machine, the cooling system is crucial for maintaining the stable operation of the laser generator and optical components. An efficient cooling system ensures timely heat removal, preventing overheating that could cause energy attenuation or beam distortion. Understanding its key components will facilitate more targeted inspection and maintenance during subsequent maintenance.

Cooling Water Tank

The cooling water tank is the core reservoir of the entire cooling cycle, primarily responsible for storing the cooling medium (deionized water or specialized coolant). During operation, the tank not only provides a stable water source for the circulating water pump but also performs initial heat dissipation and impurity precipitation.

Regularly checking the water level and maintaining clean water quality are key steps in preventing bubbles, scaling, and corrosion in the cooling system. For fiber laser cleaning machines, the cleanliness of the cooling water tank is directly related to the operational stability of the laser generator.

Circulating Water Pump

The circulating water pump is the power source of the cooling system, responsible for continuously circulating the coolant between the laser generator, heat exchanger, and water tank. A high-performance pump ensures stable flow and pressure, ensuring even heat removal.

Insufficient water pump flow or abnormal noise can lead to reduced cooling efficiency or even overheating of the laser generator. Therefore, the pump’s sealing, flow output, and internal cleanliness should be regularly checked to ensure continued efficient system operation.

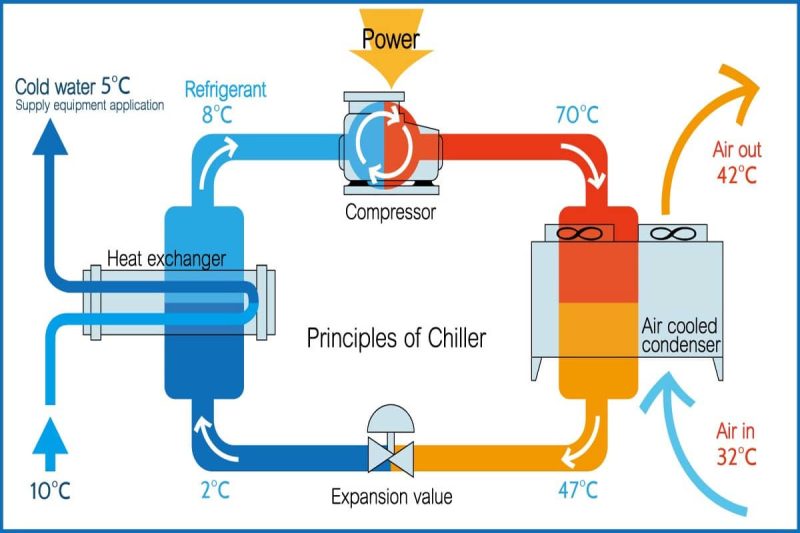

Heat Exchanger or Refrigeration Module

The heat exchanger or refrigeration module is a key component for cooling the coolant. Using air cooling or compressor cooling, it quickly transfers heat generated by the laser generator to the external environment.

For laser cleaning machines operating at high power for extended periods, a high-quality industrial chiller ensures a constant coolant temperature, preventing unstable laser output due to temperature fluctuations. During maintenance, the condenser should be regularly cleaned of dust, and the refrigerant pressure and fan operation should be checked to maintain cooling efficiency.

Water Filter

The water filter is used to filter impurities and particles from the coolant to prevent clogging of the water pump or heat exchanger lines. If the coolant is not filtered during long-term operation of a laser rust removal machine, impurities will gradually accumulate within the system, reducing heat transfer efficiency and causing corrosion.

Therefore, the filter should be cleaned or replaced every 1–2 months to maintain smooth water flow and system cleanliness, thereby ensuring cooling system stability.

Temperature Control System

The temperature control system is the brain of the cooling system. It monitors the coolant temperature in real time through temperature sensors and automatically adjusts the cooling module to maintain the temperature within the set range (generally 20–25°C).

Inaccurate temperature control system calibration or sensor failure can cause the laser generator to overheat or underheat, affecting cleaning performance and equipment life. Regular verification of sensor accuracy and temperature control response speed is key to ensuring precise system control.

The cooling system consists of several interoperable components: a cooling water tank provides the water source, a circulating water pump drives the flow, a cooling module provides cooling, a water filter ensures water purity, and a temperature control system precisely regulates the temperature.

Only when all components operate stably and are properly maintained can the laser cleaning machine’s cooling system be efficient and reliable, ensuring continuous, stable laser output. Understanding the functions and maintenance priorities of these core components is fundamental for every laser equipment user to extend equipment life and improve processing efficiency.

Common Cooling System Problems and Warning Signs

The cooling system is a critical component for the stable operation of a laser cleaning machine. Any minor anomaly can affect the output performance and lifespan of the laser generator. During daily use, operators should closely monitor the coolant status, system alarms, and water pump operation to detect potential problems early. The following are several common cooling system malfunctions and warning signs, along with their potential causes.

Coolant Discoloration or Turbidity

When the coolant becomes darker, turbid, or contains sediment, it often indicates internal contamination of the system. Possible causes of contamination include:

- Using untreated tap water, which leads to mineral deposits;

- Prolonged coolant replacement, which leads to algae growth.

- Metal corrosion or microbial contamination in the cooling circuit.

Impact: Contaminated coolant reduces heat dissipation efficiency and may clog pipes or damage the water pump. Long-term use can cause the laser generator to overheat and shorten the lifespan of the equipment.

Recommendation: Change the coolant regularly (every 3–6 months) and use manufacturer-recommended deionized water or a specialized coolant.

Unstable Laser Power

If the laser cleaning machine’s output power fluctuates during operation, it’s usually due to poor heat dissipation in the cooling system. When the coolant temperature is too high or the flow rate is insufficient, the laser generator cannot operate at the ideal temperature, resulting in reduced output power.

Impact: Unstable power not only reduces cleaning efficiency but can also result in uneven cleaning or residual machining marks.

Suggestion: Check that the coolant temperature is stable between 20–25°C and ensure that the cooling module is functioning properly.

Abnormal Cooling Pump Noise

If the circulating water pump makes unusual noises, vibrates, or experiences a drop in flow rate during operation, it’s usually due to the following:

- Intake of air into the system causes bubbles to circulate within the pump.

- Worn or fouled pump bearings;

- Clogged filters cause water flow obstruction.

Impact: Abnormal pump operation can directly affect coolant flow rate, leading to increased laser generator temperature.

Suggestion: Immediately stop operation, remove air, clean the filter, and inspect the pump seal.

System Alarm or Temperature Exceedance

When the temperature sensor detects that the coolant temperature exceeds the set value, the system will automatically alarm and stop operation. This type of warning is often triggered by conditions such as decreased cooling module efficiency, excessively high ambient temperatures, or insufficient coolant.

Impact: Continuing operation despite the warning may cause thermal deformation of the laser generator’s internal optical components.

Recommendation: Regularly clean the condenser fins, maintain adequate ventilation, and ensure accurate operation of the temperature control system sensors.

Insufficient Water Flow Warning

When the “Water Flow Error” or “Low Flow” warning appears during operation, it indicates that coolant circulation is blocked.

Possible causes include:

- Blocked or bent pipes;

- Degraded water pump performance;

- Clogged filters;

- Low coolant level.

Impact: Insufficient flow slows coolant circulation, preventing heat from being removed promptly, potentially triggering a laser generator overheating warning.

Recommendation: Check the water flow, pump operation, and liquid level, and clean the filter system if necessary.

Any abnormal signs in the cooling system should not be ignored. Coolant contamination, unstable power, pump noise, system alarms, and insufficient flow are early signs of improperly maintained laser cleaning system cooling systems.

Regular inspections, recording temperature and flow data, and promptly addressing issues based on alarms are effective ways to ensure stable laser generator operation and extend equipment life. By establishing a comprehensive cooling system maintenance plan, users can not only reduce equipment failure rates but also improve overall production stability and cleaning efficiency.

Daily Cooling System Maintenance Steps

Cooling system maintenance is crucial for ensuring the long-term, stable operation of a laser cleaning machine. A sound maintenance plan not only prevents temperature fluctuations and energy degradation but also effectively extends the life of the laser generator. The following is a standardized daily maintenance procedure for the cooling system, which can be adjusted flexibly based on equipment usage frequency and environmental conditions.

Checking the Coolant Level and Quality

A low coolant level or deteriorating coolant quality will directly affect cooling efficiency.Operational Recommendations:

- Check the water tank level weekly and maintain it within the specified range.

- If the level is too low, refill the coolant promptly.

- Use deionized water or a specialized coolant recommended by the manufacturer to prevent mineral scaling and corrosion.

Regularly Change the Coolant

Over time, coolant may lose its effectiveness due to adsorbed impurities or temperature fluctuations. Recommendations:

- Change the coolant every 3–6 months to prevent algae growth and scale deposition.

- Completely drain the old coolant and flush the piping system with clean water during the change.

- After refilling with new coolant, run the machine for several minutes to ensure there are no bubbles in the system.

Regularly changing the coolant is a key maintenance step to prevent laser generator overheating and maintain cleaning stability.

Cleaning the Filter

The filter effectively removes impurities from the circulating water, preventing water pump blockage and reducing heat exchange efficiency.Operational Recommendations:

- Check the filter every 1–2 months.

- If sediment or reduced water flow is detected, remove and clean it immediately.

- Use a soft brush or ultrasonic cleaning equipment to avoid scratching the filter surface.

Maintaining smooth water flow ensures efficient cooling of the laser cleaning machine and reduces the risk of overheating.

Checking the Water Pump

The circulating water pump is the “heart” of the cooling system, and any abnormality can cause temperature runaway. Recommendations:

- Before starting the machine each time, inspect the water pump for stable operation.

- Ensure there are no unusual noises, vibrations, or leaks.

- Regularly check the pump flow rate for compliance, and clean or replace it if necessary.

A malfunctioning water pump can lead to poor coolant circulation, which in turn affects the temperature control accuracy of the laser generator.

Checking the Cooling Temperature and Alarm System

The temperature control system is the core of the cooling system. Key operating points:

- Ensure the cooling temperature remains stable within the 20–25°C range.

- Calibrate the temperature sensor and alarm system quarterly.

- Simulate abnormal conditions (such as high temperature or low flow rate) to confirm that the alarm system responds promptly.

Accurate temperature control prevents laser generator power degradation at high temperatures, ensuring safe equipment operation.

Regularly inspect joints and pipes

The tightness of the water piping system directly determines cooling efficiency. Maintenance recommendations:

- Monthly inspect joints, hoses, and water connections for leaks, blockages, or cracks;

- Replace aging pipes promptly.

- Use corrosion-resistant and pressure-resistant hoses to extend service life.

Well-sealed cooling pipes ensure stable coolant circulation, preventing energy loss and contamination.

Cooling system maintenance should follow the principles of “regular inspection, timely cleaning, and precise calibration.” By establishing a systematic maintenance plan:

- Coolant remains pure, ensuring efficient heat transfer.

- Water pumps and filters function properly, preventing circulation interruptions.

- Temperature control systems and alarms remain responsive, ensuring safe operation of the laser generator.

Regular maintenance not only extends equipment life but also ensures stable output power and efficient cleaning performance over extended periods of operation. For industrial users, this is not just a daily routine but also a crucial step in ensuring production quality and return on investment.

Best Practices and Common Misconceptions about Cooling System Maintenance

The cooling system is crucial for the stable operation of laser cleaning machines. Proper maintenance practices not only ensure the laser generator maintains high output over time but also prevent equipment failures caused by improper temperature control. The following are best practices for cooling system maintenance and common misconceptions to avoid.

Best Practices for Cooling System Maintenance

Use clean, mineral-free deionized water

The purity of the coolant directly determines cooling efficiency and system life. Always use manufacturer-recommended deionized water or a dedicated coolant to avoid scaling and reduced thermal conductivity caused by impurities or mineral deposits.

In addition, it is recommended to test the water conductivity every 3–6 months to ensure it is within the acceptable range (generally ≤5 μS/cm).

Maintain good ventilation and ambient temperature

The cooling system’s heat dissipation efficiency depends on external air circulation. Maintaining good ventilation in the machine room or operating area and avoiding excessively high ambient temperatures (ideally 15–30°C) can effectively prevent excessive heat loads that could overload the cooling system.

Regularly calibrate the temperature control system and sensors.

The temperature control system is the core unit that prevents the laser generator from overheating. It is recommended to calibrate the temperature control sensor quarterly to ensure accurate temperature readings. If the temperature control error exceeds ±1°C, repair or replace it immediately.

Common Mistakes in Cooling System Maintenance

Using ordinary tap water or unfiltered water

Ordinary tap water contains a large amount of minerals and ions, which can form scale on the cooling pipes and heat exchanger surfaces, reducing thermal conductivity and even causing pipe blockage or corrosion. Long-term use can significantly shorten the lifespan of the laser generator and cooling system.

Ignoring Alarms and Continuing to Operate the Equipment

Never operate the laser cleaning machine when the system displays high temperature, insufficient flow, or an alarm. Ignoring the alarm may not only lead to cooling failure but also damage the laser generator’s optical cavity or unstable beam, resulting in costly repairs.

Mixing Coolants of Different Brands or Types

Coolants of different brands or types may have incompatible chemical compositions. Mixing them can cause precipitation, emulsification, and even corrosion of metal parts. When replacing coolant, completely drain the old fluid and flush the system before adding new fluid.

Maintaining an efficient and clean cooling system is crucial for ensuring the stable performance of the laser cleaning machine and a long life for the laser generator.

Proper maintenance, such as using deionized water, regularly testing the temperature control system, and maintaining adequate ventilation, can effectively prevent equipment overheating and system scaling.

Conversely, ignoring warnings, mixing coolants, or using standard water will not only reduce cooling efficiency but may also cause laser generator failure.

Summary

Cooling system maintenance is a key component in ensuring the long-term and stable operation of laser cleaning machines. An efficient, clean, and precisely temperature-controlled cooling system not only prevents laser generator overheating and power loss but also significantly extends the lifespan of the entire machine.

During routine maintenance, companies should pay attention to details such as coolant quality, filtration system cleanliness, temperature control calibration, and pump operating status. Regular inspection, replacement, and cleaning can effectively reduce failure rates and downtime while ensuring laser cleaning efficiency and stability.

Practice shows that over 30% of laser equipment failures are due to cooling system problems, and regular maintenance can reduce this risk by more than half. Maintaining the cooling system in optimal condition is not only a technical maintenance necessity but also a long-term guarantee for a company’s production efficiency and equipment investment.

Whether in heavy industrial metal derusting, mold refurbishment, or precision surface cleaning, a well-maintained cooling system ensures the highest performance of laser cleaning machines.

Laser Solutions

AccTek Laser is committed to providing efficient, stable, and energy-efficient fiber laser cleaning solutions to customers worldwide. Our equipment features an intelligent temperature-controlled cooling system to ensure the laser generator maintains constant output at an ideal temperature, enhancing overall cleaning efficiency and equipment lifespan. Whether you’re involved in metal processing, mold manufacturing, or automotive and aviation parts cleaning, we can customize the optimal laser cleaning solution for you.

In addition, our professional technical team provides comprehensive after-sales support and cooling system maintenance guidance, helping you easily understand key maintenance points during operation, reducing operating costs, and extending the lifespan of your equipment. If you’re looking for a reliable laser cleaning machine manufacturer or would like more technical advice on cooling system maintenance, please feel free to contact the AccTek Laser team. We will provide professional and sustainable laser solutions for your cleaning process.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions